Testing helps check the quality of electronics. A PCBA test jig makes testing easier by finding problems early. It lowers mistakes and speeds up work. Using a PCBA test jig gives accurate results, making PCBA production quicker and better. This tool is very important for today’s manufacturing.

Key Takeaways

PCBA test jigs help test faster and avoid mistakes. This makes production quicker and products better.

Test jigs find problems early, stopping expensive fixes later. They make sure customers get good products, improving the brand’s image.

Adding test engineers early in design helps testing go smoothly. It lowers risks, saves money, and makes products successful.

The Role of Production Testing in the Electronics Manufacturing Process

Importance of testing for quality assurance

Testing makes sure electronics meet standards before being sold. It checks quality, reliability, and performance. Without testing, bad products might reach customers, causing complaints and extra costs.

Testing also finds and fixes problems early. For precise electronics, strict testing means fewer mistakes and more reliable products. The table below shows key testing points and their benefits:

Quality Assurance Aspect | Benefit |

|---|---|

Fewer mistakes and more reliable products | |

Good materials | Better performance and longer-lasting products |

Advanced techniques | Better quality with accurate testing |

Skilled workers | Higher-quality products |

Less waste and fewer returns save money | |

Happy customers | Better products delivered on time |

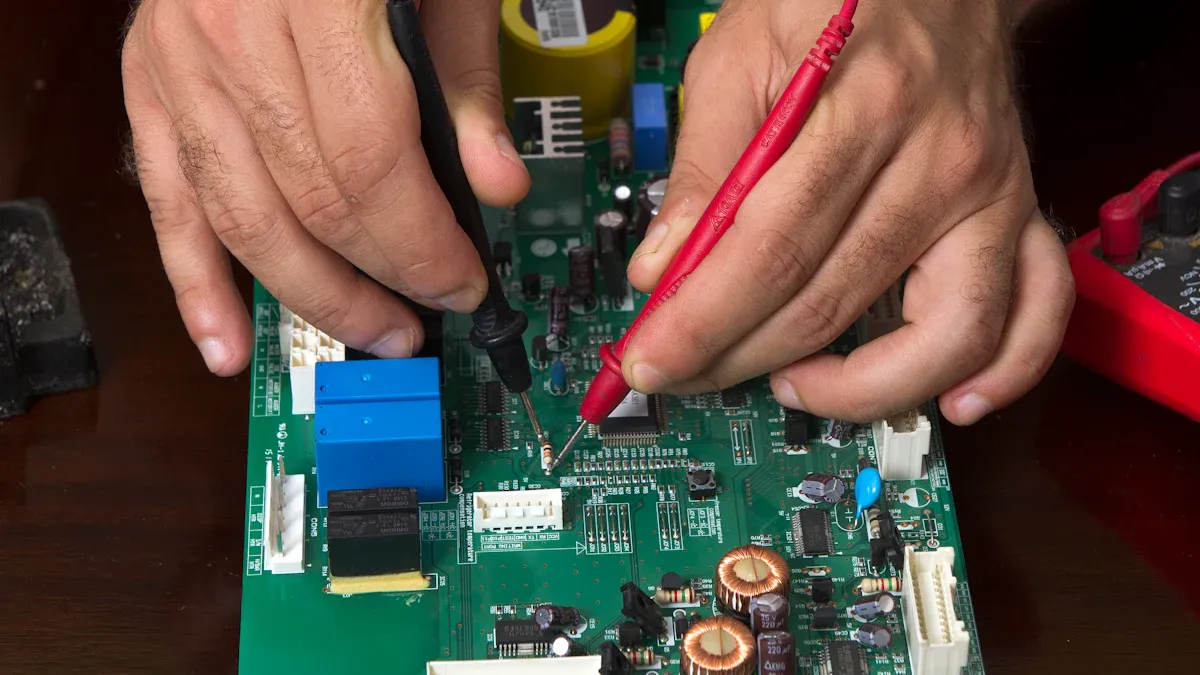

Challenges of manual testing in high-volume production

Manual testing takes a lot of time and can have mistakes. People might miss small problems, especially with complex designs. As production grows, mistakes happen more often, wasting time and money.

Manual testing also doesn’t always record data well. This makes it hard to find patterns or fix repeated problems. Without automation, keeping quality high for many products is tough.

