The rise of IIoT devices has revolutionized PCBA production and enhanced supply chain visibility. These advanced tools provide real-time updates, enabling faster and more informed decision-making. Consider these key insights:

The electronics assembly market expanded from $1.3 trillion in 2015 to $1.6 trillion by 2020, reflecting an annual growth rate of 4.0%.

Contract manufacturing increased from $430 billion in 2015 to $580 billion in 2020, demonstrating a yearly growth rate of 6.2%.

This significant growth highlights our increasing reliance on innovative technologies like IIoT. These devices not only improve supply chain visibility but also enable data tracking, predictive maintenance, and efficient supply management. Leveraging IIoT in PCBA processes can streamline operations, reduce costs, and position your business for long-term success.

Key Takeaways

IIoT tools give instant updates, helping decisions and showing supply chain clearly.

IIoT lowers costs and makes work faster by automating jobs and tracking items easily.

Predictive maintenance with IIoT stops machines from breaking, saving time and money while keeping work smooth.

Tracking materials and shipments live reduces delays and improves delivery plans, ensuring things arrive on time.

Spending on IIoT brings big savings and better operations over time, helping businesses stay ahead.

The Role of IIoT in PCBA Manufacturing

What Is IIoT and How Is It Used?

The Industrial Internet of Things (IIoT) means using smart devices in factories. These devices connect, share data, and work together. They help factories run better by collecting and analyzing information. In manufacturing, IIoT is used to check machines, automate tasks, and make better products. For example, sensors watch machines, and software predicts problems before they happen. This technology has changed industries like cars, healthcare, and electronics by saving time and cutting delays.

Why IIoT Matters in PCBA Production

In making printed circuit boards (PCBA), IIoT is very important. It helps improve how things are made and keeps quality high. IIoT devices can watch every step of the process. This makes sure everything works well and smoothly. The table below shows how IIoT makes PCBA production better:

Evidence Type | Description |

|---|---|

Process Optimization | IIoT devices give real-time data to find slow spots and problems. This boosts production and cuts waste. |

Improved Quality Control | Sensors check product quality instantly, catching mistakes early. This lowers waste and ensures good products. |

Enhanced Safety | IIoT watches for dangers and sends alerts to stop accidents, keeping workers safe. |

Remote Monitoring | IIoT lets you check and control machines from far away, which is helpful for spread-out factories. |

Inventory Management | Sensors track stock levels and reorder items automatically to avoid running out. |

Energy Efficiency | Watching energy use helps save money and cut waste, which is better for the planet. |

Using these tools, you can make PCBA production faster, cheaper, and more reliable.

Features of IIoT Devices in Factories

IIoT devices have many helpful features for factories. First, they collect data in real-time so you can see what’s happening right away. Second, they predict when machines might break and help fix them early. Third, they let machines talk to each other, making work smoother. They also track materials and parts as they move through the factory. These features help you improve processes and get better results in PCBA production.

Enhancing Supply Chain Visibility with IIoT Devices

Real-Time Tracking of Materials and Components

IIoT devices change how factories track materials and parts. Sensors and digital tools show real-time updates on where items are. This helps you know the location and condition of everything in your supply chain. With this, delays are reduced, and work becomes more efficient.

Tip: Use IIoT tracking to find slow spots and improve processes.

Here’s how IIoT helps supply chains:

It gives quick updates on where materials are moving.

It lowers the chance of losing parts by showing exact locations.

It makes tracking easier, helping you follow rules and standards.

IIoT can make your supply chain run smoothly, cutting problems and boosting productivity.

Predictive Maintenance for Equipment

Broken machines can stop production. IIoT devices help prevent this with predictive maintenance. Sensors check machines and warn you about issues early. Fixing problems before they grow saves time and money. It also keeps production steady.

Look at these numbers:

Improvement Type | Statistic |

|---|---|

Lower maintenance costs | |

Less unplanned downtime | Cut by up to 50% |

Return on investment | 10 times the return |

Savings over reactive maintenance | Save up to 40% |

Predictive maintenance makes machines last longer and lowers repair costs. It keeps quality high and strengthens your supply chain.

Optimized Inventory Management

Good inventory management is key for PCBA production. IIoT devices make it easier by automating stock checks and showing real-time levels. Sensors notice when stock is low and reorder items automatically. This stops you from running out or having too much stock.

Benefits of IIoT in inventory include:

Fewer mistakes by reducing manual work.

