Edge AI PCBA manufacturing is transforming the way circuit boards are produced. AI tools assist in placing parts and planning routes more efficiently and effectively. Intelligent systems detect errors with remarkable precision. Machines equipped with AI anticipate issues early, allowing for repairs before failures occur. These advancements save time, enhance quality, and reduce costs, making the manufacturing process smarter.

Key Takeaways

Edge AI makes PCBA manufacturing faster and more efficient. It helps machines find mistakes quickly, saving time and money.

Factories use real-time data to make fast decisions. This helps them stay ahead and adjust to production changes.

Edge AI stops machines from breaking down with predictive maintenance. It checks equipment often, so repairs happen before problems start.

Automation with Edge AI handles boring, repeated tasks. This lets workers do more important jobs and boosts productivity.

Edge AI improves product quality by finding defects early. Smart tools make sure only good products are made, keeping customers happy.

Understanding Edge AI in PCBA Manufacturing

What is Edge AI and how does it work?

Edge AI means smart systems that work directly on devices. It doesn’t need to send data to the cloud. In PCBA manufacturing, AI works right on machines or tools. Think of it like a helper inside the equipment, making quick decisions. For instance, a smart camera on a production line can spot mistakes instantly. It doesn’t need to send data far away to check for errors. This quick processing saves time and helps machines respond faster. Speed is very important in fast-moving factories.

The role of Edge AI in addressing PCBA manufacturing challenges

Edge AI solves big problems in PCBA manufacturing.

AI makes processes faster and reduces the need for human work.

It predicts problems early, so machines don’t break suddenly.

Smart tools check for mistakes, so fewer bad products are made.

AI helps design better circuit boards, avoiding common issues.

Edge AI also improves inventory management. It makes forecasting more accurate, cutting errors by up to 65%. This prevents having too much or too little stock. Better planning lowers storage costs and keeps the supply chain strong.

Why Edge AI is critical for modern PCBA processes

Today’s PCBA factories need to be fast and precise. Edge AI helps by making decisions quickly and improving processes. It lets factories adjust to changes or problems right away. With Edge AI, factories can work better, make higher-quality products, and spend less money. As factories get smarter, Edge AI becomes a must-have to stay ahead.

