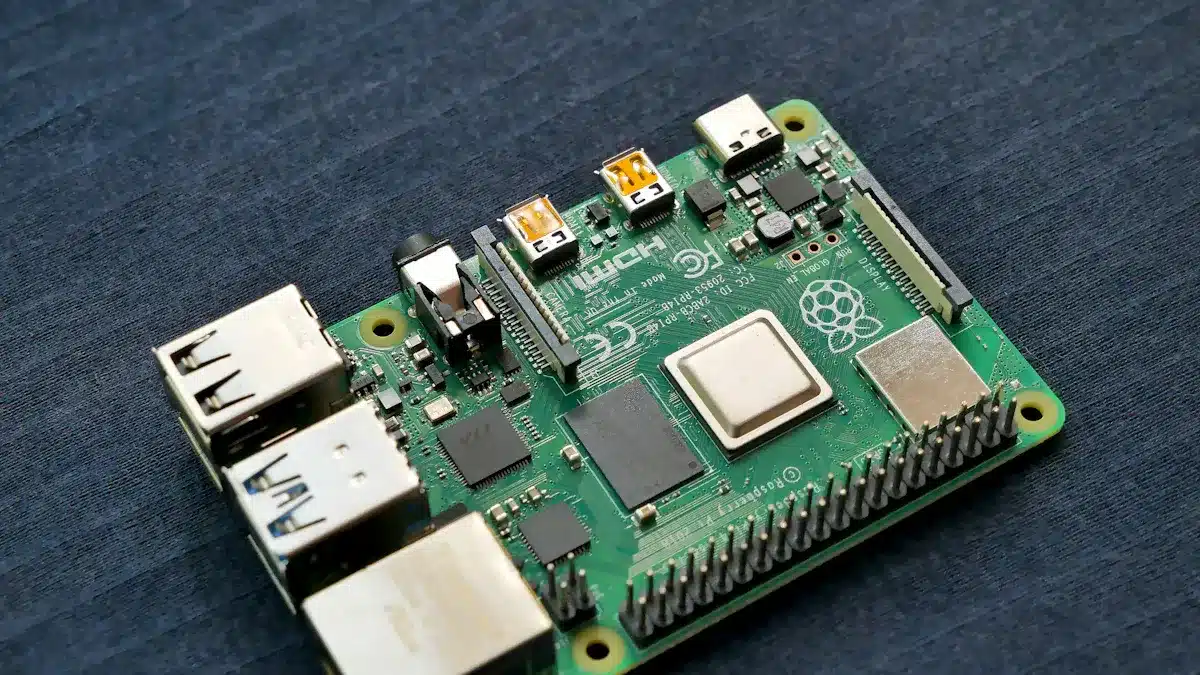

Printed circuit boards (PCBs), also known as circuit boards, are very important in today’s electronics. They help connect electronic parts, allowing devices to work well. The global market for circuit boards is expected to grow to $139.63 billion by 2032. So, it is important to know about the types of printed circuit boards. Common types are single-sided, double-sided, and multi-layer boards. Each type has different design needs and uses, making it crucial to pick the right circuit board for your needs.

Key Takeaways

Learn about the different types of printed circuit boards (PCBs). These include single-sided, double-sided, and multi-layer. Each type has its own purpose and design needs.

Use single-sided PCBs for simple and cheap projects. They work well for basic devices like calculators and toys.

Choose double-sided PCBs when your project is more complex. They can hold more parts and are often used in smartphones and medical devices.

Think about multi-layer PCBs for advanced electronics. They can handle complex circuits. This makes them good for telecommunications and aerospace uses.

Always manage heat well in LED PCBs. Good thermal management helps LED lighting last longer and work better.

Single-Sided Circuit Boards

Characteristics

Single-sided PCBs are the easiest type of printed circuit boards. They have a base layer, a metal layer, a protective mask, and a silkscreen. The copper layer is on one side. The parts are soldered on the other side. This design makes it hard to create complex circuits. Here are some key features of single-sided PCBs compared to other types:

Feature | Single-Sided PCB | Other PCB Types |

|---|---|---|

Construction | Parts and copper on one side | Parts on both sides |

Cost-Effectiveness | Usually cheaper because of simple design | More expensive for complex designs |

Complexity | Limited to simple circuit designs | Can handle complicated circuits |

Layering | One layer of conductive material | Can have many layers |

Applications

You can find single-sided PCBs in many cheap devices. They work well for simple uses where space and complexity are not big issues. Common examples include:

Consumer Electronics: Items like calculators and basic remote controls often use single-sided PCBs because they are affordable.

