Industrial Ethernet PCB assembly is very important for factories today. These assemblies help Ethernet networks work well and share data easily. About 88% of factories already use industrial Ethernet in their work areas. Strong and efficient PCB designs are now more needed than ever. Fast data transfer is a top goal for 94% of users. This shows why picking the right assembly matters. Comparing products helps you find ones that are reliable and fit your needs.

Key Takeaways

Good performance and reliability are very important for Ethernet PCBs. Pick designs that move data smoothly and last a long time.

Strong PCBs are important. Choose ones tested to handle heat, water, and shaking. This helps them work well in tough places.

PCBs must match Ethernet rules. Pick ones that follow standards like IEEE 802.3 and IEC 61850 for easy use and safety.

Think about the total cost. Spending more on good PCBs now can mean better work and fewer fixes later.

Custom designs and growth options matter for businesses. Choose modular PCBs that can change as needs grow and make systems better.

Key Criteria for Comparing Industrial Ethernet PCB Assembly Products

Performance and Reliability

When choosing industrial Ethernet PCBs, performance and reliability are key. A good PCB helps data move smoothly in your network. Reliable PCBs work well for a long time without problems. These factors affect performance and reliability:

Factor | What It Means |

|---|---|

Extreme heat, cold, or shaking can harm PCB performance. | |

Component Quality | Better parts make the PCB last longer and work better. |

Good assembly methods keep connections strong and signals clear. | |

Design Considerations | Smart layouts improve signal flow and manage heat better. |

To make PCBs more reliable, makers use strong materials like quality copper and substrates. Designs with extra pathways and good heat control help them last longer. Careful testing finds problems early, so your network runs smoothly.

Durability and Environmental Resistance

Industrial Ethernet PCBs need to handle tough conditions. Tests like Environmental Stress Screening (ESS) check if they survive heat, moisture, and shaking. These tests also see if PCBs resist electromagnetic noise, which can disrupt signals.

Strong PCBs often have fanless designs to block dust and water. Other tests, like Electrostatic Discharge (ESD) and vibration tests, prove their toughness. Picking a PCB that passes these tests ensures it works even in hard environments.

Compatibility with Industrial Ethernet Standards

PCBs must follow Ethernet standards to fit into your systems. Important standards include:

Standard | What It Does |

|---|---|

Sets rules for wired networks, making devices work together. | |

IEC 61850 | Helps power stations communicate quickly and reliably. |

IEC 62443 | Focuses on keeping industrial systems safe from cyber threats. |

IEC 60068 | Tests how well PCBs handle tough environmental conditions. |

EN 50155 | Ensures PCBs work well in trains and under stress. |

PoE Standards | Makes sure Ethernet cables can safely send power to devices. |

By following these standards, PCBs ensure smooth communication and better security. This keeps your network reliable and up-to-date with modern protocols.

Cost and Value for Money

Price is important when picking a PCB for your network. You need one that works well but stays within your budget. To find good value, compare the price with the features it offers.

Here are some things to think about:

Material Quality: Strong materials last longer and save money over time.

Assembly Techniques: Better methods mean fewer repairs and more reliability.

Warranty and Support: Long warranties and helpful support give better value.

A good PCB isn’t always the cheapest choice. Spending more at first can mean better performance and fewer replacements later. For example, a high-quality PCB with great parts may last longer and handle tough jobs better.

When looking at prices, check for extra costs like maintenance or upgrades. These can add up over time. A smart way to decide is by calculating the total cost of ownership (TCO) to see the product’s true value.

Tip: Pick a PCB that fits your needs without extra features. This keeps costs low but ensures it works well.

Customization and Scalability Options

Industrial Ethernet networks often need special designs. Customization lets you adjust the PCB to fit your needs. Scalability means the PCB can grow as your business grows.

Important parts of a customizable PCB include:

Flexible Layouts: Changeable designs fit different setups.

Modular Components: Swappable parts make upgrades simple.

Firmware Options: Custom software improves performance for specific tasks.

Scalability is just as important. A scalable PCB lets you add devices or boost data capacity without replacing everything. For example, modular PCBs can handle more work by swapping key parts.

Customization also helps in tricky situations. If your workplace has challenges like extreme heat or signal interference, a custom PCB can solve these problems.

Note: Always talk to the manufacturer about your needs. They can suggest designs that balance customization, scalability, and cost.

