Modern PCBA manufacturing requires effective communication systems to operate efficiently. You must choose between Fieldbus protocol PCBA manufacturing or Industrial Ethernet for your setup. Fieldbus protocols are slower but are well-suited for specific tasks. In contrast, Industrial Ethernet is faster and can easily manage more complex operations. Selecting the right option significantly influences the performance of your factory. It also affects how your machines collaborate and evolve over time. Understanding these systems is essential for enhancing your PCBA processes and outcomes.

Key Takeaways

Fieldbus systems work slower but handle simple jobs well. They give steady communication for basic tasks.

Industrial Ethernet is quicker and manages harder jobs. It works for big data needs and gets factories ready for new tech.

Think about how fast your factory needs to communicate. Industrial Ethernet is very fast, but Fieldbus works fine for easy tasks.

Check which network design suits your factory best. Industrial Ethernet allows flexible setups and grows with your factory.

Cost and setup difficulty are important. Fieldbus costs less and is simpler to install. Industrial Ethernet costs more at first but saves money later.

Overview of Fieldbus Protocols

Definition and Concept

Fieldbus protocols are digital systems used in factories. They help machines and controllers share data easily. This makes manufacturing work smoother and faster. Rules like the Fieldbus Standard Part 3 explain how these systems work. They focus on quick messages, simple actions, and event details. These rules create a strong system for factory communication.

Aspect | Description |

|---|---|

Standard Name | Fieldbus Standard Part 3: Data Link Service Rules |

Focus | Rules for data sharing in factory systems |

Key Features | Quick messages, simple actions, event details, and data links |

Purpose | Build better communication systems for faster factory operations |

Fieldbus protocols are supported by many machine makers. They allow fast data sharing and handle many signals at once. This makes them great for devices that need to share lots of information.

Technical Characteristics

Fieldbus uses special wires to send power and data together. This makes setup easier and cheaper. It works safely in risky areas, unlike Industrial Ethernet. This is helpful for places with strict safety rules.

Smart tools in fieldbus systems make them reliable. For example, they can reduce machine problems by up to 80%. Tests like those on the WorldFIP protocol show how well fieldbus works. These features prove fieldbus is dependable for tough factory jobs.

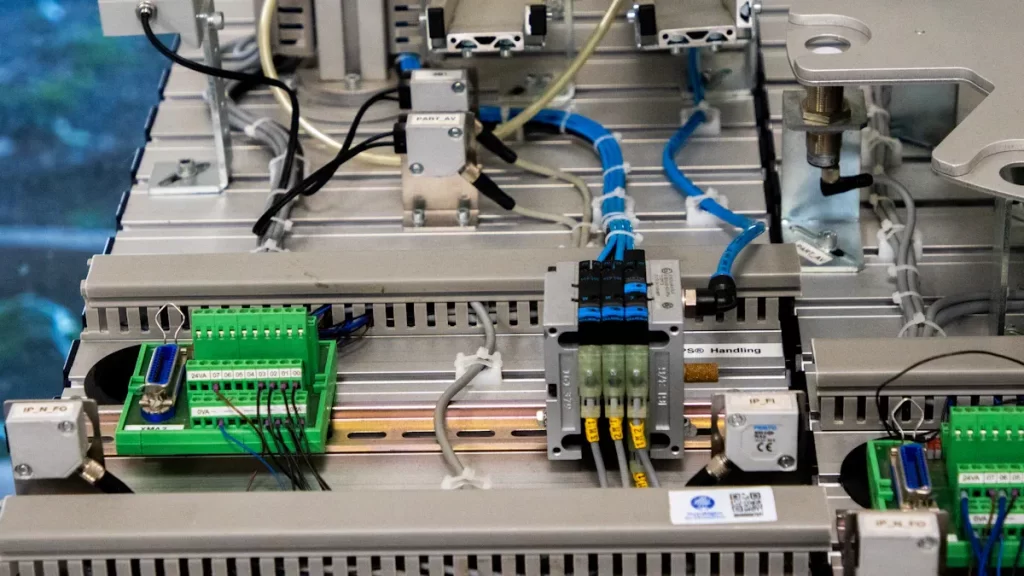

Applications in PCBA Manufacturing

Fieldbus protocols are important for PCBA manufacturing. They help machines and controllers talk clearly and quickly. This is useful for tasks like soldering and inspecting parts.

Fieldbus works safely in dangerous areas, making it good for strict safety setups. It also connects old and new systems easily. This keeps your factory ready for future changes in technology.

Overview of Industrial Ethernet

Definition and Concept

Industrial Ethernet is a fast communication system for factories. It is stronger and more reliable than regular Ethernet. It handles real-time data sharing and tough factory conditions. It uses protocols like PROFINET, EtherNet/IP, and Modbus TCP/IP to connect devices smoothly.

