Industrial environmental monitoring PCBA helps solve big environmental problems today. IoT technology makes monitoring systems better and provides real-time data. For instance, IoT checks water quality by detecting pollutants. It also enhances air quality by tracking emissions and identifying harmful gases to keep people safe. However, managing tough conditions, ensuring lasting performance, and meeting growing needs can be challenging. Addressing these issues ensures accurate monitoring and aids in making smart choices for a cleaner Earth.

Key Takeaways

Industrial PCBAs are important for tracking the environment. They help devices work well in heat and wet conditions.

IoT technology makes monitoring better by giving live data. This helps people make quick and smart choices about problems.

Picking the right PCBA maker is very important. Check for good certifications and skill in making strong PCBAs for IoT.

Checking sensors often is key for correct data. This stops wrong alerts and keeps monitoring results trustworthy.

Using smart power saves energy and makes devices last longer. Choose energy-saving designs and green energy for faraway monitoring.

Understanding Industrial Environmental Monitoring PCBA

What is PCBA and its role in environmental monitoring?

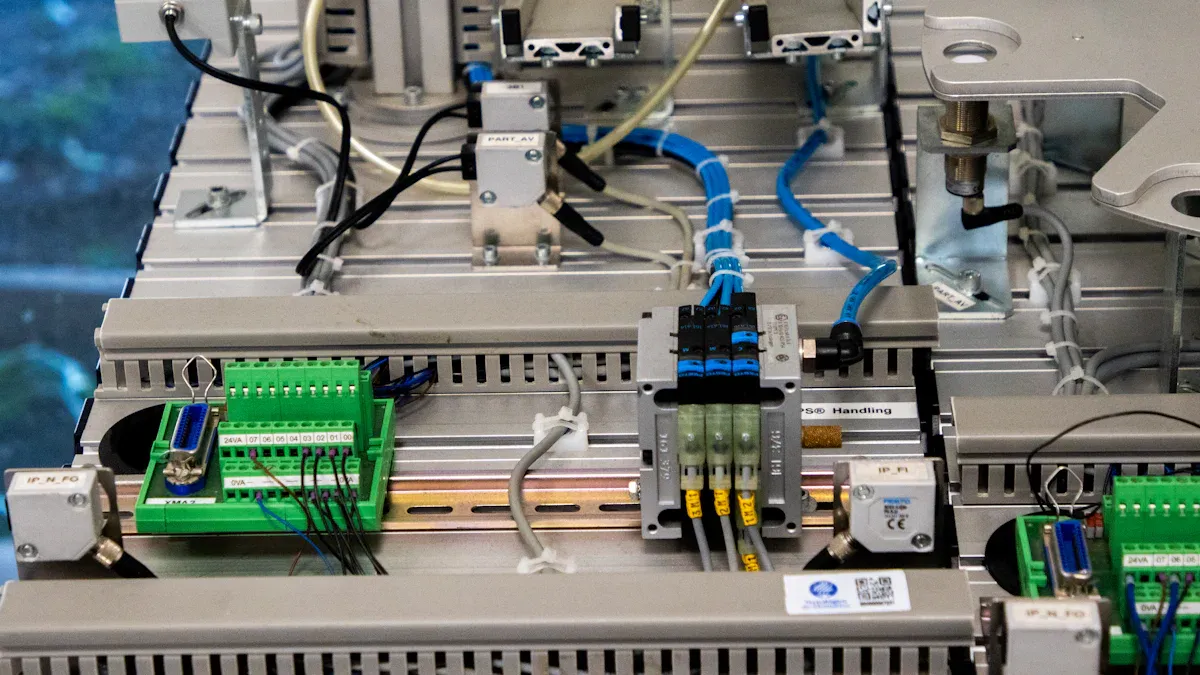

Printed Circuit Board Assembly (PCBA) is key to modern electronics. It links and supports parts like sensors and controllers. In environmental monitoring, PCBA helps devices gather and share data. For example, in air monitors, it finds harmful gases and sends alerts. Without PCBA, combining parts into a working system is hard. Its ability to sense, process, and communicate makes it vital for IoT monitoring.

Key functionalities: sensing, processing, and communication.

