Smart design is key to easy manufacturing. Using PCBA design for manufacturability (DFM) helps your assembly process work better and cost less. This method cuts mistakes and makes products more dependable.

Here’s what you get by using PCBA design for manufacturability (DFM):

More finished products with fewer fixes needed.

Faster product launches and happier customers.

By thinking about PCBA design for manufacturability (DFM), you make designs that follow rules and improve production.

Key Takeaways

Following DFM rules lowers mistakes, making PCBs better and stronger.

Work with manufacturers early to spot problems and make production easier.

Pick the right materials to make PCBs last longer and fit the process.

Use DFM tools to check designs and meet standards, saving time and money.

Keep layouts simple and designs smart to cut waste and work faster.

Understanding PCBA Design for Manufacturability (DFM)

What is DFM in PCB design?

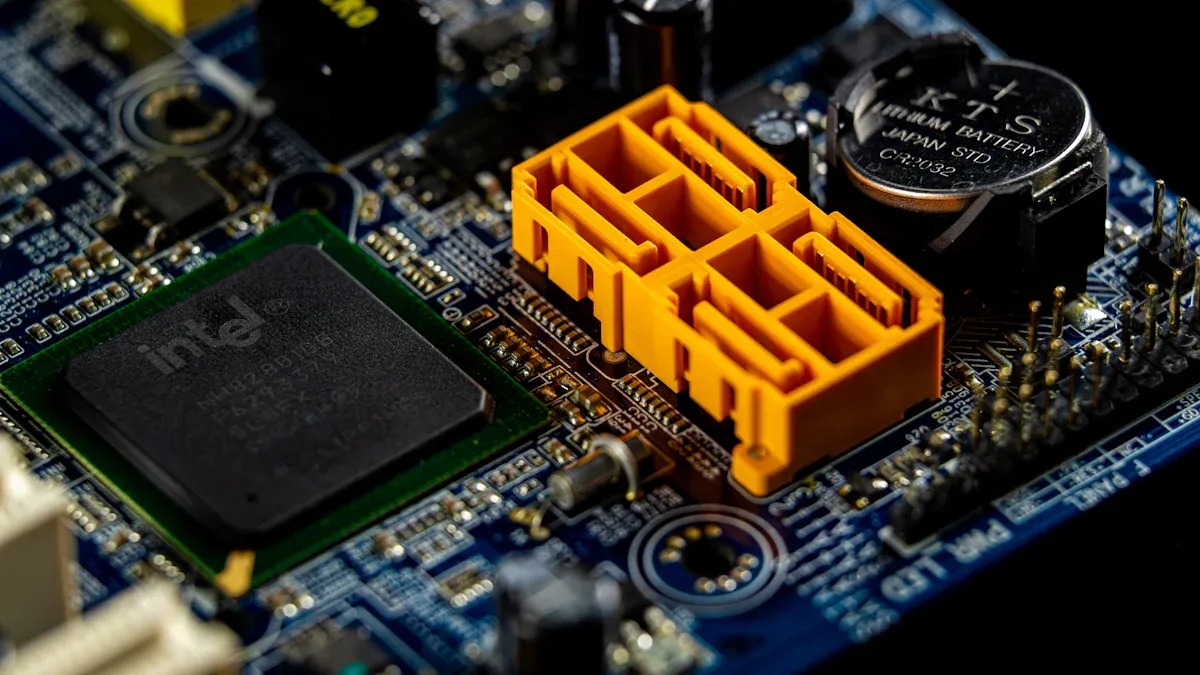

Design for Manufacturability (DFM) means making circuit boards easy to build. It focuses on keeping the board functional while simplifying production. Designers think about materials, processes, and limits during planning. Matching your design to factory needs reduces mistakes and speeds up production.

DFM stops expensive redesigns and delays. It ensures the layout, parts placement, and materials fit factory rules. This method connects design and production, so your product is ready to assemble right away.

Why is DFM critical for manufacturing success?

