High-power EV PCBA solutions are very important for electric cars. These systems use special circuit boards to handle strong electrical currents. They help move energy efficiently and keep the car working reliably. They also manage power, save energy, and stay cool under tough conditions.

New improvements in 2025 have made this technology better. Cooling methods now let electric engines use over 85% of battery power. This means they waste less energy and work more efficiently. Stronger designs and better materials make them last longer. Electric motors can now run at speeds up to 25,000 rpm because of improved cooling systems.

The global market for car PCBs shows how important they are. In 2023, it was worth $2.5 billion. By 2032, it could grow to $9.1 billion. This growth is due to the need for advanced PCBs in more complex electric cars.

Key Takeaways

High-power PCBA solutions help electric cars manage energy better.

New cooling methods, like liquid cooling, keep systems working well.

Materials like silicon carbide make parts stronger and last longer.

AI and IoT improve energy use and fix problems before they happen.

Teamwork between makers, suppliers, and tech experts helps improve EVs.

Understanding high-power EV PCBA solutions

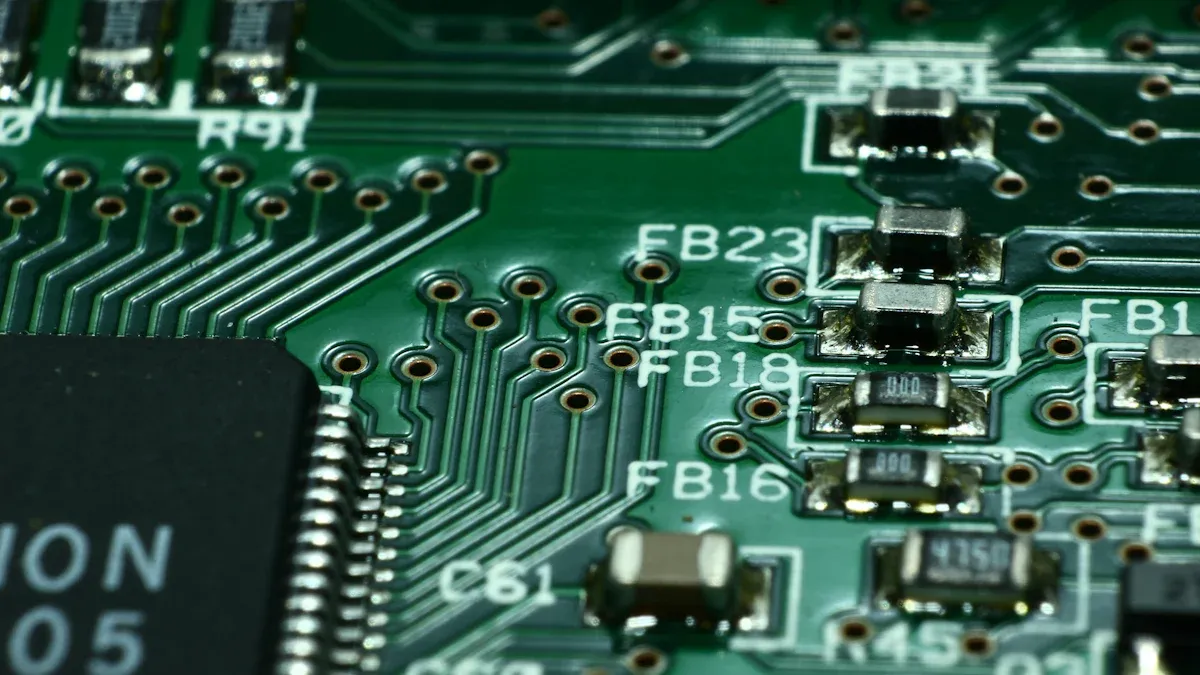

Definition and key components

High-power EV PCBA solutions are special circuit boards for electric cars. They handle the strong electrical needs of these vehicles. These boards help change and share energy efficiently. Important parts include inverters, converters, and on-board chargers. Inverters turn battery power (DC) into motor power (AC). Converters adjust voltage to run different car systems. On-board chargers change station power (AC) into battery power (DC).

New PCB designs use materials like silicon carbide (SiC) and gallium nitride (GaN). These materials help parts work with higher power and less heat loss. They also make parts smaller and more efficient. Examples include power MOSFETs and IGBTs, which handle high voltages and currents.

