Electronics manufacturing services (EMS) and EMS PCBA (printed circuit board assembly) are essential components in the production of modern electronics. EMS companies play a crucial role in designing, building, testing, and managing parts for electronic products. These services streamline production processes and facilitate the quicker launch of new devices. For example, during the 2021 chip shortage, EMS companies mitigated delays in the manufacturing of medical devices by securing necessary parts in advance. The global EMS market, which includes EMS PCBA, was valued at $590.5 billion in 2023 and is projected to experience significant growth, underscoring its vital role in enhancing speed and fostering innovation.

Key Takeaways

EMS helps companies make and test electronics, so they can focus on new ideas.

PCBA is important for connecting parts to circuit boards, making devices work well.

Hiring EMS companies can cut costs and make products faster, helping businesses compete.

Picking a good EMS company means checking their skills, quality, and flexibility.

Using tools like robots and AI with EMS can make electronics better and faster.

What Are EMS and PCBA?

Definition of Electronics Manufacturing Services (EMS)

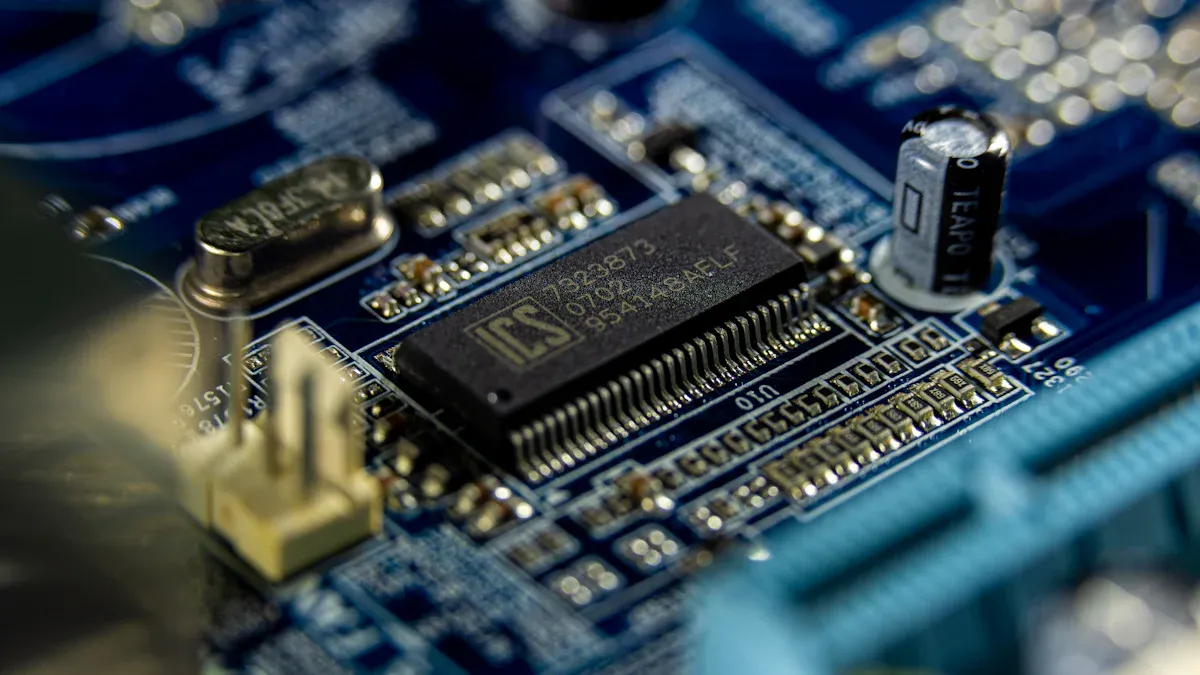

Electronics manufacturing services (EMS) are companies that design and build electronics. They also test and manage these devices for other businesses. This allows original equipment manufacturers (OEMs) to focus on research and development. EMS companies handle tasks like making samples and producing large quantities. For example, Solectron Corporation started the EMS industry in 1977. In the 1980s, surface mount technology (SMT) made assembly faster. Today, EMS is important in industries like cars, phones, and healthcare.

Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

2022 | 504.22 | N/A |

2029 | 797.94 | 6.8 |

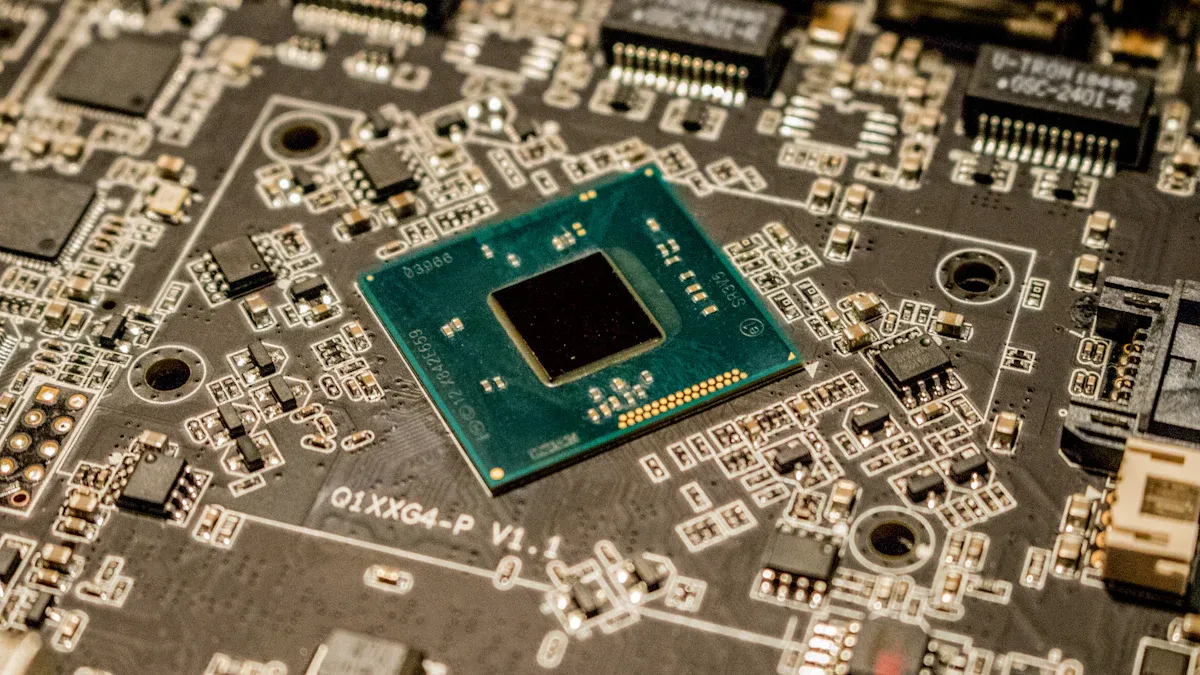

Definition of Printed Circuit Board Assembly (PCBA)