Applications of Edge AI in PCBA Manufacturing

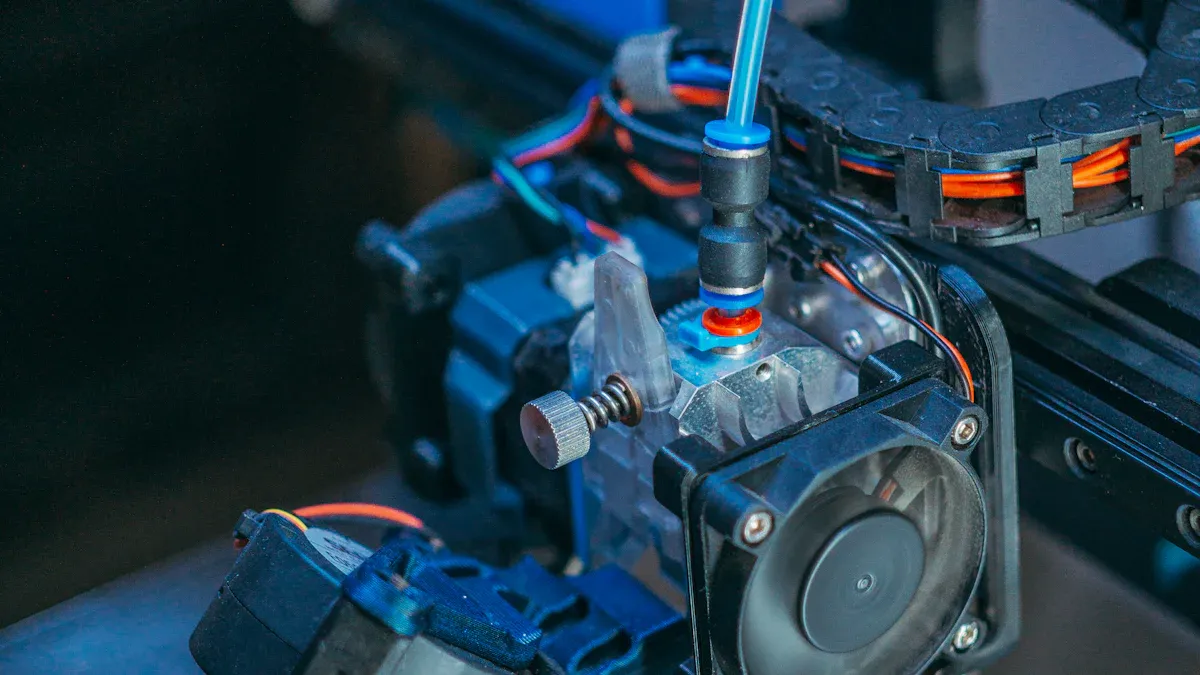

AI-driven design optimization for better PCB layouts

Edge AI helps make PCB designs smarter and more reliable. It looks at lots of data to suggest better ways to place parts and connect them. This reduces problems like signal interference and makes the boards work better. AI tools can also test different designs and predict how they will perform. This saves time and ensures the final product is high quality.

AI tools adjust quickly when designs need changes. For example, if a smaller space is needed, AI can change the layout while keeping it functional. This flexibility makes Edge AI very useful for modern PCB design.

Real-time quality inspection and defect detection

Edge AI improves quality checks by finding defects instantly. Older methods rely on people, which can lead to mistakes. AI reduces errors and lowers the number of bad products.

Here’s how Edge AI helps with quality checks:

It finds many flaws in one product in seconds.

It spots deeper issues and gives clues about their causes.

It adjusts to new product designs with little human help.

It works well across many production lines, staying accurate as production grows.

For example, an AI camera can find tiny problems like scratches or misaligned parts. This ensures only good products move forward. Using Edge AI makes inspections faster and more accurate, keeping customers happy.

Predictive maintenance for manufacturing equipment

Edge AI is great for keeping machines running smoothly. It watches equipment closely and spots problems before they cause breakdowns. This prevents delays and helps machines last longer.

Edge AI uses tools like quick problem detection and fast responses to keep machines working. Here’s a summary:

Metric | Description |

|---|---|

Finds unusual machine behavior quickly for fast fixes. | |

Reduced Latency | Analyzes and solves issues right away to avoid delays. |

Improved Reliability | Keeps machines working even if the network has problems. |

Predictive maintenance saves money and improves efficiency. For example:

A wind energy company cut downtime by 60% and made 8% more energy.

A car manufacturer saved $15 million yearly and reduced downtime by 45%.

A fleet company lowered breakdowns by 70% and downtime by 50%.

These examples show how Edge AI helps prevent machine failures. It keeps production steady and lowers costs.

Process automation and adaptive manufacturing

Edge AI is changing how PCBA factories work. It helps machines be smarter and faster. AI-powered automation removes boring tasks, so workers can focus on better ideas. With Edge AI, production lines adjust quickly to changes. This keeps things running smoothly, even when surprises happen.

How automation improves production

Edge AI automation makes production faster and better. Here’s how:

AI checks data instantly, cutting final testing by 30%. This speeds up work without losing quality.

It finds mistakes early, saving money on fixing or throwing away items.

Smarter plans keep machines running well, reducing delays and wait times.

These tools make Edge AI a big help for companies. It lets them grow while keeping high standards.

Adaptive manufacturing vs. old methods

Edge AI makes adaptive manufacturing much better than older ways. It mixes flexibility, speed, and new methods to meet today’s needs.

Feature | Adaptive Manufacturing | Old Manufacturing |

|---|---|---|

Quick Changes in Production | High – adjusts fast to new needs | Low – needs big changes to tools |

Tool Efficiency | Better – faster tools with less waiting | Basic – tools take longer to finish tasks |

Mix of Methods | Yes – uses both new and old ways together | No – sticks to one way |

Adaptive manufacturing helps factories grow without buying lots of new tools. It also mixes 3D printing and old methods to save time and improve quality. This makes it great for industries needing speed and accuracy.