Faster stock checks and order handling.

Saving money by using resources better and wasting less.

Real-time data also helps track inventory movement and usage. This information helps you make smarter choices, improving efficiency and cutting costs.

Note: Companies using IIoT for inventory often see big savings and better operations.

Streamlined Logistics and Delivery Monitoring

Good logistics and delivery tracking are key for better supply chains. IIoT devices let you see shipments in real-time. This ensures goods move smoothly and on time. These tools show where shipments are and their condition. This helps avoid delays and keeps customers happy.

Big companies like DHL use real-time tracking to improve. They study shipment data to find possible delays. Then, they change routes or adjust inventory to fix issues. DHL improved on-time deliveries by 15% using this method. This shows how IIoT can make logistics better and boost service.

Real-time tracking also helps solve problems fast. If a shipment is delayed, IIoT devices send alerts. You can then change routes or delivery plans quickly. This reduces problems and keeps your supply chain running well.

IIoT also gives full visibility of the delivery process. You can track shipments from the warehouse to the final stop. This helps find slow spots and improve routes. It also ensures deliveries meet standards, making operations better.

Adding IIoT devices to logistics makes systems more reliable. Real-time updates and smart tools lower costs and build customer trust. These technologies help you stay ahead and provide great service.

Benefits of IIoT Integration in Supply Chain Management

Improved Operational Efficiency and Cost Savings

Adding IIoT to supply chains makes work faster and cheaper. These smart tools show how machines are working in real-time. This helps find problems and fix them quickly. For example, you can spot slowdowns and improve the way tasks are done.

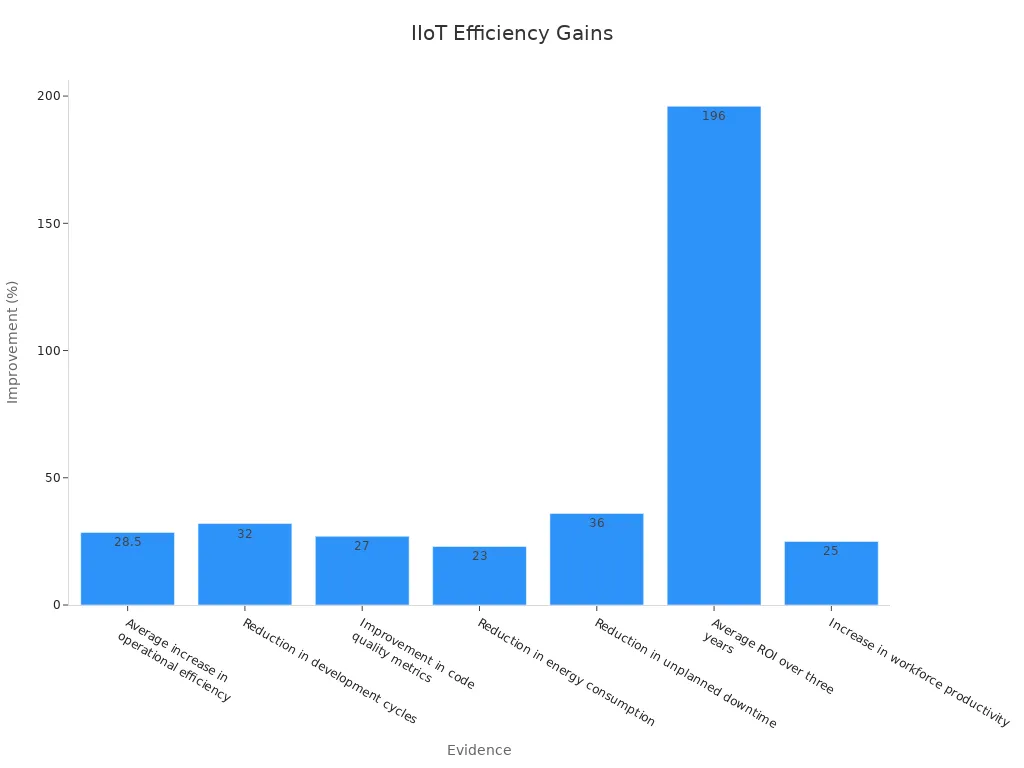

The table below shows how IIoT improves operations:

Benefit Description | Source | Improvement Percentage |

|---|---|---|

Work runs better | Deloitte Insights, 2021 | |

Shorter project times | IBM Research, 2022 | 32% |

Better product coding | IBM Research, 2022 | 27% |

Less energy used | Energy Star, 2021 | 23% |

Fewer machine breakdowns | PwC, 2021 | 36% |

Lower costs | Microsoft IoT Signals Report, 2022 | 30-33% |

Big returns on investment | Forrester Research, 2022 | 196% |

Workers get more done | BCG, 2022 | 25% |

These numbers show how IIoT saves money and cuts waste. Using smart tools helps factories work better and save energy.