Toys: Many electronic toys use single-sided designs for their simple circuits.

Home Appliances: Simple machines, like toasters and coffee makers, often use these boards for basic tasks.

Even though single-sided PCBs are cheap, they can fail sometimes. For example, broken or damaged traces can cause circuit problems. Also, bad soldering can create cold joints or bridges, which can stop them from working. Knowing these things helps you choose the right type of PCB for your project.

Double-Sided Circuit Boards

Characteristics

Double-sided PCBs are more complex than single-sided ones. They have copper layers on both sides. This allows for more parts and connections. It makes them good for detailed circuit designs. Here are some main features of double-sided PCBs compared to single-sided ones:

Feature | Single-Sided PCB | Double-Sided PCB |

|---|---|---|

Copper Foil | One side only | Both sides |

Solder Joints | On the same side | On both sides |

Wiring and Assembly | One side only | Both sides |

Wiring Capability | Lower wiring capability | Higher wiring capability |

Manufacturing Cost | Lower | Higher |

Application Scope | Simple circuit designs | Complex circuit layouts and high-density assembly |

This design lets you fit more components. You can create smaller layouts, which is important in today’s electronics.

Applications

Double-sided PCBs are used in many industries because they can handle complex circuit designs. Here are some common uses:

Consumer Electronics: Devices like smartphones, laptops, and gaming consoles use double-sided PCBs for their detailed functions.

Automotive Industry: These boards support engine control systems, infotainment systems, and safety features, ensuring reliable performance in vehicles.

Medical Devices: Equipment such as pacemakers and diagnostic devices use double-sided PCBs for their small and efficient designs.

Industrial Automation: Control systems and sensors in factories often use double-sided PCBs for their reliability and performance.

Multi-Layer Printed Circuit Boards

Characteristics

Multi-layer PCBs have many layers of copper foil. These layers let you create more complex circuits. Usually, consumer electronics have four to twelve layers. Some devices may have even more layers if they are very complex. Here are some important features of multi-layer PCBs:

Higher Component Density: Multi-layer PCBs let you fit more parts in a small space. This is important for modern electronics that need to be smaller.

Complex Routing Capabilities: They allow for detailed routing, which is needed for high-density electronics.

Signal Integrity: Multi-layer PCBs keep signals clear, especially in high-frequency uses. Controlled layers and impedance help make sure signals are sent reliably.

Dedicated Ground and Power Planes: These planes reduce electromagnetic interference (EMI), making the system more reliable.

Applications

You can find multi-layer PCBs in many advanced electronic systems. Their ability to handle complex designs makes them great for different uses:

Consumer Electronics: Devices like smartphones, tablets, and laptops use multi-layer PCBs for their detailed functions.

Telecommunications: Fast communication devices use these boards to send data efficiently.

Medical Equipment: Advanced medical tools, like imaging systems and diagnostic devices, benefit from the small size and reliability of multi-layer PCBs.

Aerospace and Defense: In these fields, multi-layer PCBs support important systems that need to work well and be reliable.

Rigid Printed Circuit Boards

Characteristics

Rigid printed circuit boards (PCBs) are a common type of circuit board. They have a solid base that gives them strength and support. Most rigid PCBs use materials like fiberglass, especially FR4. This material is very strong and stiff. The copper layer is attached to the base using heat and glue. This design allows for detailed circuits while staying strong.

Here’s a quick overview of the materials used in rigid PCBs:

Material Type | Description | Notes |

|---|---|---|

Substrate Layer | Made of fiberglass, mainly FR4, which gives strength and stiffness. | Phenolics and epoxies are less common, cheaper, but have lower performance and issues. |

Copper Layer | Attached to the substrate layer using heat and glue. | Usually, both sides are attached, but some cheaper boards may have only one layer. |

The strong nature of these PCBs helps keep electronic devices safe. This makes them last longer and work better.

Rigid PCBs offer strength and reliability because of their solid build.

They hold detailed circuits well, thanks to strong materials like fiberglass and epoxy.

Their strength is important in high-precision uses like consumer electronics, car systems, and medical devices.

Applications

You can find rigid PCBs in many electronic devices. Their strong design makes them good for uses where reliability matters. Common examples include:

Consumer Electronics: Devices like TVs, computers, and gaming consoles depend on rigid PCBs for their performance.

Automotive Systems: Rigid PCBs help important functions in cars, like engine control and safety systems.