Why adaptive manufacturing is important

Adaptive manufacturing helps factories keep up with market changes. It makes tools work faster and blends different methods easily. This boosts efficiency and makes better products. It gives factories an edge in the fast-moving PCBA world.

Benefits of Edge AI in PCBA Manufacturing

Cost reduction and improved efficiency

Edge AI helps factories save money and work faster. It takes over boring tasks, so workers can focus on other things. This saves time and reduces costs. It also uses resources wisely, cutting down on waste during production.

Many companies have already saved a lot with Edge AI:

M-KOPA Solar in Kenya cut IT visits by 70%, saving $2 million yearly.

Itaú Unibanco in Brazil reduced false fraud alerts by 60%, saving $15 million each year.

Telstra in Australia lowered weather-related outages by 40%, reducing recovery costs by 25%.

These examples show how Edge AI helps businesses save money while staying efficient. In your factory, it can make processes smoother, reduce delays, and boost productivity.

Enhanced product quality and reliability

Edge AI improves product quality by spotting problems right away. It uses smart tools to find even tiny issues during production. This means factories can make reliable, high-quality products for customers.

Here are some real-world examples of Edge AI improving quality:

A car company cut defects by 30% in one year using AI.

Nestlé uses AI to check packaging for safety and health standards.

Tesla uses AI to inspect car parts, reducing recalls.

Edge AI also makes PCB designs better. It follows design rules, places parts smartly, and finds mistakes early. This lowers the need for expensive prototypes and improves success rates.

Improvement Type | Description |

|---|---|

Better Accuracy and Reliability | AI follows design rules carefully, reducing errors and making high-quality PCBs. |

Smarter Design Optimization | AI places parts and routes connections to avoid problems and improve performance. |

Early Problem Detection | AI tests designs to find flaws early, saving money on prototypes. |

Faster Rule Checking | AI checks designs against rules quickly, spotting issues fast. |

Fewer Design Errors | AI learns from good designs to improve accuracy and first-pass success rates. |

Using Edge AI in your factory can ensure consistent quality and build customer trust.

Faster decision-making with real-time data

Edge AI helps factories make decisions quickly by processing data on-site. It doesn’t need to send data far away, which saves time. This speed is important for factories to stay competitive.

Real-time data has changed how factories work. Old methods used manual data collection, which took hours or days. Edge AI collects and analyzes data instantly, letting factories act fast.

Aspect | Old Manufacturing | Modern Manufacturing |

|---|---|---|

Data Collection | Manual and slow | |

Analysis Speed | Hours or days | Instant or near-instant |

Decision Making | Reactive | Proactive and predictive |

Process Visibility | Limited view | Full view of operations |

Optimization Approach | Step-by-step | Continuous improvement |

By 2025, Edge AI devices may handle 18.2 zettabytes of data per minute. This could cut cloud traffic by 99%, making operations faster and smoother. Factories can use this technology to make better decisions, see processes clearly, and improve production systems.

Scalability and flexibility in production

Edge AI helps factories grow and stay flexible. Old systems often can’t handle changes or new products easily. Edge AI fixes this by allowing quick changes and growth without big upgrades.

How Edge AI enhances scalability

Edge AI grows with your factory’s needs. It lets you expand without replacing everything. Here’s how it helps:

It works on-site, so you don’t need costly cloud systems.

It handles boring tasks, giving workers time for other jobs.

It fits with current machines, so upgrades don’t stop work.

Feature | Benefit |

|---|---|

Local Data Processing | Saves money and speeds up work by skipping cloud systems. |

Automation | Frees up time by doing repetitive tasks automatically. |

Seamless Integration | Adds capacity without slowing down current production. |

These tools make Edge AI perfect for factories that want to grow easily.