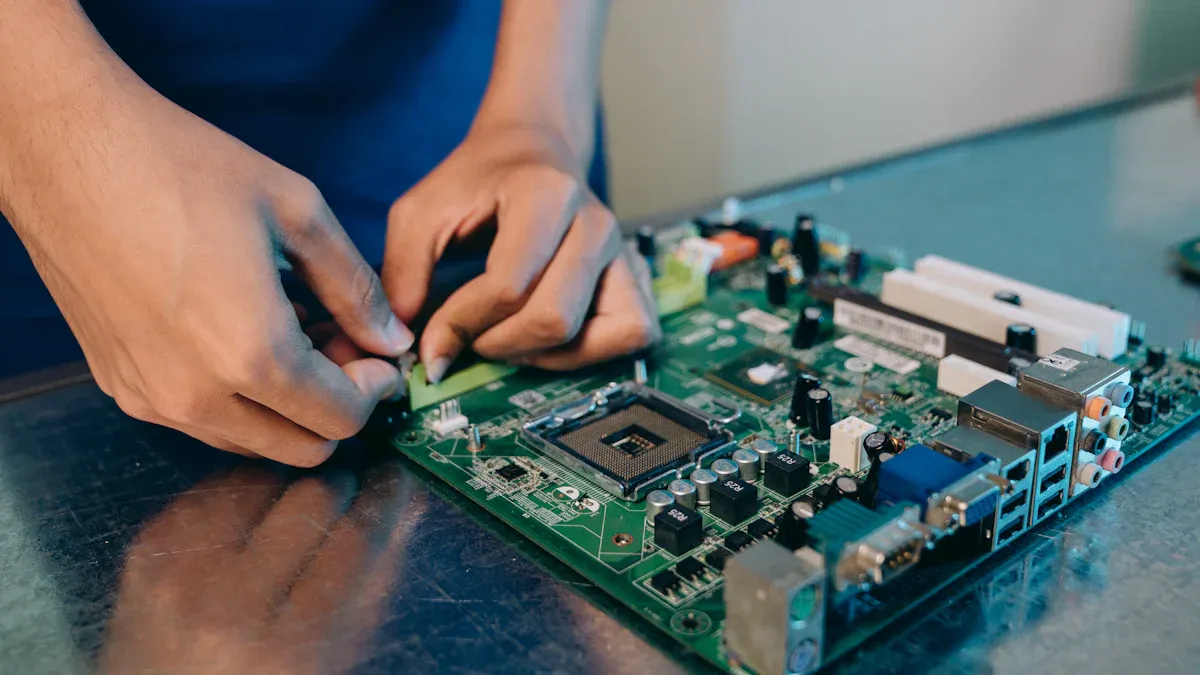

Printed circuit board assembly (PCBA) means attaching parts to a circuit board. This process makes the board work in electronic devices. PCBA uses methods like surface mount technology (SMT) and through-hole technology (THT). Quality checks are very important to ensure the boards work well. Standards like IPC-A-610 and IPC-J-STD-001 guide how PCBA is done to meet industry rules.

IPC Standard | Description |

|---|---|

IPC-A-610 | Rules for good electronic assemblies |

IPC-J-STD-001 | Rules for soldered electrical assemblies |

How EMS and PCBA Work Together in Electronics Manufacturing

EMS and PCBA work together to make modern electronics. EMS companies manage the whole production process. PCBA focuses on putting parts on circuit boards. Teams of engineers, buyers, and product managers work closely to ensure success. Engineers use data about parts to design and test products. Quality checks like Automated Optical Inspection (AOI) and X-Ray tests make sure products are safe and reliable.

Collaboration Aspect | Description |

|---|---|

Data Integration | Engineers use part data to design products. |

Team Collaboration | Teams match product ideas with production plans. |

Flexibility | Designs change based on available parts. |

Services Offered by EMS Providers

EMS providers help make electronics easier to produce. They offer services like design, assembly, testing, and managing supplies. Working with an EMS provider can speed up your product creation. This lets you focus on making new ideas. Below are some key services they provide.

PCB Design and Engineering Support

Good PCB design is key to making great electronics. EMS providers use Design for Manufacturability (DFM) to improve designs for production. This helps avoid mistakes and lowers costs. Experienced manufacturers find design problems early, saving time and money.

For example, skilled EMS providers improve your designs using advanced tools. They ensure the manufacturing process is smooth and error-free. This makes your products more reliable and faster to launch. Fixing design issues early prevents expensive changes later.

PCB Assembly (PCBA) Using SMT and THT

PCBA is an important step in making electronics. EMS providers use Surface Mount Technology (SMT) and Through-Hole Technology (THT) to attach parts to boards. SMT works well for small designs, while THT is strong for heavy-duty parts.

EMS providers follow rules like IPC-A-610 to ensure quality. They test boards using tools like Automated Optical Inspection (AOI) and X-rays. These checks make sure your products are safe and work well.

Component Sourcing and Supply Chain Management

Getting parts and managing supplies is crucial for saving money. EMS providers use global networks to find good parts at fair prices. Tools like Part Analytics and CalcuQuote help them work faster and smarter.

By automating tasks and using ERP systems, EMS providers improve order accuracy. They also manage inventory better. This approach saves money and reduces risks. With EMS providers handling supplies, you can focus on creating new products.

Tip: Let EMS providers manage your supply chain to avoid delays and save money.

Testing and Quality Assurance Processes

Testing and quality checks are key to making reliable electronics. EMS providers use strict methods to find and fix problems early. This improves how products work and builds trust with users.

Different tests ensure products are high-quality and dependable. Functional tests check if the product works correctly. Stress tests see how it performs in tough conditions. Fault tolerance tests show if it can recover from errors. Metrics like mean time between failures (MTBF) and mean time to repair (MTTR) measure reliability over time. Rules like IPC-A-610 ensure all assemblies meet the same quality standards.

