In PCB assembly, safety is very important, especially when it comes to IEC 61508 compliant PCB assembly. You must follow safety rules to keep things working well in risky places. IEC 61508 helps manage risks in many industries, ensuring that your PCB assembly meets the necessary safety standards. ISO 26262 is specifically designed for car safety. Comparing these rules helps you pick the best one for your work. Knowing what they cover can improve safety and meet special industry needs.

Key Takeaways

IEC 61508 is a safety rule used in many fields. ISO 26262 is only for car safety.

Safety levels like SIL (IEC 61508) and ASIL (ISO 26262) help design and test PCBs. They lower risks and make them more reliable.

Using approved parts and keeping clear records makes following rules easier.

IEC 61508 is good for general PCB work in many areas. ISO 26262 is best for car tech like self-driving systems.

Picking the right safety rule makes PCBs safer and fits industry needs better.

Scope and Industry Application of Functional Safety Standards

Industry applications of IEC 61508

IEC 61508 is used in many industries where safety matters a lot. You see it in energy, making things, and healthcare. It makes sure systems work well, even in dangerous places. For example, hardware parts get tested a lot to check for problems and toughness. Software parts also have strict rules to make sure they work right in different situations. This standard lets you approve parts based on how well they did before, so it works in many fields.

Automotive focus of ISO 26262

ISO 26262 is made just for cars. It deals with car safety, especially with new tech like smart driving aids and self-driving cars. This standard fits with old safety ideas, making sure it works with car processes now. It focuses on checking both hardware and software parts to meet tough safety rules. If you build car PCBs, ISO 26262 gives a clear plan to handle risks and make things safer.

Relevance of functional safety standards to PCB assembly

Safety standards are key in making PCBs. They help you design and test PCBs to be safe. Whether you use IEC 61508 or ISO 26262, these rules help you deal with hardware and software risks. For example, they make sure PCBs can handle tough conditions and work well in important jobs. By following these standards, you can make PCBs safer and meet what your industry needs.

Safety Levels in IEC 61508 and ISO 26262

Understanding SIL in IEC 61508

Safety Integrity Levels (SIL) are key to IEC 61508. They show how reliable safety systems are and measure failure chances. SIL levels go from 1 to 4. SIL 4 is the safest and least likely to fail. To pick the right SIL level, you do a Process Hazard Analysis (PHA). This checks risks and finds the Risk Reduction Factor (RRF) needed to lower them.

Higher SIL levels mean stricter rules. SIL 4 systems need careful testing and checking to meet top safety standards. The table below shows numbers for each SIL level:

SIL | PFD (low demand) | RRF (low demand) | PFD (continuous) | RRF (continuous) |

|---|---|---|---|---|

1 | 0.1–0.01 | 10–100 | 0.00001-0.000001 | 100,000–1,000,000 |

2 | 0.01–0.001 | 100–1000 | 0.000001-0.0000001 | 1,000,000–10,000,000 |

3 | 0.001–0.0001 | 1000-10,000 | 0.0000001-0.00000001 | 10,000,000–100,000,000 |

4 | 0.0001–0.00001 | 10,000–100,000 | 0.00000001-0.000000001 | 100,000,000–1,000,000,000 |

This system helps make PCB assembly safer for important uses.

Understanding ASIL in ISO 26262

Automotive Safety Integrity Levels (ASIL) are part of ISO 26262. They check risks using three factors: how bad the harm is, how often it might happen, and how easy it is to control.

Severity: Goes from S0 (no harm) to S3 (very serious harm).

Probability of Exposure: Has five levels, from E0 (rare) to E4 (likely).

Controllability: Ranges from C0 (easy to control) to C3 (hard to control).

For example, if a part has medium risk (E3), is usually controllable (C2), and could cause serious harm (S3), it gets an ASIL B rating. Higher ASIL ratings need tougher safety checks to keep cars safe.

