PCB board parts are very important in electronics. They help make devices smaller and more efficient. The different PCB board parts allow for smaller designs, which improves how well they work. You can get better reliability and performance by using different components. Knowing about these PCB board parts helps you meet your project needs and keep up with changing technology.

Key Takeaways

Learn about the three main types of PCB parts: passive, active, and electromechanical. Each type has a special job in how circuits work.

Pick parts carefully by knowing what your project needs. Think about power use, environment, and if parts will work together to make sure it goes well.

Put parts in the right spots on the PCB. Good placement helps signals work better and makes fixing things easier, which improves overall performance.

Look into part details and the reputation of the makers. This helps make sure your electronic designs are good and reliable.

Watch out for supply chain problems and fake parts. Build good relationships with trusted suppliers to avoid delays and get real parts.

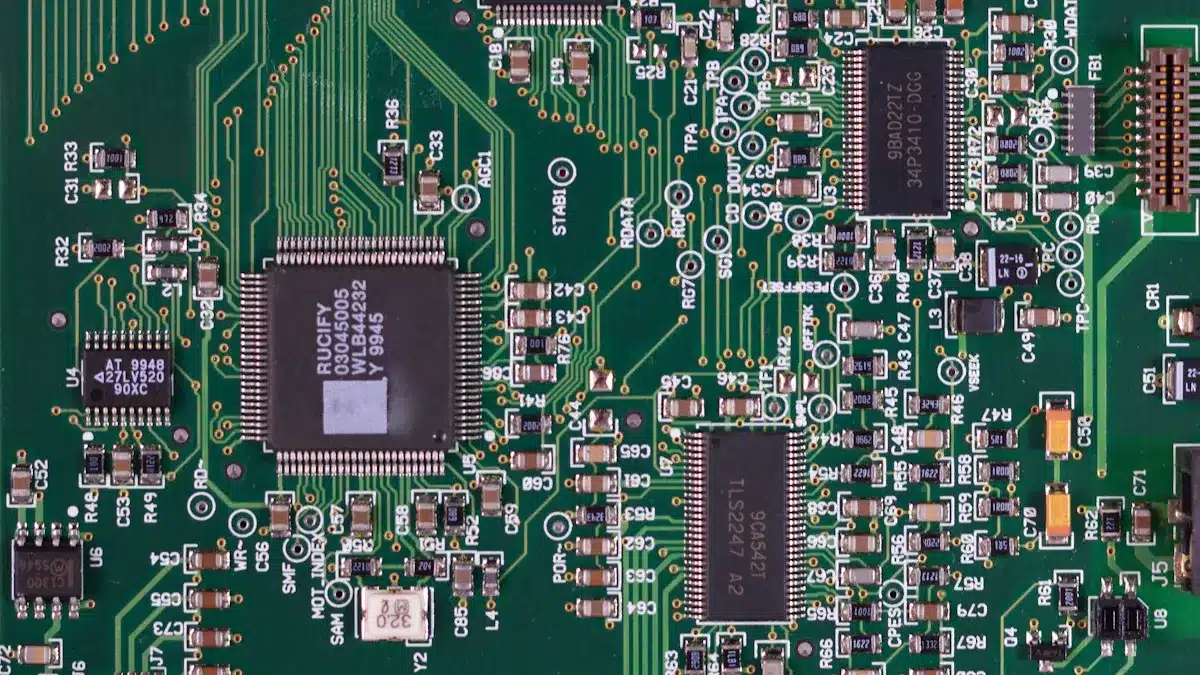

Types of PCB Components

When you make a printed circuit board (PCB), you will see different types of PCB components. Knowing about these components is very important for good circuit board designs. Let’s look at the three main types: passive components, active components, and electromechanical components.

