When you need strong and lasting boards, high-reliability process control boards are the best choice. These boards perform exceptionally well in tough conditions and maintain their reliability. Standard boards, however, are cheaper and suitable for simple, low-risk tasks. Your choice depends on how much reliability your project requires, as well as your budget. Understanding these differences will help you select the right board.

Key Takeaways

High-reliability boards work well in harsh places. They are great for important uses like airplanes and medical tools.

Standard boards are cheaper and good for easy jobs. They are best for projects with small budgets.

High-reliability boards have tools to find problems early. This lowers delays and keeps things safer.

Pick the right board based on your project’s needs and money. Think about these things carefully.

Standard boards are simple to use and fix. They are good for beginners and daily tasks.

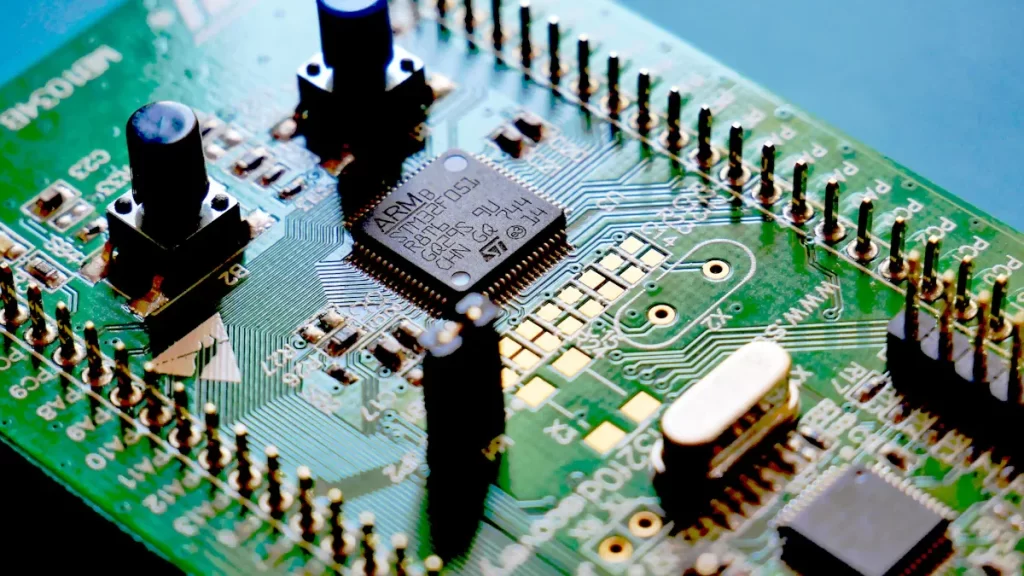

Key Features of High-Reliability Process Control Boards

Durability and Reliability

High-reliability boards are built to handle tough conditions. They keep working well even in extreme environments. These boards use strong parts that last a long time. To avoid failures, makers add extra backup systems. For example, they may use two or three backups for important circuits. If one part breaks, the system still works without stopping.

These boards go through hard tests to prove their strength. Tests like High Temperature Operating Life (HTOL) and Highly Accelerated Stress Test (HAST) mimic harsh conditions. This helps predict how long the boards will last. Below is a table showing some key tests used to check durability:

Test Type | Description |

|---|---|

High Temperature Operating Life (HTOL) | Checks how well it works in high heat. |

Failures in Time (FIT) | Counts how many failures happen over time. |

Mean Time to Fail (MTTF) | Predicts how long before something breaks. |

Autoclave (PCT) | Tests under high pressure and heat. |

Highly Accelerated Stress Test (HAST) | Speeds up aging to see long-term performance. |

High Temperature Storage (HTS) | Looks at effects of staying in high heat for a long time. |

Temperature Cycling Test (TCT) | Tests strength with repeated hot and cold changes. |

Temperature Humidity Bias (THB) | Checks reliability in heat and humidity together. |

Thermal Shock Test (TST) | Tests if it can handle sudden temperature changes. |

Unbiased HAST | Tests without adding extra electrical stress. |

These tests make sure the boards work well in critical places like hospitals or space missions, where failure is not allowed.

Advanced Monitoring and Feedback Mechanisms

These boards have smart systems that watch and report problems fast. They help find issues early so you can fix them quickly. For example, remote monitoring lets you check systems from far away. Predictive maintenance helps you fix things before they break. This reduces downtime and keeps everything running smoothly.

