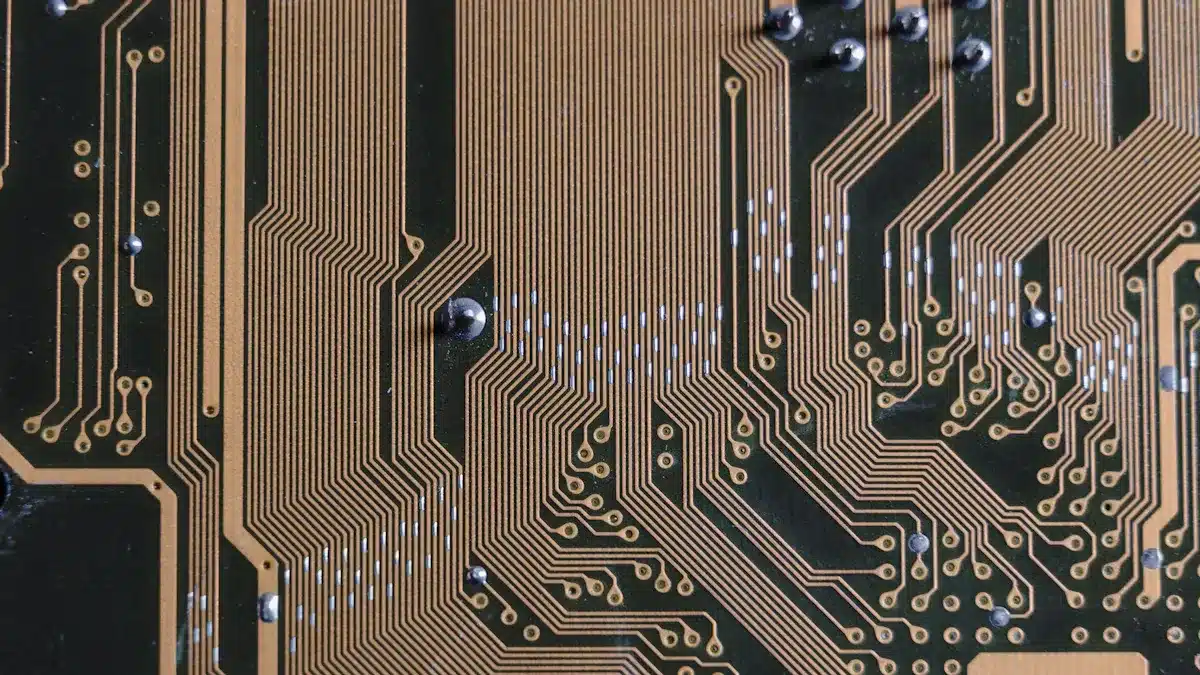

Printed circuit boards are very important in today’s technology. You might not know it, but these parts are everywhere. They are in your smartphone and home appliances. The market for printed circuit boards is growing fast. It is expected to rise from $84.4 billion in 2023 to $139.63 billion by 2032. This growth shows that people want more new and useful electronic devices. In the last ten years, many things have increased this demand. These include more IoT devices and better car technology. As you learn about PCBs, you will see how they help the devices you use every day.

Key Takeaways

Printed circuit boards (PCBs) are very important in today’s electronics. You can find them in devices like smartphones and medical tools.

Single-sided PCBs are cheap and easy to make. This makes them great for simple devices like calculators and remote controls.

Double-sided PCBs can handle more complex circuits. They are good for advanced electronics like smartphones and medical devices.

Multi-layer PCBs are used in high-performance systems. They are very important in fields like telecommunications and aerospace.

Flexible PCBs are light and can change shape. They are perfect for small devices like wearables and IoT gadgets.

Single-Sided PCBs

Features of Single-Sided PCBs

Single-sided PCBs are popular in electronics. They are simple and cheap to make. These boards have one layer that conducts electricity. The base is usually made from materials like FR-4 or CEM-1. Here are some important features of single-sided PCBs:

Cost-Effectiveness: They use fewer materials, so they cost less to make, especially in large amounts.

