Electronic contract manufacturing means hiring experts to make electronic parts. These companies design, build, and put together products for other businesses. This helps businesses get quality products without needing their own factories.

Electronic contract manufacturing is becoming more important in many industries. Data shows its growing value. For example:

Reports say the global market for these services could grow from $400 billion in 2022 to $600 billion by 2027. This is because more people want advanced and custom-made electronics.

This growth shows how important electronic contract manufacturing is. It helps industries like consumer electronics and medical devices meet their needs.

Key Takeaways

Electronic contract manufacturing (ECM) helps businesses focus on their main goals. Experts take care of production, saving time and money.

The ECM market is growing fast and may reach $1.3 trillion by 2032. It is important in industries like electronics and healthcare.

Hiring ECM companies can save money by sharing tools and using better methods. They also provide good materials.

Using new technologies like robots and AI makes ECM faster and better. This helps businesses stay ahead in a busy market.

Being eco-friendly is now important in ECM. Companies use green methods to help the planet and make customers happy.

Understanding Electronic Contract Manufacturing

What is Electronic Contract Manufacturing?

Electronic contract manufacturing means hiring experts to make electronic products. These companies handle design, assembly, and testing tasks. This lets you focus on your main business goals. It is very useful in industries needing advanced technology and accuracy.

Here’s some data to show its importance:

Metric | Value |

|---|---|

Market Size in 2023 | |

Forecast Period 2023-30 CAGR | 9.82% |

Market Size in 2032 | USD 1312.89 Bn |

This fast growth shows how much industries depend on electronic contract manufacturing today.

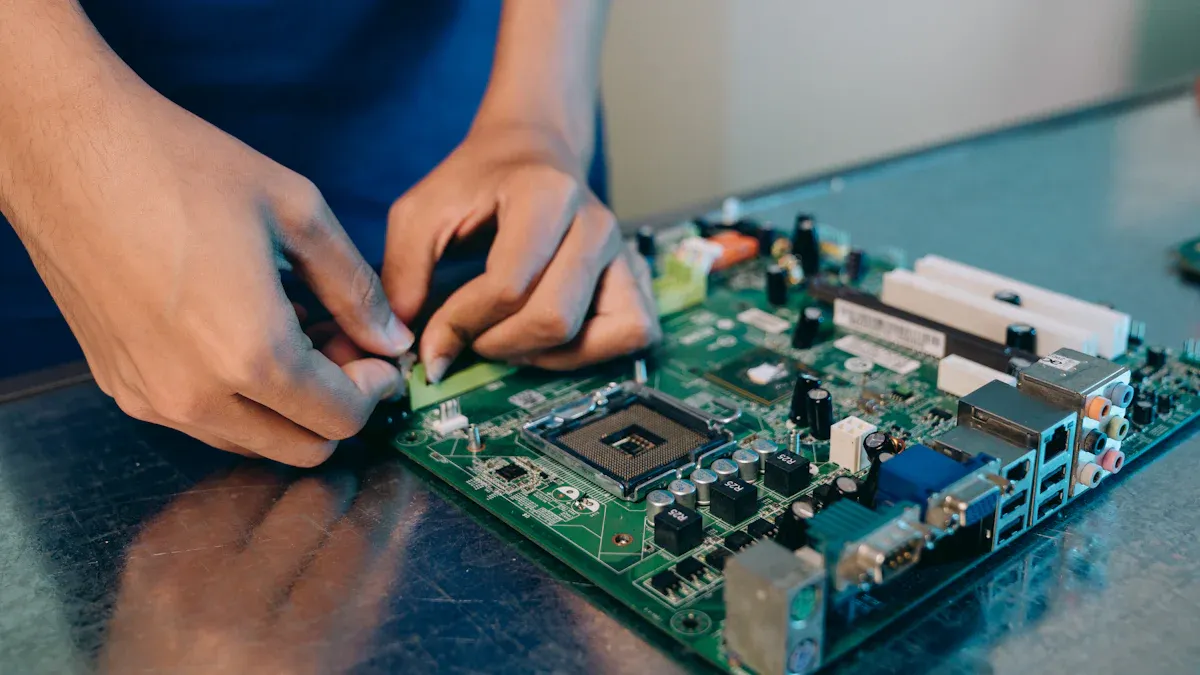

Key Processes in ECM

Electronic contract manufacturing includes important steps to ensure good results. These steps are:

