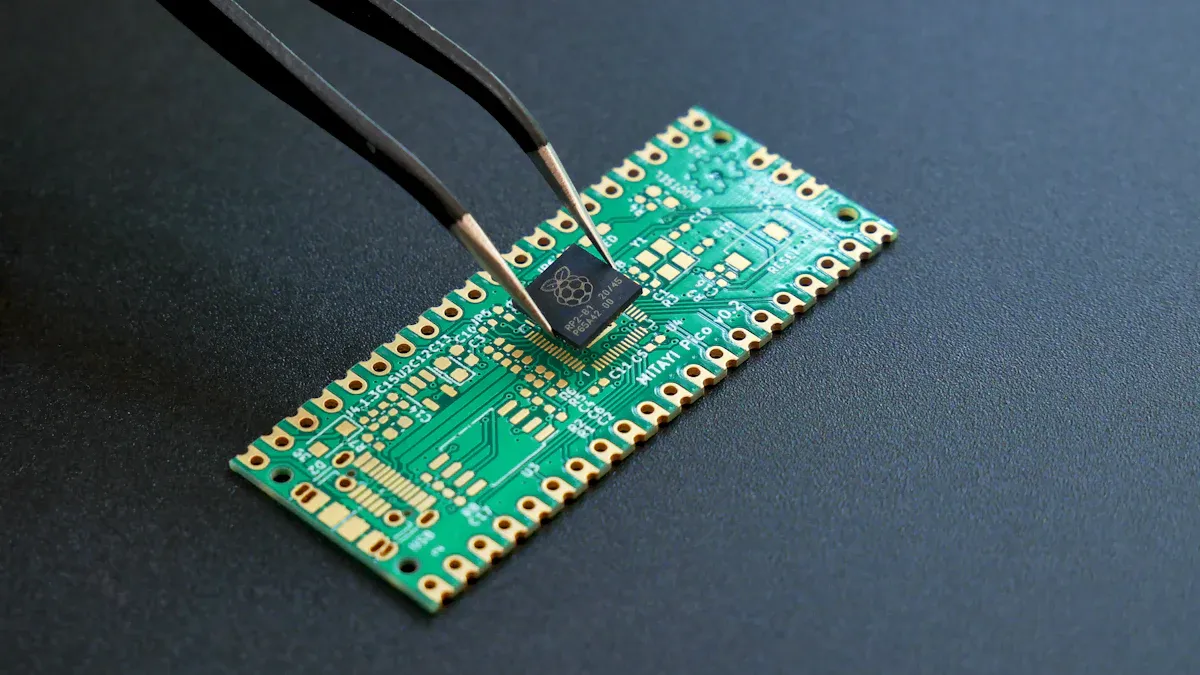

Printed circuit board assemblies (PCBAs) are essential for industrial automation PCBA. They connect components like microcontrollers and sensors on circuit boards, enabling machines to perform complex tasks accurately and automatically. For instance, PCBAs operate control systems, ensuring that programmable controllers and automated machines function effectively.

As automation expands, factories will require more industrial automation PCBAs. By 2024, the PCB market could be valued at $79.3 billion, and by 2033, it may reach $123.5 billion. This rapid growth highlights the significance of industrial automation PCBAs in enhancing production and quality control.

In manufacturing environments, industrial automation PCBAs connect sensors, actuators, and other components. They enhance system performance, making operations faster, more reliable, and easier to scale. Industrial automation PCBAs are indispensable for contemporary production systems.

Key Takeaways

PCBAs are important for linking parts in industrial machines. They help machines work correctly and quickly.

The need for industrial PCBAs is growing fast. The market might reach $123.5 billion by 2033, showing how valuable they are in factories today.

PCBAs make systems work better by being more reliable. They also cut down on machine breaks and boost factory production.

PCBAs with modular designs are easy to upgrade. This makes them great for using new tech and growing production lines.