Simplified Design: With just one layer for traces, they are less complicated. This is great for low-density circuits.

Faster Turnaround: Fewer steps in making them mean quicker production times for prototypes and mass production.

Straightforward Assembly: You can easily place and solder parts on the same side of the board.

These features make single-sided PCBs good for many uses where being cheap and simple is important.

Applications in Simple Devices

You can see single-sided PCBs in many everyday items. Their simple design makes it easy to use them in products that do not need complex circuits. Common uses for single-sided PCBs include:

Remote controls

Low-end toys

Portable radios

LED strip lights

Phone chargers

Small adapters

Battery management systems

These uses show how single-sided PCBs are important for many simple electronic devices. Their ability to meet the needs of low-cost and simple products makes them a popular choice in the market.

Double-Sided PCBs

Double-sided PCBs are a big step up from single-sided ones. They have copper layers on both sides. This gives more space for traces and parts. This design allows for more complicated circuits and more parts in a small area. Here are some important features of double-sided PCBs:

Higher Component Density: You can fit more parts in a small space. This is important for small devices.

Improved Circuit Complexity: These PCBs can handle complex circuits without needing extra jumpers. They use vias to connect traces easily.

Better Signal Integrity: Using both sides reduces interference. This is important for fast applications.

Enhanced Durability: Spreading parts on two sides can make them last longer in tough conditions.

These features make double-sided PCBs a popular choice for many uses, especially in consumer electronics.

Applications in Consumer Electronics

Double-sided PCBs are very important in many consumer electronics. Their flexible design allows for complex circuits, which are needed for modern devices. Here are some common uses for PCBs in consumer electronics:

Smartphones: These devices need compact designs and high performance. Double-sided PCBs give the space for complex parts and routing.

Medical Devices: Reliability is very important here. Double-sided PCBs provide cost-effective ways to use electronics in medical tech.

LED Lighting: These systems often deal with high heat. Double-sided PCBs can manage heat well, making them great for LED lights.

Air Conditioning Systems: These devices benefit from good heat management and simple circuits that double-sided PCBs offer.

TV Remote Controls: They are key parts of modern electronics, being cheap and easy to make.

The market for double-sided printed circuit boards is growing fast. This growth comes from the rising need for advanced electronic devices. While exact numbers for double-sided PCBs in consumer electronics are not given, the overall market was worth millions in 2022. It is expected to keep growing because of more consumer electronics and tech improvements.