Design and Prototyping: Experts help create designs and test models. This step ensures the product works before making it in large amounts.

Component Sourcing: Companies find quality parts from trusted suppliers. This keeps costs low and ensures good quality.

Assembly and Testing: Parts are carefully put together. Then, they are tested to make sure they work properly.

Packaging and Distribution: After passing tests, products are packed and sent to customers.

Each step is needed to make reliable and high-quality products.

Types of ECM Services

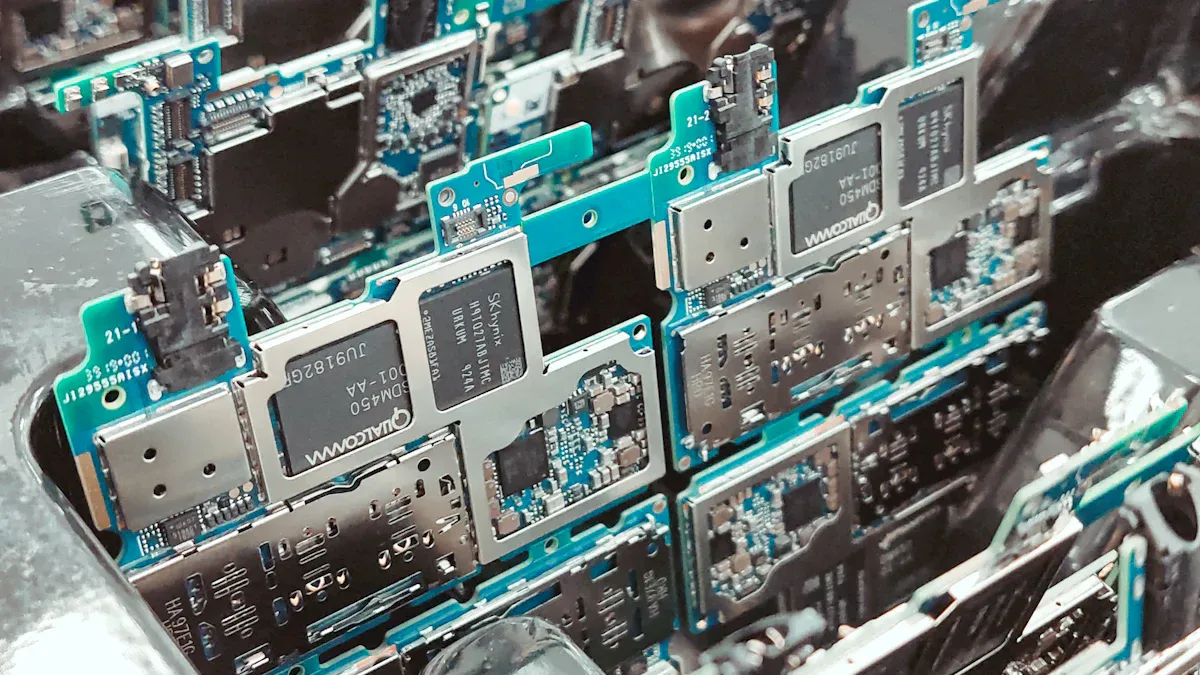

Electronic contract manufacturing offers different services for various needs, such as:

Full-Service Manufacturing: This includes everything from design to delivery. It’s great if you want one company to handle all tasks.