Big organizations stress the need for good monitoring systems. Groups like The Joint Commission (TJC) and Centers for Medicare & Medicaid Services (CMS) focus on safety and quality checks. Below is a table showing some examples of performance tracking:

Evidence Source | Description |

|---|---|

The Joint Commission (TJC) | Requires regular checks to ensure safety and reliability. |

National Database for Nursing Quality Indicators (NDNQI) | Shares tips to improve results through monitoring. |

Centers for Medicare & Medicaid Services (CMS) | Encourages quality checks to boost system performance. |

With these tools, high-reliability boards keep important systems working well, even in tough situations.

Sensitivity to Operations in High-Reliability Organizations

These boards are made for places like hospitals and aerospace companies. These places need systems that focus on safety and details. Sensitivity to operations means paying attention to small tasks and doing them carefully.

Experts say teamwork and respect are very important. This helps people look at data honestly and improve systems. For example:

Sensitivity to Operations

In high-reliability places, even small tasks are treated as important. This means always being aware of what’s happening and thinking about the big picture.

Looking at data helps find ways to get better. A team that works well together makes sure systems stay strong and flexible.

By focusing on these things, high-reliability boards help important systems work safely and reliably every day.

Key Features of Standard Process Control Boards

Cost-Effectiveness

Standard boards are made to be affordable. They save money in projects where high reliability isn’t needed. Manufacturers use simple designs and cheaper materials to lower costs. This makes them great for projects with small budgets.

Here’s why they save money:

Avoided Cost: Standard boards reduce repair costs and prevent downtime losses.

Financial Expenditures Tracking: Watching material, labor, and overhead costs helps find savings.

Overall Operations Effectiveness (OOE): These boards help check efficiency by tracking performance and quality.

Standard boards are a smart choice for systems where saving money matters more than extra features.

Simplicity and Efficiency

These boards are simple to use. Their basic designs make setup and maintenance easy. You don’t need special tools or training, which saves time.

They are also efficient. Standard boards work well for basic tasks and give steady results. For example, they are used in home electronics and simple industrial systems. Their easy design ensures smooth use, even for beginners.

Tip: If your project doesn’t need advanced tools, standard boards are a simple and effective option.

Limitations in Durability and Performance

Standard boards are less durable than high-reliability boards. They can’t handle extreme heat, humidity, or pressure. This makes them unsuitable for critical jobs like medical devices or space equipment.

Their performance is also limited. They don’t have advanced tools like remote monitoring or predictive maintenance. They aren’t built for tough, long-term use. If your project needs high reliability, these boards might not work well.

Note: Standard boards are best for safe environments where durability and advanced tools aren’t needed.

Cost Analysis

Why High-Reliability Boards Are More Expensive

High-reliability boards cost more because they meet strict rules. They use strong parts that last a long time. These boards have backup systems to avoid failures. For example, medical devices and space tools need to work all the time. These boards are made to handle tough conditions without breaking.

Making these boards involves hard tests like HALT and FMEA. These tests find weak spots and check if the board works under stress. Features like remote monitoring and predictive maintenance also add to the price. These tools help find and fix problems early, which is important for critical systems.

Even though they cost more upfront, they save money later. They reduce failures and downtime, making them worth the investment. These boards are perfect for industries where reliability is a must.

Cost Benefits of Standard Boards

Standard boards are cheaper and good for simple projects. They use basic designs and affordable materials to keep costs low. These boards work well in non-critical systems like home electronics or simple industrial tools.

One big benefit is how fast they can be made. Manufacturers can produce them quickly and in large amounts, saving money. Maintenance is easy too, since no special tools or skills are needed. This makes them great for projects with small budgets or tight deadlines.

While they don’t have advanced features, standard boards are reliable for everyday tasks. If your project doesn’t need to handle tough conditions, these boards are a smart and affordable choice.

Tip: Pick standard boards when saving money matters more than extra features.

Applications of High-Reliability Process Control Boards

Aerospace and Defense

High-reliability boards are crucial for aerospace and defense work. These fields need systems that never fail during important tasks. These boards are used in satellites, missiles, and aircraft controls. They handle tough conditions like heat and strong vibrations. This ensures they work perfectly during missions.