PCBA does three main jobs: sensing, processing, and communication. Sensors on the PCBA notice changes like gas levels or temperature. Processors study this data, often using AI to spot problems fast. Communication parts send the data to a cloud or central system. For example, a PCBA with an ESP32-S3 chip uses AI and saves power. LoRa modules send data far, making them great for remote areas.

Here’s a simple table of sensor types used in monitoring:

Sensor Type | What It Does | Limits |

|---|---|---|

RGB Cameras | Takes clear pictures for land mapping. | Affected by light and glare. |

Multispectral Cameras | Checks crop health with detailed images. | Costly but very clear. |

Thermal Cameras | Finds heat to spot problems. | Small view and sensitive to shaking. |

LiDAR | Makes 3D maps of land. | Needs training and is expensive. |

Radar Sensors | Tracks object distance and speed in bad weather. | Works well in tough conditions. |

Why industrial-grade PCBAs are critical for environmental monitoring.

Industrial PCBAs are built for tough conditions, making them important. They work in extreme heat, wet places, and with constant shaking. For example, remote sensor networks need strong PCBAs to last long. They also allow systems to grow as needed. Their accuracy helps collect good data for smart decisions. Picking the right PCBA ensures your devices work well, even in hard environments.

Challenges in IoT Environmental Monitoring Applications

Working in tough conditions (heat, moisture, shaking)

Environmental monitoring often happens in rough and changing places. IoT devices may face extreme heat, wet areas, or constant shaking. These tough conditions can harm parts, causing wrong data or broken devices. For example, in oil and gas fields, devices deal with dangerous gases, fumes, and bad weather. They also need special designs to prevent explosions and stay safe.

To solve these problems, industrial PCBA solutions use strong designs. These PCBAs can handle shocks, shaking, and big temperature changes. They also have features like water-resistant coatings and sturdy cases. This helps devices keep working, even in the hardest conditions.

Tip: Use devices with long-lasting batteries in remote or risky areas. This cuts down on repairs and keeps them running longer.

Making sure devices last and work well

IoT devices need to work well for a long time. This is very important in faraway places where fixing them is hard. You can check how strong PCBAs are by looking at certain numbers. These include how long they last, how often they fail, and how they handle stress. These numbers help guess how long devices will work in real life.

For example:

Time to Failure: Shows how long a PCBA works before breaking.

Failure Rate: Tells how often problems happen over time.

Acceleration Factor: Links test results to real-world use to predict strength.

Picking PCBAs with good reliability numbers lowers repair costs and downtime. This ensures your IoT devices give correct data without stopping, even in hard places.

Growing systems for bigger IoT monitoring projects

Scaling up is key when adding more IoT devices. As needs grow, you might need thousands of devices in many places. For instance, researchers have set up over 2,700 sensors to track farming and environmental data. These systems use open-source tools to handle lots of data and fit different uses.

To scale up, choose PCBAs with modular designs. These let you add sensors or communication tools easily. Also, pick service plans that work for both your team and outside users. This makes sure your system can grow, whether you’re checking city air or farm soil.

Note: Scalable systems save money and work better. They combine data from many places, giving a full picture of the environment.

Keeping data correct and reliable.

Good data is key for environmental monitoring to work well. If data is wrong, decisions can be bad, and monitoring fails. IoT devices must always give good data, especially for air, water, or soil checks.

Why Correct and Reliable Data Matters

Accuracy means data is close to the real value. Precision means data stays the same in repeated tests. Both are important for monitoring. For example, an air sensor must find harmful gases correctly and give steady results. Bad or mixed-up data can cause false alarms or missed dangers, risking health and safety.

Tip: Calibrate sensors often to keep them accurate and precise. This helps devices match real-world conditions.

Things That Affect Data Quality

Many things can mess up IoT device data:

Environmental Problems: Dust, wetness, or signals from other devices can confuse sensors.

Worn-Out Sensors: Over time, sensors may stop working as well.

Data Errors: Problems during data transfer can mix up information, especially far away.

Power Issues: Unsteady power can make sensors and processors act up.

How Industrial PCBA Helps Keep Data Good

Industrial PCBAs are made to fix these problems. Here’s how they help:

Better Signal Processing: They use smart tools to remove noise and make data clear.

Strong Sensor Support: They work with sensors that handle tough conditions better. For example, gas sensors with temperature fixes stay accurate.

Error Fixing Tools: PCBAs often have ways to find and fix data mistakes during transfer.