Flexibility in production with Edge AI

Being flexible is key in today’s fast-changing world. Edge AI helps factories adjust quickly to new needs, like customer demands or new products. Here’s how it works:

Quick changes: Production lines can be updated fast for new tasks.

Fast responses: On-site data processing helps react to market changes quickly.

Handles demand shifts: It easily adjusts to more or less customer orders.

For example, if a new PCB design is needed, Edge AI can update the production line in minutes. This speed keeps you ahead of competitors and satisfies customers.

Why scalability and flexibility matter

To stay competitive, factories need to grow and adapt. Edge AI helps meet higher demands while staying flexible. By automating tasks and making quick changes, it saves money and boosts efficiency.

Lower costs: Automation cuts labor costs and reduces waste.

Easy growth: AI expands with your needs without big spending.

Better adaptability: Quickly adjust to new challenges or opportunities.

Edge AI turns factories into smart, future-ready operations. It gives tools to grow and adapt to market changes. With Edge AI, factories can succeed in the fast-moving PCBA industry.

Future Innovations in Edge AI PCBA Manufacturing

Self-healing PCBs and advanced AI algorithms

Imagine a circuit board fixing itself when damaged. Self-healing PCBs are now possible with smart AI systems. These systems find problems quickly and start repairs right away. For example, special materials inside the PCB can reconnect broken circuits automatically. This new technology reduces downtime and makes devices last longer.

AI also helps improve how PCBs are designed. It studies lots of data to find weak spots and suggest fixes. This way, products become more reliable and work better. As these tools get smarter, factories will see fewer mistakes and better performance.

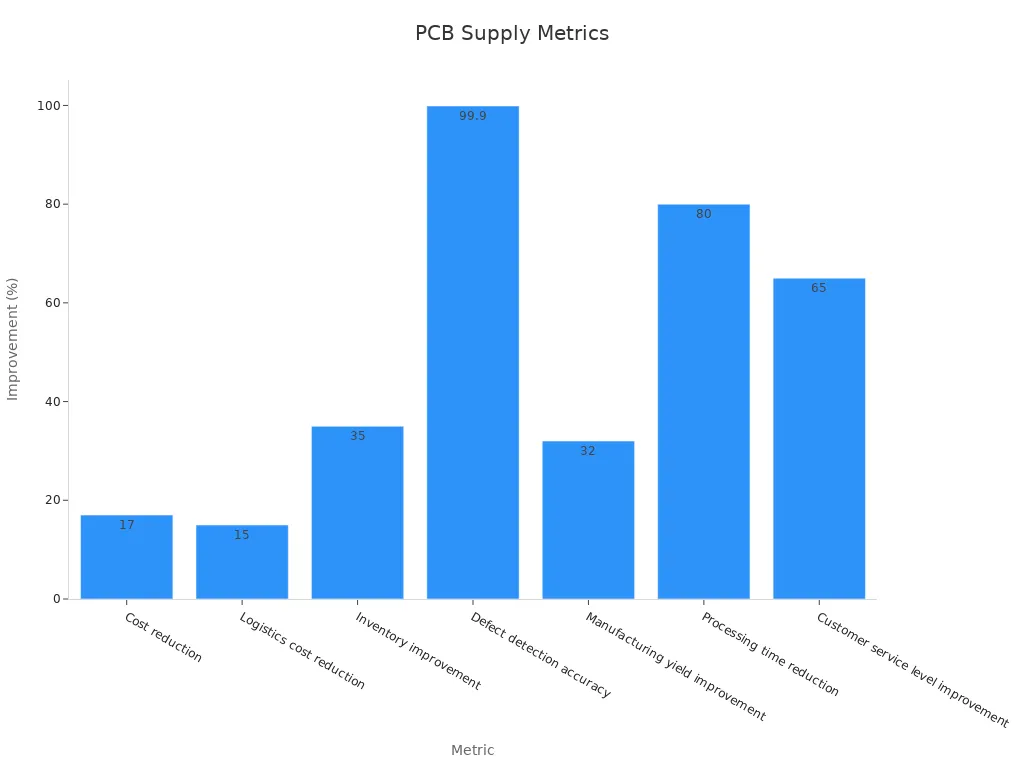

AI-driven supply chain management

Running a supply chain can be tricky, but AI makes it easier. Edge AI improves every step, like tracking inventory and delivering goods. It predicts what you’ll need, so you always have the right supplies. This cuts waste and saves money.