To meet strict rules, makers follow special certifications. These include MIL-HDBK-217 and MIL-STD-1629. These rules check reliability and prevent failures. Below is a table of key certifications:

Standard | Description |

|---|---|

MIL-HDBK-217 | Sets reliability rules for military electronics. |

MIL-STD-1629 | Studies failure risks and prevents major problems. |

SAE ARP4754A and SAE ARP4761 | Gives safety checks for airplane systems. |

MIL-HDBK-472 | Helps plan maintenance to avoid issues. |

These certifications make sure boards meet aerospace and defense needs, where failure isn’t allowed.

Medical Devices

Medical devices need high-reliability boards to stay safe and accurate. Machines like ventilators and imaging tools depend on these boards. They work perfectly in life-saving situations.

Hospitals need boards with smart tools like monitoring and predictive fixes. These tools find problems early to keep patients safe. Reliable systems in healthcare save lives. For example, over 100 ICUs in Michigan reduced infections by using structured plans. This shows how reliable boards improve patient care.

Choosing high-reliability boards helps medical devices stay safe and dependable in tough conditions.

High-Reliability Organizations and Critical Systems

High-reliability organizations use these boards to stay strong and safe. These groups work in places where small mistakes can cause big problems. Examples include nuclear plants, air traffic control, and emergency systems.

These boards help by offering tools like remote checks and predictive fixes. They also use smart designs like backup circuits and failure checks. These features keep systems running during hard times.

For instance, healthcare groups use proven methods to improve reliability. This ensures critical systems work well, even under pressure.

Using high-reliability boards builds systems that focus on safety and strength in important areas.

Applications of Standard Process Control Boards

Consumer Electronics

Standard boards are important in everyday electronics. They are used in things like phones, laptops, and home gadgets. These boards are cheap and simple, making them great for making lots of products. You’ll find them in most devices you use daily.

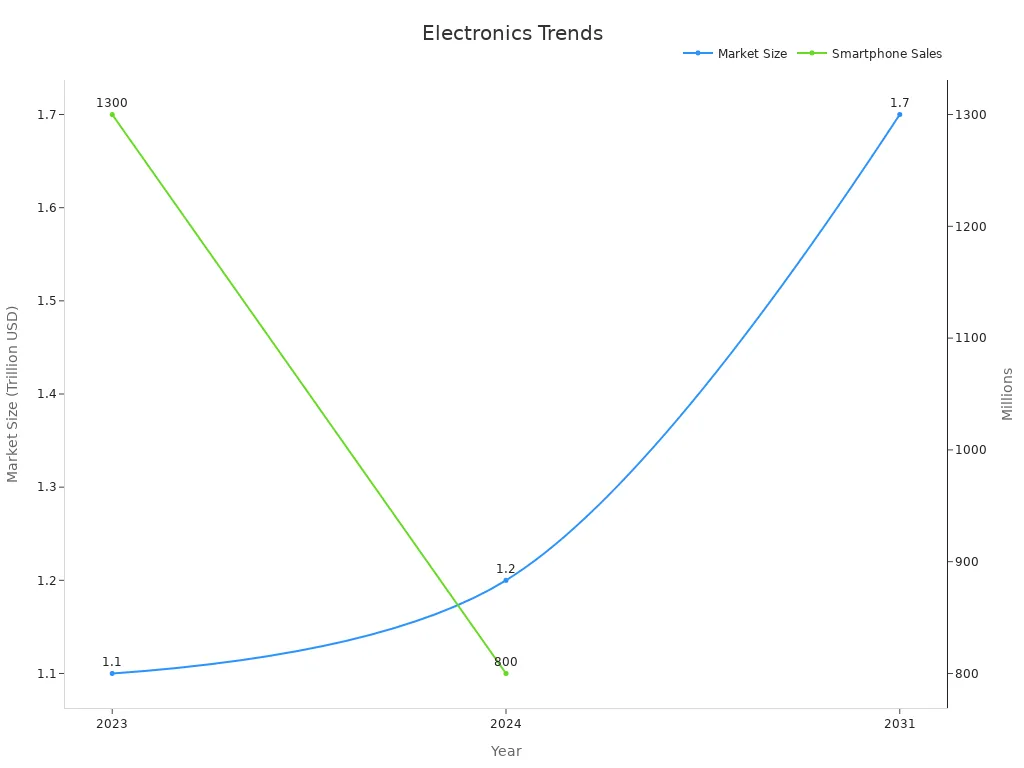

The electronics market is growing fast. In 2023, it was worth $1.1 trillion and could reach $1.7 trillion by 2031. It’s growing at a rate of 4.5% each year. In 2023, 1.3 billion smartphones were sold. By 2024, 800 million 5G phones are expected to be sold.

