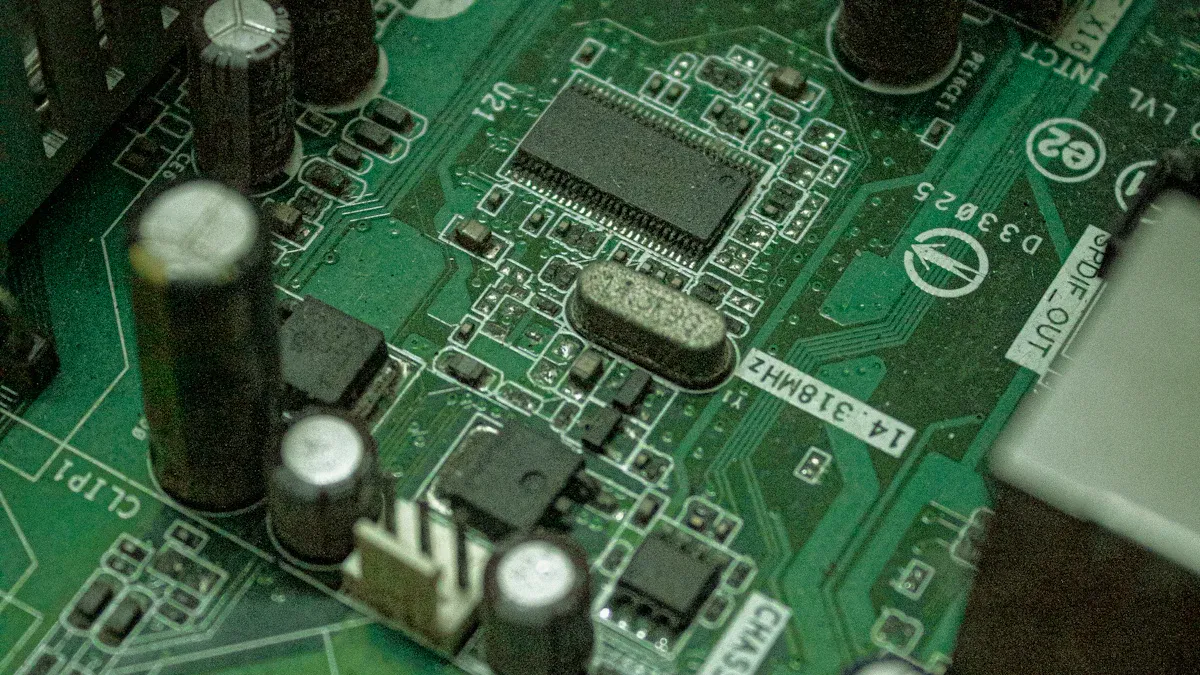

Electromagnetic interference (EMI) can disrupt electronic devices. EMI shielding prevents this by blocking harmful electromagnetic waves. In the context of an EMI shielded industrial automation PCBA, shielding is crucial. It ensures that systems operate smoothly without interruptions, maintaining clear and reliable signals. Without proper shielding, sensitive components may fail, leading to costly delays. An EMI shielded industrial automation PCBA performs better and remains dependable, even in environments with strong electromagnetic waves.

Key Takeaways

EMI shielding stops harmful electromagnetic waves, keeping devices working well.

Different EMI types, like radiated and conducted, need special shields to protect parts.

Using strong materials like copper and carbon makes shields work better and last longer.

Testing for electromagnetic compatibility often helps meet rules and keeps systems reliable.

Spending on EMI shielding lowers repair costs and boosts system efficiency, increasing productivity.

Understanding EMI and Its Impact

What is EMI?

Electromagnetic interference (EMI) happens when unwanted electromagnetic waves disturb electronics. These waves can cause devices to work poorly or even stop working. For example, you might hear buzzing in speakers when a phone is nearby. Or, lights might flicker when a fridge turns on. EMI comes from natural events like lightning or solar storms. It also comes from human-made things like broken devices or strong radio signals.

In factories, EMI is a big problem. Machines often create electrical signals that can mess up sensitive parts. That’s why using good EMI shielding is so important. It keeps devices safe and helps them work properly.