DFM is important for making reliable circuit boards quickly. Following DFM rules lowers defects and improves success rates in testing. For instance, one medical company cut defects by 60% using DFM. This shows how DFM boosts product quality and dependability.

Using DFM also lowers failure rates and warranty claims. Careful designs mean fewer mistakes during production, saving time and money. By focusing on manufacturability, your product meets standards and works well for a long time.

Common pitfalls of neglecting DFM in PCB design

Skipping DFM can cause big problems. One issue is high defect rates during production. Designs that ignore factory limits need fixes, which cost more and slow things down.

Another problem is low success in first tests, wasting time and materials. Poor DFM can also lead to uneven product quality, upsetting customers and hurting your brand.

Fixing these problems early makes designs better for production. Planning ahead leads to smoother building and better results for your circuit board projects.

Key DFM Guidelines for PCB Design

Layout design for manufacturability

Making a good PCB layout is the first step. The layout should help with easy assembly, like using SMT. Place parts so assembly mistakes are less likely. For example, putting parts in the same direction makes soldering easier.

Don’t put parts too close together. Crowded layouts can cause soldering problems and make inspections harder. Leave enough space between traces, pads, and vias to avoid short circuits. A neat layout lowers risks and makes production smoother.

Material selection and its impact on production

The materials you pick affect how well the PCB is made. Using strong materials makes the board last longer and work better. For example, the right base material can handle heat and stop warping during assembly.

Make sure your materials work with your factory’s methods. Some materials can’t handle the heat needed for soldering. Always check with your manufacturer to pick the right materials. Good material choices make production faster and follow DFM rules.

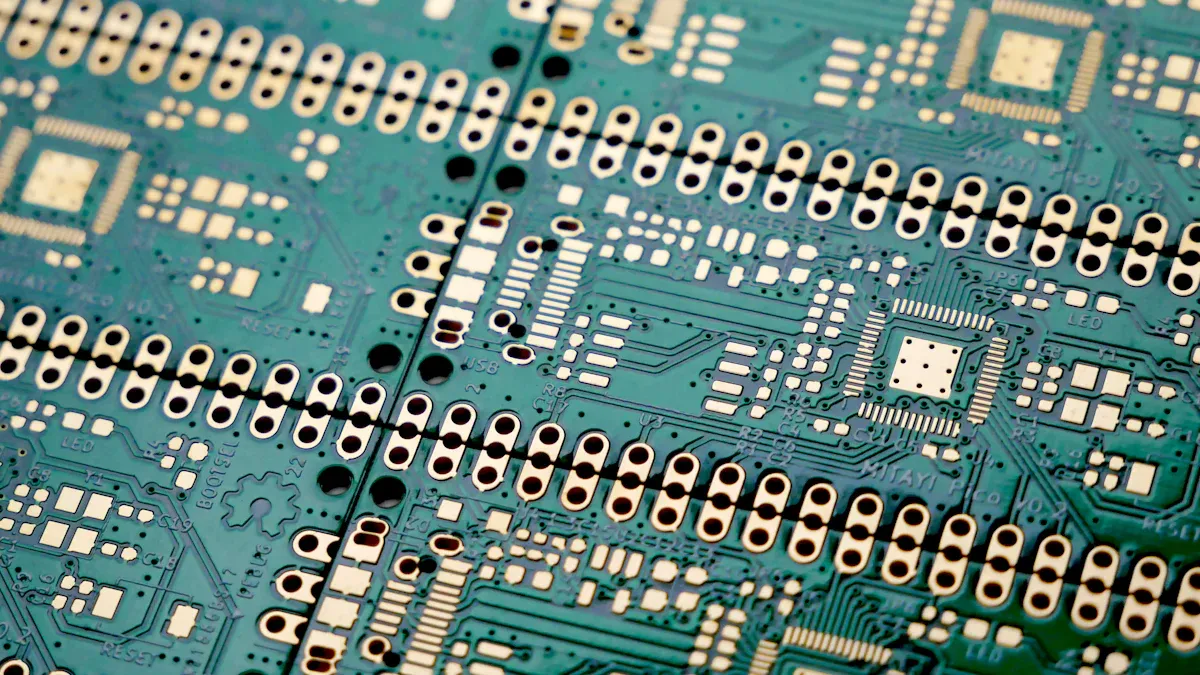

Addressing manufacturing constraints effectively

Knowing factory limits helps you design a PCB that works. For SMT, make sure pad sizes and stencils fit the machines. This helps avoid solder paste problems.