Medical Devices: Tools like monitors and diagnostic machines rely on the strength of rigid PCBs for accurate readings.

When thinking about how to dispose of rigid PCBs, remember that throwing them away wrong can cause environmental problems. They can pollute soil and water if not handled properly. So, it’s important to encourage recycling and good waste management to reduce their impact on the environment.

Flexible Circuit Boards

Characteristics

Flexible circuit boards, or flex PCBs, have many benefits that make them great for today’s electronics. Here are some important advantages of using flexible PCBs:

Space Efficiency: You can bend or fold flex PCBs to fit in small spaces. This helps design your devices better.

Weight Reduction: They are light, which is important in places where weight matters, like in airplanes and cars.

Enhanced Reliability: With fewer connections, there are fewer chances for problems. This makes them good for tough environments.

Improved Signal Integrity: Flex PCBs keep signals clear, which is very important in signal-sensitive uses.

Benefit | Description |

|---|---|

Adaptability | Flexible circuits can fit into products with tricky shapes. |

Space Efficiency | They can be bent or folded to fit in tight spots, making the most of space in devices. |

Weight Reduction | Their light weight is key in areas like aerospace and automotive. |

Enhanced Reliability | Fewer connections and solder points lower the risk of failure, making them good for tough areas. |

Improved Signal Integrity | They help reduce signal loss and mismatches, ensuring strong performance in important uses. |

Environmental Benefits | Cleaner ways to make them and less material used help the environment. |

Applications

Flexible circuit boards are used in many places where space is limited. You can often find them in:

Consumer Electronics: Gadgets like cameras, entertainment devices, and fitness trackers use flex PCBs for their small designs.

Medical Devices: Tools like pacemakers and hearing aids need flexible circuits to fit well in small spaces.

Automotive Applications: Control systems and sensors in cars benefit from the flexibility of flex PCBs.

Industrial Equipment: Robots and advanced sensors use flexible circuits to work better in tight areas.

In wearable tech, flexible PCBs are very important. They move with the body and last through daily use. Their thin design and bending areas help spread out stress evenly, stopping cracks when moving. For example, a smart patch for checking glucose fits around the arm nicely, showing how these boards can shape to the body without causing discomfort.

Rigid-Flex Circuit Boards

Characteristics

Rigid-flex circuit boards mix the best parts of rigid and flexible designs. This special setup lets you bend the flexible parts while keeping a strong structure. Here are some important features that make rigid-flex PCBs different from other types:

Hybrid Design: Rigid-flex PCBs combine rigid and flexible technologies. They have a solid circuit board linked to a flexible one.

Multilayered Flexibility: The flexible parts usually have many layers, which improves their use and allows for complex designs.

Space Efficiency: These boards can create complex shapes and take up less space, making them great for small devices.

The mix of rigid and flexible parts gives a strong base for complex electronic pieces. You can make detailed designs that fit into tight spots without losing performance.

Applications

Rigid-flex PCBs are useful in many areas, especially in complex devices. Here are some common uses:

Medical Devices: In healthcare, rigid-flex PCBs improve reliability. They lower the chances of failure, which is very important for life-saving tools.

Aerospace and Military: These boards work well for critical missions. Their flexible design allows for complex shapes that meet strict needs.

Consumer Electronics: Many modern gadgets, like smartphones and tablets, use rigid-flex PCBs. Their ability to fit in small spaces while still working well makes them a popular choice.

The advantages of rigid-flex PCBs go beyond just their design. They also boost electrical performance. For example, they provide features like controlled impedance and EMI shielding, which protect against electromagnetic interference. This helps keep signals steady and improves the overall reliability of the device.

Feature | Benefit |

|---|---|

Air gaps | Better electrical insulation |

Controlled impedance | Steady signal transmission |

EMI shielding | Protection from electromagnetic interference |

Stiffeners | Support for better reliability |

High-Density Interconnect (HDI) PCBs

Characteristics

High-Density Interconnect (HDI) PCBs are special circuit boards made for high-performance uses. They have some unique features that make them work better:

Microvia Technology: This lets smaller vias connect different layers without taking up much space.

Layer Stacking: Engineers arrange layers carefully to keep signals strong and working well.

Advanced Manufacturing Techniques: Methods like laser drilling and lamination are important for today’s electronic designs.

HDI PCBs also use special types of vias to boost performance:

Blind Vias: These connect the outer layer to one or more inner layers.

Buried Vias: These connect only inner layers, which helps save space.