Types of EMI

There are different kinds of EMI based on how it spreads:

Radiated EMI: Moves through the air. For example, a phone near speakers can cause noise.

Conducted EMI: Travels through wires. Lights might flicker when appliances turn on.

Coupled EMI: Happens when energy jumps between circuits, like in PCB designs.

Continuous Wave (CW) Interference: Includes narrowband or broadband signals.

Electromagnetic Pulses (EMP): Strong bursts of energy that can damage electronics.

Knowing these types helps find EMI sources and plan proper shielding.

Effects of EMI on PCBA in Industrial Environments

In factories, EMI can harm printed circuit board assemblies (PCBA). The table below shows how EMI affects them:

Aspect | Description |

|---|---|

How EMI Happens | Machines create unwanted electrical signals. |

Noise Types | Different noises lower performance and disturb systems. |

Following rules helps reduce EMI problems in factories. |

Without EMI shielding, PCBA can lose signals, become less reliable, or break down. This causes expensive repairs and wasted time. Fixing EMI keeps systems working well and meeting industry rules.

How EMI Shielding Works

Principles of EMI Shielding

EMI shielding stops electromagnetic waves from disturbing electronics. It uses a barrier made of conductive materials. This barrier absorbs the waves and safely sends them to the ground. When waves hit the shield, currents form in the material. These currents cancel out the interference, keeping electronics safe.

For instance, machines in factories create electromagnetic noise. This noise can harm nearby devices. With good shielding, printed circuit boards stay protected. This helps devices work well, even in tough conditions.

Tip: Always ground the shielding material properly. Without grounding, the interference cannot be safely removed, making the shield less effective.

Materials Used in EMI Shielding

The material used for shielding is very important. Different materials block interference better depending on their properties. Below is a table comparing common materials:

Material Type | Frequency Range (GHz) | Shielding Effectiveness (dB) | Notes |

|---|---|---|---|

Carbon Nanofiber-filled Composites | 8.2-12.4 | < 26 | Works better with more material added. |

Multi-walled Carbon Nanotube Composites | 8.2-12.4 | > 26 | Performs well with less material compared to nanofibers. |

Metals like copper and aluminum are popular for industrial use. They are strong and conduct electricity well. Newer materials, like carbon nanotube composites, are lighter and offer better shielding.

Note: Pick a material based on the environment and type of interference. This ensures better noise control and long-lasting performance.