Talk to your manufacturer early to find possible issues. For example, if your design has blind vias, check if the factory can make them. Fixing these issues early saves time and money. Following DFM rules makes your design easy to build and reliable.

Ensuring compliance with industry standards

Meeting industry rules makes your PCB design safe and ready to build. Standards like IPC, RoHS, and UL help you follow global rules. These standards improve product quality and build trust with users and factories.

Learn the main standards for your project. For example:

IPC Standards: These cover PCB design and assembly rules. IPC-2221 gives basic design tips.

RoHS Compliance: This limits harmful materials in electronics for safety.

UL Certification: This checks fire safety and material strength.

Tip: Ask your factory which standards they use. This avoids problems later.

Use design software to check if your design follows the rules. Many programs have built-in tools for IPC and RoHS checks. These tools spot problems early and save time.

Good documentation is key for meeting standards. Make detailed files with material lists, layer info, and assembly steps. Factories use these files to confirm your design meets the rules.

Here’s a simple checklist for compliance:

Check materials match RoHS and UL rules.

Follow IPC tips for trace size and spacing.

Review your design with the factory to fix issues.

By focusing on compliance, you lower risks and meet industry needs. This makes production easier and your PCB more reliable.

Benefits of Implementing DFM Guidelines

Minimizing manufacturing errors and defects

Using DFM guidelines helps reduce mistakes during PCB assembly. Designing with factory limits avoids problems like misaligned parts or soldering errors. For example, adjusting SMT pad sizes ensures solder paste is applied correctly, lowering assembly mistakes.

DFM improves production by solving issues early in the design stage. Fixing problems ahead of time reduces rework and lowers defect rates. Tools like Automated Optical Inspection (AOI) and X-ray testing find hidden flaws, but good PCB designs make inspections easier.

Tip: Work with your manufacturer to spot risks early. Talking early prevents expensive errors and makes production smoother.

Achieving cost efficiency in production

Using DFM guidelines saves money by making production faster and easier. Designing for manufacturability cuts material waste and assembly time. For example, ordering parts in bulk can lower costs and save money.

Working with manufacturers early helps pick cheaper parts that meet needs. Simple layouts for assembly, like SMT-friendly designs, also lower costs. DFM reduces failures, meaning fewer warranty claims and fixes.

Cost-saving benefits of DFM:

Less wasted materials

Cheaper parts through bulk buying

Easier assembly steps

Focusing on efficient production saves money while keeping quality high.

Enhancing production speed and reliability

DFM guidelines make production faster by improving designs for assembly. Well-planned parts are easier to build, cutting cycle times and speeding up delivery. For example, better SMT layouts help place parts faster during assembly.

DFM also boosts reliability by reducing errors and differences. Tools like In-Circuit Testing (ICT) check performance, but DFM designs lower defect chances. This leads to better products that customers trust.

Benefits of DFM for speed and reliability:

Quicker delivery times

Higher product quality

Following DFM guidelines creates designs that are quick to make and dependable to use.

Improving overall product quality and customer satisfaction

Using DFM guidelines makes your PCB designs better and keeps customers happy. When you focus on manufacturability, your products work well and meet user needs.

How DFM Improves Product Quality

Designing for manufacturing reduces mistakes during production. This creates consistent boards with fewer problems. For example, adjusting trace widths and spacing stops electrical issues, helping the board work properly.

Picking strong materials makes your PCB last longer. Heat-resistant bases and reliable parts keep the board safe in tough conditions. These choices make your product last longer and need less fixing.