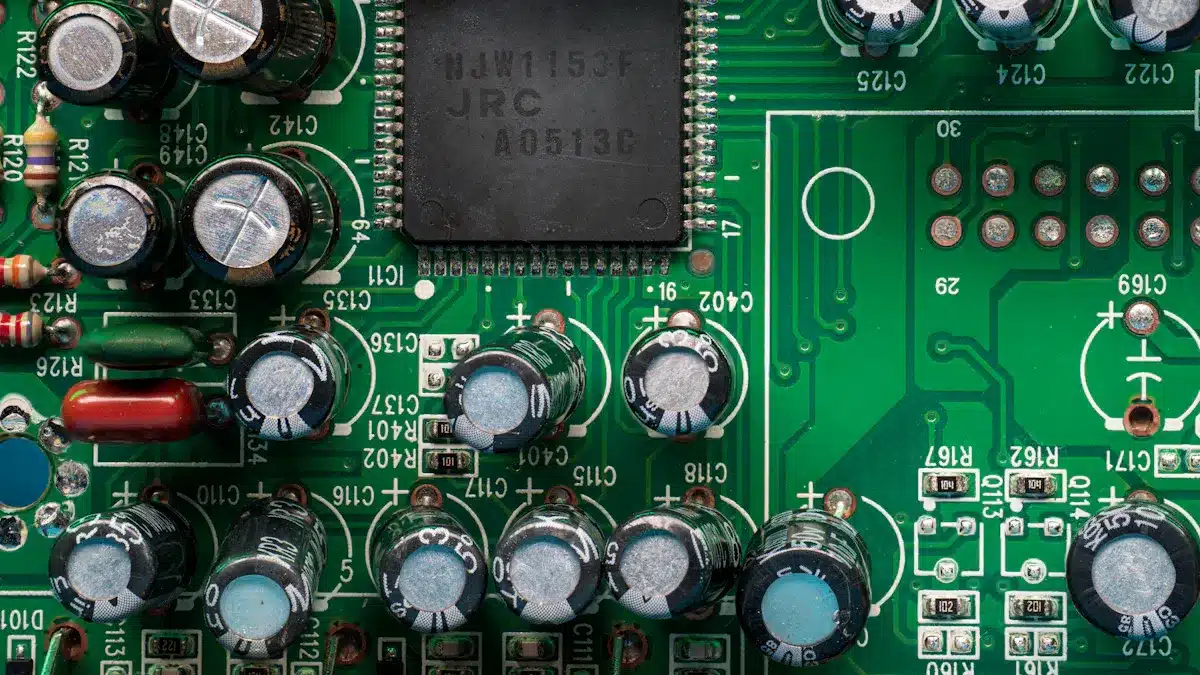

Passive Components

Passive components are very important for how circuits work. They do not need extra power to work. Instead, they use energy from the circuit itself. Here are some common passive components:

Resistors: These parts limit electric current flow. They help control voltage levels and stop overloads in the circuit.

Capacitors: Capacitors store and release electrical energy. They filter out noise and keep voltage levels stable for smooth operation.

Inductors: Inductors store energy in a magnetic field. They help reduce current changes and filter signals.

About 87% of the parts on a printed circuit board are passive components. Their ability to manage signals and provide stability makes them very important for any circuit design. They filter noise and set bias points, helping active components work properly.

Active Components

Active components are very different from passive components. They need an external power supply to work and can control current or voltage flow. Here are some key active components you might see:

Transistors: These act as amplifiers or switches. They are very important for amplifying and changing signals.

Diodes: Diodes let current flow in one direction. They are often used in rectification and signal modulation.

Integrated Circuits (ICs): ICs are small packages that improve performance and lower power use.

Active components make up about 13% of all parts on a PCB. They provide power gain and control over current and voltage, making them essential in modern electronics.

Feature | Active Components | Passive Components |

|---|---|---|

Power Supply | Need an external power supply | Do not need an external power supply |

Power Gain | Have power gain greater than one | Do not have power gain abilities |

Control over Current/Voltage | Can control current or voltage flow | Cannot control current or voltage flow |

Power Delivery | Deliver power to the circuit | Use power from the circuit |

Examples | Transistors, SCRs, FETs | Resistors, Capacitors, Inductors |

Electromechanical Components

Electromechanical components connect electrical and mechanical systems. They are important for keeping signals clear and ensuring reliable data transfer. Common electromechanical components include:

Connectors: These parts connect different parts of the circuit. They help keep signals clear and reduce electromagnetic interference (EMI).

Relays: Relays act as switches that control electricity flow in a circuit. They are very important for automation and control tasks.

Electromechanical components are very important in fast PCB design. They help reduce signal loss and improve overall system performance. By choosing components with low dielectric constants and built-in shielding, you can make your circuit board more reliable.

Understanding Circuit Board Parts

When you create a printed circuit board (PCB), how you place the parts is very important. The right layout helps the circuit work better. Good placement of circuit board components can improve signal quality and reduce interference. Here are some important things to think about:

Trace Width and Thickness: Wider traces lower resistance, making things work better. Thicker traces can carry more current and let heat escape. Traces that are the wrong size can cause overheating and signal problems.

Component Placement: Place parts carefully so they are easy to reach for repairs. This setup also helps manage heat better.

Routing: How you route the traces affects how well the circuit works. Keeping track lengths short and avoiding sharp turns helps keep signals clear and cuts down on electromagnetic interference (EMI).