ISO 26262 uses these factors to make car PCBs safer. It helps balance risks and meet industry rules.

Impact of SIL and ASIL on PCB Assembly Processes

Both SIL and ASIL affect how PCBs are made. SIL levels help design systems for industries like healthcare and manufacturing. For example, SIL 3 systems in healthcare need strong PCBs to avoid failures during important tasks.

ASIL ratings focus on cars. They help manage risks in new tech like self-driving systems. For example, an ASIL D-rated PCB needs strict testing to handle serious risks safely.

Safety trends show why these levels matter. In manufacturing, injury rates dropped from 2.8 in 2022 to 2.4 in 2023. Healthcare also saw fewer injuries, showing how safety rules help.

By following SIL and ASIL rules, PCB assembly becomes safer, reduces problems, and meets industry needs.

Development Approaches for IEC 61508 Compliant PCB Assembly

Functional safety lifecycle in IEC 61508

The functional safety lifecycle outlined in IEC 61508 provides a structured approach to designing, developing, and maintaining safety-related systems. This lifecycle ensures that every safety function meets the necessary requirements for reliability and performance. It begins with a hazard and risk assessment, where you identify potential risks and determine the required Safety Integrity Level (SIL).

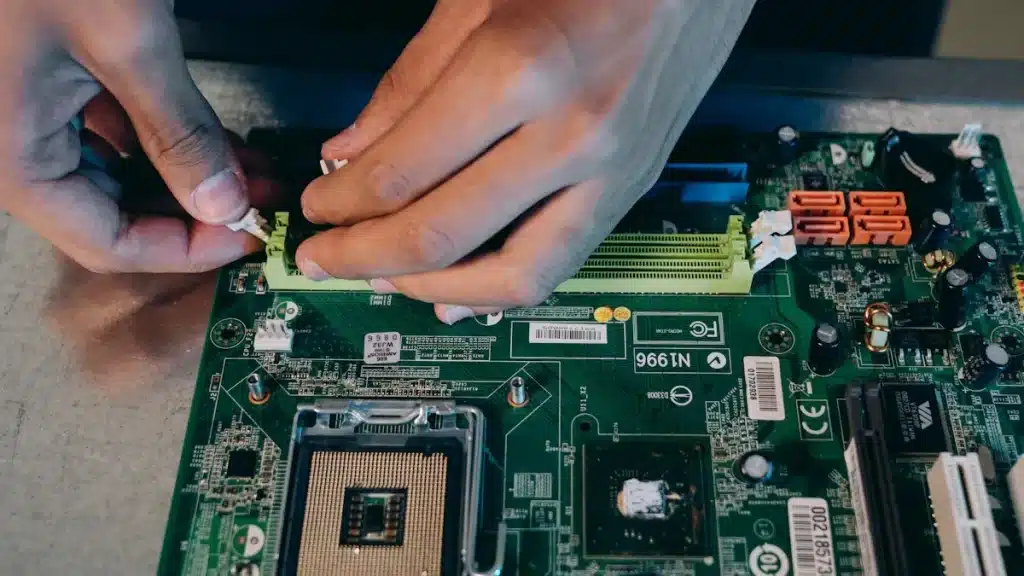

Once the SIL is established, you proceed to the design phase. Here, you must ensure that all safety-critical components meet the required SIL rating. For example, using SIL-rated components like dual-core lockstep microcontrollers can enhance the reliability of your PCB assembly. The lifecycle also emphasizes verification and validation at every stage. This ensures that the safety function performs as intended under all operating conditions.

IEC 61508 encourages the use of pre-certified safety solutions to simplify compliance. For instance, adopting pre-certified PCB modules can reduce the certification burden and streamline the development process. Additionally, maintaining complete safety lifecycle documentation is crucial. This includes traceable records of design, validation, and verification activities, which support certification processes and demonstrate compliance with safety regulations.