Enhanced Risk Mitigation and Quality Control

IIoT tools help catch mistakes early and keep products good. Sensors check items during production to find problems fast. This stops bad products from being sent to customers and reduces waste.

IIoT also helps track parts and materials as they move. This ensures everything follows rules and stays safe. For example, medicine makers use IIoT to check quality. This has cut product recalls by 25%, showing how helpful it is.

Tip: Use IIoT to predict machine problems before they happen. Fixing issues early avoids delays and keeps production smooth.

With IIoT, you can make your supply chain safer and keep quality high.

Faster Decision-Making with Granular Data Insights

IIoT gives detailed data to help make quick decisions. Real-time updates show what’s happening, so you can act fast. For example, car makers use IIoT to manage inventory better. This cut extra stock by 30% while keeping production steady.

Here’s how IIoT helps decisions:

Predicting demand stops having too much or too little stock.

Finding defects quickly keeps products good and fixes problems fast.

Note: IIoT tools prevent machine breakdowns, keeping work going and saving money.

Using IIoT makes decisions smarter and faster. It helps businesses adapt to changes and work better.

Challenges of IIoT Implementation in PCBA Production

Addressing Data Security and Privacy Concerns

Using IIoT devices means protecting sensitive data is very important. These devices collect and share lots of information. If not secured, hackers can attack and steal this data. Cyberattacks may cause big problems like data leaks or stopping operations.

To keep systems safe, use strong cybersecurity tools. Encryption and firewalls protect your data from threats. Regular software updates also help block hackers. Train workers to spot phishing emails and avoid risky actions. This lowers the chance of security problems. By focusing on safety, you protect your business and keep customers happy.

Tip: Check your system often to find and fix weak spots.

Overcoming Integration Issues with Legacy Systems

Connecting IIoT devices to old machines can be hard. Older systems may not work well with new technology. Fixing this can cost money and take time. Old systems also store data separately, making it hard to use all the information together.

Here are common problems with integration:

Key Problems | What Happens |

|---|---|

Old Machines | Older equipment doesn’t match new IIoT tools, needing expensive fixes. |

Separate Data | Different systems keep data apart, making it hard to analyze everything. |

Not enough trained workers slows down setup and use of IIoT devices. |

To solve these problems, use tools that connect old and new systems. Hiring experts or working with IIoT specialists can make the process easier.

Managing High Initial Investment Costs

Starting with IIoT can cost a lot at first. Buying devices, updating systems, and training workers all need money. But these costs usually pay off later by saving time and reducing problems.

To save money, begin with small projects. Focus on areas where IIoT can help quickly. For example, using predictive maintenance can lower repair costs fast. Slowly adding more IIoT tools lets you spread out spending while seeing early benefits.

Note: Many businesses recover their costs within two to three years of using IIoT.

Workforce Training and Adaptation

Using IIoT devices in PCBA production means workers need new skills. They must learn to use, check, and fix these smart tools. Without training, workers might face problems, causing mistakes or delays.

Why Training Is Important

IIoT devices bring new things like sensors and automation. These tools may seem hard to use at first. Training helps workers feel comfortable with them. It also teaches them how to solve problems and get the most out of these tools.

Tip: Use hands-on practice to teach workers about IIoT tools. Doing tasks helps them learn faster than just listening.

Steps to Train Your Team

Check Current Skills: Find out what your team knows and where they need help. Focus on areas like machine use or data safety.

Offer Custom Training: Give lessons that fit your team’s needs. Use online videos, in-person classes, or expert-led sessions.

Keep Learning Going: IIoT changes quickly. Regular lessons help workers stay updated.

Encourage Teamwork: Let workers share tips and ideas. Learning together builds skills and teamwork.

Handling Fear of Change

Some workers might worry about learning new tools. Explain how IIoT makes their jobs easier and faster. Show them the benefits, like less work and better results.

