PCBA numbers are very important for making manufacturing efficient. They let you track each printed circuit board assembly (PCBA) during its life. This tracking helps you see operations clearly and control quality better. For example:

The IPC-1782 standard helps with tracking and improves reliability.

Factories now collect detailed data to find defect causes faster.

With over 800 quality checks per PCB, tracking is key for handling complex tasks.

These numbers also help simplify work and follow industry rules. This makes them essential for today’s manufacturing.

Key Takeaways

PCBA numbers are like special IDs for circuit boards. They help track boards during manufacturing.

These numbers make it easier to find and fix problems fast, improving quality control.

Using PCBA numbers helps follow industry rules, making inspections easier and faster.

Tracking with PCBA numbers lowers the chance of fake parts, keeping products safe and reliable.

Adding PCBA numbers to tools like RFID and cloud systems makes work faster and organizes data better.

Understanding PCBA Numbers

What Is a PCBA Number?

A PCBA number is a special code for each circuit board. It works like a digital ID, helping track its entire life. This code shows where it came from, how it was made, and its parts. Using PCBA numbers helps control production and improve quality checks.

These codes are very important for handling complex manufacturing. They help find specific boards fast, making it easier to fix problems. They also ensure the boards meet industry rules. Without PCBA numbers, tracking boards in big factories would be very hard.

Components of a PCBA Number

A PCBA number has several important parts. Each part gives details about the board. Here’s how it works:

Component | Description |

|---|---|

Part Category | A 3-digit code showing the type of item. |

Family Code | A 4-digit code for a group of similar items. |

Member Code | A 3-digit code for specific items in the group. |

These parts make every PCBA number unique and useful. For example, the part category tells the board type. The family and member codes give more details. This setup makes it easy to identify and track boards in the supply chain.

The Role of PCBA Numbers in PCB Traceability

PCBA numbers are key for tracking circuit boards. They let you follow boards from making to use. This tracking improves quality and meets rules. Here’s why they matter:

Following Rules: Meet strict industry standards easily.

Supply Chain Safety: Check parts are real and safe.

Strong labels keep PCBA numbers readable for a long time. These labels often show lot numbers and dates. With PCBA numbers, you can find defect sources and make production better.

Tracking isn’t just about following boards. It’s about improving how things are made. PCBA numbers give better control, ensuring every board is high quality.

The Importance of PCBA Numbers in Manufacturing

Enhancing Traceability in the Supply Chain

Traceability is very important in manufacturing today. Each circuit board gets a special PCBA number. This number helps track its path through the supply chain. It shows where parts come from and how they were made. Traceability helps find fake or broken parts and fix errors. It also ensures only real components are used.

Using machines to collect data reduces mistakes and saves time. Adding PCBA numbers to workflows makes tracking easier. Regular checks make sure processes are followed correctly. Working with trusted suppliers and using traceability tools make the supply chain stronger.

Supporting Quality Control and Defect Management

PCBA numbers help keep manufacturing quality high. They let you check every step of production and find problems fast. Numbers like Defects per Million Opportunities (DPMO) and First Pass Yield (FPY) show how well things are working. A high FPY means most boards pass tests the first time.

Here’s what these metrics mean:

Metric | Description |

|---|---|

Defects per Million Opportunities (DPMO) | Counts defects per million chances, helping compare quality. |

First Pass Yield (FPY) | Shows the percentage of boards passing tests the first time. |

Rework Rate | Tracks boards needing fixes after assembly, showing efficiency. |

Scrap Rate | Measures boards that can’t be used, showing waste levels. |

PCBA numbers also track defect rates and production times. Shorter times mean faster work, and fewer defects mean better quality. Using advanced testing tools and regular checks keeps quality systems strong. Following rules like IPC Class 2 and IPC Class 3 makes products more reliable.

Ensuring Compliance with Regulatory Standards

Following rules is very important in industries like healthcare and aerospace. PCBA numbers make it easier to follow these rules. For example, FDA Class 3 Medical Devices need detailed tracking. PCBA numbers help document every production step. This helps pass inspections without problems.