Tip: Work with your factory to pick materials that balance cost and quality.

Why Customer Satisfaction Matters

Happy customers trust your brand and share good reviews. A well-made PCB that works perfectly builds confidence in your company. Fewer defects and dependable products mean fewer complaints and returns.

Quick production also makes customers happy. Designs that follow DFM rules are faster to build. This helps you meet deadlines and deliver products on time.

Key Benefits of DFM for Quality and Satisfaction

Consistency: Good designs make production smoother.

Durability: Strong materials create long-lasting boards.

Efficiency: Faster production meets customer needs.

Benefit | Impact on Customers |

|---|---|

Fewer Defects | Builds trust and lowers returns |

Reliable Products | Makes users happy |

On-Time Delivery | Keeps customers loyal |

Using DFM guidelines helps you make great PCBs that follow industry rules and impress customers. This improves your reputation and supports long-term success.

Practical Steps to Implement DFM in PCB Design

Collaborating with manufacturers early in the design process

Start working with manufacturers early to match your PCB design to their production abilities. This helps spot problems before they become expensive fixes. Manufacturers share helpful tips about assembly, materials, and processes.

Using common formats for design files makes sharing easier and reduces mistakes. Regular reviews with manufacturers improve layouts and follow DFM guidelines. Collaborative software lets you get quick feedback and make changes faster.

Testing prototypes is very important. It finds hidden issues and ensures the design works well. This step saves time and avoids costly redesigns.

Tip: Keep communication open with your manufacturer. Frequent updates and feedback make the design better and easier to build.

Leveraging DFM software tools for validation

DFM software helps find design problems early. These tools check your PCB layout for issues like spacing, pad sizes, and part placement. Using DFM software ensures your design meets industry rules and factory limits.

Many programs automatically check for IPC and RoHS compliance. They also suggest ways to improve manufacturability, like changing trace widths or moving parts.

Some software lets you simulate how the PCB will be made. This shows possible problems before production starts, helping you fix them early.

Note: Choose DFM software that works well with your design tools. This makes learning easier and speeds up the checking process.