The aspect ratio of microvias is very important for reliability. Engineers need to adjust this ratio to meet the need for smaller designs.

Applications

HDI PCBs are very important in many fast electronic uses. Their ability to support smaller sizes and quick signal sending makes them great for many fields. Here are some common uses:

Application Area | Description |

|---|---|

Smartphones | |

Medical Devices | Used in advanced medical tools for checking and imaging. |

Automotive Electronics | Helps improve electrical performance in car systems. |

Aerospace | Important for keeping signals strong in precise uses. |

Advanced Computing Systems | Allows for more functions in smaller devices. |

In mobile devices, HDI PCBs can cut board sizes by up to 60% compared to older designs. This helps make thinner phones, often less than 8 mm thick. They support tiny parts, fitting small surface-mount components like 0201-sized resistors and capacitors. The compact design of HDI PCBs allows for bigger batteries or extra parts, like wireless charging coils, without making the phone larger.

By knowing the features and uses of HDI PCBs, you can see how important they are in today’s electronics.

LED Printed Circuit Boards

Characteristics

LED printed circuit boards (PCBs) are different from regular PCBs. Here are some important things to remember:

Electrical Requirements: Make sure your PCB has the right electrical connections and traces.

Optical Design: Your PCB design should match how light needs to be spread out.

Manufacturability: Design your PCB so it can be made easily and reliably.

Cost Considerations: Keep design needs in mind while watching manufacturing costs.

Thermal Management: Pick the right material to help with heat loss. Metal-core PCBs work best for high-power uses.

Power Design: A steady power supply stops LEDs from flickering and getting damaged. Use filtering methods to improve performance.

Driver Circuitry: Choose between constant current and constant voltage drivers. This choice affects how well the LEDs work.

Managing heat is very important for LED PCBs. Here are some ways to control heat:

Evidence | Description |

|---|---|

Thermal Vias | Small holes in the PCB help move heat from LED parts to heat sinks. |

Metal Core PCBs | These PCBs have a metal base that helps carry heat away from the LEDs. |

Heat Sinks | Attached to the PCB, they help get rid of heat through conduction, convection, and radiation. |

Improving thermal vias can lower the temperature of LEDs by 10-20°C. This helps them last longer and keeps their light steady.

Applications

LED PCBs are used in many areas because they are efficient and effective. Here are some common uses:

Lighting Systems: LED PCBs power streetlights, indoor lights, and decorative lamps.

Consumer Electronics: Gadgets like TVs and monitors use LED PCBs for backlighting.

Automotive Lighting: Cars use LED PCBs for headlights, taillights, and inside lights.

Medical Devices: Tools like surgical lights and diagnostic machines benefit from LED technology.

By knowing the features and uses of LED PCBs, you can make smart choices when designing or picking PCBs for your projects.

In conclusion, knowing the different types of printed circuit boards (PCBs) is important for your electronics projects. Each type, like single-sided and HDI PCBs, has special features for different uses. When picking a PCB, think about where parts go, how traces connect, and how to manage heat. These things affect how well your devices work and how reliable they are.

Choosing the right PCB can improve electrical performance and lower mechanical stress. Take time to think about what you need. This will help you find the best circuit board for your project.

FAQ

What are printed circuit boards (PCBs)?

Printed circuit boards, or PCBs, are boards that connect electronic parts. They create paths for electrical signals. You can find them in almost every electronic device, like smartphones and medical tools.

How do I choose the right PCB type?

Think about your device’s size, complexity, and cost. For simple designs, single-sided PCBs are a good choice. For more complex needs, double-sided or multi-layer PCBs might be better. Check your assembly processes to make sure they fit.

What materials are used in PCBs?

Common materials are fiberglass, epoxy resin, and copper. Fiberglass gives strength, while copper helps conduct electricity. The materials you choose affect how well the PCB works and how long it lasts.

Can I recycle PCBs?

Yes, you can recycle PCBs. Many companies focus on recycling electronic waste. Proper recycling helps lessen environmental harm and recover valuable materials. Always check local rules for disposal guidelines.

What is the role of assembly processes in PCB manufacturing?

Assembly processes include placing and soldering parts onto the PCB. These steps make sure the board works correctly. Good assembly processes improve the overall quality and reliability of the final product.

See Also

Understanding Key Functional and Structural Variations of PCBA and PCB

An Overview of PCBA Coating Fundamentals and Varieties

In-Depth Comparison of PCBWay and Competing PCB Manufacturers