Specialized Services: Some companies only do specific jobs like PCB assembly. You can pick services that match your needs.

Consulting and Support: Many companies give advice to improve your product and process. They also help solve problems after production.

More businesses now want these services. They need expert help to create custom solutions and avoid problems. Industries like healthcare, government, and retail use these services to handle their unique needs.

Benefits of Electronics Contract Manufacturing

Cost Savings and Efficiency

Hiring an electronics contract manufacturer can save you money. These companies are experts in making large amounts of products. They share tools and factories, so you don’t need your own. This saves you from spending a lot on setting up production. It also lowers costs by reducing waste and improving processes.

They also know how to get good parts at low prices. Their supplier connections help them find quality materials for less money. This makes production cheaper and faster. Many industries now want quicker and more affordable solutions. This method has become very popular.

Access to Advanced Technology

Electronics contract manufacturers use the latest technology, saving you big investments. They use tools like automation, IoT, and AI to make production better and faster. For example:

Aspect | Description |

|---|---|

Technological Expertise | |

Flexibility | Their services adjust to meet changing customer needs. |

Industry 4.0 Integration | Automation, IoT, and AI improve speed and efficiency. |

This technology helps you stay ahead in a fast-changing market. As industries use more digital tools, the need for advanced electronics grows. Working with a contract manufacturer keeps you updated with the latest innovations.

Faster Product Development

Speed matters in today’s business world. Electronics contract manufacturing helps you make products faster. They use smart processes and skilled teams to save time. Studies show half of companies now develop products quicker. Also, 82% look for ways to speed up even more. This is important because 65% think faster development beats competitors.

Contract manufacturers often use Lean and Six Sigma methods to improve speed. For example, a medical company cut rework by 30% using Six Sigma. This saved money and made customers happier. By outsourcing, you can focus on new ideas while they handle production. This ensures your products reach customers quickly.

Focus on What Your Business Does Best

Working with electronics contract manufacturers lets you focus on your strengths. By letting them handle production, you can spend time on new ideas, planning, and helping customers. This way, your business grows while experts take care of making products.

Focusing on your strengths helps you earn more money. Contract manufacturers are great at saving time and reducing waste. They also follow rules to keep your brand safe and avoid problems. The table below shows how this partnership helps financially:

KPI | What It Measures | How It Helps Financially |

|---|---|---|

Yield Rates | Tracks how many good products are made. | Fewer bad products mean less waste and more profit. |

Lead Times | Shows how fast products are delivered. | Faster delivery avoids delays and saves money. |

Compliance Metrics | Checks if rules and safety standards are followed. | Following rules prevents recalls and protects your brand. |

Customer Satisfaction | Measures how happy customers are with the service. | Happy customers return and help your business grow. |

Cost Efficiency | Compares costs to product quality. | Managing costs well increases profit without lowering quality. |

With these benefits, you can spend more time creating new products or improving services. For instance, instead of worrying about production, you can build better customer connections or explore new markets. This helps your business stay ahead and grow over time.

Electronics contract manufacturers also have special skills and advanced tools. They make production faster and cheaper. This teamwork helps you focus on what you do best while they handle the rest. It’s a win-win for everyone involved.

Applications of ECM in Key Industries

Consumer Electronics

Electronic contract manufacturing is key for consumer electronics. Companies use it to meet the demand for gadgets like phones, laptops, and smartwatches. This lets businesses focus on creating new ideas while manufacturers handle making products. The market for these services is expected to grow a lot. It could reach about $850.9 billion by 2030, up from $420.0 billion in 2020. This shows a yearly growth rate of 11.5% from 2021 to 2030.

Reports show how important ECM is in this field. These studies look at market size, trends, and future growth. They give useful information to business leaders. By using ECM, companies get access to better technology and faster production. This ensures their products have high-quality electronic parts.

