Electromagnetic interference (EMI) shielding is very important, especially for EMI shielded PCBA for industrial communication modules. It stops unwanted electromagnetic waves from harming sensitive circuits. Industries like telecom and cars use complex electronics and 5G, making EMI shielding a must-have. A well-designed EMI shielded PCBA improves electromagnetic compatibility (EMC), which boosts reliability and performance. To achieve this, follow a step-by-step design process for EMC. This ensures that devices meet regulations and operate effectively in tough conditions.

Key Takeaways

EMI shielding helps protect delicate circuits in communication devices from bad electromagnetic signals.

Use good grounding methods and layer designs to make devices work better and last longer.

Pick the right materials for EMI shielding based on the interference type and where the device will be used.

Test early during design to find and fix EMI problems, meeting rules like MIL-STD-461.

Use shielding tools like Faraday cages and special coatings to block EMI and make devices work well.

Key Challenges in EMI Shielding for Industrial Communication Modules

Common EMI Issues in Industrial Environments

Factories and industries have many sources of electromagnetic interference (EMI). Machines like motors, power systems, and heavy equipment create strong interference. This can harm sensors, networks, and other delicate devices. For instance, networks such as Ethernet and Profibus are easily affected by EMI. This can cause data errors or loss of control signals. To fix these problems, use grounding, shielding cases, and surge protectors. These tools protect devices and keep them working well in tough environments.

Impact of EMI on Module Performance

EMI can make communication modules work poorly. It can break connections between devices, making systems unreliable. Interference can also mess up data, causing errors or wrong readings. Over time, this might lead to lost data or broken systems. EMI slows down data transfer and uses more power, lowering system performance. These problems show why good EMI shielding is needed to keep communication modules working properly.

Regulatory and Environmental Constraints

Following rules and standards is key for EMI shielding in communication modules. Rules like MIL-STD-461 and IEC 61000 set limits for emissions and testing. These rules change often to match new tech and stricter limits. For example, MIL-STD-461 works with global rules like CISPR and IEC for EMI control. The FCC also has rules under Title 47, Part 15, for home and business devices. Following these rules helps your modules work well and avoid causing interference.

Design Principles for EMI Shielded PCBA for Industrial Communication Modules

Grounding Techniques for EMI Mitigation

Good grounding is key to blocking EMI. It gives unwanted electromagnetic waves a safe path to escape, protecting circuits. Use a solid ground plane in your PCB design. This lowers resistance and keeps signals steady. For high-frequency signals, keep the return path short to reduce noise.

Different grounds have different jobs. Signal ground is for signal voltages, while power ground handles power returns. Chassis ground connects to the case, helping block EMI. Separating digital and analog grounds stops them from interfering with each other. Star grounding links all grounds at one point to avoid noise loops.

Adding filters like ferrite beads and capacitors can block high-frequency noise. These parts stop unwanted signals, keeping your circuits clean. Together, good grounding and these tools create strong EMI protection in tough environments.