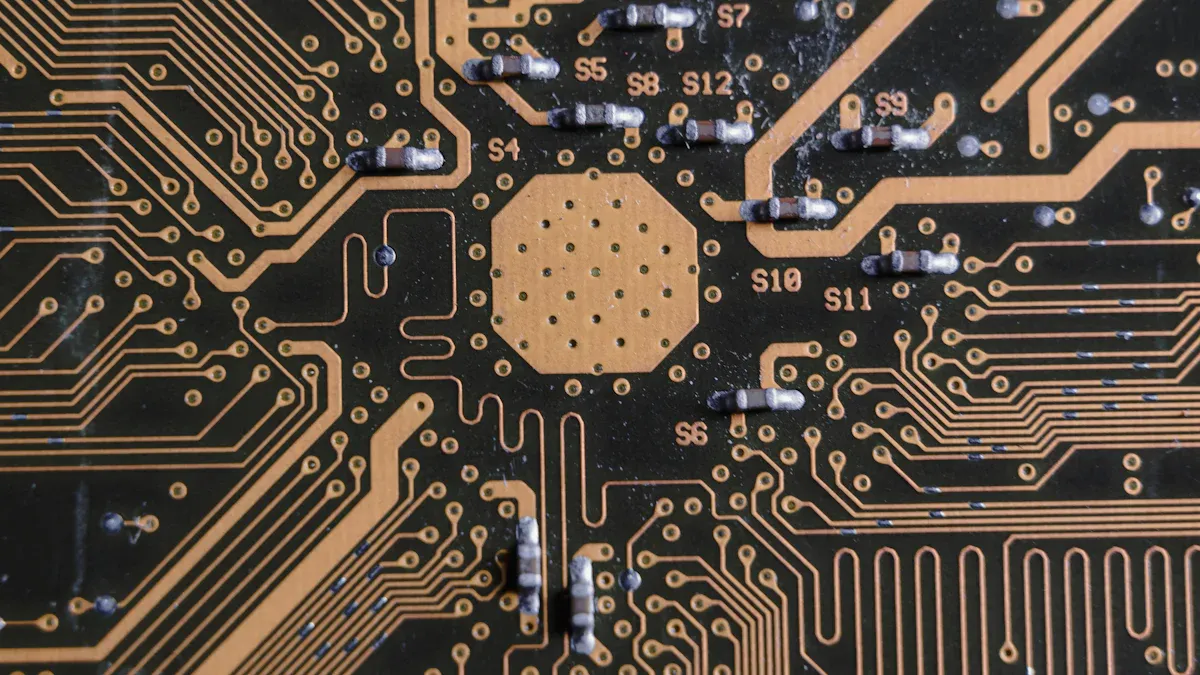

Conducting thorough design reviews and audits

Regular reviews and audits are key to better PCB designs. These checks look at everything, like trace paths and part placement. Audits confirm your design follows DFM guidelines and works with factory needs.

Focus on areas where mistakes happen often, like solder points and vias. Manufacturers can give advice to fix these spots. Testing prototypes and using feedback improves the design for both function and manufacturability.

Keep track of changes during audits to avoid repeating errors. This organized method makes designs better and lowers risks during production.

Tip: Plan reviews at important stages of development. Early and frequent checks catch problems before they grow, saving time and effort.

Iterative prototyping and testing for optimization

Making and testing prototypes is key to improving your PCB design. Prototypes help find problems and fix them before mass production starts. This step ensures your design works well and fits factory needs.

Why Prototyping Matters

Prototyping lets you test your PCB in real-life situations. It checks if the board works and meets performance goals. For example, testing can show issues like heat buildup or signal problems. Fixing these early saves both time and money.

Steps for Effective Prototyping

Build a Basic Prototype: Start with a simple version to test main functions. This step confirms the design works as planned.

Test and Check: Use tools like thermal cameras to see how it performs. Look for weak spots, like areas that overheat or fail under stress.

Fix and Improve: Use test results to adjust your design. For example, you might move parts or change trace sizes to make it better.

Finish the Design: Once the prototype passes all tests, finalize it. Make sure it follows DFM guidelines to avoid production problems.

Benefits of Iterative Testing

Testing again and again makes your PCB more reliable. Each test gives new ideas to improve the design. This lowers the chance of mistakes and ensures the board works well. It also helps meet industry rules and customer needs.

Tip: Work with your factory during prototyping. Their advice can help match your design to their tools, making production easier.

Tools for Prototyping and Testing

You can use many tools to help with prototyping:

Simulation Software: Programs like SPICE show how circuits behave before building them.

Testing Equipment: Tools like multimeters check electrical parts and find problems.

DFM Software: These programs ensure your design meets DFM guidelines for easy manufacturing.

By using these tools and testing often, you can make your PCB design better for both performance and production.

Overcoming Challenges in DFM Implementation

Balancing design complexity with manufacturability

Complicated PCB designs can make manufacturing harder. Adding layers, processors, or tricky routing slows production and raises costs. It’s important to balance how the PCB works with how easy it is to make.

Factor | Effect on Manufacturing |

|---|---|

PCB Layers | |

Processors | Extra parts make placement and routing harder. |

Routing and Placement | Complex paths can lower efficiency and quality. |

Simplify your design when possible. For example, use fewer SMT parts or improve trace paths. This makes assembly quicker and more dependable. Working with your manufacturer early helps find ways to simplify without losing performance.

Bridging communication gaps between designers and manufacturers

Good communication between designers and manufacturers is very important. Misunderstandings can cause delays, mistakes, and higher costs. The PCB industry changes often, so clear communication is even more necessary.

Talking openly helps handle problems like material shortages or customer demands.

Manufacturers share tips for faster production and better quality checks.

Clear discussions help get good parts on time and avoid delays.