Statistic | Value |

|---|---|

Global electronics market size (2023) | USD 1.1 trillion |

Projected market size (2031) | USD 1.7 trillion |

Growth rate (2023-2031) | 4.5% |

Smartphone sales (2023) | 1.3 billion units |

Expected 5G phone sales (2024) | 800 million units |

The need for semiconductors, sensors, and PCBs is increasing. As smart devices and AI tools grow, standard boards will be even more needed. These boards help keep electronics affordable for everyone.

Non-Critical Industrial Systems

Standard boards are useful in simple industrial machines. These include tools for making, packing, and assembling products. They work well for jobs that don’t need fancy features or extreme strength.

For example, in factories, these boards control conveyor belts or basic robots. They do simple tasks without needing expensive parts. Their easy design makes them quick to set up and fix, saving time and money.

Tip: Use standard boards if your machines don’t face tough conditions.

General-Purpose Applications

Standard boards are great for everyday projects. They are used in school experiments, hobby builds, and DIY electronics. Their low price and simple design make them easy for anyone to use.

For example, you can use a standard board in a science project or a smart home setup. These boards give the basic tools needed to make creative ideas work. They are easy to find and perfect for quick, simple tasks.

Note: Standard boards are ideal for beginners, offering a mix of usefulness and affordability.

Pros and Cons

Advantages and Disadvantages of High-Reliability Boards

High-reliability boards are perfect for important and tough tasks. They are built to last and work precisely, even in hard conditions.

Advantages:

Exceptional Reliability: These boards stay strong in extreme environments.

Advanced Features: Tools like remote checks find and fix problems early.

Compliance with Standards: They follow strict rules for safety and reliability.

Support for hro principles: Their design focuses on safety and solving problems fast.

Disadvantages:

High Cost: Strong materials and testing make them expensive.

Complexity: Special skills are needed to set up and maintain them.

Limited Accessibility: Smaller projects may not afford or need these boards.

Tip: Use high-reliability boards for projects needing safety and long-term use.

Advantages and Disadvantages of Standard Boards

Standard boards are great for simple and everyday tasks. They are easy to use and don’t cost much.

Advantages:

Cost-Effective: These boards are affordable for small-budget projects.

Ease of Use: Simple designs make them easy to install and fix.

Versatility: They work well in many areas, like gadgets and hobbies.

Disadvantages:

Limited Durability: They can’t handle tough conditions for long.

Basic Features: They lack tools like remote checks or problem prediction.

Unsuitable for hro principles: They aren’t reliable for critical systems.

Note: Pick standard boards when saving money and simplicity are most important.

High-reliability boards are strong and work well in tough jobs. They are used in fields like space, hospitals, and defense. These boards are made to never fail when it matters most.

Standard boards are cheaper and good for simple tasks. They work well in things like home gadgets or school projects.

To pick the right board, think about your needs. Look at your project, money, and how reliable it must be. Studies show reliability is key for hard jobs. Knowing what your project needs helps you choose wisely.

FAQ

What is the main difference between high-reliability and standard process control boards?

High-reliability boards are made for important jobs needing strength and precision. Standard boards are cheaper and simpler, best for easier tasks.

Can you use standard boards in critical systems?

No, standard boards shouldn’t be used in critical systems. They aren’t strong or reliable enough for jobs like medical tools or space missions.

Why are high-reliability boards more expensive?

They cost more because they use top-quality parts and tough tests. These boards also have smart tools to work well in hard conditions.

Are standard boards easier to maintain?

Yes, they are easier to take care of. Their simple design means you don’t need special tools or training to fix them.

How do you decide which board to choose?

Think about your project’s needs. Pick high-reliability boards for tough jobs. Choose standard boards for simple tasks or when saving money matters.

Tip: Always check the risks and needs before deciding.