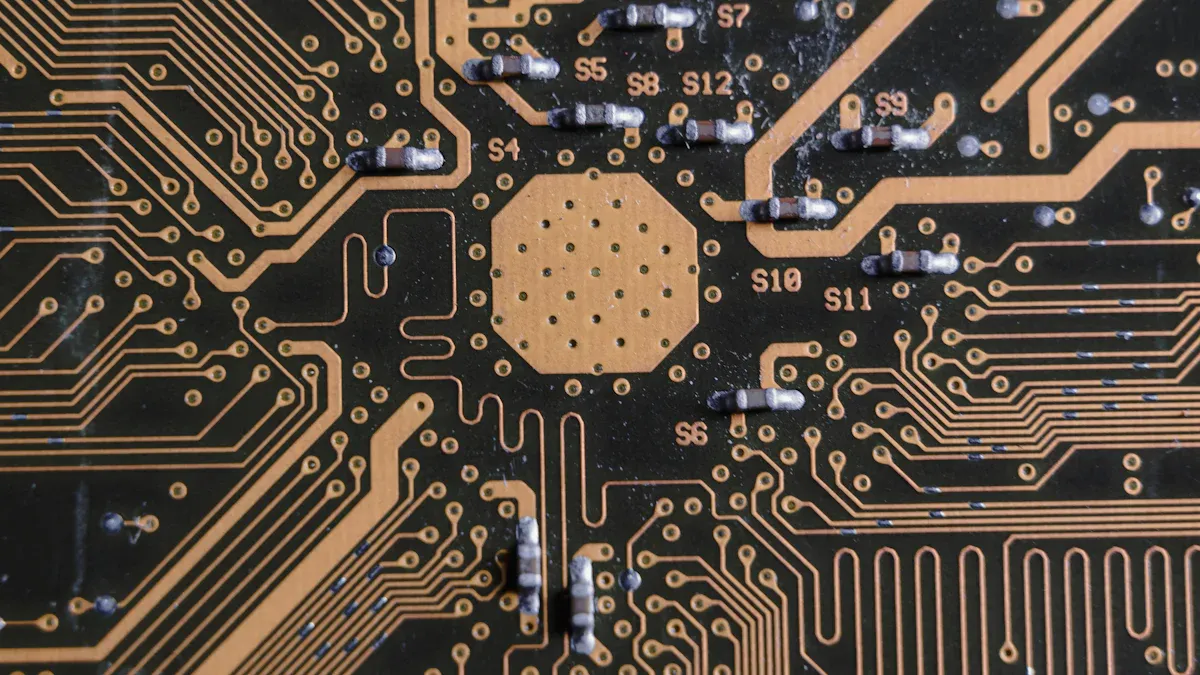

Layer Stack-Up Design for EMC Compliance

The way PCB layers are arranged affects EMI shielding. A good stack-up lowers electromagnetic waves and keeps signals clear. Use a balanced design with layers for power, ground, and signals.

For example, placing a ground layer next to a power layer reduces noise. Signal layers should sit between ground layers when possible. This setup cuts crosstalk and shields sensitive parts from outside interference.

High-speed designs need controlled impedance. Choose the right materials and layer thickness to achieve this. A symmetrical stack-up also keeps the board stable and prevents bending during production. By planning your layers well, your PCB will meet standards and work reliably.

Trace Routing and Signal Integrity

Trace routing is important for EMI shielding. Bad routing can cause signal problems and more EMI. Keep traces short and direct to protect signals. Avoid sharp turns, as they can reflect signals and raise resistance.

Leave enough space between traces to reduce crosstalk, especially in high-frequency circuits. Group similar signals together and keep noisy traces away from sensitive ones. For high-speed signals, route differential pairs close together to lower EMI.

Plan your layout carefully to improve signal quality. Place parts to make trace routing easier and reduce loop areas. This also helps with heat management. These steps improve EMI shielding and ensure your PCB works well in tough conditions.