Testing and checking quality are key to making sure PCBAs work well. This stops problems and keeps automation systems running smoothly.

Applications of PCBA in Industrial Automation

PCBA in Industrial Control Systems

PCBAs are key parts of industrial control systems. They help machines work accurately and reliably. These systems use PCBAs to link sensors, microcontrollers, and programmable logic controllers (PLCs). PCBAs make sure these parts communicate and work well together.

For example, companies like Siemens use PCBAs in their SIMATIC HMI systems. These PCBAs help operators manage and monitor machines easily. This improves factory automation. ABB’s RTU560 also uses PCBAs to work in tough places like energy grids.

PCBAs include advanced designs like multi-layer boards. These designs save space and make systems more energy-efficient. They improve system performance and reliability. PCBAs are vital for controlling and improving industrial automation systems.

PCBA in Industrial Robotics and Automation

Robots in factories depend on PCBAs to work precisely and efficiently. PCBAs help robots do tasks like moving materials, assembling parts, and checking quality. Robotic arms use PCBAs to control their movements. This lets them handle items carefully and place them correctly during assembly.

Robots also speed up production by reducing mistakes and delays. For example, a PCB company used robots to inspect boards faster and more reliably than humans. This allowed remote monitoring and extra shifts without needing more workers. Robots also move materials safely, avoiding risks like electrostatic discharge (ESD).

PCBAs help robots work with humans. They improve scheduling and decision-making in factories. Robots can recycle PCB parts and improve quality checks. PCBAs allow robots to do tasks that humans find hard or inefficient.

PCBA in Sensors, Actuators, and IoT Devices

PCBAs are crucial for sensors, actuators, and IoT devices in modern factories. These devices use PCBAs to connect microcontrollers, antennas, and power circuits. IoT sensors with PCBAs collect and send data for real-time monitoring and maintenance.

Sensors like temperature, humidity, and pressure sensors need PCBAs to work. Actuators, which turn electrical signals into actions, also rely on PCBAs for precise control. Compact PCB designs save space and ensure reliable operation in tight areas.

IoT devices often have PCBAs with antennas for wireless communication. This helps systems share data and stay connected. PCBAs make sensors and actuators work together smoothly. They are driving the future of smart factories and automated systems.

PCBA in Human-Machine Interfaces (HMIs)

Human-Machine Interfaces (HMIs) are important in factory automation. They let people control machines using screens, buttons, or panels. PCBA is the main part of HMIs. It helps machines and people communicate easily. Commands from workers are processed and carried out correctly.

In factories, HMIs with PCBA improve work by showing live updates. Touchscreens let workers change machine settings quickly and safely. In oil and gas, HMIs make it easier to check equipment. This boosts efficiency and saves time. Energy systems use HMIs with PCBA to manage power use. This helps save energy and supports eco-friendly practices.

Here’s how industries use PCBA in HMIs:

Industry | Use | Benefits |

|---|---|---|

Manufacturing | Screens and control systems | Live updates, better work, safer workplaces |

Oil and Gas | Equipment monitoring | Better efficiency, simpler energy processes |

Energy Management | Power control systems | Manages energy use, supports green practices |

PCBA makes HMIs strong and dependable, even in tough conditions. Its small size and sturdy build make it perfect for precise and lasting use.

PCBA in Quality Control and Monitoring Systems

Quality control systems keep products up to high standards. These systems use PCBA to read data from sensors and cameras. This ensures every product is made correctly. PCBA helps find mistakes, check performance, and give useful information.

For example, in assembly lines, PCBA systems spot bad parts early. This cuts waste and makes work faster. PCBA also powers advanced cameras for detailed checks. These cameras inspect products with great accuracy.

PCBA is also key for fixing problems before they happen. It studies sensor data to find issues early. This stops delays and keeps machines running longer. In industries like medicine and electronics, where accuracy matters, PCBA keeps quality systems working perfectly.