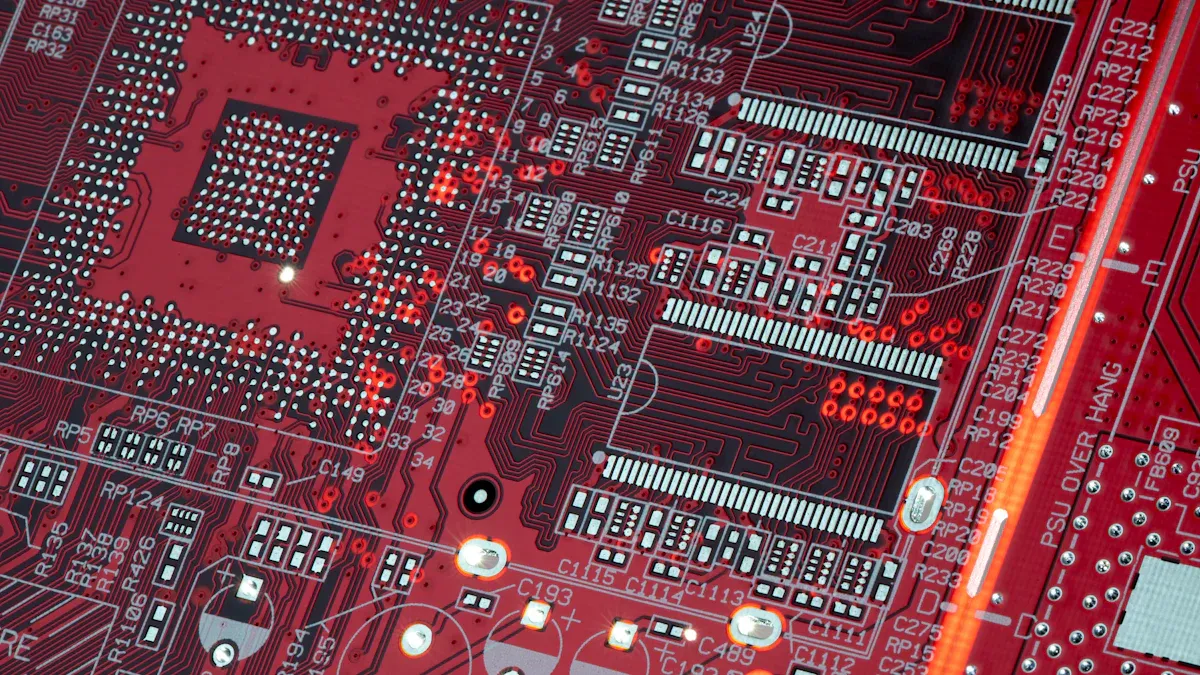

Methods for Implementing EMI Shielding in PCBs

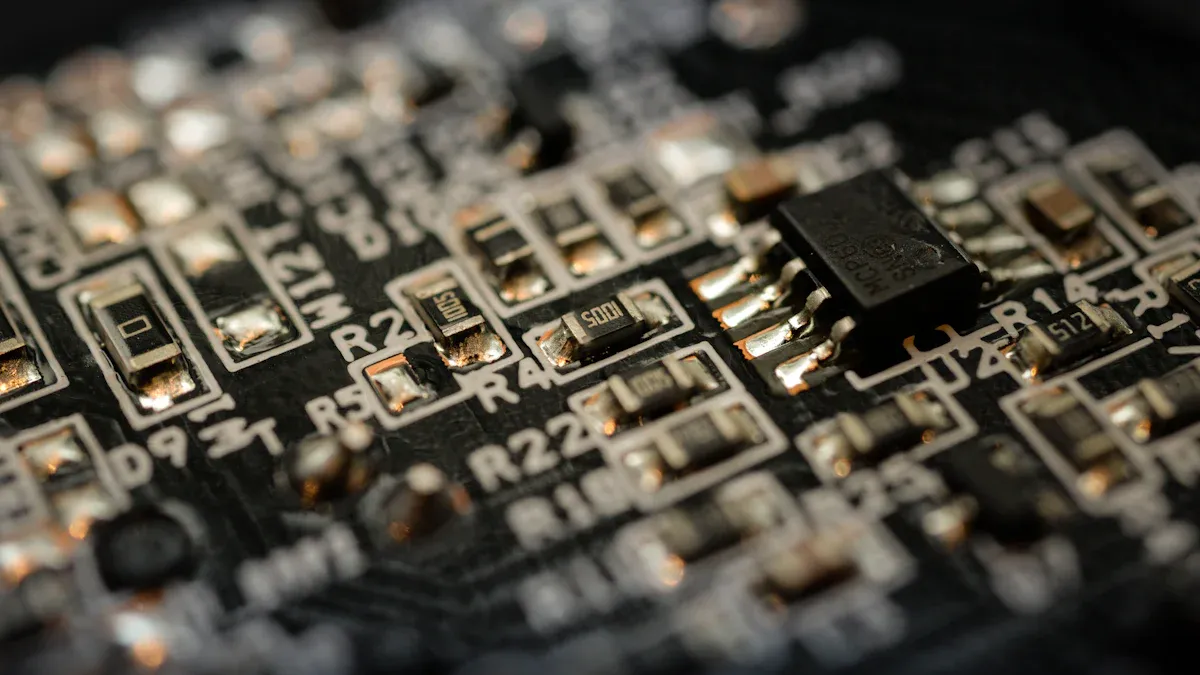

There are many ways to add EMI shielding to PCBs. These methods help reduce interference and keep signals clear. Here are some examples:

Ground Planes: A ground plane in the PCB absorbs interference. It works well for stopping conducted EMI.

Shielding Cans: Metal covers are placed over sensitive parts. These block radiated EMI and protect circuits.