To show how these factors matter, look at this table:

Factor | Impact on Performance and Reliability |

|---|---|

Heat Dissipation | Good heat dissipation prevents overheating and keeps devices reliable. |

Component Placement | Where you place parts affects how easy they are to reach for repairs. |

Design Rules | Following design rules makes sure the board can be made and meets industry standards. |

Routing | Good routing affects how well the circuit works, including signal quality and power flow. |

Signal Integrity | Keeping track lengths short and avoiding sharp turns helps keep signals clear and lowers EMI risks. |

Thermal Management | Wider tracks and thermal vias help remove heat from high-current paths, stopping device failure. |

Knowing how different pcb board parts work together is key for getting the right electrical results. For example, temperature changes can affect PCB materials, which can change electrical and thermal behavior. This knowledge is important for good thermal management.

To reduce signal interference, follow these tips:

Keep enough space between traces to lower crosstalk.

Route fast and sensitive traces at right angles across layers.

Use ground planes to separate noisy signals.

By planning your circuit board design carefully, you can improve performance and reliability. This method will also help you fix and test circuit board components better.

Selecting Components for Your Needs

When you pick parts for your printed circuit board (PCB), you need to think about your project needs. This step is very important because it helps you understand what your PCB must do. Think about things like power use, the environment, and the electrical features needed for your project. By writing down these needs, you make a clear plan that helps you choose the right parts.

Here are some important steps to follow when picking components:

Define Your Requirements: Write down what your PCB needs, like power use and environmental conditions.

Research Component Specifications: Look at datasheets for voltage limits and temperature ranges.

Consider Cost and Availability: Check prices and make sure parts will be available for a long time to avoid problems.

Review Quality and Reliability: Choose parts from trusted makers to ensure they last and work well.

Ensure Compatibility: Make sure voltage levels and communication methods match to prevent circuit issues.

You should also think about different factors when choosing PCB parts. These include:

Manufacturer Reputation: Pick parts from well-known makers to ensure quality.

Quality Certifications: Look for certifications that show reliability and performance.

Reliability Data: Check data that shows how parts work in different situations.

Component Availability: Make sure the parts you want are easy to find to avoid delays.

Lead Time: Think about how long it will take to get the parts after ordering.

Cost versus Quality: Balance your budget with the need for good-quality parts.

Electrical and Mechanical Characteristics: Check the specs that fit your project needs.

Environmental Factors: Think about how parts will work in the environment they will be used in.

Budget is very important when you choose parts. You want to make your Bill of Materials (BOM) to find ways to save money. Building good relationships with different suppliers can help you get better deals. This way, you can create competition and take advantage of bulk pricing.

Here’s a quick look at how costs can change based on part type and supplier:

Type of PCB | Cost Range | Application Area |

|---|---|---|

High-end PCBs | Up to millions | Defense and Space |

Consumer Goods PCBs | A few bucks to hundreds | Daily Use Equipment |

You should also know about common problems when getting PCB parts. Supply chain issues can happen suddenly, so it’s smart to have connections with different suppliers. Counterfeit parts are another risk, so it’s important to work with trusted suppliers and check quality. Fast changes in technology mean you need to keep up with industry trends.

In conclusion, knowing the different types of PCB parts—passive, active, and electromechanical—is very important for your electronic designs. Each part has a special job that affects how well things work and how reliable they are.

Keep these important points in mind when choosing parts for your projects:

Write down key electrical and physical details to make sure they fit.

Place parts correctly to improve how they work.

Think about supply chain issues for cheaper options.

Think about what your project needs and use this information to make good PCB designs. Paying attention to details can help you succeed in your electronics projects! 🌟

FAQ

What are the main types of PCB components?

The main types of PCB components are passive components (like resistors and capacitors), active components (such as transistors and diodes), and electromechanical components (including connectors and relays). Each type has a special job in how the circuit works.

How do I choose the right PCB components?

To pick the right components, first, write down what your project needs. Then, look up the specifications, think about cost and availability, and check for compatibility. This way, you can choose parts that fit your project’s electrical and environmental needs.

Why is component placement important on a PCB?

Where you place components affects signal quality, heat control, and how easy it is to fix things. Good placement reduces interference and improves performance, making sure your circuit works well.

What should I consider regarding PCB costs?

Think about things like the type of components, the reputation of suppliers, and how easy they are to find. Make a Bill of Materials (BOM) to help manage costs. Building good relationships with suppliers can also help you get better prices.

How can I avoid counterfeit PCB components?

To avoid fake components, buy from trusted suppliers and check for quality certifications. Always confirm that parts are real before using them to ensure they work well and are reliable in your projects.

See Also

Tips for Choosing the Right PCBA Manufacturer for You

Selecting the Ideal PCBA Factory for Your Unique Needs

Uncovering Key Differences Between PCBA and PCB Explained

Essential Tips for Choosing Top PCB Assembly Services

Understanding PCBA Testing Methods in Electronics Production