Benefits of Industrial Automation PCBA

Reliability in Harsh Industrial Environments

Factories often have tough conditions like heat, moisture, and stress. PCBAs are built to handle these challenges and work reliably. Companies test PCBAs carefully to ensure they last.

Purpose | What it Shows | |

|---|---|---|

Environmental Stress Testing | Mimics real-life conditions for PCB/PCBA. | Checks durability and solder joint strength. |

Temperature Cycling | Tests against temperature changes. | Finds thermal stress effects on parts. |

Humidity Testing | Checks resistance to moisture and rust. | Shows risk of corrosion or moisture damage. |

Vibration Testing | Tests against shaking and vibrations. | Checks if parts stay secure under stress. |

Shock Testing | Tests against sudden impacts or drops. | Finds weak spots in structure or attachments. |

Electrical Stress Testing | Checks electrical performance and strength. | Tests power stability and heat effects. |

Power Cycling | Tests repeated on/off power cycles. | Checks solder strength and heat resistance. |

These tests prove PCBAs can handle tough factory demands. For example, stress testing shows how well a PCBA works over time. This makes PCBAs perfect for systems where reliability is crucial.

Efficiency and Performance Optimization

PCBAs help automation systems work better and faster. Their smart designs connect parts like sensors and controllers. This keeps systems running smoothly with less downtime.

Strong and Durable: PCBAs last long, so replacements are rare.

Better Data Flow: They keep signals clear for real-time tasks.

Energy Efficient: PCBAs save energy in busy environments.

Fast Data Sharing: They send information quickly for quick responses.

For example, robotic arms in factories use PCBAs for precise movements. This reduces mistakes and speeds up production. By improving performance, PCBAs help factories make more products with better quality.

Cost-Effectiveness in Automation Systems

Using PCBAs in automation saves money. Studies show European factories improved productivity by 30% with automation. Some saved as much as 100% in worker costs.

Higher Productivity: PCBAs make systems faster, needing less human work.

Less Waste: They improve quality, reducing bad products and materials.

Lower Repair Costs: PCBAs last longer, so repairs are less frequent.

Stable Systems: Fewer breakdowns save time and money.

For instance, PCBAs in control systems keep machines running smoothly. This avoids expensive downtime. By being efficient and reliable, PCBAs help businesses save money over time.

Scalability for Advanced Industrial Applications

Scalability is an important part of PCBA in factories. As factories grow or use new tools, scalable PCBAs help systems adjust without big changes. This saves time and money while supporting advanced uses.

Modern PCBAs use modular designs that make upgrades and fixes simple. You can swap or improve parts without stopping the whole system. This cuts downtime and keeps things running well. Modular designs also prepare systems for future changes as technology improves.

Tip: Modular PCBAs work best for industries that often update tools or grow production lines.

Scalable PCBAs also boost production. They make it easier to add new parts or technologies. Better repair options lower costs and keep systems useful for a long time. These features make PCBAs a dependable choice for advanced factory needs.

Here’s how scalability helps advanced uses:

Feature | Benefit |

|---|---|

Checks millions of PCBAs with accuracy | |

Modular Designs | Makes upgrades and repairs easier |

Enhanced Production Efficiency | Speeds up work and adapts to changes |

Scalable PCBAs support AI systems, which are key in automation. AI tools can check millions of PCBAs with great accuracy. This keeps product quality high and reduces mistakes.

You’ll also enjoy easier assembly and future-ready designs. These features make scalable PCBAs a smart choice for staying ahead in a fast-changing market.

Design Considerations for Printed Circuit Boards

Material Selection for Industrial Applications

Picking the right materials for PCBs is very important. It helps them stay strong and work well in tough places. Think about things like strength, heat resistance, and how they handle electricity. For example, polyimide is great because it can handle high heat and stress.