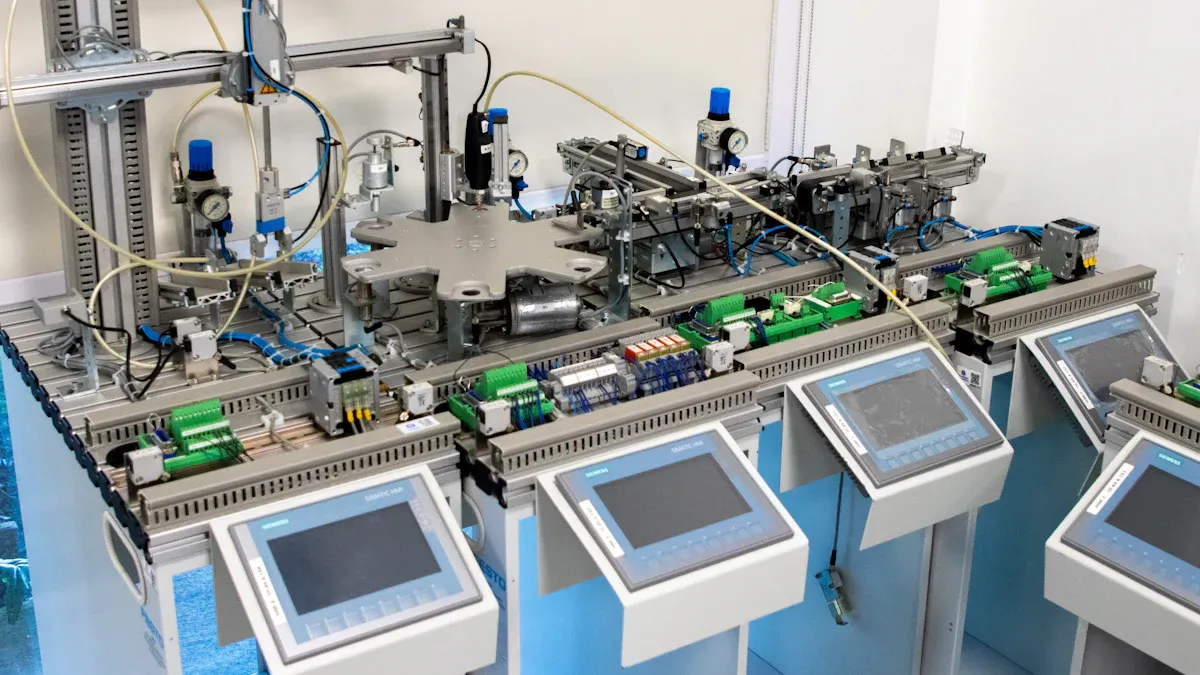

How production test jigs address these challenges

Test jigs solve many problems of manual testing. They automate tasks and give consistent results. A PCBA test jig finds problems fast, saving time on checks.

Test jigs combine test data with production info to improve quality. Reports show trends and issues, helping track product quality. Automated systems reduce waste and improve performance.

Test jigs also remove human mistakes by making testing the same for all units. Every product gets the same careful checks, no matter how many are made. These tools make testing faster, more reliable, and keep quality high.

Key Benefits of Using PCBA Test Jigs

Saving time and working faster

Testing in production can be slow and repetitive. A PCBA test jig speeds things up by automating these tasks. It makes sure every unit is tested quickly and correctly. This saves time compared to doing checks by hand, letting you focus on other work.

Test jigs also make the process smoother. They cut out extra steps and give steady results. For instance, automated systems can test many parts at once, saving hours over manual testing.

Benefit Description | |

|---|---|

Test Coverage | Checks all parts to find problems early. |

Manufacturing Costs | Finds defects early, saving money on fixes. |

Automation Precision | Replaces hand checks, making results steady and accurate. |

Stopping human mistakes in testing

Manual testing depends on people, and people can make mistakes. A test jig removes this problem by making testing the same for every product. You can trust that all items are checked equally, no matter how many are made.

Automated tools also find problems people might miss. They catch defects before products leave the factory. By cutting errors, you save time and avoid fixing broken items later.

Keeping track of data automatically

Tracking test data is key to keeping quality high. A PCBA test jig works with systems like MES to collect live data. This helps you watch and control the whole production process.

It collects data at every step, improving quality and tracking.

Automated data helps find and fix problems faster.

With automatic data tracking, you can spot patterns and fix repeated issues. This helps you make better choices and improve your work. Tracking also ensures your products meet industry rules, proving they are reliable.

Cost Efficiency of Production Test Jigs

Balancing upfront costs with long-term savings

Buying a PCBA test jig might seem expensive at first. However, it saves money over time by automating testing. This reduces labor costs and speeds up production. Faster work means lower overall expenses. For example, Siemens Amberg plant used test systems to save money. They cut product introduction time by 50% and reached a 99.99885% quality rate. These changes saved them up to 25% in costs.

Test jigs also help avoid delays. They make the process faster, so orders are completed quickly. At Siemens, changeover time was cut in half. New orders were finished in just 24 hours. This speed helps businesses stay competitive.

Catching defects early to avoid extra costs

Finding defects early saves money on repairs and warranties. Test jigs spot problems before products leave the factory. This ensures only good-quality items reach customers. Early detection also reduces waste by fixing fewer defective units.