V-model and safety processes in ISO 26262

ISO 26262 adopts the V-model development lifecycle, which is a cornerstone of its approach to functional safety compliance. The V-model emphasizes a systematic process where each development phase corresponds to a testing phase. For example, the requirements defined during the concept phase are verified during system testing. This ensures that the final product aligns with the initial safety requirements.

One key aspect of ISO 26262 is its focus on Hazard Analysis and Risk Assessment (HARA). This process evaluates the severity, exposure, and controllability of risks to determine the Automotive Safety Integrity Level (ASIL). Unlike IEC 61508, which provides broader guidelines, ISO 26262 requires a more exclusive and detailed scope delimitation.

To achieve compliance, you must integrate safety processes into every stage of development. This includes using certified safety design patterns and components, such as watchdog timers and cyclic redundancy checks (CRC), to enhance fault detection. Additionally, ISO 26262 emphasizes the importance of modular and reusable safety design libraries. These libraries accelerate development while ensuring that safety-critical functions meet the required ASIL levels.

Best practices for achieving compliance in PCB assembly

Achieving compliance with functional safety standards like IEC 61508 and ISO 26262 requires a combination of robust design practices and thorough documentation. Here are some best practices to follow:

Adopt pre-certified safety solutions: Using pre-certified PCB modules and components simplifies the certification process. For example, IEC 61508 compliant PCB assembly can benefit from SIL2/3 certified modules, while automotive applications can use ASIL-D certified components.

Implement partitioned design strategies: Isolate safety-critical functions, such as emergency shutdown systems, from non-safety-related systems. This reduces the risk of failures affecting critical operations.

Optimize safety architectures: Use hardware-based safety controllers, like TI Hercules™, to monitor safety functions without impacting system performance.

Maintain comprehensive documentation: Keep detailed records of design, validation, and verification activities. This supports certification audits and demonstrates compliance with safety regulations.

Leverage reusable safety libraries: Develop libraries of pre-validated safety logic, such as diagnostic routines and fault-tolerant designs. These libraries save time and ensure consistency across projects.

By following these practices, you can streamline the development process, reduce costs, and ensure that your PCB assemblies meet the stringent requirements of functional safety compliance.

Scalability and Technological Adaptability of Safety Standards

Scalability of IEC 61508 across industries

IEC 61508 is flexible and works in many industries. It fits energy, healthcare, and manufacturing needs. You can adjust its rules for specific jobs. For example, in energy, it helps make power systems reliable. In healthcare, it ensures medical devices are safe during critical use.

This standard handles both low-risk and high-risk tasks. It gives clear steps to reach the needed Safety Integrity Level (SIL). This makes safety easier without making designs too complex. Using IEC 61508, you can build safe PCBs for many industries.

Adaptability of ISO 26262 to modern automotive PCB technologies

ISO 26262 matches the needs of modern car PCBs. It focuses on safety for systems like ADAS and EV power. This standard helps design safe PCBs with advanced features.

ISO 26262 covers safety from start to finish.

It sets strict rules for PCB design and use.

Car PCBs must handle tough tasks like real-time data checks. ISO 26262 ensures they work safely in all conditions. By following it, you can make PCBs for new car tech while keeping safety high.

Comparison of scalability and adaptability for PCB assembly

IEC 61508 and ISO 26262 have different strengths for PCBs. IEC 61508 is great for many industries because it’s scalable. It’s good for projects needing flexible safety plans. ISO 26262 is best for cars, focusing on their special needs.

For general PCBs, IEC 61508 offers a wide safety guide. For car PCBs, ISO 26262 gives detailed safety steps. Both improve safety, but they focus on different goals. Pick the one that fits your industry and project needs.

Key Similarities and Differences Between IEC 61508 and ISO 26262

Shared principles in safety and risk assessment

Both IEC 61508 and ISO 26262 focus on safety and risk checks. These rules share ideas to help manage risks better:

Plan risk steps to get steady and clear results.