When choosing materials, check their dielectric constant (Dk) and dissipation factor (Df). Materials with low Dk work better at high speeds. Low Df materials lose less signal. Also, make sure the materials stay stable at different frequencies. This is key for good performance in hard conditions.

Here are some things to think about when picking materials:

Dielectric Constant (Dk): Use low Dk materials for fast signals.

Dissipation Factor (Df): Pick low Df materials to keep signals strong.

Frequency Stability: Make sure materials stay steady at all frequencies.

By checking these points, you can make PCBs that work well in factories.

Thermal Management in High-Performance Systems

Keeping PCBs cool is very important for their performance. Heat from parts like CPUs can make them work poorly or break faster. To fix this, use smart cooling methods and good layouts.

Put parts that use a lot of power in the middle of the PCB. This helps spread heat evenly. Use coolers like the QuadFlow CPU cooler to improve airflow. You can also study airflow with special tools to make cooling better.

Here are some tips to manage heat:

Plan the layout to spread heat evenly.

Add heat sinks and thermal vias to remove heat.

Place high-power parts where they cool faster.

These ideas will help your PCBs last longer and work better.

Signal Integrity and Noise Reduction

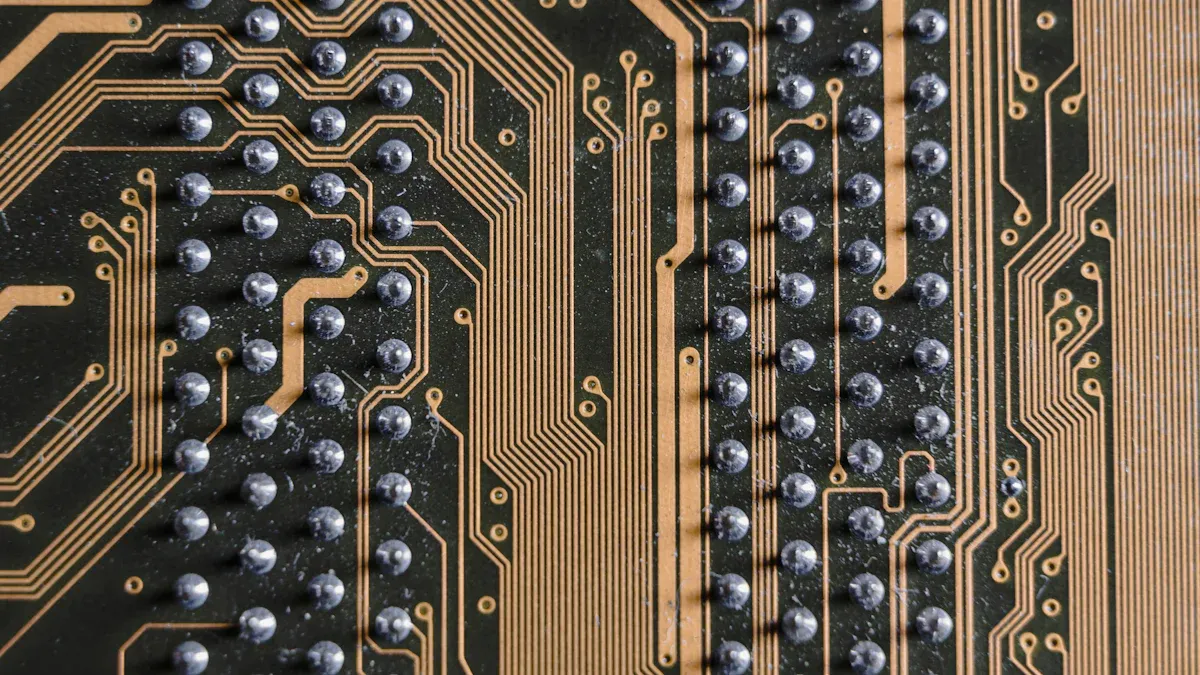

Keeping signals clear is very important for PCBs in noisy places. You can do this by planning the layout and using good grounding.