Automated testing gives consistent and reliable results. You can trust the system to find issues. This builds confidence in your production and protects your reputation. Customers get dependable products every time.

Growing production with reusable test jigs

Reusable test jigs make it easier to grow production. As you produce more, these tools can adapt to new designs or higher volumes. This saves money since you don’t need new equipment for every change.

Test jigs also support automation, which is key for large-scale production. Reusing and adjusting these tools keeps costs low while staying efficient. This method helps your business grow without spending too much.

Popular Testing Methods in Electronics Manufacturing

In-Circuit Testing (ICT)

In-Circuit Testing (ICT) is a trusted way to find defects in PCBAs. It uses a test jig to check parts and connections on a board. This method ensures that problems don’t come from making errors. ICT works fast and is great for testing many boards at once.

High fault coverage, checking circuits thoroughly for issues.

Easy troubleshooting by finding problems in specific parts.

Works well with complex PCBAs and detailed designs.

Saves money by catching defects early and reducing rework.

Cost Factors | Small-Scale Production | Large-Scale Production |

|---|---|---|

Initial Setup Costs | High per unit | Lower per unit |

Operational Costs | High per unit | Lower per unit |

Economies of Scale | Limited | Significant |

Maintenance & Calibration | High relative cost | Lower relative cost |

Rework & Scrap Rates | Higher chance | Lower due to better checks |

Flying Probe Testing

Flying Probe Testing works well for prototypes and small batches. Unlike ICT, it doesn’t need custom tools, so it’s cheaper for smaller jobs. This method uses probes to test parts without touching them.

Flying Probe Testing adjusts easily to different board designs. It needs little programming to work. But it’s slower than ICT, so it’s not ideal for big production runs. Still, it’s great for testing new designs and keeping quality high in small-scale work.

Functional Circuit Testing (FCT)

Functional Circuit Testing (FCT) checks if a PCBA works as it should. It mimics real-world conditions to see if the board performs correctly. This method finds problems like bad connections or rule-breaking before mass production starts.

Evidence Description | Key Points |

|---|---|

FCT Complexity | Simple checks to advanced in-circuit tests. |

Objectives of FCT | Ensures proper connections and follows rules. |

Role in Quality Assurance | Stops recalls and ensures good performance. |

Testing Process | Uses special tools to test board responses. |

Performance Evaluation | Mimics real use to find possible problems. |

FCT is vital for quality control. It helps avoid recalls and keeps customers happy.

Planning for Production Testing During the Design Phase

Making products easy to test during production

Designing for testability makes testing simpler and cheaper. Thinking about testing early saves time and money. For example, a self-test in a medical device cut test time by 70%. Using shared test tools for similar products saved millions in costs.

Here are ways to improve testability:

Plan testing needs early to make it easier.

Fix possible problems during design to boost reliability.

Use simple testing methods to save time and money.

Find issues early to avoid long debugging later.

Test well to build trust with high-quality products.

Focusing on testability makes designs easier to check and ensures better results.

Working with test engineers from the start

Including test engineers early helps meet testing needs. This teamwork keeps schedules on track and production smooth. For example, working together early speeds up learning and delivery. Testing prototypes early lowers risks and improves success.

Benefit | Description |

|---|---|

Better Test System Design | Ensures designs work well and production is smooth. |

Lower Risks | Allows fixing designs without big delays. |

Higher Product Success | Improves reliability by testing new parts and prototypes early. |

Starting early with test engineers saves time and ensures products work well.

Saving money by planning testing early

Skipping testing plans during design can cost a lot later. Studies show fixing problems later costs much more than early fixes. These costs make up most of a product’s life expenses. Planning testing early improves performance and cuts these costs.

For example, using Design for Maintainability (DfM) reduces risks and boosts reliability. This lowers total costs and ensures good quality. Automated testing tools also catch problems early, avoiding costly redesigns.

Planning testing early saves money and builds trust in your reliable products.

PCBA test jigs are crucial in making electronics today. They save time, give accurate results, and prevent mistakes like wrong readings or bad labels. For instance, manual testing can take an hour per module. A test jig, however, finishes the job in 30 seconds to 3 minutes. Starting early helps ensure success.

FAQ

What is a PCBA test jig?

A PCBA test jig is a tool used to check PCBAs. It finds problems and makes sure the boards work properly.

Why use automated testing instead of manual testing?

Automated testing is faster and makes fewer mistakes. It gives steady results, tracks data automatically, and works well for big production runs.

Tip: Automated testing helps grow production while keeping quality high.

Can PCBA test jigs work with different designs?

Yes, many test jigs can be reused and changed. They can test new designs or handle more products, saving money over time.

🛠️ Note: Reusable jigs are a smart choice for growing companies.

See Also

The Impact of PCBA on Advancing Modern Electronics

Essential In-Circuit Testing Tools for PCBA You Should Know

Understanding PCBA Test Fixtures: Key Features and Uses