Tough Parts: They use parts that last long and work well over time.

Tips for Keeping Data Right

Follow these steps to get the best data:

Use Extra Sensors: Add more sensors to check data against each other. This avoids trusting bad readings.

Do Regular Maintenance: Check and fix devices often to keep them working well.

Pick Good PCBAs: Use industrial PCBAs with strong records for accuracy. Look for trusted certifications like ISO 9001.

Watch Data Patterns: Study old data to spot strange changes or sensor problems.

Example: Water Monitoring Accuracy

Think of a system checking water pH, clarity, and oxygen. If the PCBA gives wrong data, it might say water is safe when it’s not. A PCBA with good tools for fixing errors ensures the system gives correct data. This helps take action quickly when needed.

Note: Good data helps make better choices and builds trust in systems. People act more on data they know is right.

By focusing on accuracy and precision, your monitoring systems will work better. Industrial PCBAs give the tools to make sure devices provide solid data, even in tough places.

Industrial IoT Solutions for Environmental Monitoring

Strong PCBA design for tough environments

Environmental monitoring happens in hard places like hot, wet, or shaky areas. Devices need strong PCBAs to work well in these conditions. These PCBAs use tough materials and go through special tests to last longer. For example, different PCB materials expand and shrink differently, causing stress. High heat can crack solder or damage layers. It also makes circuits less efficient by increasing resistance.

Strong PCBAs are tested carefully to ensure they last. These tests check how they handle the environment, physical stress, and electrical performance:

Test Type | Examples of Tests |

|---|---|

Environmental Tests | Checks for corrosion, humidity, heat shock, water resistance, and fire safety. |

Physical Tests | Includes vibration, drops, solder strength, and shock resistance. |

Electrical Tests | Tests for circuit performance and proper functioning. |

Using strong PCBAs saves money over time. They last longer, fail less, and work better under stress. For example:

Advantage | What It Means |

|---|---|

Devices last longer before needing replacement. | |

Better reliability | Fewer failures in tough conditions. |

Steady performance | Works well even under stress. |

Fewer early failures | New devices are less likely to break quickly. |

Lower long-term breakdowns | Reduces problems as devices age. |

Choosing strong PCBAs keeps devices working in tough places, like during floods or in smart cities.

Smart sensors for air, water, and soil checks

Sensors are very important for environmental monitoring. Smart sensors make it easier to collect accurate data about air, water, and soil. For example, Brewer Science makes sensors that give real-time data and help follow rules. These sensors improve how well monitoring systems work.

Modern systems use SCADA, IoT, and AI to monitor and report automatically. For instance, XMPro uses digital twins to track air quality. It collects data to find patterns, predict problems, and follow rules. This helps find pollution, manage waste, and keep the environment safe.

Benefits of smart sensors include:

Real-time data for quick decisions.

Better accuracy for finding pollution in air, water, and soil.

Helps follow environmental rules.

Works with IoT for easy data sharing and analysis.

For water checks, smart sensors measure pH, find harmful chemicals, and check clarity. These features are useful for flood monitoring, irrigation, and finding leaks. Using smart sensors ensures accurate and reliable data.

IoT and instant data updates

IoT makes environmental monitoring faster and smarter. Devices share data instantly, giving quick updates and useful insights. This saves time, cuts costs, and improves efficiency. For example:

Improvement Area | Benefit | Source |

|---|---|---|

Efficiency Boost | Deloitte Insights, 2021 | |

Less Downtime | 36% fewer unexpected stops | PwC, 2021 |

Cost Savings | 30-33% lower operational costs | Microsoft IoT Signals Report, 2022 |

IoT also helps systems grow easily. For example, smart meters and irrigation systems use IoT to save water and find leaks. These systems give real-time data, helping you act fast when things change.

PCBAs are key to IoT for good connections and data handling. Industrial PCBAs use tools like LoRa and Wi-Fi for long-distance data sharing. This is great for remote monitoring, like checking water levels or floods.

By using IoT PCBA designs, you can build strong systems for many uses. These include smart cities and farming. These systems collect and process data in real-time, helping solve environmental problems effectively.

Power management for remote and off-grid monitoring systems.

Remote monitoring systems need good power management to work well in faraway places. These systems often face problems like no power sources, tough weather, and the need to run for a long time without fixing. By managing power wisely, your devices can keep working, even in hard conditions.

