Industrial control PCB assembly USA plays a crucial role in advancing automation across the nation. It enhances machine control, driving efficiency in key industries such as automotive, healthcare, and electronics. The market for industrial control PCB assembly USA is expanding rapidly, with PCB equipment projected to reach $15 billion by 2025 and maintain a 6% annual growth rate thereafter. Choosing the right manufacturers ensures high-quality, customized boards tailored to your specific requirements. Companies like TTM Technologies and Sanmina Corporation exemplify the strength of industrial control PCB assembly USA manufacturers, with TTM generating $2.4 billion annually. Evaluating providers based on expertise, quality, and delivery capabilities ensures your assembly needs are met effectively.

Key Takeaways

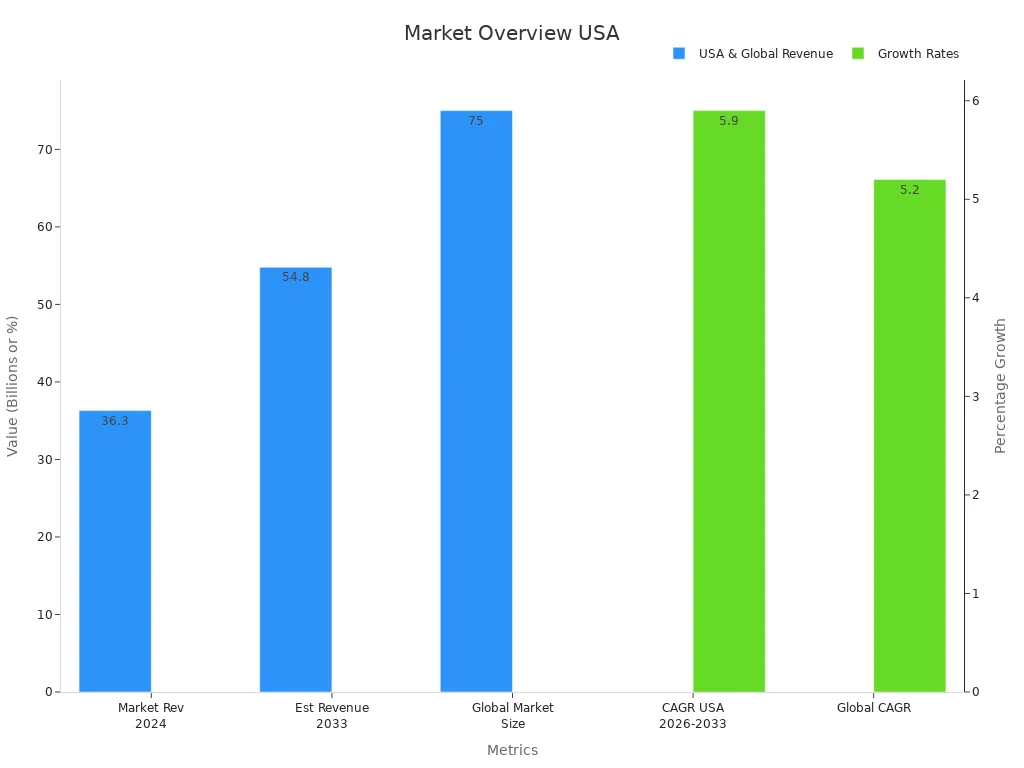

The PCB assembly market in the USA is growing fast. It might reach $36.3 billion by 2024. This shows more industries need good-quality PCBs.

Picking the right PCB maker is very important. Find companies with certifications like ISO 9001 or AS9100D for reliable products.

Quick delivery helps projects succeed. Top companies now deliver faster, cutting wait times from 6-8 weeks to 4-5 weeks.

Think about the overall value of a PCB company, not just price. Paying more upfront can mean better quality and fewer fixes later.

Good customer support and clear updates are key. Pick a company with account managers and regular updates to keep your project moving.