Product Type | Description |

|---|---|

TV Remote Controls | Key parts of modern electronics, cheap and easy to make. |

Air Conditioning Systems | Devices with simple circuits that manage heat well. |

LED Lighting | Used in high-heat situations when paired with metal parts. |

Medical Technology | Cost-effective for using electronics in medical devices. |

Industrial Projects | Easy to produce, suitable for many industrial uses. |

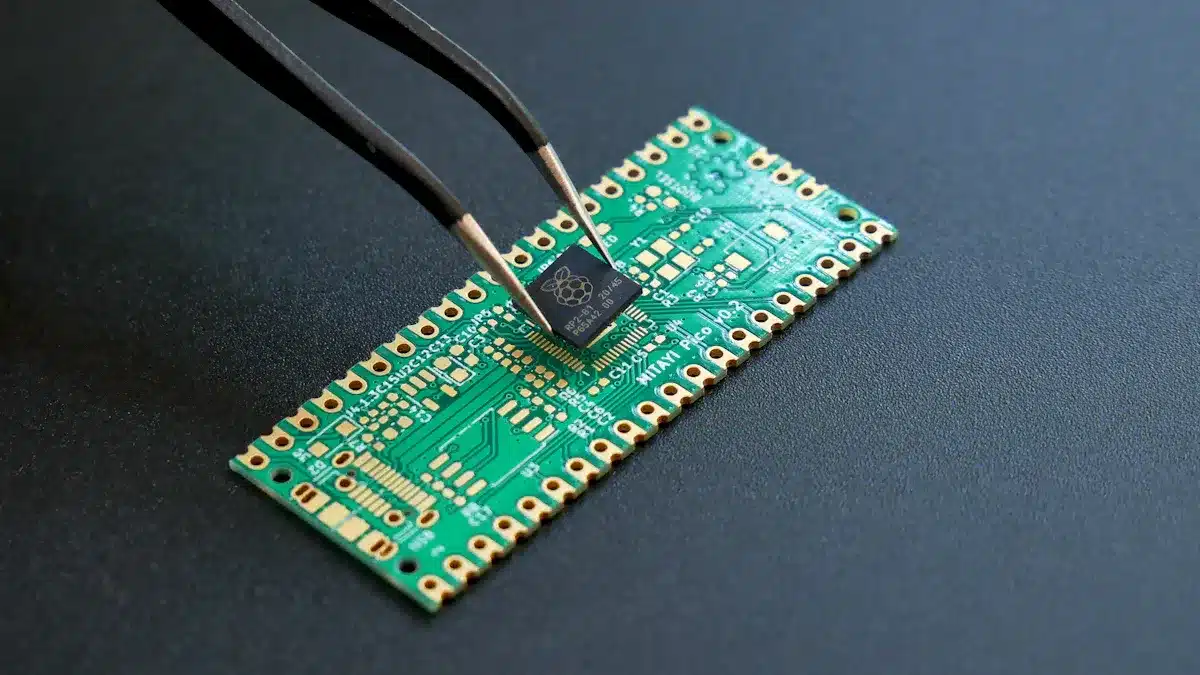

Multi-Layer PCBs

Features of Multi-Layer PCBs

Multi-layer PCBs have three or more layers of conductive material. These layers are separated by insulating layers. This design helps create complex circuits in a small space. Here are some important features of multi-layer PCBs:

Layer Structure: The outer layers connect electronic parts. The inner layers handle signal transmission and power distribution. Each substrate layer has conductive metal on both sides, with insulating material in between.

Vias: Vias are important for connections in multi-layer PCBs. You can find blind and buried vias based on your design needs. These vias help connect different layers. They ensure good communication between components.

Layer Stackup: The order of layers affects how the PCB works. You can classify conducting layers as power, ground, or signal layers. This classification is important for keeping signal quality and performance.

Multi-layer PCBs can have different setups. Basic designs may have 2 or 4 layers, while more complex ones can have up to 100 layers. This flexibility makes them good for advanced uses.

Applications in High-Performance Systems

Multi-layer PCBs are very important in high-performance systems across many industries. Their ability to support complex circuits and many components makes them essential for modern technology. Here are some common uses for PCBs in high-performance systems:

Industry | Application Description |

|---|---|

Consumer Electronics | Multi-layer PCBs are key for smartphones, tablets, gaming consoles, and wearable devices. They allow compact design and high component density. |

Telecommunications | They help transmit voice, data, and video signals. This ensures reliable communication across networks. |

Industrial Control | Used in machine control panels, robotics, and automation systems. They manage complex control and monitoring systems. |

Medical Devices | Critical for diagnostic equipment and patient monitoring systems. They ensure precision and reliability. |

Automotive | Used in advanced driver-assistance systems, engine control units, and infotainment systems for better functionality. |

Aerospace | Found in avionics and radar systems. They provide reliability under stress and protect connections from damage. |

Military | Important for high-speed circuits in defense applications, including atomic and nuclear systems. |

These applications show how multi-layer PCBs drive innovation and performance in many fields. As technology keeps advancing, the need for multi-layer PCBs will keep growing.

Rigid PCBs

Features of Rigid PCBs

Rigid PCBs are a popular choice in electronics. They are made from solid materials like fiberglass or composite epoxy. This design gives them some important features:

Robustness: Rigid PCBs can handle stress and high heat. This strength makes them good for tough environments.