Use materials that lose less signal and keep noisy parts apart. Route signals carefully to avoid problems like crosstalk. Add grounding and capacitors to keep voltages steady.

Here are common problems and fixes:

Crosstalk: Keep traces apart to stop unwanted signals.

Reflections: Match signal paths to avoid interference.

Ground Bounce: Use strong grounding to stop voltage changes.

By solving these problems, your PCBs will work well in tough environments.

Compliance with Industrial Standards

Making PCBs for factories means following important rules. These rules make sure PCBs are safe, work well, and are good for the environment. They also help meet laws and industry needs.

Some rules focus on harmful materials. RoHS stops the use of things like lead and mercury in PCBs. REACH works to limit dangerous chemicals during production. Both rules aim to make manufacturing safer and greener.

Other rules guide how PCBs are made. IPC standards give steps for picking materials and putting parts together. Following these rules ensures PCBs are high-quality and work well in factories.

For medical devices, ISO 13485 is very important. It sets safety and performance rules for making PCBs. Meeting this standard builds trust with customers and regulators.

Tip: Check for updates to these rules often. Rules can change, and staying current keeps your PCBs legal and competitive.

By following these rules, you can make PCBs that are safe, reliable, and ready for modern automation systems.

Testing and Quality Assurance for PCBA

Why Testing Matters in Industrial Automation

Testing is crucial to make sure PCBs work well. These boards must handle tough conditions without failing. Even small problems can stop automation systems from working. Testing checks if each PCB meets electrical rules and works as planned. Automated tools like Automated Optical Inspection (AOI) and In-Circuit Testing (ICT) are very helpful. They reduce mistakes, speed up checks, and find problems like bad soldering or wrong parts early. This helps PCBs last longer and work better in automation systems.

Common Ways to Test PCBA

Factories use different tests to check PCBs for quality. Each test has its own purpose:

Testing Method | What It Does |

|---|---|

Manual Visual Inspection | Uses human eyes to check parts, but not great for tiny parts. |

Automated Optical Inspection (AOI) | Spots soldering problems fast by looking at how parts look. |

In-Circuit Test (ICT) | Finds open or short circuits and checks soldering, making production faster and cheaper. |

Functional Test (FCT) | Tests how the board works in real situations, checking voltage and current. |

X-Ray Inspection | Looks at hidden solder joints to find problems like open circuits or not enough solder. |

Aging Test | Runs the board for a long time to find weak spots. |

For example, AOI is quick and good for making lots of boards. But it might miss odd designs. ICT, on the other hand, finds detailed problems and checks if all parts work right. Using a mix of these tests ensures PCBs meet high standards.

Keeping PCBs Reliable Over Time

To make sure PCBs stay reliable, they need tough tests. Burn-in testing runs the board at high heat to catch early failures. Aging and fatigue tests mimic long-term use to find weak spots before they break.

Other advanced tests include:

High Accelerated Temperature and Humidity Stress Testing (HAST): Checks if the board can handle heat and moisture for a long time.

Temperature Cycling Testing: Tests how well the board handles big temperature changes.

HAST is great for finding moisture problems that can cause shorts. Adding these tests to your process ensures PCBs work well in tough factory conditions.

Future Trends in Industrial Automation PCBA

Advancements in Miniaturization and Integration

Smaller and better devices are changing PCBA designs. High-Density Interconnect (HDI) technology helps make circuits denser. HDI adds more layers and thinner lines, making devices smaller. These changes boost performance and save space. Industries like 5G, IoT, and wearables benefit a lot from this.

Making tiny PCBs can be tricky, especially for IoT. You need to know design rules and work with experts. Small PCBs save space and use less energy. This makes them perfect for modern factory systems.

Tip: Work with skilled vendors to make small PCBs that are reliable and high-quality.