This system helps factories share data quickly and stay connected. It works with wireless tech like 5G, even in areas with signal problems. Rules like IEC 61158 and IEC 61784 make sure it works well in harsh places. Industrial Ethernet is key to modern factories and Industry 4.0.

Technical Characteristics

Industrial Ethernet has features that make it great for PCBA work. It sends data fast, so machines and controllers stay in sync. For example, PROFINET allows precise timing for factory tasks.

It uses special cables and grounding to avoid interference. Devices with IP65 ratings resist dust and water, lasting longer in tough spots. It also connects virtual and real PLCs, making work more efficient.

Feature | Benefit |

|---|---|

Fast data sharing | Real-time machine communication |

Special cables and grounding | Less interference, more reliability |

IP65-rated devices | Protection from dust and water |

Supports many protocols | Works with PROFINET, EtherNet/IP, and Modbus TCP/IP |

Applications in PCBA Manufacturing

Industrial Ethernet is great for PCBA factories. It helps machines, controllers, and monitors work together easily. Its speed is perfect for precise jobs like solder inspections.

It connects old systems to new ones without big changes. For example, PROFINET works with older PROFIBUS setups. Its strong design handles high EMI, which is common in PCBA work.

Using Industrial Ethernet prepares your factory for the future. It grows with new tech like 5G and advanced tools. This keeps your factory ready for changes in the industry.

Detailed Comparison: Fieldbus Protocols vs Industrial Ethernet

Communication Speed and Bandwidth

Industrial Ethernet is faster than Fieldbus protocols. It works at speeds from 100 Mbps to several Gbps, making it great for tasks needing lots of data. Fieldbus protocols, like PROFIBUS and CAN bus, are slower. PROFIBUS reaches up to 12 Mbps, while CAN bus goes up to 1 Mbps. This speed difference matters when machines need quick data sharing.

Protocol | Speed | Nodes Supported |

|---|---|---|

PROFIBUS | Up to 126 | |

CAN bus | Up to 1 Mbps | Up to 127 |

Modbus | Up to 115K baud | Up to 247 |

CC-Link | Up to 10 Mbps | Up to 64 |

Industrial Ethernet | 100 Mbps to Gbps | Unlimited |

Industrial Ethernet handles more data at once. This helps with real-time communication in complex setups. Fieldbus works well for simpler tasks with lower speed needs. For example, PROFIBUS can manage up to 126 nodes, making it good for small networks.

Tip: Choose Industrial Ethernet for high data needs or future growth.

Network Architecture and Topology

Fieldbus and Industrial Ethernet use different network designs. Fieldbus often uses a bus layout, where devices connect in a line. This setup is simple but hard to expand. PROFIBUS and CAN bus use this design, which works for small setups but struggles with bigger networks.

Industrial Ethernet supports flexible layouts like star, ring, and mesh. These designs fit different needs. A star layout connects devices to one switch, making fixes easy. Ring layouts add backups, so the network works even if one link breaks.

Aspect | Description |

|---|---|

Fieldbus uses bus layout; Industrial Ethernet supports star, ring, and mesh designs. | |

Operation and Performance | Industrial Ethernet offers high reliability and works across different systems, perfect for modern PCBA factories. |

Technological Contributions | ServiceNet improves real-time network management, making Industrial Ethernet better for complex setups. |

Empirical Results | Tests show Industrial Ethernet handles tough factory conditions well. |

Fieldbus is easier to set up but less flexible. Industrial Ethernet lets you add new devices and tech as your factory grows.

Real-Time Capabilities

Real-time communication is key for PCBA work. Timing and accuracy affect product quality. Fieldbus protocols like PROFIBUS send data on time, making them reliable for tasks like machine control.

Industrial Ethernet has improved real-time features. Protocols like PROFINET and EtherCAT send data quickly, with cycle times of just milliseconds. PROFINET works over multiple channels, making it useful for many tasks.

Protocol | Description |

|---|---|

PROFINET | Used for fast and reliable communication in factories. |

Ethernet/IP | Known for high speed and dependability in automation. |

PROFINET sends data fast between devices, perfect for critical tasks.

EtherCAT handles data efficiently, allowing precise control in fast operations.

Industrial Ethernet is better for high-speed jobs but harder to set up. Fieldbus is still a good choice for simpler tasks needing accurate timing.

Note: Use Industrial Ethernet for fast and precise operations, like PROFINET or EtherCAT.

Scalability and Flexibility

Scalability and flexibility are important for PCBA manufacturing systems. They show how well your setup can grow or change with new needs.

Fieldbus can connect up to 65,535 devices in one network. This makes it great for modular designs where each part works on its own. It supports layouts like bus or line setups, which make adding devices easy. Decentralized gateways in fieldbus systems save space by shrinking industrial PCs. This allows smaller designs without needing extra slots.