Note: Praise workers who do well in training. Rewards encourage others to join in and learn too.

Training your team makes switching to IIoT smoother. It helps workers adjust, improve, and succeed with new technology.

The Future of IIoT in PCBA Manufacturing and Supply Chain Management

New Technologies in IIoT

IIoT is changing PCBA manufacturing with exciting new tools. One example is digital twins, which are virtual copies of real systems. These let you watch and improve processes from anywhere. Another big change is 5G technology, which makes IIoT devices share data faster and more smoothly.

Edge computing is also becoming popular. It processes data close to where it’s made, speeding up decisions. Plus, artificial intelligence (AI) is being added to IIoT devices. This makes systems smarter and able to improve themselves over time.

Other technologies like wireless communication and industrial robotics are also making a difference. In 2023, wireless tools became very popular because they connect devices easily. From 2024 to 2030, industrial robots will grow quickly, helping factories automate more tasks. These tools will make smart pcbs better and more dependable.

Automation Trends in Supply Chains

Automation is changing how supply chains work. With IIoT, you can collect real-time data and see everything clearly. This helps track materials and shipments better, cutting delays and improving deliveries.

A report called Automation in Industry: The Impact of IIoT on Manufacturing and Supply Chain shows how IIoT improves supply chain visibility. Another study, Driving Efficiency Gains With IIoT and Connected Applications, explains how predictive maintenance and tracking make logistics smoother. These changes help smart pcbs arrive faster and with fewer mistakes.

AI and machine learning are also helping supply chains. They use data to predict needs and manage inventory better. As IoT combines with other technologies, supply chains will become faster and more flexible.

Long-Term Advantages for Manufacturers

Using IIoT in factories brings many lasting benefits. It saves money by finding and fixing problems. It also boosts productivity, giving companies an edge over competitors. Better workflows mean less downtime and smoother operations.

A study on IIoT lists these key benefits:

Benefit | What It Does |

|---|---|

Cost Savings | Finds problems and fixes them, saving money. |

Higher Productivity | Improves processes, helping factories work faster and better. |

Greater Efficiency | Makes workflows smoother, reducing wasted time and resources. |

Smarter Decisions | Uses data to make better choices and keep improving. |

Skill Development | Trains workers to use IIoT tools, making the most of the technology. |

These benefits help manufacturers make smart pcbs more efficiently and stay competitive. By using IIoT, you can improve your factory and prepare for future success.

IIoT devices are changing how factories make pcbs and handle supply chains. These smart tools help you see everything clearly and work better. With real-time data, you can follow pcbs through each step, keeping things fast and high-quality. Fixing machines early and automating stock checks also save time and cut waste.

There are challenges like keeping data safe and connecting old systems. But the good things about IIoT are worth it. Using IIoT keeps your pcbs production strong and up-to-date. As tech improves, factories will get even smarter and more efficient.

Tip: Begin with small IIoT projects to quickly improve your pcbs production.

FAQ

What is IIoT, and how is it different from IoT?

IIoT stands for Industrial Internet of Things. It is used in factories and supply chains to connect machines and systems. This makes work faster and smoother. IoT, however, is for everyday devices like smart home gadgets. IIoT focuses on improving work, while IoT makes life easier.

How does IIoT help supply chains?

IIoT tools track materials, parts, and shipments in real-time. Sensors collect data and share it quickly. This helps you see inventory, avoid delays, and improve deliveries. With IIoT, you can clearly follow every step in your supply chain.

Is IIoT costly to start?

Starting with IIoT needs money for devices, software, and training. But it saves money later by making work faster, reducing downtime, and cutting waste. Most companies get their money back in two to three years through savings and better results.

What problems come with using IIoT?

Some problems include keeping data safe, connecting old machines, and training workers. You can fix these by using strong security, hiring experts to update systems, and teaching employees how to use the tools.

Can small factories use IIoT?

Yes, small factories can start with simple IIoT tools like tracking stock or fixing machines early. These tools save money and make work easier. Starting small lets you add more tools as your business grows, making IIoT useful for smaller companies.

See Also

Why PCBA Manufacturing Skills Matter in Electronic Design

Enhancing Workflow Productivity in PCBA Manufacturing Processes

Best Practices for Achieving Quality and Efficiency in PCBA

The Role of PCBA in Advancing Modern Electronics

Choosing Advanced PCBA Manufacturing Services for Optimal Results