Why Power Management Matters

Power management is very important because it affects how long devices last and how well they work. Without good energy use, devices might stop working early or give wrong data. For example, a water monitoring system in a farm must always check for bad stuff in water. If power is not steady, it might miss important changes, which could harm crops and nature.

To solve these problems, industrial PCBAs use smart power-saving designs. They include energy-efficient setups, heat control, and strong materials to make devices last longer.

Key Features of Power Management in Industrial PCBAs

Industrial PCBAs for remote systems have special power-saving features. These help devices work well while using less energy. Here’s a simple table of these features:

Feature | What It Does |

|---|---|

Saves energy by reducing power loss. | |

Advanced Thermal Management | Keeps devices cool with special layers and copper parts. |

Durable Materials | Uses strong materials to handle tough conditions. |

Smart Integration | Works with IoT to control and check devices from far away. |

Industry Compliance | Follows safety rules to ensure devices are safe and reliable. |

These features save energy and make devices stronger. For example, heat control stops parts from getting too hot, which can break them.

Power Solutions for Remote Monitoring

Remote systems often use solar panels, wind power, or batteries. To make these power sources work better, try these ideas:

Energy Harvesting: Use solar panels or wind power to run devices. Solar panels work great in sunny places.

Low-Power Components: Pick PCBAs with parts that use less energy.

Battery Optimization: Use long-lasting batteries like lithium-ion ones.

Smart Power Management: Add IoT tools to watch and control energy use. These tools find waste and fix it.

By using these ideas, you can make a strong power plan for your devices. For example, a weather station in a remote area can use solar panels and batteries to keep running, even on cloudy days.

Benefits of Efficient Power Management

Good power management helps in many ways:

Longer Device Life: Parts last longer and don’t wear out fast.

Lower Maintenance Costs: Fewer repairs or battery changes save money.

Better Data Accuracy: Steady power means fewer mistakes in data.

Eco-Friendly: Using solar or wind power helps the planet.

By focusing on power management, your devices will work better and last longer. This saves money and helps the environment, making it a smart choice.

Tip: Check your power systems often to catch problems early. This keeps your devices running smoothly and reliably.

Case Studies: How Industrial Environmental Monitoring PCBA Works

Tracking air quality with IoT systems

Checking air quality is important for keeping people healthy. IoT helps track harmful gases and pollution instantly. Industrial PCBAs are key in these systems. They connect sensors that find carbon dioxide, nitrogen oxides, and dust particles. These sensors gather data and send it to the cloud for study.

For example, cities use IoT air monitors to find polluted areas. These devices have strong PCBAs to handle outdoor heat and moisture. By studying the data, you can act fast to cut pollution and clean the air.

Tip: Place IoT air monitors in schools and hospitals. This keeps the air safer for kids and patients.

Monitoring water quality with smart PCBAs

Checking water quality is vital for safe drinking water and nature. IoT systems with advanced PCBAs make this easier. These systems use sensors to check pH, clarity, and oxygen levels in water.

For example, water plants use PCBAs to watch water quality in real time. They process sensor data and warn workers about problems. This helps find pollution early and fix it fast. In faraway places, solar-powered IoT devices monitor water levels, helping save water.

Note: Keep water monitoring systems in good shape. This makes them work better and last longer.

Watching climate and weather with IoT tools

Climate and weather systems use IoT and PCBAs to collect accurate data. Sensors measure temperature, humidity, and wind speed. This data helps predict weather and prepare for storms or droughts.

For example, remote weather stations use IoT PCBAs to send data far away. These devices use little power and survive tough weather like storms or freezing cold. By studying the data, you can plan better for farming, disasters, or city growth.

Tip: Use IoT weather systems to water crops at the right time. This saves water and helps plants grow.

Choosing the Right PCBA Manufacturer for IoT Environmental Monitoring

Why quality assurance and testing matter.

Picking a PCBA maker for IoT monitoring needs careful thought. Quality checks and testing are very important. Good manufacturers follow strict rules to make sure their products work well. These rules help PCBAs handle tough conditions and give correct data.