Via Stitching: Small holes, called vias, are added around the PCB edges. This creates a strong shield and reduces coupled EMI.

Filtering Components: Filters like ferrite beads or capacitors block high-frequency noise from entering or leaving the PCB.

Device | Description | |

|---|---|---|

Apple iPhone | Uses shielding, grounding, and filters | Prevents interference; tested for EMC compliance. |

Sony PlayStation | Advanced PCB design and strong shielding | Meets EMC rules while handling fast processors and wireless links. |

Fitbit Wearables | Tiny filters, good grounding, and shielding | Solves EMC issues in small devices with constant wireless use. |

Using these methods together makes PCB shielding stronger. This ensures the board works well, even in areas with lots of electromagnetic interference.

Pro Tip: Test your PCB shielding during design. This finds weak spots and ensures it meets industry rules.

Importance of EMI Shielding in Industrial Automation PCBA

Keeping Signals Clear and Reliable

Industrial systems need clear signals to work properly. Electromagnetic interference (EMI) can mess up signals, causing errors. EMI shielding stops this by blocking interference. It keeps signals clean and steady. This is very important in factories with many machines creating electromagnetic noise.

For example, in an EMI shielded industrial automation PCBA, shielding stops outside interference. This helps sensors, controllers, and actuators work together smoothly. Without shielding, signals can weaken or fail. This may cause system problems, delays, and lower productivity.

Tip: Test your PCBA often for electromagnetic compatibility. This ensures it meets standards and works reliably.

Following Industry Rules

Meeting electromagnetic compatibility rules is required, not optional. Groups like IEC and FCC set strict guidelines for EMI shielding. Following these rules makes sure equipment works safely and avoids interference.

The table below shows why compliance matters:

Evidence Description | Key Points |

|---|---|

Equipment must follow EMC rules during its entire use. | |

Adequate Availability | EMC immunity standards are needed for many applications. |

Lifecycle Compliance | Regular EMC tests and extra checks improve EMI protection. |

By following EMC rules, you avoid fines and meet safety standards. This protects your equipment and builds trust with customers who depend on your products.

Boosting System Efficiency

EMI shielding helps industrial systems run better. It reduces interference, letting parts work at their best. This lowers the chance of shutdowns and keeps systems running. Reliable systems mean fewer breaks, more productivity, and less maintenance cost.

The table below explains why EMI shielding improves performance:

Metric/Aspect | Description |

|---|---|

Meets EMC rules to avoid fines from groups like IEC and FCC. | |

Safety | Prevents equipment failure and keeps operations safe. |

Reliability | Keeps systems running without unexpected stops, boosting productivity. |

Cost Savings | Cuts repair costs and avoids fines, saving money. |

Customer Satisfaction | Ensures systems work well, making customers happy and loyal. |

Adding good shielding to your PCBA design improves efficiency and saves money over time. This makes EMI shielded industrial automation PCBA essential for modern factories.

Note: Use high-quality shielding materials for better protection and long-lasting systems.

Benefits of EMI Shielding in Industrial Applications

Better Performance and Longer Life for PCBA

EMI shielding helps printed circuit board assemblies (PCBA) work better and last longer. It blocks electromagnetic interference, keeping sensitive parts safe. This is very useful in factories where machines make lots of noise. Shielding reduces errors and helps PCBA last longer.

New shielding technologies make protection even stronger. For example:

Lightweight materials solve problems in tiny, high-frequency parts.

New tests check shielding in wireless designs to meet rules.

These improvements show how shielding protects PCBA and handles modern challenges.

Less Maintenance and Fewer Breakdowns

Good EMI shielding lowers the need for repairs. Noise can mess up signals and cause equipment to fail. Shielding stops this, keeping systems running smoothly. This means fewer breaks and lower repair costs.

In factories, shielding helps controllers and sensors work well together. This prevents problems caused by interference. Investing in shielding saves time and money while keeping systems productive.

Tip: Check shielding materials often to make sure they still work. This can help avoid downtime.

Safer Systems and Better Efficiency

EMI shielding keeps industrial systems safe and efficient. It stops interference from breaking important parts. This is very important in places like airplanes, where safety matters most. Shielding makes sure communication and control systems work properly.