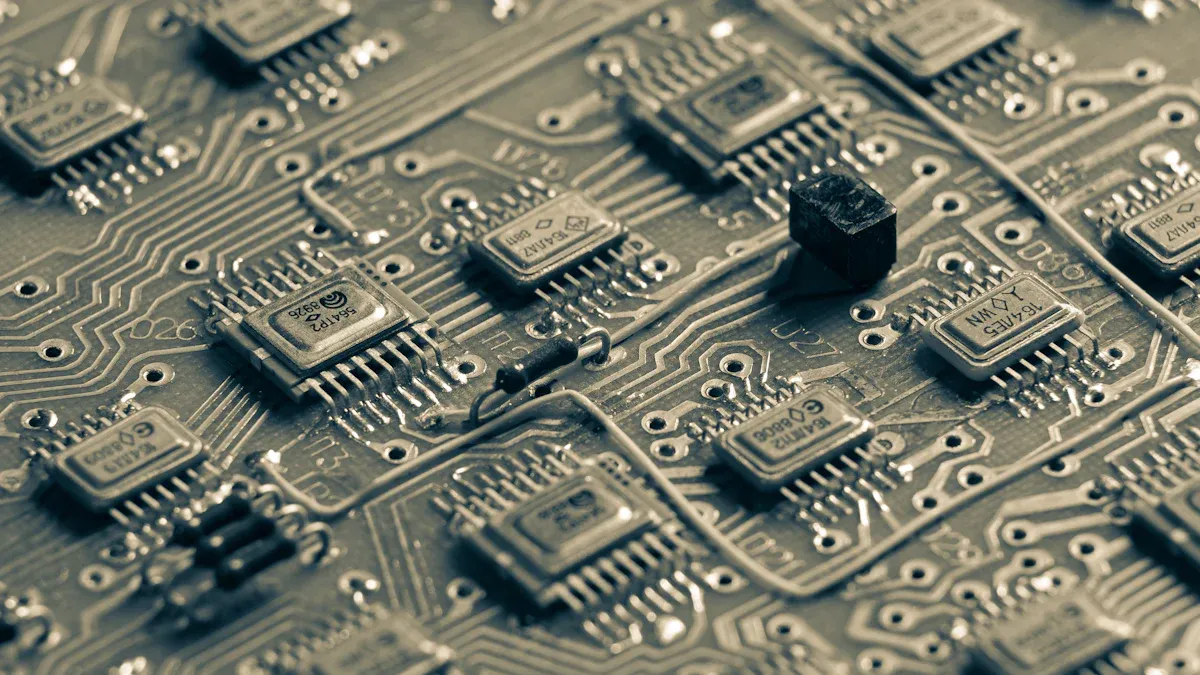

Component Placement Strategies

Placing parts correctly helps reduce EMI and improves PCB reliability. By arranging parts smartly, you can lower noise, improve signals, and boost the performance of your EMI shielded PCBA for communication modules.

Arrange Parts to Reduce EMI

Organize parts to cut down on electromagnetic interference. Group similar parts together and make zones for different circuits. For example:

Keep analog circuits far from digital ones to avoid interference.

Place power parts away from sensitive signal paths to stop noise.

Create separate areas for mixed-signal boards like digital, power, and analog zones.

This setup reduces current loops and keeps signals cleaner.

Manage Return Currents Well

A good return path is key for guiding currents back. Place parts so return currents have a clear, short path. This lowers noise and stops signals from interfering with each other.

Use Layered Design for Better Shielding

Layered designs can make EMI shielding stronger. You can improve shielding by designing both small and large PCB structures carefully. Advanced methods, like 3D printing with special materials, can boost shielding by up to 200%.

Place Parts for Strong Signals

When placing parts, focus on keeping signals strong. Keep high-speed signal paths short and straight. Don’t put noisy parts, like oscillators, near sensitive analog circuits. Keep differential pairs close together to lower EMI.

Balance Space and Accessibility

Compact designs save space but can increase EMI. Spread parts out enough to reduce interference and make repairs easier. Leave space between parts to avoid crosstalk.

Tip: Test your part placement using simulation tools before finalizing. These tools help find EMI trouble spots and improve your layout.

By using these tips, your PCB design will meet EMC rules and work well in tough environments.

Effective EMI Shielding Techniques

Faraday Cages and Shield Cavities

Faraday cages are great for blocking EMI. They work by moving electric charges in their conductive material. This movement cancels outside electromagnetic fields, keeping parts inside safe. Use Faraday cages in places with high EMI, like factories or labs.

How well a Faraday cage works depends on:

How conductive the material is.

The thickness of the shielding material.

The frequency of the electromagnetic waves it blocks.

Thicker shields are better for low-frequency waves. This is because most current stays near the surface, improving shielding.

In factories, shielded rooms made of metal mesh or sheet metal block outside EMI. These rooms are great for testing communication devices. Adding Faraday cages or shield cavities to your design can cut EMI and make modules more reliable.