Automotive and EVs

The car industry, especially electric vehicles (EVs), benefits from ECM. Modern cars need many electronic parts like sensors and battery systems. ECM companies are experts at making these parts well and quickly. This helps carmakers save money and make cars faster.

Outsourcing also helps EV makers use new tech like self-driving systems and smart entertainment features. As more people want EVs, ECM helps carmakers meet their goals without losing quality. This teamwork supports new ideas and helps the car industry move toward eco-friendly solutions.

Medical Devices

In healthcare, ECM helps make safe and reliable devices. Manufacturers must follow strict rules, like IEC 60601-1 for safety and IEC 62366-1 for usability. These rules make sure devices work well and are safe to use. ECM companies are skilled at meeting these tough standards.

For example, they test devices to ensure safety and protect patient data with cybersecurity. By outsourcing, medical companies can focus on research and new ideas. ECM lowers costs and keeps up with changing rules. This makes it a valuable partner in the medical field.

Aerospace and Defense

The aerospace and defense fields need precise and reliable parts. These parts must meet strict safety and performance rules. Electronic contract manufacturing (ECM) helps make these high-quality components.

ECM companies create advanced electronics for planes, satellites, and defense tools. They follow strict rules like AS9100 for aerospace quality. This ensures the parts are safe and work well.

A big benefit of ECM is using advanced technology. They use tools like automated machines and AI testing systems. These tools help make radar, navigation, and communication devices with great accuracy.

Tip: Working with an ECM company ensures top-quality products and fewer risks.

Outsourcing to ECM saves time and money. Making aerospace electronics yourself costs a lot and takes time. ECM companies already have the skills and tools to do this. This lets you focus on new ideas and important tasks.

Here’s how ECM helps aerospace and defense:

Custom Solutions: They design parts to fit your exact needs.

Scalability: They can quickly make more parts when needed.

Compliance: ECM ensures all parts meet global safety standards.

Using ECM keeps you ahead in this tough industry. It helps you deliver safe, high-quality products for modern aerospace and defense needs.

The Scope of Electronic Contract Manufacturing in 2025

Trends Shaping ECM

The electronic contract manufacturing field is changing quickly. Many trends are influencing how companies make and deliver products:

High-Mix Low-Volume (HMLV) Production: Companies now want more custom electronics. This requires flexible factories that can handle small batches with different designs.