Here’s a simple table of key standards:

Standard Type | Why It Matters |

|---|---|

Proprietary Standards | Avoid these; they may not meet industry rules. |

These ensure PCBAs are reliable and high-quality. |

Certified standards like IPC-6012 and ISO 9001:2015 are also important. They make sure PCBAs last long and work well. Check out this table for details:

Standard | What It Ensures |

|---|---|

IPC-6012 | Reliable rigid board manufacturing. |

ISO 9001:2015 | Consistent quality in production. |

RoHS | Limits harmful substances for safer electronics. |

Choosing a manufacturer with these certifications ensures your IoT devices work reliably.

Tip: Check if the manufacturer uses trusted parts and follows global inspection rules.

Checking expertise in industrial-grade PCBA solutions.

Not all PCBA makers can handle tough IoT needs. Look for those with experience in making strong PCBAs for hard conditions. They should know how to work with advanced sensors and IoT systems.

Ask these questions to check their skills:

Have they made IoT PCBAs for environmental monitoring before?

Can they show examples of similar successful projects?

Do they use advanced tests to check durability?

Experienced manufacturers understand challenges like heat, moisture, and shaking. This ensures your devices will work well in tough places.

Why scalability and customization are important.

Your IoT needs might grow, so pick a flexible PCBA maker. They should handle both small and big orders. A good manufacturer can adjust to your changing needs.

Here’s a table of what to consider:

Factor | What It Means | Why It’s Important |

|---|---|---|

Time from order to delivery. | Shorter times avoid delays. | |

Production Volume | Ability to make small or large quantities. | Supports both small and big projects. |

Scalability | Can increase production as needed. | Helps expand without issues. |

Customization is also key. IoT monitoring often needs special designs. A good manufacturer can add unique sensors, communication tools, or power features to fit your needs.

Note: A flexible manufacturer helps your IoT systems grow without losing performance.

Industrial PCBA solutions are crucial for better environmental monitoring. They help devices work well in tough conditions and give correct data. With IoT, these systems share real-time updates to solve environmental issues quickly. For example, eco-friendly manufacturing is becoming popular. Studies predict that by 2033, 20% of PCBs will be made using green methods. This will cut emissions and save resources.

Report Title | Key Findings | Numerical Data |

|---|---|---|

Sustainable Electronics Manufacturing 2023-2033 | Shows eco-friendly PCB production methods | 20% of PCBs to be green by 2033 |

Sustainable Electronics and Semiconductor Manufacturing 2025-2035 | Tracks energy and water use in the industry | Energy use grows 12%, water use grows 8% by 2035 |

Using strong, precise, and flexible PCBA solutions keeps systems effective and eco-friendly. These advances not only boost sustainability but also help make smarter choices for a cleaner Earth.

FAQ

What makes industrial PCBAs different from regular PCBAs?

Industrial PCBAs are made to survive tough conditions like heat and moisture. They use strong materials and go through strict tests to stay reliable. These features make them perfect for monitoring in hard-to-reach places.

Tip: Pick industrial-grade PCBAs for outdoor or faraway monitoring systems.

How do IoT-enabled PCBAs improve environmental monitoring?

IoT-enabled PCBAs help devices gather, study, and share data quickly. This lets you check air, water, and soil conditions better. They also allow remote access, so you can watch changes from anywhere.

Emoji Insight: 🌍 IoT makes monitoring faster and smarter!

Can industrial PCBAs work in remote areas without power?

Yes, they can! Many industrial PCBAs work with solar panels, wind power, or long-lasting batteries. These energy options keep devices running in places without electricity.

Note: Use designs that save energy to make devices last longer.

How do I ensure my PCBA provides accurate data?

Calibrating sensors often is very important. Choose PCBAs with tools to fix errors and process signals well. These features help your devices give correct and steady data.

Pro Tip: Look for PCBAs with certifications like ISO 9001 for better accuracy.

What should I look for in a PCBA manufacturer?

Focus on quality checks, flexibility, and custom designs. Make sure the manufacturer has experience with strong PCBAs and IoT systems. Certifications like IPC-6012 and RoHS are also important.

Reminder: A skilled manufacturer ensures your devices work well in tough places.

See Also

Grasping EMS And PCBA Solutions In Contemporary Electronics

Uses And Advantages Of PCBA In Today’s Electronics

Flex PCBA In Contemporary Electronics: Pros And Cons

Significance Of PCBA Production Skills In Electronics Design

Investigating PCBA Testing Methods For Cutting-Edge Electronics Production