Rules like NIST 800-171 need strong security to protect information. Security steps include controlling access and checking risks. PCBA numbers help keep designs safe and meet rule requirements.

Using machines to collect data and control processes improves compliance. These tools make it easy to find product history reports. This helps build trust with rule agencies. Adding PCBA numbers to your processes ensures products are safe and high-quality.

Stopping Fake Parts

Fake parts are a big problem in manufacturing. These bad parts can harm how circuit boards work and make them unsafe. You can stop this by using PCBA numbers and strong tracking systems.

Tracking helps you follow every part used in a circuit board. Giving each board a special PCBA number lets you see its full history. This shows where parts came from, what materials were used, and how it was made. If a fake part gets into the supply chain, you can find and remove it fast.

PCBA tracking also checks if parts are real. For example, you can match a part’s details with your records. If they don’t match, the part is fake. This keeps your boards safe and meets quality rules.

Using tools like barcodes and RFID tags makes tracking better. These tools let you scan parts and track them instantly. You can connect these tools to your systems to make tracking automatic. This lowers mistakes and finds fake parts faster.

Stopping fake parts isn’t just about protecting products. It’s also about keeping your customers’ trust. When you use tracking to make sure your boards are good, you show you care about safety and quality.

Technical Solutions for PCBA Number Implementation

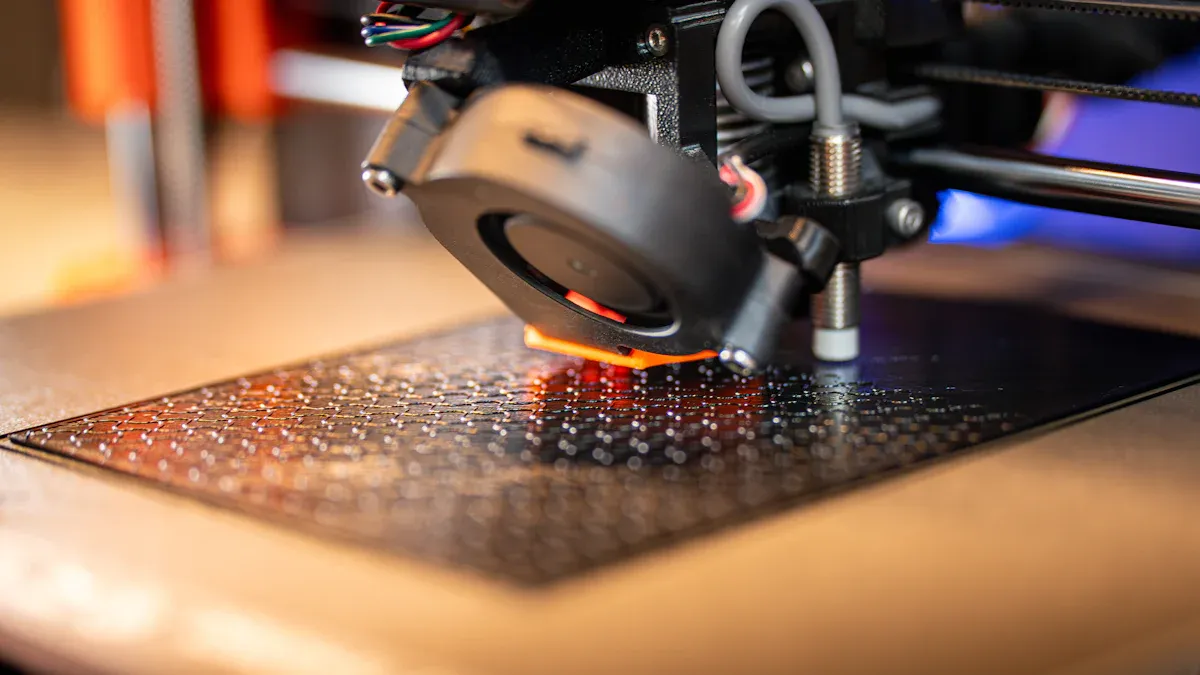

Barcodes and QR Codes for PCBA Traceability

Barcodes and QR codes are key tools for tracking PCBA. These codes work like unique IDs for each board. Scanning them shows where the board came from and how it was made.