Feature Description | Benefit for Scalability and Flexibility |

|---|---|

Decentralized gateways | Smaller industrial PCs for compact designs. |

Multiple topologies | Supports bus or line setups with many nodes. |

Large device connection capacity | Connects up to 65,535 devices for big networks. |

EtherCAT P technology | Sends data and power through one cable. |

Industrial ethernet is very flexible. It works with layouts like star, ring, and mesh, fitting different factory designs. It also connects with wireless tech like 5G, making it adaptable. Protocols like PROFINET link old systems with new ones, keeping factories ready for future changes.

Tip: Choose industrial ethernet if your factory needs frequent updates or expansions.

Interoperability and Compatibility

Interoperability and compatibility help devices work well together in automation systems. Fieldbus protocols, like PROFIBUS, are supported by many manufacturers. This makes them work with lots of devices. But connecting fieldbus to newer tech can be tricky because of different standards.

Industrial ethernet supports many protocols, such as PROFINET and Modbus TCP/IP. These allow devices from different brands to communicate easily. Studies show interoperability is key for factory systems. For example:

Study | Focus Area |

|---|---|

Cavaleri and Cutuli | Ways to measure OPC UA performance. |

Imtiaz and Jasperneite | Using OPC-UA for devices with limited resources. |

Anitha et al. | Comparing protocols based on layout and speed. |

Lin and Pearson | Need for unified platforms in industrial ethernet. |

Industrial ethernet may need extra tools to connect older systems. Protocol conversion gateways help older fieldbus setups work with modern ethernet networks.

Note: Use protocol converters if your factory has both old and new equipment.

Cost and Implementation Complexity

Cost and setup difficulty affect your choice between fieldbus and industrial ethernet. Fieldbus systems, like PROFIBUS, are reliable and simple to use. They cost less to set up and need less training. This makes them good for small factories or basic systems. For example:

Modbus works well for cheap, simple setups.

PROFIBUS handles fast and complex tasks.

Foundation Fieldbus is great for steady process control.

Scaling fieldbus systems can cost more because of limited design options.

Industrial ethernet costs more at first but saves money later. It handles large data loads and works with advanced tech like 5G. This reduces the need for upgrades. Its setup is harder because of features like real-time communication. These need special skills for setup and maintenance.

Alert: If your factory needs growth and advanced tools, industrial ethernet is worth the investment.

Selecting the Right Protocol for PCBA Manufacturing

Key Factors to Consider

Picking between fieldbus and industrial ethernet depends on key factors. Look at your factory’s setup, goals, and needs. First, check the communication speed required. Industrial ethernet sends data fast, perfect for tasks like soldering checks. Fieldbus is slower but works well for simpler jobs.

Next, think about the network topology that fits your factory. Fieldbus uses a simple bus design. Industrial ethernet supports layouts like star and ring, which are flexible. If your factory grows often, industrial ethernet is better for expansion.

Also, review the real-time capabilities of each system. For precise timing, profinet and profibus are good choices. Profinet handles fast tasks, while profibus works for simpler ones needing accuracy.

Finally, consider cost and complexity. Fieldbus costs less and is easier to set up, ideal for small factories. Industrial ethernet costs more but saves money later. It adapts well to new tech like 5G.

Tip: Match your choice to your factory's needs and future plans for the best results.

Picking between Fieldbus protocols and Industrial Ethernet depends on your factory’s needs. Fieldbus protocols are great for simple tasks with predictable actions. Industrial Ethernet is faster and can grow with complex setups. Ethernet systems are becoming more popular because they are reliable. They handle big data well but need tools to keep timing accurate.

Choosing the right system helps your factory work better. Small factories or basic setups can use Fieldbus for easy and low-cost communication. For advanced tasks, Industrial Ethernet offers fast data sharing and future upgrades.

Tip: Think about your factory's size, data needs, and future plans to pick the best system.

FAQ

What is the main difference between Fieldbus protocols and Industrial Ethernet?

Fieldbus protocols are slower but good for simple tasks. Industrial Ethernet is faster and handles complex jobs well. Pick based on your factory’s data needs and growth plans.

Can Fieldbus and Industrial Ethernet work together in the same factory?

Yes, they can work together. Use protocol converters or gateways to link them. This helps older machines connect with modern systems easily.

Which protocol is better for small PCBA factories?

Fieldbus protocols are best for small factories. They cost less, are simple to install, and manage basic tasks well. Industrial Ethernet might be too much for smaller setups.

How does Industrial Ethernet prepare factories for Industry 4.0?

Industrial Ethernet works with new tech like 5G and IoT. It shares data in real-time, helping factories become smarter and ready for Industry 4.0.

Is it expensive to switch from Fieldbus to Industrial Ethernet?

Switching costs more at first because of new tools and training. But Industrial Ethernet saves money later by supporting upgrades and managing more data.

Tip: Upgrade step by step to control costs better.