Role in electric vehicles

High-power EV PCBA solutions are very important for electric cars. They help energy move smoothly between the battery, motor, and other systems. By managing energy well, they improve car performance and save power.

For example, inverters and converters give the motor the right power to work best. On-board chargers make charging easy and work with different stations. These boards also help with regenerative braking, which saves energy during braking and stores it in the battery.

The global EV charging market shows why these boards matter. Rules, customer needs, and new tech increase demand for better PCBA designs. This proves how important strong and efficient parts are for electric cars.

Importance of thermal and power management

Keeping PCBA solutions cool is very important for safety and efficiency. Parts like inverters, converters, and batteries get hot when working. Without cooling, they can overheat and stop working well.

Cooling systems stop overheating by using air, liquid, or special materials. Studies show cooling methods affect how well electric cars work. Liquid cooling is great for keeping hot parts cool, even in tough conditions.

Power management is just as important. It spreads energy evenly across the car’s systems. This reduces wasted power and uses the battery better. New PCB designs with silicon carbide improve cooling and energy use. These upgrades make electric cars more reliable and efficient.

Latest advancements in high-power EV PCBA solutions in 2025

Innovations in thermal management

Managing heat is key to keeping EV PCBA solutions safe and efficient. In 2025, new cooling methods have greatly improved how heat is controlled. Engineers now use copper-graphene composite bases in on-board charger (OBC) PCBs. These bases transfer heat better, up to 800 W/m·K, and lower temperatures by 25°C. This helps power devices work better without getting too hot.

Liquid cooling systems with phase change materials (PCM) are also popular. They keep temperature changes under 2°C in fast-charging modules, ensuring steady cooling. Tools like ANSYS Twin Builder help engineers plan where to place parts and manage heat paths. This digital modeling ensures heat is handled well, even with high power use.

Tip: Better cooling systems not only boost performance but also make parts last longer, improving electric car reliability.

Higher power density designs

New PCB designs aim to pack more power into smaller spaces. In 2025, multilayer PCBs and flexible layouts are used for compact designs. These allow more parts to fit while keeping performance high.

Materials like silicon carbide (SiC) and gallium nitride (GaN) are now common in PCBs. They allow faster switching and less heat loss, making power devices smaller and more efficient. For example, SiC-based power MOSFETs and IGBTs handle higher voltages and currents without losing efficiency.

AI and IoT technologies also improve power density. AI helps spread energy evenly across systems, and IoT sensors track performance in real time. These tools ensure all parts work their best, improving the car’s overall performance.

Advanced materials for durability and performance

Strong and reliable materials are important for EV PCBA solutions. In 2025, manufacturers use advanced materials to meet these needs. Liquid crystal polymer (LCP) bases are popular because they resist water and stress. They absorb less than 0.02% water, staying reliable in tough conditions.

Surface finishes like ENIG (Electroless Nickel Immersion Gold) with OSP (Organic Solderability Preservative) protect parts from corrosion. These finishes are tested in 85°C/85% humidity for 1,000 hours to prove their strength.

Testing methods like Highly Accelerated Life Testing (HALT) find weak spots early. HALT uses fast temperature changes and vibrations to test PCBs in extreme conditions. These new materials and tests make high-power EV PCBA solutions last longer and work better.

Integration of AI and IoT technologies

Artificial intelligence (AI) and the Internet of Things (IoT) are changing how high-power EV PCBA solutions work. They make systems more efficient, reliable, and flexible. These tools help manage energy better, predict problems early, and monitor systems in real time.

Smarter Energy Distribution

AI programs improve how energy is shared in EV systems. They make sure power is used wisely. For example, AI-powered units balance energy between the battery, motor, and other parts. IoT sensors check voltage and current levels. They send real-time data to adjust power flow as needed. This teamwork cuts energy waste and boosts car performance.

Predictive Maintenance and Safety

AI helps find problems before they happen, making EVs safer. Machine learning studies data from IoT sensors in PCBs to spot signs of wear or damage. For instance, special devices detect small electrical leaks and take action to stop bigger issues. This method keeps parts safe and makes them last longer.