Overview of the Industrial Control PCB Assembly Market in the USA

Market Trends and Growth in USA PCB Manufacturing

The industrial control PCB market in the USA is growing fast. By 2024, it could make $36.3 billion, and by 2033, $54.8 billion. This means it will grow about 5.9% each year from 2026 to 2033. Around the world, the PCB industry is also getting bigger. It is worth $75 billion and growing 5.2% yearly for the next 10 years.

Many trends are helping this growth. Smaller electronics, better HDI technology, and flexible PCBs are changing the industry. More PCBs are needed for cars, healthcare tools, and IoT devices. For instance, electric car sales went from 206,000 in 2013 to over 10.5 million in 2022. This shows how important advanced PCBs are becoming.

Key Challenges in Industrial Control PCB Assembly USA

Even with growth, the industry has problems. Raw materials are getting more expensive, and strict environmental rules add pressure. Supply chains are often delayed due to global issues. Cheaper producers outside the USA also make it hard for local companies to compete on price. Because of these challenges, picking a good PCB maker is very important.

Importance of Choosing the Right PCB Assembly Manufacturers

Choosing the right PCB maker is key to good results. Skilled companies with certifications like AS9100D and ISO 9001 follow strict standards. They use advanced tools, check quality carefully, and deliver on time. Companies that focus on industrial control PCBs can improve your project. Good communication and support help keep your project on schedule and meet your needs.

Detailed Comparison of Top Providers

TTM Technologies: Skilled in Heat Control and High-Frequency Signals

TTM Technologies is known for its skill in managing heat and high-frequency signals. They design special parts for high-frequency uses, keeping devices stable and small. These parts are perfect for modern wireless tools. Their resistors can handle more power, which is important for industrial control PCBs in the USA.

Their products work across a wide range of frequencies, from DC to 6 GHz. This shows they are good at handling high-frequency signals. TTM also uses eco-friendly materials that meet global rules. This supports the need for green manufacturing. Choosing TTM means you get advanced materials and strict quality checks, making your PCBs more reliable.

Sanmina Corporation: All-in-One Solutions for Many Industries

Sanmina Corporation is a top PCB maker in the USA. They provide solutions for industries like cars, healthcare, aerospace, and factories. They make strong PCBs designed for each industry’s needs.

Sanmina stands out because they use advanced materials and follow ITAR rules. These rules ensure they meet strict standards. Their fast PCB prototyping helps speed up product development. They also offer design help and easy online ordering, making it simple to create your products.

Sanmina focuses on quality and new ideas, making them a trusted choice for industrial control PCBs. Whether you need strong PCBs or flexible designs, they have solutions for many needs.

Company | Location | Specialization | Key Features |

|---|---|---|---|

Sanmina Corporation | USA | Strong PCBs, Military and Aerospace | Advanced materials, strict quality checks, ITAR rules |

Jabil Inc.: Trusted PCB Maker with a Big USA Presence

Jabil Inc., based in St. Petersburg, Florida, is a trusted PCB maker in the USA. Founded in 1966, Jabil offers full manufacturing services and has many locations in the country. They focus on quality and eco-friendly practices, making them a leader in PCB assembly.

Jabil follows important certifications like ISO 9001 for quality, ISO 13485 for medical devices, and AS9100 for aerospace. These show their commitment to high standards in all their work.

Certification | What It Means |

|---|---|

ISO 9001 | Quality management system |

ISO 13485 | Quality for medical devices |

AS9100 | Quality for aerospace industry |

Jabil also cares about the environment, making sure their processes are green. Their skill in industrial control PCBs makes them a reliable partner for businesses needing top-quality solutions.

Flex Ltd.: Flexible and Reliable PCB Designs

Flex Ltd. makes flexible PCBs that are light and small. Their designs save space and work well for modern devices. These PCBs lower noise and electromagnetic interference (EMI), keeping signals clear.

Flex PCBs can bend and move without breaking. This makes them less likely to fail, which is great for industrial use. Their small size removes the need for big connectors and cables. This helps make devices lighter and more compact.