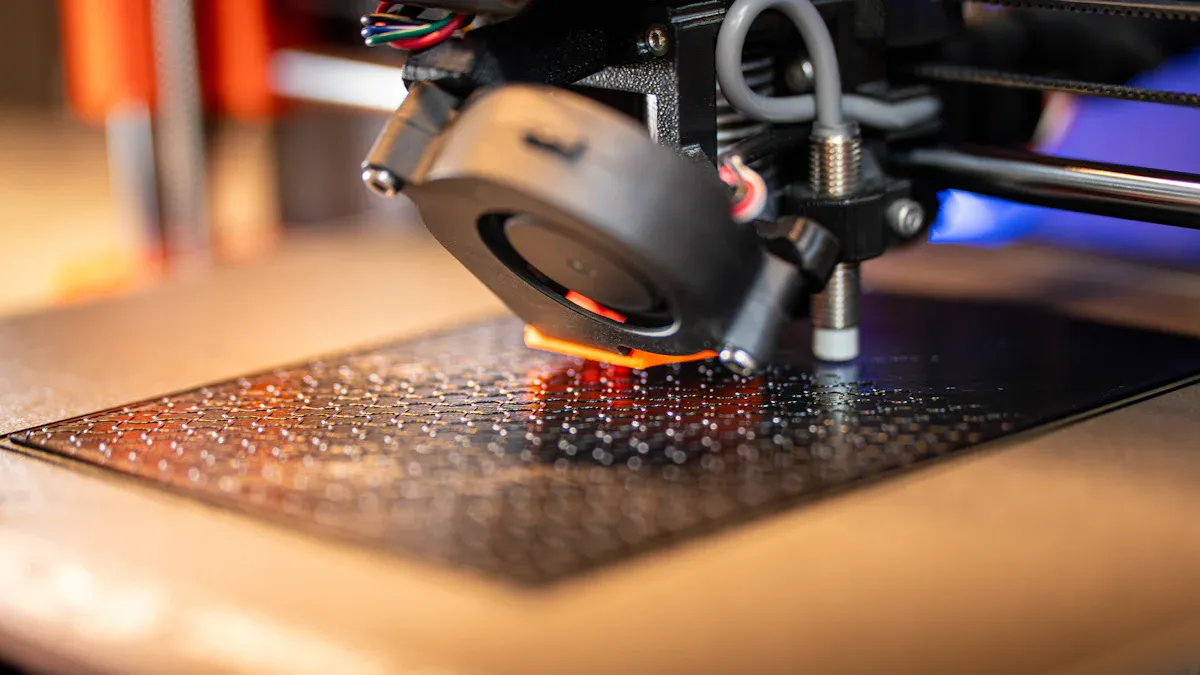

Advanced Manufacturing Technologies: Tools like robots, IoT, and AI are now common. These tools make production faster, cheaper, and improve quality.

Nearshoring and Regional Hubs: Businesses are moving factories closer to customers. This reduces delivery times and lowers risks in the supply chain.

Eco-Friendly Practices: Many factories now focus on being green. They cut waste, use clean energy, and design products that are easier to recycle.

Extra Services: Factories now help with design, shipping, and customer support. This makes business operations smoother and keeps customers happy.

Countries like China, India, and Japan in Asia are growing fast in this field. Governments are investing in technology, and more people want consumer electronics. For example, China’s market for home automation devices is expected to grow three times bigger.

Innovations in ECM

New technology is changing electronic contract manufacturing. By 2025, digital tools and stricter rules will reshape the industry. These changes bring new chances to grow while solving big problems.

Factories now use advanced tools to stay competitive. For example, “digital twins” let them test and improve processes before making products. This saves time and reduces mistakes. Better materials are also helping create smaller, more efficient parts. These are important for industries like healthcare and aerospace.

But challenges like data safety and tech integration remain. Companies must protect their systems from cyber threats. They also need to make sure new tools work well with old ones. Solving these issues will help factories grow and succeed.

Automation and AI in ECM

Automation and AI are changing how electronic contract manufacturing works. These tools make production faster and smarter.

AI can study large amounts of data to find problems early. For example, it can predict when machines might break and fix them before they stop working. This avoids delays and keeps things running smoothly. Automation handles repetitive jobs like putting parts together and testing them. This helps factories make better products faster.

Industry 4.0 tools, like IoT and machine learning, are improving factories even more. Smart factories use connected devices to share information instantly. This improves workflows and reduces waste. These tools are especially helpful in industries like cars and electronics, where speed and accuracy are very important.

As automation and AI improve, they will shape the future of electronic contract manufacturing. Using these tools will help businesses stay competitive and meet the demand for high-quality electronics.

Sustainability in ECM

Sustainability is now very important in electronic contract manufacturing (ECM). As industries grow, they need greener ways to work. ECM companies are finding smart ways to save energy, cut waste, and follow global eco-rules.

One big change is green manufacturing. Factories now use clean energy like solar and wind power. This helps the planet and lowers costs. For example, many factories have added solar panels to run their machines. These steps reduce pollution and save money.

Another way is cutting waste. Companies recycle materials like metal and plastic from old electronics. This keeps trash out of landfills and supports reusing resources. Some products are also made to be easier to fix or recycle. This helps businesses meet customer demands for eco-friendly products.

“Locus has offered online eco-solutions since 2002, covering key Global Reporting Initiative (GRI) rules for the environment and fair work,” said Locus President and CEO, Neno Duplancic.