Barcodes and QR codes have many benefits:

DataMatrix Codes: These small 2D codes hold up to 2,335 characters. They are common in industries like healthcare and manufacturing.

QR Codes: These codes store up to 4,296 characters and work with most devices.

Benefit | Description |

|---|---|

Helps avoid using fake or low-quality parts. | |

Improved quality control | Tracks parts to fix problems quickly and correctly. |

Regulatory compliance | Helps meet global rules and standards. |

Supply chain visibility | Makes the supply chain clearer and more efficient. |

DataMatrix codes are great for PCBA tracking because they are small but hold a lot of data. They are perfect for labeling tiny electronic parts like circuit boards. The U.S. Electronic Industries Alliance suggests using these codes for small components. Adding these codes improves quality, stops fake parts, and meets industry rules.

Tip: Use automatic scanners to read barcodes and QR codes fast. This reduces mistakes and saves time.

RFID Tags for Advanced Tracking

RFID tags make tracking even better by offering real-time updates. Unlike barcodes, RFID tags don’t need to be scanned directly. This makes them great for managing inventory and tracking items in the supply chain.

Studies show RFID can make inventory accuracy as high as 99.9%. Barcode systems usually reach only 60-80%. Another study found RFID improved accuracy from 63% to 95%. These results show how RFID boosts manufacturing efficiency.

Feature | Description |

|---|---|

RFID Readers | Send radio signals to find and track tags quickly. |

Real-time Tracking | Gives instant updates on items through software dashboards. |

Workflow Insights | Automates tasks, ensuring smooth operations and better accountability. |

Efficiency Gains | Saves time by making it easier to find items. |

Adding RFID tags to your system automates tracking and reduces errors. It also gives useful insights into your processes. RFID improves PCBA tracking and makes production more efficient.

Note: RFID tags cost more upfront than barcodes. But their long-term benefits often make them worth it.

Integration with Manufacturing Execution Systems (MES)

To get the most out of PCBA numbers, connect them to a Manufacturing Execution System (MES). An MES is software that tracks and manages production in real time. Linking PCBA numbers to an MES makes work smoother and decisions smarter.

Here’s how MES helps manufacturing:

Centralized Data Management: Keeps all production data in one place for easy tracking.

Real-Time Monitoring: Lets you see progress and fix delays right away.

Improved Traceability: Tracks every PCBA from start to finish.

Enhanced Quality Control: Flags defects and tracks fixes to keep quality high.

For example, if a defect is found, the MES can trace it to the exact batch or part. This helps fix problems fast, reducing waste and downtime.

Tip: Pick an MES that works with barcode scanners, RFID readers, and cloud systems for more flexibility.

Cloud-Based Solutions for Data Management

Cloud systems have changed how factories handle data. These tools store and manage information online, so you can access it anywhere. For managing PCBA and PCB data, cloud platforms offer great flexibility, safety, and speed.

A big benefit of cloud systems is handling lots of data. As production grows, the cloud adjusts to fit your needs. You don’t need to worry about running out of space or buying new equipment. This makes sure your PCBA tracking works well, even during busy times.

Cloud platforms also help teams work better together. Everyone can see the same updated data, making teamwork easier. For example:

Company A used a tool called Bit to fix version problems and keep teams on the same page.

Company B switched to Component.io to improve speed and cut maintenance time as they grew.

These examples show how cloud tools can fit your needs and keep things running smoothly as your business expands.

Another advantage is stronger data protection. Cloud providers use encryption and backups to keep your PCB and PCBA data safe. This lowers the chance of losing data or having it stolen. You can also control who sees important information by setting permissions.