Here’s a simple look at their features:

Feature | What It Does |

|---|---|

Clear Signal Quality | Reduces noise and EMI for better signal strength. |

Strong and Reliable | Bends without breaking, lowering the chance of failure. |

Small and Space-Saving | Fewer cables and connectors make devices lighter and smaller. |

Tough Against Stress | Handles more mechanical pressure, staying stable under tough conditions. |

Flex Ltd. focuses on making strong and smart PCBs. They are trusted by industries like healthcare, cars, and IoT. Their designs meet your needs with care and precision.

Benchmark Electronics: Trusted for Tough Jobs

Benchmark Electronics is known for making reliable PCBs in the USA. They work with industries like aerospace, defense, and automation, where quality is very important. Their PCBs are built to handle tough conditions and last a long time.

Benchmark uses advanced testing to make sure their PCBs work perfectly. Their industrial control PCBs are made to survive hard environments and heavy use.

They also have great customer service. Their team listens to your needs and makes sure the final product is just right. This teamwork and skill make Benchmark a top PCB maker in the USA.

Creation Technologies: Focused on Quality and Speed

Creation Technologies stands out for their focus on quality and fast delivery. They use special tools like automated optical inspection (AOI) and X-ray checks to find problems early. This helps make sure every PCB is high quality.

Their quality steps include:

Smart assembly methods that save time and money.

Careful checks to avoid fixing mistakes later.

Plans to keep standards high and make customers happy.

Here’s a closer look at their process:

Quality Step | How It Helps |

|---|---|

Early Problem Detection | AOI and X-ray checks catch issues before they grow. |

Careful Quality Checks | Every step is watched to ensure the PCB works well. |

Skilled Workers | Experts build and test PCBs with great care. |

Creation Technologies also works fast by improving their processes. Their trained team and advanced tools help deliver PCBs quickly. Their focus on quality and customer happiness makes them a top choice for PCB assembly.

Key Factors to Think About When Picking a Provider

Skills and Knowledge in PCB Assembly

When picking a company for your PCB needs, their skills matter most. A good company offers different assembly methods like Surface Mount Technology (SMT), Through-Hole Technology (THT), and mixed assembly. These methods help meet your specific needs.

Experts in advanced PCB types, like flexible, rigid-flex, and High-Density Interconnect (HDI), can handle tricky designs easily. They can also manage small or large orders, from quick prototypes to big productions. Special tests, like Automated Optical Inspection (AOI) and x-ray checks, make sure your PCBs work well.

Here’s a simple table of what to look for:

Feature | What It Means |

|---|---|

Assembly Types | Offers SMT, THT, and mixed assembly for flexibility. |

Advanced PCB Knowledge | Skilled in flexible, rigid-flex, and HDI designs. |

Order Sizes | Handles small prototypes to large-scale production. |

Has ISO 9001, ISO 13485, or AS9100D for quality assurance. | |

Testing Methods | Uses AOI, x-ray, and other tests for reliability. |

Supply Chain Management | Manages parts sourcing and inventory well. |

Choosing a skilled provider ensures your PCBs are reliable and meet your needs.

Quality Rules and Certifications in USA PCB Making

Quality certifications show a company cares about making good products. In the USA, certifications like ISO 9001, ITAR, and RoHS are important. They prove the company follows safety and environmental rules. These also show they can make PCBs for tough jobs.

Here’s a list of key certifications:

Certification | What It Means |

|---|---|

ITAR | Controls defense-related items and services in the US. |

ISO | Global standard for quality management systems. |

RoHS | Limits harmful materials in electronics. |

UL Listing | Ensures safety in electronic devices. |

IPC | Sets quality rules for PCB assemblies. |

MIL | US military standards for electronics. |

Pick companies with these certifications to ensure your PCBs are safe and high-quality.

Delivery Speed and Timing of PCB Makers

Getting your PCBs on time is very important. Companies with faster delivery and good timing can help your project succeed. Top companies have cut delivery times from 6-8 weeks to 4-5 weeks. On-time delivery rates have also improved from 85% to 97%.