Important reliability factors include:

How efficiently energy is used.

Time systems are down.

How well they work in various situations.

By following these rules and measures, EMS providers make sure products are reliable. This helps devices work well in real-life situations.

Note: Spending on quality checks early saves money and avoids recalls later.

Box Build and System Integration Services

Box build and system integration go beyond just assembling circuit boards. These services include putting together cases, wiring, and combining parts into a finished product. EMS providers make sure all parts work smoothly together.

For example, in 2016, an EMS company worked with Forte Micro to automate shoe production. They built six automated systems, improving reliability with better integration. Forte Micro also helped a hygiene company design a floor mat antenna for monitoring. Their assembly methods ensured the product worked consistently.

Case Study | Description |

|---|---|

Major Shoe Brand | Automated systems improved shoe production reliability. |

Hygiene Solutions Manufacturer | Designed a reliable floor mat antenna for hygiene monitoring. |

These examples show how box build and system integration improve product quality. By letting EMS providers handle these tasks, you can focus on creating new ideas while ensuring top-notch products.

Aftermarket Services, Including Repairs and Maintenance

Aftermarket services help electronics last longer. EMS providers fix, maintain, and upgrade devices to keep them working well. These services reduce downtime and make customers happy.

EMS providers use advanced tools to find problems fast. They replace broken parts and test products to meet original standards. Regular maintenance, like cleaning and adjusting, prevents future issues. These services help keep your products reliable and high-quality over time.

Tip: Work with EMS providers for repairs and maintenance to stay competitive.

Benefits of Outsourcing to EMS Providers

Outsourcing to EMS providers offers many benefits for electronics businesses. Their skills help simplify production, cut costs, and speed up product launches. Below are some key advantages you can gain.

Saving Money and Growing Production Easily

Using EMS providers saves money by removing the need for your own factories. They handle buying parts and making products, so you can focus on new ideas. Their supplier connections ensure you get good parts at fair prices.

Good supply chain management means you don’t need buying teams.

Strong supplier ties make parts reliable and affordable.

Bulk buying by EMS providers lowers costs for you.

Scaling production is another big benefit. EMS providers let you adjust to market changes quickly. For example, they can take on extra work or be your main manufacturer. This helps you grow or shrink production without wasting resources. Whether demand rises or falls, they keep your production smooth.

Tip: Working with an EMS provider avoids problems like making too much or wasting resources.

Using Advanced Technology Without Big Costs

EMS providers give you access to advanced tools and expert knowledge. The industry uses new tech like automation and artificial intelligence (AI) to improve production.

Automation and AI are changing how EMS providers work.

Modern tools allow custom designs and better production.

Demand for electronics and electric cars drives new ideas in EMS.

By outsourcing, you can use these tools without spending a lot on equipment. This helps your products meet today’s standards while keeping costs low. With EMS providers, you can work faster and more efficiently.

Launching Products Faster

Speed is very important in the electronics world. EMS providers help you make and deliver products quicker. They manage schedules and supplies to get your products to market fast.

Benefit | Explanation |

|---|---|

Shorter Production Times | Real-time data helps adjust schedules quickly. |

Faster Product Launches | Working with EMS providers speeds up development and production. |

Staying Competitive | Quick launches give you an edge over competitors. |

By outsourcing, you can focus on creating new products while they handle production. This saves time and ensures your products are high-quality and reliable.

Note: Launching products faster keeps you ahead in a fast-changing market.

Focus on Core Business Competencies

Outsourcing to EMS providers lets you focus on your strengths. Instead of handling tough manufacturing tasks, you can work on what your company does best. This shift makes your business more efficient and competitive.

When EMS providers take over production, you save time and resources. Many companies are great at designing products but struggle with making them. By outsourcing, you can spend more time creating new ideas and improving customer satisfaction.

Selling factories and skipping production tasks saves money for research.

Relying on EMS providers lowers costs with their advanced tools.

Using their skills ensures high-quality products without big investments.

This method keeps you flexible in a fast-changing market. By focusing on your strengths, you can quickly meet customer needs and follow new trends. EMS providers handle production, so you can grow and innovate without distractions.

Tip: Focus on your best skills to build a strong brand and give customers great value.

With help from EMS providers, your business runs smoother and gets better results. This teamwork lets you concentrate on creating new ideas and moving your company forward.