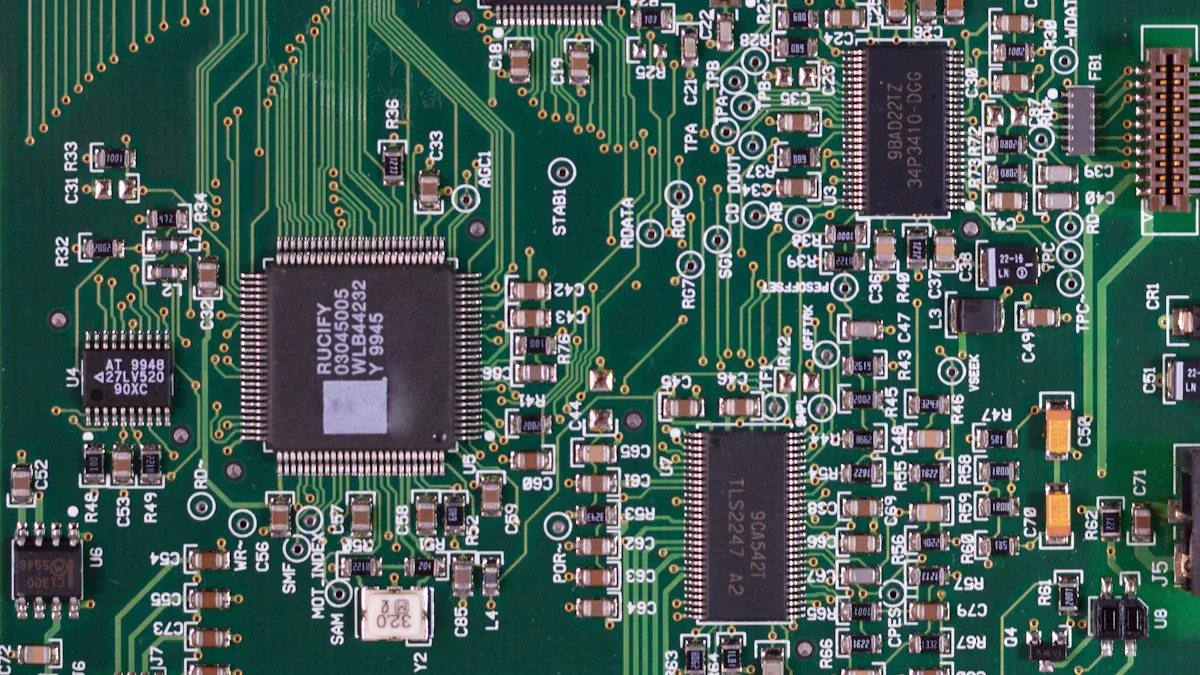

Conductive Coatings and Shielding Materials

Conductive coatings and materials are flexible for EMI shielding. These coatings, made from metals like copper or nickel, block electromagnetic waves. Apply them to cases, PCB surfaces, or parts to improve protection.

Different industries use these materials for specific needs:

Military uses metal coatings for heat resistance.

Aerospace prefers polymers for corrosion resistance.

Medical devices use conductive paints to protect electronics.

Pick materials based on where your module will be used. Conductive fabrics work for flexible designs, while metal coatings are better for rigid cases. Choosing the right material ensures your design meets EMC rules and works well.

EMI Gaskets and Board-Level Shielding

EMI gaskets and board shields block interference in specific areas. EMI gaskets, made of conductive materials, seal gaps between parts. They stop electromagnetic waves from leaking in or out.

Board-level shielding uses metal covers on the PCB to protect parts. These shields are helpful for high-frequency circuits or sensitive components. They can isolate noisy parts, like oscillators, from other circuits.

When using EMI gaskets or shields, focus on:

Material choice: Use gaskets that conduct well and last long.

Placement: Put shields over the most sensitive PCB areas.

Fit: Make sure gaskets and shields don’t interfere with other parts.

These methods improve EMI protection and help meet EMC standards. Combining gaskets and shields with other techniques creates strong designs for communication modules.

Picking the Best Shielding Method

Choosing the right shielding keeps your module working well. Each method has its own benefits. Pick the one that fits your needs best.

Know the Interference Type

Find out the frequency of the interference affecting your module. High and low frequencies need different materials. Thick materials block low-frequency EMI better. Thin coatings work for high-frequency EMI.