Adjust risk plans to fit your goals and needs.

Listen to ideas from everyone involved in the project.

Be ready for changes and handle risks quickly.

Use past and current data to make smart choices.

Understand how people and culture affect risk plans.

Keep improving by learning from past efforts.

These ideas help make PCB assembly safer, no matter the job or industry.

Differences in scope, terminology, and industry focus

While both aim for safety, their focus and use are different. IEC 61508 works for many industries, but ISO 26262 is just for cars. The table below shows key differences:

Aspect | ISO 26262 | IEC 61508 |

|---|---|---|

Industry Focus | Cars and automotive systems | Many industries like energy and healthcare |

Safety Levels | ASIL (Automotive Safety Integrity Level) | SIL (Safety Integrity Level) |

Level Range | ASIL A to D (D is safest) | |

Development Approach | Made for car tech | Flexible for different industries |

Scalability | Focused on advanced car systems | Base standard for other industry rules |

Knowing these differences helps you pick the best rule for your PCB work.

Summary comparison of IEC 61508 and ISO 26262 for PCB assembly

Both IEC 61508 and ISO 26262 care about safety but serve different needs. IEC 61508 is flexible and works for many jobs, making it great for general PCB assembly. ISO 26262 is made for cars, helping with safety in systems like self-driving tech and electric vehicles.

If your PCB work is for cars, ISO 26262 gives detailed steps for safety. For other industries, IEC 61508 offers broad and useful safety rules. Picking the right one for your job ensures safety and better PCB designs.

Knowing how IEC 61508 and ISO 26262 are alike and different helps you choose wisely. Both focus on safety but work for different industries. IEC 61508 is flexible and fits many fields, while ISO 26262 is made for cars. Each gives clear steps to handle risks and keep PCB assembly reliable.

Pick a standard based on your industry’s needs and the benefits of each method. The table below shows helpful tips to guide your choice:

Technique | Best For | Strengths | Limitations | Regulatory Alignment |

|---|---|---|---|---|

Profile-Based Monitoring | Steady and predictable processes | Tracks normal changes well | Needs lots of baseline data | High (Clear documentation provided) |

Statistical Process Control | Processes sensitive to changes | Measures performance with numbers | Hard to set up | Excellent (FDA prefers this method) |

Machine Learning Detection | Data-heavy and complex systems | Finds errors before they happen | Costs a lot to start | Emerging (Rules are growing for this) |

Rule-Based Validation | Strictly controlled manufacturing | Checks for compliance closely | Not flexible for changes | Very High (Meets strict rules directly) |

Match your safety efforts to your industry’s goals. This ensures your PCB assemblies meet safety and legal rules, making them safer and more dependable.

FAQ

What is IEC 61508, and why does it matter for PCB assembly?

IEC 61508 is a worldwide safety rule for electronics. It helps make sure PCBs follow strict safety rules. By using its steps, you can lower risks and meet safety needs in healthcare, energy, and factories.

How is ISO 26262 different from IEC 61508?

ISO 26262 is for cars, while IEC 61508 works in many fields. ISO 26262 uses ASIL ratings to check safety, but IEC 61508 uses SIL levels. Both help make PCBs safer but are used for different jobs.

How do diagnostics help with PCB assembly safety?

Diagnostics find problems and keep systems working well. Adding diagnostics to PCBs helps spot issues early. This meets safety rules for IEC 61508 and ISO 26262. It also makes systems safer and better.

Why use pre-certified parts for safety compliance?

Pre-certified parts make safety checks easier. They already meet IEC 61508 and ISO 26262 rules. Using them saves time, cuts costs, and makes PCBs safer and more reliable.

How do safety checks affect PCB assembly?

Safety checks look at risks and set safety levels for PCBs. IEC 61508 uses SIL ratings, while ISO 26262 uses ASIL ratings. These checks guide designs and help find problems, making systems safer and meeting rules.