Here’s how AI helps supply chains:

Metric | Improvement |

|---|---|

Lower costs | |

Cheaper logistics | 15% |

Better inventory management | 35% |

More accurate defect detection | 99.9% |

Higher manufacturing yield | Up to 32% |

Faster processing times | 80% |

Improved customer service | 65% |

AI also makes supply chains stronger. It lowers risks by 25% and handles problems better by 20%. These upgrades make operations smoother and more dependable.

Integration of Edge AI with IoT for smart factories

Edge AI and IoT together create smarter factories. IoT sensors collect machine data, and Edge AI processes it fast. This helps stop breakdowns before they happen. For example, sensors can notice strange vibrations, and Edge AI can pause the machine to prevent damage.

Smart factories also save energy. AI improves cooling systems and production to use less power. It also plans better delivery routes, saving fuel and time.

Cloud-based AI connects production lines better. Data from one line can help automate others, keeping everything consistent. With these tools, factories become flexible and ready for future challenges.

Emerging trends in AI for sustainable manufacturing

Making factories eco-friendly is now very important. AI helps by making work faster, cutting waste, and improving quality checks. These changes are good for the planet and save money too.

AI systems help use materials wisely. They study data to find where waste happens. For example, AI can change machine settings to use less energy. This lowers pollution while keeping production high.

AI also helps fix machines before they break. Sensors spot problems early, stopping big breakdowns. This means fewer repairs, less waste, and lower energy use. It also keeps factories running without delays.

Quality control gets better with AI. Smart tools find mistakes quickly. This stops bad products from being made. Catching errors early saves materials and builds customer trust.

Here’s how AI helps factories go green:

Makes production faster and smarter.

Spots defects and fixes machines early.

AI is helping factories become greener and smarter. Using these tools makes your factory better for the planet and stronger in business. 🌍

Edge AI is changing how PCBA manufacturing works. It solves problems and brings new ideas. It helps factories work faster and make fewer mistakes. For instance, tools like Cendiant® software use smart learning to find defects accurately. This saves money and makes products safer. Factories also rely less on people for inspections, speeding up production. These changes make factories smarter and better at competing. As tech improves, Edge AI will keep improving PCBA manufacturing. It will help create greener and smarter production systems.

FAQ

What is the main benefit of Edge AI in PCBA manufacturing?

Edge AI works on-site, making decisions faster. It avoids delays from cloud systems. You can spot defects, improve designs, and fix machines quickly. This boosts efficiency and makes better products.

How does Edge AI help with quality checks?

Edge AI uses smart tools like cameras to find defects fast. It catches tiny problems people might miss. This ensures only good products are made, cutting waste and keeping customers happy.

Can Edge AI lower production costs?

Yes, Edge AI handles boring tasks and uses resources wisely. It reduces waste, stops machine breakdowns, and avoids delays. These changes save money and make factories work better.

Is Edge AI useful for small PCBA factories?

Definitely! Edge AI fits small factories easily. It works with current tools and skips costly cloud systems. Small factories can save money and improve efficiency with Edge AI.

How does Edge AI help eco-friendly manufacturing?

Edge AI saves energy and cuts waste. It predicts repairs, avoiding extra fixes. By working smarter and using fewer resources, it helps factories go green. 🌱

See Also

Exploring The Processes Behind PCBA Manufacturing And Assembly

Why PCBA Manufacturing Skills Matter In Electronics Development

Best Practices For Achieving Quality And Efficiency In PCBA

Essential Strategies To Overcome Challenges In PCBA Production

Emerging Trends Shaping PCB And PCBA Design And Manufacturing