Cloud systems connect easily with other tools like Manufacturing Execution Systems (MES). This lets you track every PCB and PCBA in real time. You can create reports, find delays, and improve workflows without extra work. The cloud makes hard tasks simpler, saving time and money.

Using cloud tools also cuts costs. You only pay for what you use, so you don’t need to spend on physical servers. This smart spending lets you invest in other parts of your business.

Benefits of PCBA Numbers for Manufacturing Efficiency

Simplified Production Steps

PCBA numbers make production easier by giving each PCB a unique ID. This ID helps track every board during assembly, testing, and packaging. It ensures no step is missed or skipped.

For example, when a PCB moves to a new station, its PCBA number helps workers and machines recognize it right away. This avoids delays and mistakes like misplacing or mislabeling boards. Machines like barcode scanners can quickly read these numbers, saving time and improving accuracy.

Using PCBA numbers in your production line keeps things organized. It speeds up work, reduces waste, and lowers the need for rework.

Quicker Fixes for Problems

If something goes wrong during production, PCBA numbers help find the cause fast. You can trace a faulty PCB back to its batch, supplier, or assembly step. This makes solving problems quicker and stops them from happening again.

For instance, if a group of PCBs fails tests, their PCBA numbers can show if the issue is from a bad part or a process mistake. Fixing the exact problem saves time and keeps production running smoothly.

Quick problem-solving saves resources and keeps quality high.

Happier Customers

PCBA numbers help make better products, which keeps customers happy. Tracking PCBs with these numbers lowers the chance of sending out defective items. This builds trust and improves your reputation.

If a customer has a problem, PCBA numbers let you check the product’s history. You can find the issue and fix it fast. This shows you care about quality and customer satisfaction.

By making reliable products and solving issues quickly, you earn loyal customers.

Saving Money by Improving Operations

PCBA numbers help save money by making production smoother. They show where things can be improved and stop waste. Each PCB gets a special number to track it from start to finish. This tracking makes sure resources are used wisely.

These numbers also cut costs by reducing rework. If something goes wrong, you can quickly find the problem. For example, if some PCBs fail tests, the numbers show if it’s a part or process issue. Fixing the exact problem saves time and money.

PCBA numbers also improve inventory management. They let you see materials and parts in real time. This stops overbuying or running out of important items. Better inventory control lowers storage costs and keeps work on schedule.

Tools like barcode scanners and RFID readers save even more money. These tools work with your systems to avoid mistakes and speed up tasks. Scanning a PCB’s number updates its status right away. This removes the need for slow manual updates.

By making processes better and tracking easier, PCBA numbers cut costs. They make sure every dollar spent on production is worth it.

PCBA numbers are key to making manufacturing better. They help track every step of a PCB’s process. This tracking improves quality checks and follows strict rules. Using smart tools like AI or machine learning can save money and time. For instance, a medical company made products 40% faster while meeting FDA rules. An aerospace company reached a 99.8% success rate on first tests with better inspections. These tools make production quicker, safer, and cheaper.

FAQ

What are PCBA numbers used for?

PCBA numbers help track circuit boards during their life. They identify and manage boards in production, testing, and delivery. This keeps quality high and follows industry rules.

How do PCBA numbers improve manufacturing efficiency?

PCBA numbers make production smoother by reducing mistakes. They help find defects fast, manage inventory better, and stop fake parts. This saves time and money.

Can PCBA numbers help with regulatory compliance?

Yes, PCBA numbers record production steps and improve tracking. They help meet strict rules in industries like healthcare and aerospace. This makes inspections easier.

Are barcodes or RFID better for PCBA tracking?

Barcodes are cheaper and good for basic tracking. RFID tags give real-time updates and automate tasks. Pick based on your budget and needs.

How do PCBA numbers prevent counterfeit components?

PCBA numbers track all parts in a circuit board. They check where parts came from and if they’re real. This helps remove fake parts quickly.

See Also

Understanding PCBA Services And Their Importance In Electronics

Enhancing Workflow Efficiency In PCBA Manufacturing Processes

Best Practices For Ensuring Quality And Efficiency In PCBA