Role of AI in PCBA Design and Manufacturing

Artificial intelligence (AI) is changing how PCBs are made. AI tools now handle hard tasks like placing and connecting parts. These tools use smart algorithms to plan paths early, saving time and money.

AI also makes inspections better. It finds mistakes more accurately, ensuring top-quality products. Plus, AI improves signal clarity, which is key for high-speed PCBs. Using AI in your process boosts efficiency and keeps you ahead in automation.

AI doesn’t just make things faster. It also adds accuracy and dependability to PCBA production, making it vital for future tech.

Adoption of Smart Materials for Enhanced Performance

Smart materials are now key in PCB designs. These materials adjust to their surroundings, making PCBs stronger and better. For example, materials with low dielectric constants improve signal clarity. This is crucial for fast systems.

Eco-friendly materials are also gaining attention. Rules and customer demands push companies to use greener options. These choices cut waste and support global green goals.

By using smart materials, your PCBs will last longer and work better. They also meet the needs of advanced factory systems and follow environmental rules.

PCBA in the Growth of Smart Factories

Smart factories are the future of industrial automation. They use advanced technologies like PCBs to connect sensors, controllers, and devices. This helps machines share data and make smart decisions.

PCBs are key for building systems that work better and adapt easily. For example, companies use PCBs to improve how cars and electronics are made. These improvements also help build smart cities and connected devices.

Note: PCBs are the heart of smart factories. They make sure machines and systems work well together.

Big companies show how PCBs change smart factories:

Porsche created a digital factory with better workflows and modern tools.

Siemens used real-time data to improve how factories run.

These examples show how PCBs help factories make faster, smarter decisions. Adding PCBs to smart factories reduces mistakes, speeds up production, and saves resources.

Smart factories also use modular PCB designs. These designs let you upgrade systems without stopping work. This makes it easy to add new technology. As factories grow, PCBs will keep driving new ideas like AI checks and predictive repairs.

Tip: Use strong PCBs to keep your smart factory ready for the future.

Smart factories powered by PCBs are changing industries like cars and electronics. By using these tools, factories can be faster, scalable, and eco-friendly.

PCBs are key parts of automation systems in factories. They help machines work accurately, share data well, and run smoothly. Using better materials and strict quality checks, PCBA production improves how industries work. This leads to stronger systems, saving space, and cutting costs.

Learning about new PCBA technology is very important. As machines get smaller and need to do more, PCBA helps build powerful and flexible systems. By using these new ideas, you can keep your systems working well and ready for the future.

FAQ

What is PCBA, and why is it important in industrial automation?

PCBA means Printed Circuit Board Assembly. It links electronic parts so machines work well. In factories, PCBA helps robots, sensors, and controllers work together. This boosts efficiency and makes systems more reliable.

How does PCBA handle harsh industrial environments?

PCBAs are made with strong materials and tested for tough conditions. They can handle heat, moisture, and shaking. Features like cooling systems and protective layers keep them working well in hard environments.

Can PCBA designs be customized for specific industries?

Yes, PCBA designs can fit different industry needs. For example, medical devices need small and accurate PCBAs. Cars need strong and flexible PCBAs. Custom designs make sure systems work their best.

How does PCBA contribute to cost savings in automation?

PCBAs save money by making systems run better and last longer. They cut repair costs and reduce downtime. Automation with PCBAs also lowers labor costs and waste, saving money over time.

What trends are shaping the future of PCBA in industrial automation?

Smaller designs, AI, and smart materials are changing PCBA. Tiny, energy-saving PCBAs save space. AI helps make and check PCBAs faster. Smart materials make PCBAs stronger and better for advanced factory systems.

Tip: Learn about new PCBA trends to keep your systems ready for the future.

See Also

Why PCBA Manufacturing Skills Are Crucial for Electronics Design

Exploring PCBA Uses and Advantages in Contemporary Electronics

Understanding PCBA’s Role and Significance in Electronics