Here’s a quick look at delivery improvements:

Metric | Before | Now | Improvement |

|---|---|---|---|

Average Delivery Time | 6-8 weeks | 4-5 weeks | 30-35% faster |

On-time Delivery Rate | 85% | 97% | 14% better |

Customer Happiness | N/A | Up by 25% | N/A |

Production Costs | N/A | Down by 15% | N/A |

Choose a company that delivers quickly and manages supplies well. This keeps your project on track without lowering quality.

Customer Support and Communication in Industrial Control PCB Assembly

Good customer support and clear communication are very important. You need a company that listens to your needs and keeps you updated. Clear updates help your project stay on track and meet your goals.

Top PCB companies in the USA focus on keeping customers happy. They have special teams to solve problems and offer helpful solutions. For example, they might suggest design changes or better parts to make your PCB stronger.

Here are important things to look for in customer support:

Dedicated Account Managers: One person handles your account for easy communication.

Technical Expertise: Support teams should know PCB assembly well to solve issues.

Proactive Updates: Regular updates keep you informed about progress and delays.

Accessible Channels: Options like email, phone, and chat make reaching them simple.

Tip: Pick a company that works with you and gives clear documents. This avoids confusion and ensures your PCB meets standards.

Strong support makes your experience better and lowers the chance of mistakes. Companies that focus on communication build trust and long-term relationships.

Cost and Value Proposition of USA PCB Manufacturing Providers

Cost is important when choosing a PCB company, but don’t focus only on price. Cheaper options can mean lower quality and less reliable products. Instead, think about the value USA manufacturers offer.

USA PCB makers follow strict rules to make high-quality boards. They use advanced tools and strong materials to make durable products. While they may cost more at first, the benefits last longer and save money over time.

Here’s how USA PCB makers add value:

Factor | How It Adds Value |

|---|---|

Quality Assurance | Careful tests like AOI and X-ray ensure strong, problem-free PCBs. |

Compliance | Certifications like ISO 9001 and ITAR ensure safety and good performance. |

Customization | Custom designs fit your needs, so no redesigns are needed. |

Supply Chain Management | Good planning avoids delays and keeps costs low. |

Durability | Strong materials make PCBs last longer with fewer repairs. |

Cheaper overseas companies may not follow strict quality checks. This can lead to more repairs and shorter product life.

Note: Spending more on a good PCB company saves money later by avoiding downtime and improving efficiency.

When comparing costs, think about the total value, not just the price. A company that delivers quality, reliability, and good support is worth the investment.

Picking the right PCB assembly company in the USA is important. Each company has its own strengths. TTM Technologies is great at handling heat and high-frequency designs. Sanmina Corporation offers complete solutions for many industries. Jabil Inc. is known for its certifications and eco-friendly methods. Flex Ltd. makes lightweight, bendable PCBs, while Benchmark Electronics creates strong PCBs for tough jobs. Creation Technologies focuses on fast delivery and high quality.

Think about what matters most to you when choosing. For fast prototypes, RUSH PCB Inc. in San Jose can deliver in just 24 hours. If you need top-quality PCBs quickly, Amphenol Printed Circuits in Nashua is a great option.

Doing good research helps you find the right partner. Compare their skills, certifications, and delivery times to decide. A good company will not only meet your needs but also improve your work.

FAQ

What makes USA PCB manufacturers special?

USA PCB makers are known for quality and reliability. They follow strict rules like ISO 9001 and ITAR. This helps them create strong and high-performing PCBs for industries.

How can I pick the best PCB assembly company?

Check their skills, certifications, and delivery record. Choose companies with advanced testing, flexible order options, and good support. These things help your project succeed.

Why is fast delivery important in PCB assembly?

Getting PCBs on time keeps your project on track. Good companies handle supplies well, avoid delays, and keep quality high. This saves time and money.

Are USA PCB makers worth the cost?

USA PCB makers may cost more upfront but save money later. Their strong quality checks and materials mean fewer repairs and longer-lasting products.

What certifications should a PCB maker have?

Look for certifications like ISO 9001 for quality, ITAR for defense, and RoHS for safety. These show the company meets important industry standards.