Shielding also improves efficiency by stopping signal problems. This helps equipment work better and follow industry rules. Whether in factories or airplanes, shielding protects systems and workers.

Note: Pick shielding materials that fit your needs. Good materials give stronger protection and last longer.

Future Trends in EMI Shielding

New Ideas in Shielding Materials

The future of EMI shielding depends on better materials. These materials need to work well and be flexible. As devices get smaller and more advanced, shielding must keep up. New discoveries in materials science are making this possible.

Smaller Devices: Tiny gadgets need lightweight and compact shielding.

5G Networks: Faster 5G signals create more interference, needing stronger shields.

Electric Cars: Electric and self-driving cars need shielding to avoid system problems.

New materials like silver ink shields, copper layers, and shielding films are leading the way. The table below shows their features:

Shielding Material | Description | Key Features |

|---|---|---|

Silver Ink Shields | Flexible inks that conduct electricity. | Sticks to plastics and composites. |

Copper Layer Shields | Blocks magnetic and electrical waves. | High conductivity, reduces noise. |

Shielding Films | Resists rust and fire, fits odd shapes. | Flat design for tight spaces. |

These materials improve shielding and meet modern industrial needs.

Fitting into Modern PCBA Designs

Modern PCBA designs need shielding that fits without causing problems. One way is to add shielding layers inside the PCB. This saves space and protects against interference.

For example, shielding films are popular because they are flat and fit tight spaces. They resist rust and fire, making them great for factories. Using these materials keeps PCBA designs small, efficient, and compliant with rules.

Importance in IoT and Industry 4.0

With IoT and Industry 4.0 growing, EMI shielding is more important than ever. Smart devices and factories need clear communication, which interference can disrupt. Good shielding ensures these systems work reliably.

The table below shows trends increasing the need for shielding:

Trend | Description |

|---|---|

5G Technology Growth | Faster connections need better shielding. By 2028, 8 billion people may use 5G. |

Smaller Devices | Tiny gadgets like wearables need compact shielding. In 2023, 148.4 million wearable devices were shipped globally. |

Healthcare Electronics Demand | Medical tools need strong shielding to avoid interference. |

Using advanced shielding methods helps prepare designs for the future needs of IoT and Industry 4.0.

EMI shielding is important for keeping industrial automation PCBA safe. It blocks electromagnetic interference, stopping outside signals and crosstalk. This reduces noise, protects data, and keeps devices working well, even in secure places.

The advantages go further than just reliability. EMI shielding helps meet industry rules and improves system performance. As technology grows, better shielding materials and designs will solve new problems. This ensures your systems stay strong and ready for the future.

FAQ

1. What is EMI shielding, and why is it important?

EMI shielding stops electromagnetic interference from harming electronics. It protects delicate parts, keeps devices working well, and meets rules. This is very useful in noisy places like factories or industrial areas.

2. What materials are best for EMI shielding?

Popular materials include copper, aluminum, and carbon composites. Copper is great for conducting electricity. Aluminum is light and affordable. Carbon nanotubes work well in small designs. Pick a material based on your device’s needs and where it will be used.

3. How do you check if EMI shielding works?

You can check shielding with EMC tests. These tests show how well your device blocks interference. Tools like spectrum analyzers find weak spots and make sure your device follows the rules.

4. Can EMI shielding help devices last longer?

Yes, EMI shielding keeps parts safe from interference damage. It lowers noise, keeps signals strong, and stops problems. This helps devices last longer and cuts repair costs.

5. Do IoT devices need EMI shielding?

Yes! IoT devices need clear signals to work right. EMI can mess up these signals and cause errors. Shielding keeps them running smoothly, even in places with lots of wireless devices or strong interference.

Tip: Always design shielding to fit your device’s specific needs.

See Also

Exploring EMS And PCBA Services In Today’s Electronics

Defining PCBA And Its Function In Electronic Devices

What PCBA Means And Its Importance In Electronics

Why PCBA Manufacturing Skills Matter In Electronics Design

Understanding PCBA Services And Their Significance In Electronics