Measure Shielding Strength

Check how much shielding your module needs. Shielding strength shows how well a material blocks EMI. Compare options like Faraday cages, coatings, or gaskets. Modules in factories often need stronger shielding.

Think About the Environment

Look at where your module will be used. Heat, moisture, and chemicals affect material choice. Aerospace needs rust-proof polymers. Factories may need tough metal coatings.

Check Mechanical Needs

The module’s design affects your choice. Flexible designs may need thin coatings or fabrics. Rigid designs work better with metal shields or board-level shielding. Match the shielding to your PCB’s design.

Improve Gasket Design

Pick strong, conductive gaskets. Make sure they seal tightly without breaking parts. Good gaskets stop EMI leaks and improve shielding.

Tip: Test shielding methods with simulation tools first. These tools show EMI trouble spots and help improve your design.

Use a Shielding Plan

Follow these steps to pick the best shielding:

Find the interference frequency.

Measure needed shielding strength.

Check environmental factors.

Look at mechanical needs.

Test gasket pressure.

Pick the right gasket material.

Design gaskets for top performance.

This plan helps you choose the best shielding for your module.

Balance Cost and Quality

Better shielding costs more but works better. Stay within budget while meeting your module’s needs. For cheaper designs, mix methods like coatings and gaskets.

Picking the right shielding takes planning. By knowing interference, environment, and design needs, you can make a reliable module that meets EMC rules.

Testing and Validation for EMC Compliance

EMI Testing Standards and Protocols

To make sure your design meets EMC rules, follow EMI testing standards. These rules check if your module can handle interference and control emissions. Common standards include:

Standard | What It Covers |

|---|---|

Tests for HEMP and HPEM effects on systems | |

Protecting facilities from HEMP and IEMI risks | |

Immunity rules for industrial environments | |

Emission rules for industrial environments | |

Military EMI testing standards |

Follow these steps for testing:

Check your design to ensure EMC techniques are included.

Test early in-house to find and fix problems quickly.

Use certified labs for official tests like MIL-STD-461.

This process helps you catch and fix issues early, saving time and money.

Tools and Equipment for EMI Analysis

Special tools are needed to check EMI. These tools find interference sources and test your design. Some helpful tools are:

Tool/Equipment | Features | How It Helps with EMI |

|---|---|---|

Noise checks, signal simulations | Finds noise and fixes impedance issues | |

Cadence Allegro | Advanced routing, signal checks | Great for fast, high-frequency designs |

ANSYS EMIT | Interference tracing, problem summaries | Pinpoints interference causes |

These tools let you test real-world conditions. For example, Altium Designer can show where EMI filters are needed, keeping signals clean.

Iterative Design Improvements Based on Test Results

Testing should happen more than once. Use test results to improve your design step by step. Look at the data to find where interference is too high. Then, adjust your PCB layout, shielding, or grounding to fix it.

For example:

Add EMI filters if high-frequency noise is found.

Use better shielding if emissions are too high.

Test again after each change. This cycle of testing and fixing helps your design meet EMC rules and work better. By improving your design over time, you’ll create a strong and reliable communication module.

Common Mistakes in EMI Shielded PCBA Design

Weak Grounding and Shielding Methods

Good grounding and shielding are key for stopping EMI. But, they are often done wrong. Bad grounding, like using many ground points without linking them well, causes problems. This can create voltage differences, letting noise move between circuits. This weakens how industrial modules work. For example, an engineer showed how current moved between two ground rods due to bad grounding. This caused noise issues. It shows why having one strong, connected ground is so important.

Shielding errors, like using aluminum instead of ferrous metals, also cause trouble. Ferrous metals block magnetic fields better, which are common noise sources in factories. To avoid these mistakes, make sure your grounding and shielding are strong and fit your module’s needs.

Wrong Material Choices

Picking the wrong materials for EMI shielding can hurt your PCB. Each material blocks electromagnetic waves differently. For example, copper or nickel coatings are great for high-frequency noise. Thicker ferrous metals work better for low-frequency noise. Using thin aluminum for low-frequency noise won’t work well and may fail EMC tests.