ECM companies also follow strict eco-rules. They report greenhouse gas (GHG) emissions and follow GRI standards. This shows they care about the planet and builds trust with customers.

“Locus Technologies has shown great eco-leadership by studying its environmental impact,” said Doug Scott, Chair of The Climate Registry.

Eco-friendly practices are helping the ECM market grow. More businesses now want manufacturers who care about the environment. This has increased demand for green electronics. Choosing a sustainable ECM partner helps the planet and matches what customers want.

“We hope Locus inspires other companies worldwide to value GRI and GHG reporting.”

Still, there are challenges. Going green can cost a lot at first. But in the long run, it saves money and improves a company’s image. As sustainability becomes more important, ECM companies will keep finding new ways to protect the planet.

Challenges in Electronic Contract Manufacturing

Supply Chain Management

Handling the supply chain in electronic contract manufacturing (ECM) is tricky. Problems like delays, shortages, and high costs can happen. These issues often come from getting parts from many suppliers worldwide. If one area has trouble, the whole process can slow down.

To fix this, companies now use smart tools like AI and machine learning. These tools help predict problems and manage suppliers better. For example, 81% of companies say AI makes processes smoother. Machine learning also helps with shipping and supplier tasks, making things run better. But there are still challenges, like being eco-friendly and picking the best tools.

Evidence Type | Description |

|---|---|

AI in Vendor Risk Management | 81% of respondents believe AI improves content-heavy processes. |

Machine Learning Applications | Used for risk management, supplier management, and transport optimization. |

Using these tools can lower risks and make supply chains work better.

Quality and Compliance

Keeping quality high and following rules is very important in ECM. Products must meet standards while keeping mistakes low. Numbers like defect rates and first-pass yield help check quality. For instance, tracking how many products are made right the first time shows efficiency.

Defect Rates: Show where product quality needs fixing.

First Pass Yield: Tracks how well processes work without redoing tasks.

Audit Findings: Checks if rules and standards are followed.

Better quality means saving money. Fewer mistakes mean less waste and fewer recalls. Faster teamwork and smooth workflows also speed up production. By focusing on these numbers, you can keep quality high and save costs.

Data Security and IP Protection

Keeping data and ideas safe is a big worry in ECM. Important details, like designs and customer info, must stay private. Cyber threats, like hacking and data leaks, are serious risks.

To protect this data, ECM uses tools like encryption and access controls. Regular checks also find weak spots in security. For example, encryption stops hackers, and audit trails track file changes. These steps keep data safe and follow rules.

Outsourcing ECM can be risky if security is weak. Picking a partner with strong protections keeps your ideas safe and builds trust. By focusing on security, you can work on new ideas without fear of breaches.

Outsourcing electronic manufacturing helps industries save money and work better. It lets you focus on new ideas while experts make the products. This method brings quicker deliveries and higher-quality results. By 2025, new technology like automation and eco-friendly practices will boost growth even more. Smarter systems and greener methods will meet what the market needs. Adopting these changes keeps your business strong and prepared for the future.

Tip: Choosing the right manufacturer saves money and ensures success.

FAQ

What does electronic contract manufacturing mean?

It means hiring experts to make and test electronics. They handle production, so you can focus on creating new ideas.

Why is outsourcing helpful for your business?

Outsourcing saves money and makes production faster. You don’t need costly tools or factories, so you can focus on important tasks.

Can ECM create custom products?

Yes, ECM companies make products to fit your needs. They adjust their work to give you high-quality, custom-made results.

Is ECM good for small businesses?

Yes! ECM works for all business sizes. Small businesses save money and use advanced tools without spending a lot.

How do ECM companies keep products high-quality?

They test products carefully and follow strict rules. This ensures the products are safe, reliable, and meet industry standards.

See Also

Detailed Overview of the PCBA Production Procedure

Essential Advice for Selecting a PCBA Manufacturer

Thorough Guide to the Steps in PCBA Production