How to Choose the Right EMS Provider

Checking Technical Skills and Certifications

To pick the best EMS provider for PCBA, start by checking their skills and certifications. A good EMS partner should know your industry well and have the right certifications. Certifications like ISO 9001 and IPC standards show they follow quality rules. For example, an EMS provider with IPC-A-610 certification ensures top-quality electronic assemblies.

You can confirm their skills through technical audits. Providers with trained auditors, like Lead Auditors, have lots of experience. For instance, a Lead Auditor must finish a 32-hour training course and lead three full audits. This shows they can handle tough manufacturing tasks while keeping quality high.

Grade | Training Needed | Work Experience Needed | Audit Experience Needed |

|---|---|---|---|

Lead Auditor | Finish a 32-hour lead auditor training course | At least five years’ work experience, two in environmental management | Lead at least three full audits (minimum 9 days total) |

By reviewing these points, you can find an EMS provider that meets your technical and quality needs.

Looking at Quality Standards and Testing Methods

Quality certifications are very important when choosing an EMS provider. Check their testing methods to ensure they meet industry standards. Top EMS providers use advanced tests like Automated Optical Inspection (AOI) and X-rays to find problems early. These tests make sure products work well and meet requirements.

Also, check if they follow standards like IPC-A-610 or ISO 13485 for medical devices. These certifications show they care about quality and reliability. Providers with strong quality systems often deliver products without defects. This focus on quality lowers the chance of recalls and keeps customers happy.

Tip: Always ask for proof of their testing methods and certifications to confirm their quality commitment.

Reviewing Supply Chain and Delivery Skills

A strong supply chain is key for on-time production and delivery. When checking their skills and facilities, also look at their supply chain and delivery abilities. Good EMS providers have plans for problems, share data clearly, and use strong IT systems. These help keep things running smoothly even during issues.

Why It Matters | What to Check | |

|---|---|---|

Problem Recovery Plans | Keeps work going during disruptions. | Look at backup plans, data recovery, and risk management. |

Clear Data Sharing | Gives real-time updates on production. | Check how they share data and if the info is accurate. |

IT Systems | Helps with smooth operations and data safety. | Review their data management, cybersecurity, and system integration abilities. |

Financial health is also important. A stable EMS provider can keep delivering good service and invest in better technology. By understanding these factors, you can choose a partner who delivers on time and ensures high-quality products.

Considering Flexibility and Customization Options

Flexibility and customization are key when picking an EMS provider. You need a partner who adjusts to your needs. They should deliver solutions that fit your product goals.

Customized Solutions: EMS providers create solutions that match your project needs. They can handle unique PCB designs or special assembly methods. Their processes adapt to meet your expectations.

Agility in Operations: These providers are quick to adjust. They handle changes in your project without delays. This is helpful when market demands shift or problems arise.

Customer Success Stories: Many EMS providers share stories of past successes. These examples show how they solved tough challenges for their customers.

Working with a flexible EMS provider keeps your production smooth. Their adaptability helps your products stay competitive in a fast-changing market.

Tip: Choose EMS providers who show they can adapt. Look for examples of how they’ve helped other customers succeed.

Reviewing Reputation and Customer Support

Reputation and customer support are very important when choosing an EMS provider. A good partner communicates well and delivers quality work. You can check this by looking at feedback and key performance metrics.

Metric | What It Shows |

|---|---|

Response Time | How fast they reply to your questions or fix issues. |

Quality of Work | How well they make and test your products. |

Staff Professionalism | How skilled and polite their team is during interactions. |

Communication | How clear and helpful they are when working with you. |

About 70% of customers are happy when EMS providers communicate well and act professionally. But poor service can lower satisfaction by 20%. To improve, many providers use surveys or QR codes to collect feedback. This helps them learn and get better.

Note: A provider with a good reputation and strong support makes a big difference. Pick one that values clear communication and customer happiness.

Future Trends in EMS and PCBA

Automation and AI in Electronics Manufacturing

Automation and AI are changing how electronics are made. Industry 4.0 tools help EMS providers improve product development. AI and IoT create smart production lines that work faster. These systems predict problems and improve product quality. This means fewer mistakes and more reliable products.