Think about the environment when choosing materials. Factories with heat or moisture need rust-proof coatings. Aerospace designs may need lightweight polymers. Picking the right material helps meet EMC rules and makes your design more reliable.

Ignoring Trace Routing Rules

Bad trace routing can raise EMI and hurt signals. Poor practices, like big loop areas or uneven impedance, make noise worse. Follow these tips to fix this:

Key Point | Explanation |

|---|---|

Use vias to switch layers, lowering impedance problems. | |

Small Loop Area | Keep signal loops small to reduce EMI. |

Steady Impedance | Keep impedance even to protect signal quality. |

Also, place EMI filters near noisy parts to improve signals. By following these steps, your PCB will have less EMI and meet EMC standards.

Skipping Proper Testing

Not testing enough can cause big problems in your EMI-shielded PCBA. Testing checks if your design meets EMC rules and works well. Without it, you might face failures, break rules, or need expensive fixes.

Why Testing is Important

Testing finds hidden EMI issues that can harm your module. It checks if shielding, grounding, and routing work correctly. For instance, high-frequency noise might pass filters if not tested in real conditions. Testing also ensures your design follows rules like IEC 61000 or MIL-STD-461.

Common Testing Errors

Designers often make mistakes during testing. Here are some examples:

Only Using Simulations: Simulations help but can’t replace real-world tests. Things like heat and moisture affect EMI differently.

Delaying Testing: Waiting until the end to test can lead to big problems. Early testing helps catch and fix issues sooner.

Ignoring Tough Conditions: Testing only in easy conditions won’t show how your module works in harsh places.

How to Do Testing Right

Follow these steps to test properly:

Start Early: Test during the design phase. Use prototypes to find and fix problems early.

Use Certified Labs: Official tests at trusted labs ensure your design meets industry rules.

Test Real Conditions: Check your module in environments like where it will be used. Include noise, heat, and moisture.

Improve with Results: Use test data to make your design better. Fix shielding, grounding, or routing as needed.

Tip: Get good tools like spectrum analyzers and EMI probes. These tools help find interference and confirm your design works.

Proper testing makes sure your EMI-shielded PCBA works well and meets rules. By focusing on testing, you can avoid costly errors and build a strong communication module.

EMI shielding is key to keeping industrial communication modules reliable. Using EMC rules helps build strong systems that follow standards. These systems work well even in tough conditions. Good grounding, smart layer designs, and careful trace routing lower EMI problems. Methods like Faraday cages and conductive coatings add extra protection. Testing in labs checks for compliance and ensures reliability. Future designs with full-shielding layers can cut interference by 400 times. These steps make EMI shielded PCBA reliable, affordable, and rule-compliant.

Tip: Test sensitive devices first to save money and time.

FAQ

What is EMI shielding, and why does it matter for PCBA?

EMI shielding stops electromagnetic waves from messing up circuits. It helps your PCBA work well in tough industrial places. Without it, sensitive parts might fail or cause communication errors.

How can you make grounding better in PCB design?

Use a strong ground plane to keep signals steady. Separate digital and analog grounds to stop interference. Add ferrite beads to block high-frequency noise.

What materials are best for EMI shielding?

Copper and nickel coatings block high-frequency noise well. Ferrous metals are good for low-frequency interference. Pick materials based on the environment, like rust-proof ones for aerospace or strong ones for factories.

What tools are useful for EMI testing?

Tools like Altium Designer and Cadence Allegro check signals and noise. Spectrum analyzers and EMI probes find interference spots. These tools help improve designs and meet rules.

How do you test for EMC compliance?

Start testing early with prototypes. Use certified labs for official tests like MIL-STD-461. Test in real conditions, like heat and noise, to ensure your module works and meets standards.

See Also

Streamlined PCBA Solutions for Your Electronics Projects

A Guide to EMS and PCBA Services in Electronics

Choosing the Right RF PCBA Provider for Your Requirements

Investigating Testing Methods for PCBA in Electronics Production