Cost-Effectiveness: They usually cost less than flexible PCBs. This lower price is helpful in regular electronics where space is not an issue.

Structural Support: Rigid PCBs give strong support for electronic parts. They help make good electrical connections, which are key for how devices work.

Here’s a quick comparison of rigid PCBs with flexible PCBs:

Feature | Rigid PCBs | Flexible PCBs |

|---|---|---|

Construction Material | Solid materials (fiberglass or composite epoxy) | Flexible materials (polyimide) |

Mechanical Properties | Strong and can handle stress and high heat | More flexible but not as strong |

Cost-Effectiveness | Usually lower cost, especially in regular electronics | Higher cost because of complexity |

Applications | Commonly used in consumer electronics | Used in places needing flexibility |

Applications in Electronics

Rigid PCBs are very important in many electronic devices. You can find them in many consumer products like smartphones, TVs, and computers. Their strength and low cost make them a favorite choice. Here are some common uses for PCBs in electronics:

Consumer Electronics: Rigid PCBs are key parts of devices like smartphones, laptops, and gaming consoles. They help connect different parts, which is important for high-performance devices.

Medical Equipment: Rigid PCBs are found in MRI machines, ECG monitors, and X-ray devices. These tools need to be reliable and precise.

Automotive Systems: Rigid PCBs are crucial in engine control units and infotainment systems. They help manage complex circuits in cars.

Aerospace Technology: In avionics and satellite systems, rigid PCBs provide reliability under pressure. They keep connections secure during flights.

Industrial Automation: Rigid PCBs are used in PLC controllers and robotic arms. They help control and monitor factory processes.

Military & Defense: You can find them in secure communication devices and radar systems. These uses need fast circuits and reliability.

Rigid PCBs are very common. They are expected to make up about 38.96% of the PCB market by 2035. Their strength and flexibility help explain their wide use in many applications.

Flexible PCBs

Features of Flexible PCBs

Flexible PCBs are special because of their unique features. You can bend, fold, and stretch these boards. This allows them to fit different device shapes. Here are some important features that make flexible PCBs different from rigid ones:

Feature | Flexible PCB | Rigid PCB |

|---|---|---|

Design Customization | You can customize designs for better control | Limited design options |

Heat Dissipation | They cool better because of their compact design | Not as good at cooling |

Wiring Errors | Fewer wiring mistakes due to built-in connections | More chances for wiring mistakes |

Circuit Design | Simple wiring reduces connections needed | More complicated connections |

Flexibility | Can be bent and shaped for complex designs | Stiff structure, less flexible |

Cost Efficiency | More parts lead to higher costs | |

Durability | Works well even after bending | Less strong under pressure |

Flexible PCBs are usually lighter and thinner than rigid PCBs. This makes them easier to carry. They keep working well even after bending and folding many times. These features make flexible PCBs great for many uses.

Applications in Compact Devices

You can find flexible PCBs in many small devices. Their ability to fit in tight spaces is very important for modern tech. Here are some common uses for flexible PCBs:

Smartphones and Wearables: Flexible PCBs are key for small designs in smartphones and smartwatches.

Automotive Electronics: They fit into dashboards and sensors in cars.

Medical Devices: Flexible PCBs help make light and portable medical tools, like health trackers.

Consumer Electronics: They help make laptops and gaming consoles smaller and lighter.

Communication Devices: Important for fast signal transmission in 5G devices and antennas.

Aerospace and Defense: Used in avionics and satellites, where light circuits are very important.

Industrial Equipment: Support sensors in machines, saving space.

IoT Devices: Help create small designs for smart home gadgets and wearables.

Flexible PCBs are especially useful in wearable devices. They provide comfort and movement, making them perfect for smartwatches and fitness trackers. In consumer electronics, you can find them in smartphones, tablets, and laptops, allowing for thinner and lighter designs. Their flexibility and efficiency make flexible PCBs a popular choice for many applications.