Robots powered by AI make factories more efficient. They reduce delays and keep production steady. Automation also lowers costs by cutting human errors and saving materials. New methods like 3D printing help companies adjust quickly to market needs. This gives businesses a strong advantage.

Tip: Work with EMS providers using AI and automation for better results.

Sustainability and Green Manufacturing Practices

Green manufacturing is now a big focus for EMS providers. They aim to cut waste and save resources. Many follow global rules like ISO to track eco-friendly goals. They check energy use, waste, and pollution to stay environmentally responsible.

By using green systems, EMS providers lower their impact on nature. They focus on saving resources and reducing waste. These efforts help the planet and boost your brand’s image with eco-friendly customers.

Note: Picking a green EMS provider helps the environment and attracts eco-conscious buyers.

Growth of IoT and Smart Device Manufacturing

The demand for IoT and smart devices is growing fast. Industries like cars and electronics are using these technologies more. For example, electric and smart cars need advanced electronics. EMS providers now make complex parts for these products.

IoT is also expanding into everyday items like smart homes and wearables. EMS providers lead this growth by ensuring products meet modern tech standards. Their skills help your products stay competitive in the market.

Tip: Use EMS providers’ IoT expertise to succeed in the smart device industry.

Regional Changes in Electronics Manufacturing 🌍

The way electronics are made around the world keeps changing. Some areas are becoming more important in the EMS industry. These changes happen because of new technology, government rules, and what people want to buy.

Asia Pacific is the biggest area for making electronics. Countries like China, Vietnam, Japan, and South Korea lead here. They have great factories and skilled workers. China is strong in making gadgets, and Vietnam is growing in assembly work. This region makes over $300 billion worth of electronics, showing how important it is globally.

North America also matters a lot, with a market size over $90 billion. Cities are growing fast, and there’s a big focus on research and new ideas. People want high-tech gadgets, which helps this region grow. The U.S. and Canada are known for making high-quality products.

Latin America is another area to watch. Brazil, Mexico, and Argentina are the main players. Together, they make about $60 billion worth of electronics. These countries are improving their ability to make electronics, which could lead to more growth soon.

The Middle East and Africa are starting to grow in this field. While exact numbers aren’t clear, electric cars and car electronics are helping these regions develop. More research and new ideas are also making them more important.

Region | Market Size (2022) | Key Factors |

|---|---|---|

North America | > $90 billion | Growing cities, research in tech, demand for cool gadgets. |

Latin America | ~$60 billion | Brazil, Mexico, Argentina lead; better electronics production expected. |

Middle East & Africa | N/A | Electric cars, car electronics, and more research help growth. |

Asia Pacific | China, Vietnam, Japan, Korea are key; huge role in global electronics. |

These changes show how the EMS industry adjusts to global needs. Knowing this can help your business find new chances to grow. 🚀

Electronics manufacturing services (EMS) and PCBA are key for modern devices. They help with designing, building, and testing electronics. These services make sure products are reliable and high-quality. Working with EMS providers saves money and boosts efficiency. It also gives you access to expert knowledge and tools. This lets you focus on creating new ideas while they manage production. Picking the right EMS provider keeps your business strong in a changing market. Check their skills, certifications, and ability to adapt to your needs.

FAQ

What is the difference between EMS and PCBA?

EMS covers designing, making, and managing electronics. PCBA focuses only on attaching parts to circuit boards. EMS often includes PCBA as one of its services.

Why should you outsource to an EMS provider?

Outsourcing saves time and money. EMS providers handle making products, managing supplies, and checking quality. This lets you focus on creating new ideas and growing your business.

How do EMS providers ensure product quality?

They use advanced tests like Automated Optical Inspection (AOI) and X-rays. These tests find problems early. Providers also follow strict rules, like IPC-A-610, to keep products reliable.

Can EMS providers handle small production runs?

Yes, many EMS providers can adjust to your needs. They manage both small and large production sizes easily.

What industries benefit most from EMS services?

Industries like cars, healthcare, electronics, and telecom rely on EMS services. They help make things like medical tools, phones, and electric cars.

Tip: Share your project details with the EMS provider. This ensures they meet your industry’s needs.

See Also

Understanding The Importance Of PCBA Services In Electronics

Exploring The Uses And Advantages Of PCBA Today

Streamlined PCBA Solutions For Quick Electronics Projects

Innovative Testing Methods For PCBA In Electronics Production