Enhanced Battery Management

AI and IoT improve how batteries are managed. IoT-connected chargers and monitors track battery health, temperature, and charging cycles. AI uses this data to set the best charging speed and stop overheating. IoT sensors in cooling systems keep batteries at safe temperatures, ensuring they work well.

Location Analytics for Charging Infrastructure

AI and IoT help grow EV charging networks. Machine learning and mapping tools find the best spots for new charging stations. They look at traffic, energy needs, and nearby stations. This smart planning makes charging easier and faster for EV drivers.

Digital Engineering and Cloud Integration

Digital tools like EDA software make PCB design faster and better. AI-based platforms test cooling and electrical performance to meet safety rules. IoT links PCBs to cloud systems for remote checks and updates. This makes EV systems smarter and more adaptable.

Note: The move to electric cars and smart tech increases the need for better semiconductors. AI and IoT are key to building PCBs that meet these new demands.

Category | Description |

|---|---|

Panels and control units for EV power systems. | |

Battery Management | Chargers and monitors for lithium-ion batteries. |

Control & Actuation | Systems for steering, brakes, and motor drives. |

Digital Engineering | Cloud tools and AI for better designs. |

Adding AI and IoT to high-power EV PCBA solutions makes energy use smarter, improves safety, and boosts performance. These changes lead to better and more reliable electric cars.

Benefits of advancements in electric vehicle charging and performance

Better power delivery and efficiency

New charging systems now deliver power more smoothly and efficiently. They use smart algorithms like Chicken Swarm Optimization (CSO) with Open Ended Learning (OEL). This mix improves how batteries measure their charge levels, making power delivery steady. These methods also save energy by using fewer resources during charging cycles.

High-power chargers now transfer energy faster and with less waste. Silicon carbide (SiC) parts in circuit boards help reduce energy loss. This allows quicker energy flow to the battery. These upgrades improve car performance and lower the environmental impact of energy use.

Note: Better power delivery helps electric cars work more efficiently, making them a great choice over gas-powered cars.

Stronger reliability and longer-lasting parts

Making parts more reliable and durable is a big focus now. Techniques like Physics of Failure (PoF) and Accelerated Life Testing (ALT) find weak spots early. These methods study how parts fail and test them under stress to ensure they last longer.

Modern circuit boards use tough materials like liquid crystal polymers (LCPs) and special finishes like ENIG+OSP. These materials resist damage from heat and moisture, helping parts last longer. Systems that monitor parts in real time now check their health. This helps fix problems early and avoids sudden breakdowns.

Methodology | Description |

|---|---|

Physics of Failure (PoF) | Finds weak points to make parts last longer. |

Accelerated Life Testing | Tests parts in tough conditions to check reliability. |

Condition Monitoring | Tracks part health to fix issues early. |

Faster charging and smarter battery care

New battery systems make charging quicker and easier. Better algorithms now balance battery cells, cutting down charging time. These systems also improve how batteries share energy, making them last longer and go farther.

Battery systems now use IoT sensors to track battery health and temperature. These sensors send data in real time to adjust charging speeds and stop overheating. This tracking also lowers repair costs by spotting problems early.

Benefit | Description |

|---|---|

Balanced cells make batteries more efficient for longer trips. | |

Faster charge times | Smart algorithms speed up charging. |

Decreased maintenance costs | Real-time tracking helps avoid expensive repairs. |

Extended battery lifespan | Better monitoring makes batteries last longer. |

Tip: Faster charging and smarter battery care make electric cars easier to use and cheaper to maintain, encouraging more people to buy them.

Contribution to overall EV performance

High-power PCBA solutions greatly improve how electric vehicles work. They boost energy use, make cars more reliable, and speed up charging. These changes help drivers save money and enjoy better rides.

Modern pcb design helps cars handle fast charging safely. Engineers use smaller layouts and better materials to move energy smoothly. This setup cuts down wasted energy and keeps power steady, even during quick charging. Cars can now speed up faster and run more smoothly.

Better battery management systems help batteries last longer and go farther. These systems check battery health and share energy evenly. They stop batteries from getting too hot and use energy wisely. This lowers repair costs and makes electric cars more dependable.

Improved charging systems make charging quicker and waste less energy. High-power chargers with silicon carbide parts save energy during charging. This tech allows faster charging, so drivers spend less time waiting. Smarter charging infrastructure planning places stations in handy spots, making EVs easier to use.