Rigid-Flex PCBs

Features of Rigid-Flex PCBs

Rigid-flex PCBs mix the best parts of rigid and flexible technologies. This special design lets you make circuits that can bend and twist while still working well. Here are some important features of rigid-flex PCBs:

Characteristic | Description |

|---|---|

Rigid-flex PCBs use both flexible and rigid board technologies. | |

Design Complexity | They are made in 3D space, which helps save space. |

This involves putting together conductive layers with flexible or rigid insulation, needing different steps for each. | |

Reliability | It cuts down on the need for solder joints and weak wiring, making connections more reliable. |

Cost Considerations | They cost more than regular circuits because of their complex making and design needs. |

Assembly Process | Careful handling is needed to prevent breaks when bending them into shape. |

Benefits | They save space, lower weight, make assembly easier, and boost reliability. |

Rigid-flex PCBs are great for uses that need both flexibility and strength. The flexible parts can bend in certain spots, while the rigid parts provide toughness and shock resistance. This mixed design improves strength and reliability, making them perfect for tough applications.

Applications in Complex Assemblies

You can find rigid-flex PCBs in many complex assemblies in different industries. Their flexibility makes them important in many devices. Here are some key uses of rigid-flex PCBs:

Consumer Devices: Rigid-flex PCBs are key in smartphones and digital cameras, allowing for complex functions in small designs.

Medical Devices: They are used in pacemakers and portable diagnostics, where reliability is very important because maintenance is hard.

Automotive Components: Found in driver assistance systems and entertainment consoles, rigid-flex PCBs can handle high vibrations and heat.

Aerospace: Used in avionics, satellite systems, and UAVs, they improve performance and functionality.

Telecommunications: They are used in communication devices and satellites for strong signal quality and low interference.

These uses show how rigid-flex PCBs are vital in modern technology. Their ability to mix flexibility with strength allows for creative designs that meet the needs of today’s complex electronic devices.

In conclusion, printed circuit boards are very important in today’s electronics. You have learned about different types, like single-sided, double-sided, multi-layer, rigid, flexible, and rigid-flex PCBs. Each type has special uses, from simple gadgets to complex devices.

As technology moves forward, some trends are changing the future of PCBs:

Miniaturization and High-Density Interconnects (HDI): Smaller gadgets need more parts in tight spaces.

Flexible and Stretchable PCBs: There is a growing need for bendable electronics.

Advanced Materials: New materials improve performance, especially for 5G technology.

The flexible PCB market is expected to hit USD 50.90 billion by 2030, with a CAGR of 13.7%. This growth shows how important new ideas are in PCB design and making. Following these trends will help you keep up in the fast-changing world of electronics.

FAQ

What are the common uses for PCBs in consumer electronics?

You can find PCBs in many everyday devices like smartphones, tablets, and laptops. They connect parts and help these devices work well in fast applications.

How do PCBs support medical devices?

PCBs are very important in medical devices. They make sure equipment like MRI machines and ECG monitors work reliably and accurately, which is crucial for taking care of patients.

Why are high-frequency PCBs important?

High-frequency PCBs are key for applications that need quick signal transmission. They reduce signal loss and interference, making them great for telecommunications and fast circuits.

What types of PCBs are used in automotive applications?

In cars, they often use rigid, flexible, and rigid-flex PCBs. These types are strong and reliable in tough conditions, helping with things like engine control and entertainment systems.

How do LEDs benefit from PCBs?

LEDs depend on PCBs for good heat management and electrical connections. PCBs made for LEDs help control heat well, leading to longer life and better performance in lighting.

See Also

Essential Insights Into PCBA Prototypes And Their Applications

Innovative PCBA Testing Methods For Modern Electronics Production

Unveiling The Advantages Of PCBA Surface Mount Technology