Share detailed design files and give regular updates to stay connected. Using teamwork tools keeps everyone on the same page and lowers mistakes during production.

Managing cost constraints while adhering to DFM principles

Balancing costs and manufacturability is a common problem in PCB design. Following DFM rules makes production better but can cost more at first. For example, picking strong materials or SMT-friendly layouts may seem expensive but saves money later by avoiding fixes.

To control costs:

Work with your manufacturer to find cheaper options, like buying parts in bulk.

Simplify your design to reduce wasted materials and save time.

Use DFM software to check your design and prevent costly mistakes.

By designing smartly and working closely with your manufacturer, you can keep costs low while making high-quality PCBs.

Adapting to evolving manufacturing technologies

PCB manufacturing keeps improving with new tools and methods. To stay ahead, adjust your designs to match these changes. These advancements make pcb assembly faster, cheaper, and more precise. But they also mean you need to change old design habits.

Learn about the latest manufacturing trends. For example, laser drilling for microvias or automated optical inspection (AOI) can affect your board designs. Knowing these tools helps you create designs that use their benefits.

Talk to your manufacturer about their equipment. Some factories use advanced tools like 3D printing for prototypes or fast SMT machines for assembly. Matching your design to their tools saves time and improves quality.

Use software that supports modern manufacturing methods. Many programs simulate processes like solder paste application or heat performance. These features help you spot problems early and avoid delays.

Stay flexible with your design process. Manufacturing changes quickly, so update your practices often. What works now might not work later. Reviewing your designs regularly keeps your pcb assembly efficient and reliable.

Tip: Join industry events or webinars to learn about new technologies. Talking to experts gives helpful ideas about future trends.

By adapting to these changes, you can improve your designs and stay competitive.

Using PCBA design for manufacturability (DFM) makes PCB projects easier to build. Following DFM rules lowers mistakes, saves money, and improves product quality. These steps help match your design to factory needs for smoother assembly.

DFM guidelines offer clear benefits. They boost efficiency, cut waste, and improve production. The table below shows how these benefits help PCB manufacturing:

Benefit | How It Helps PCB Manufacturing |

|---|---|

Better Use of Machines and Workers | Less downtime and higher productivity |

Less Waste and Fewer Errors | Saves money by avoiding fixes and rework |

Correct Part Placement | Makes soldering faster and more accurate |

Fewer Signal Problems | Stops signal loss and interference |

Improved PCB Production | Leads to more finished boards in less time |

Faster Prototype Testing | Speeds up delivery by fixing problems early |

You can get these results by working with factories, using smart tools, and improving your designs. Start using DFM today to make assembly better and create great products.

FAQ

What is the main purpose of DFM in PCB design?

DFM makes sure your PCB is simple to build. It cuts down mistakes, saves money, and speeds up production. By using DFM rules, your design matches factory needs, making assembly quicker and more dependable.

How early should you involve manufacturers in the design process?

Start working with manufacturers as soon as you begin designing. Early teamwork finds problems, checks materials, and matches your design to their tools. This saves time and avoids expensive changes later.

Can DFM guidelines help reduce production costs?

Yes, DFM rules help cut waste and improve assembly steps. Simple layouts, smart material choices, and fewer mistakes lower costs. Buying parts in bulk and efficient designs also save money.

What tools can you use to implement DFM effectively?

Use DFM tools like Altium Designer or Siemens Valor. These programs check your design, ensure it follows rules, and simulate how it’s made. They help you fix problems before production starts.

Why is compliance with industry standards important in PCB design?

Following standards keeps your PCB safe, reliable, and high-quality. Rules like IPC and RoHS build trust and meet global needs. They also stop legal troubles and help your product succeed worldwide.

Tip: Always check with your manufacturer to ensure your design meets the required standards.

See Also

Best Practices for Achieving Quality and Efficiency in PCBA

Enhancing Workflow Efficiency in PCB Assembly Processes

Essential Tips for Increasing Efficiency in PCB Assembly