New cooling methods also help cars perform better. Liquid cooling and special materials keep parts at safe temperatures. This stops overheating and ensures everything works well, even under stress.

Note: These upgrades not only make cars better but also help the planet by using energy more wisely.

High-power PCBA solutions are changing electric cars. They make them faster, safer, and more trustworthy. These advancements bring us closer to a future where electric cars are the main way we travel.

Challenges and future outlook for high-power EV PCBA solutions

Current manufacturing limitations

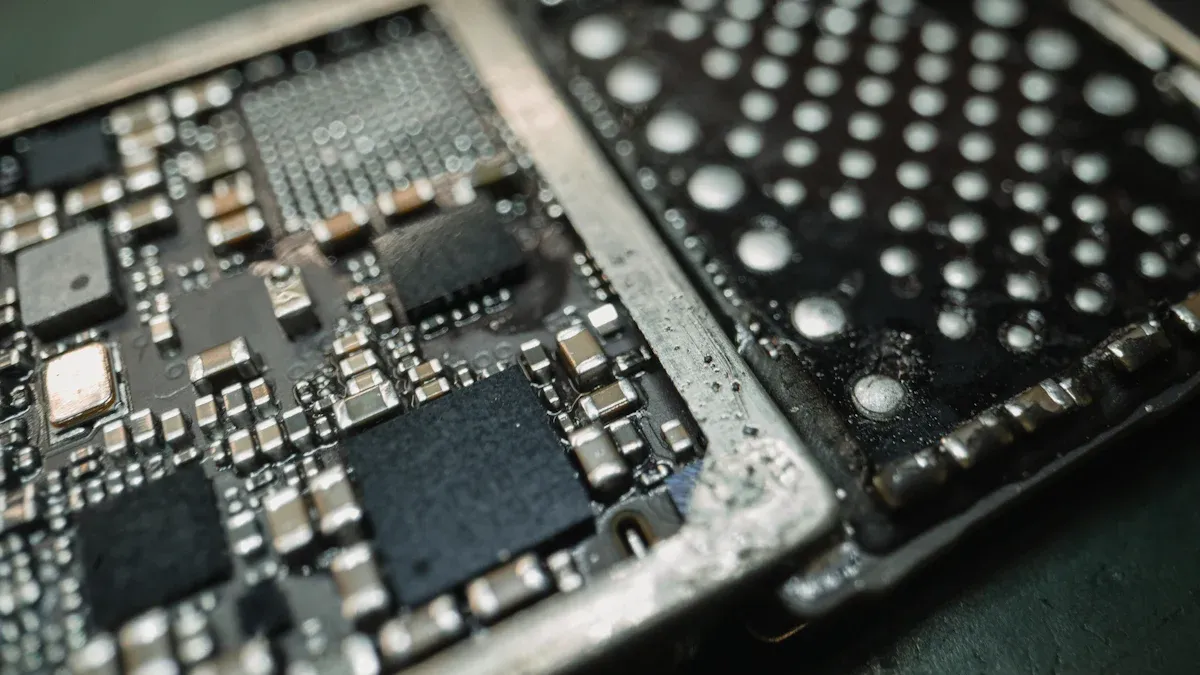

Making high-power PCBA solutions for EVs has tough challenges. These boards must handle strong currents and voltages. For example, EV batteries need boards that manage 100V DC and 180 amps. Regular copper foil can’t handle this well. Engineers now use copper busbars to move currents better. They also calculate busbar sizes and add MOSFETs to designs for efficiency.

Keeping parts cool is another big problem. High-power chargers create a lot of heat, which can harm parts. Using copper-graphene bases and tiny liquid cooling channels helps remove heat. But these methods make manufacturing harder and more complex.

Finding materials is also difficult. EV growth and better power electronics increase the need for special materials. However, getting silicon carbide and gallium nitride is still a challenge. Political issues and shortages make this even harder.

Cost and scalability issues

Making more high-power PCBA solutions costs a lot of money. Advanced materials and methods are expensive. For instance, liquid crystal polymer bases and special finishes need costly processes. This raises production costs.

Supply and demand are uneven in different regions. In Europe, PCB production is worth €1.37 billion, but demand is €7.87 billion. This creates a big gap. East Asia leads with 68.3% of the market, but they also face production delays.

Automation and digital tools could lower costs. Tools like ANSYS Twin Builder help design and speed up production. But these tools need big investments, which smaller companies may not afford.

Potential future developments

The future of high-power PCBA solutions looks bright with new ideas. Better insulation, like high-CTI bases and special coatings, can make boards safer. Devices that monitor leaks in real time may stop failures before they happen.

Cooling systems will keep improving. Mixing copper-graphene bases with phase change materials could cool parts even better. Digital twin models might help plan where to place parts for better heat control.

Boards will also last longer in tough conditions. Materials like low-water-absorption LCPs and fast testing methods like HALT will make them stronger.

Teamwork between industries will help solve problems. Manufacturers, material suppliers, and tech developers can work together to cut costs and scale production. As more people use EVs, these efforts will lead to better and cheaper PCBA solutions.

Importance of industry collaboration

Working together is key to improving high-power PCBA solutions for electric cars. Partnerships between manufacturers, material suppliers, and tech developers help solve problems like high costs, scaling production, and creating new ideas.

Shared Resources and Expertise

Teamwork lets companies share tools and knowledge. Manufacturers can team up with suppliers to get advanced parts like silicon carbide and gallium nitride. Tech developers can design better cooling systems and digital tools for making PCBs. This cooperation lowers costs and speeds up progress.

Tip: Working together helps reduce the need for rare materials and makes supply chains work better.

Standardization and Compatibility

Collaboration helps create shared rules for the EV industry. Companies can agree on common PCB designs, testing steps, and safety rules. Shared designs make it easier to build more parts and add new technology. For example, having the same standards for on-board chargers makes building charging stations simpler.

Accelerated Innovation

Team research leads to faster new ideas. Schools, labs, and companies can join forces to create advanced solutions. For instance, they can study new materials like liquid crystal polymers or better cooling methods using phase change materials. These ideas make PCBA solutions stronger and more efficient.

Collaboration Type | Benefits |

|---|---|

Manufacturer-Supplier | Helps get top-quality parts and materials. |

Industry-Research | Speeds up new ideas with shared testing and knowledge. |

Cross-Company Standards | Makes parts work together and easier to produce. |

Global Impact

Working together also helps with worldwide problems. Companies can team up to make EV production greener. They can focus on recycling and finding eco-friendly materials. These efforts make EVs cheaper, better, and more available around the world.

Note: Partnerships are crucial for making more EVs and meeting the need for cleaner transportation.

Collaboration makes the EV industry stronger by combining tools, skills, and ideas. It ensures high-power PCBA solutions keep improving, helping us move toward a cleaner and smarter future.

High-power EV PCBA solutions are key to improving electric cars. They help manage energy better, make cars more reliable, and allow faster charging. By 2025, new cooling methods, compact designs, and AI tools have greatly improved EVs. Solid-state batteries store more energy and charge faster, changing the industry. These batteries will need smarter systems to manage and charge them. New materials and designs will solve today’s problems. This will lead to greener and more efficient electric cars in the future.

FAQ

1. What do high-power PCBA solutions do in electric cars?

These solutions help move energy between the battery and motor. They make power delivery smooth, improve car performance, and support fast charging and energy-saving braking.

2. How do special materials make PCBA work better?

Materials like silicon carbide and gallium nitride cut heat loss. Liquid crystal polymers stay strong against water and stress, making parts last longer.

3. Why is keeping PCBA cool important for electric cars?

Cooling stops parts from overheating, which can cause damage. Methods like liquid cooling and copper-graphene bases remove heat and keep systems safe.

4. How does AI make PCBA solutions smarter?

AI helps share energy better, spot problems early, and manage batteries. It uses data from IoT sensors to adjust power and avoid failures.

5. What problems do companies face when making more PCBA parts?

Companies deal with expensive materials, tricky designs, and shortages. Working together and using digital tools can solve these problems and make production easier.

See Also

PCBA Revolutionizes Electronics Performance Like Never Before

PCBA Elevates Contemporary Electronics To Unprecedented Levels

Emerging Trends in PCB and PCBA Design and Manufacturing

Benefits and Challenges of Flex PCBA in Today’s Electronics

Significance of PCBA Manufacturing Skills in Electronics Development