Top Industrial Ethernet PCB Assembly Products

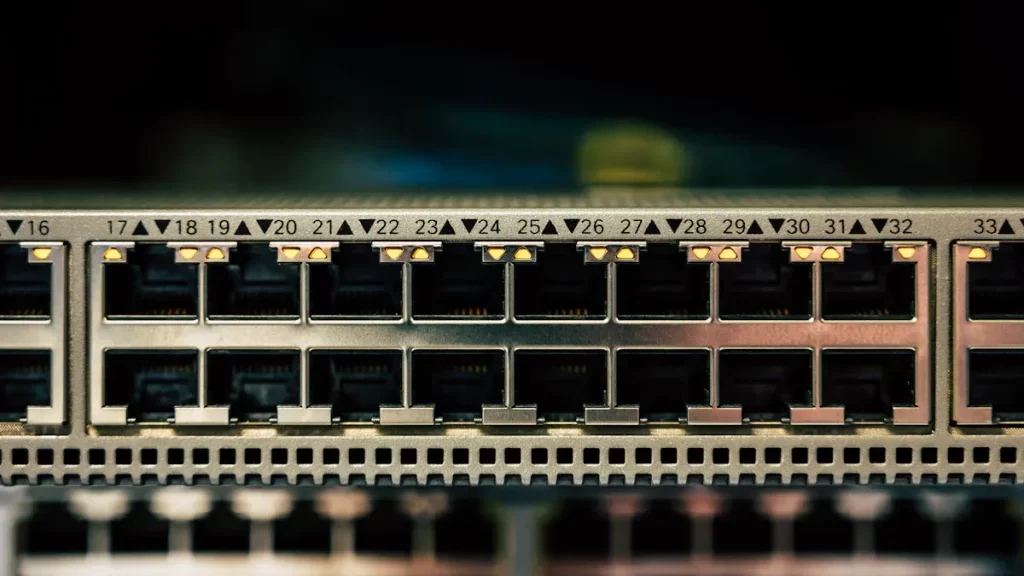

Product 1: EtherNet/IP PCB Assembly

EtherNet/IP PCBs are common in factory automation. They allow fast data transfer, perfect for real-time systems. Their modular design connects easily with many industrial devices. Programmable controllers let you update firmware for new protocols, keeping them future-ready.

These PCBs are reliable and perform well. They use special techniques to block electromagnetic interference, ensuring stable communication in noisy areas. Their tough design handles extreme heat, cold, and vibrations.

A big benefit is their ability to link old systems with new networks. Protocol converters help connect older devices to Ethernet setups. This makes upgrades smooth and hassle-free.

Did You Know? EtherNet/IP is a widely used protocol with many supported devices.

Product 2: PROFINET PCB Assembly

PROFINET PCBs are built for fast and precise communication. They follow strict Ethernet rules, working with many devices. Their modular design allows switching between different protocols easily.

These PCBs are very durable. They pass tough tests to handle electromagnetic interference. Strong connectors and designs make them last in harsh conditions.

PROFINET PCBs are also scalable. You can add devices or increase data capacity as needed. This makes them great for growing factories. Their advanced features ensure top performance and reliability in tough jobs.

Tip: For tasks needing exact timing, PROFINET PCBs are a great pick.

Product 3: Modbus TCP PCB Assembly

Modbus TCP PCBs are simple and effective for Ethernet communication. They are easy to use and cost-friendly, ideal for basic needs.

Their modular design works with other protocols like RS-485 and CAN. This lets you connect different devices in your network. Programmable controllers allow firmware updates for added features.

These PCBs are tough and handle rough environments. They use grounding and shielding to block interference. Their strong design works well in humid or vibrating conditions.

Modbus TCP PCBs are great for control cabinets, which are growing in demand. Their simplicity and flexibility make them useful for many industries.

Fun Fact: Modbus TCP is one of the oldest protocols but still popular for its reliability.

Product 4: EtherCAT PCB Assembly

EtherCAT PCBs are made for fast communication in factories. They work well in tasks needing exact timing, like robots and motion control. Their special design moves data quickly, cutting delays and boosting network speed.

Key Features of EtherCAT PCBs:

Exceptional Speed: These PCBs handle data faster than most others. They are great for jobs where timing is critical.

Compact Design: Their small size fits into tight spaces easily.

Advanced Error Detection: Built-in tools find and fix errors for steady communication.

EtherCAT PCBs are flexible and easy to use. You can add them to current systems without big changes. They grow with your needs, making them perfect for changing workplaces.

To make them better, makers use strong materials and smart assembly methods. These PCBs go through tough tests to ensure they last. They block electromagnetic noise and survive heat, cold, and shaking.

Tip: Choose EtherCAT PCBs if you need fast and accurate data transfer.

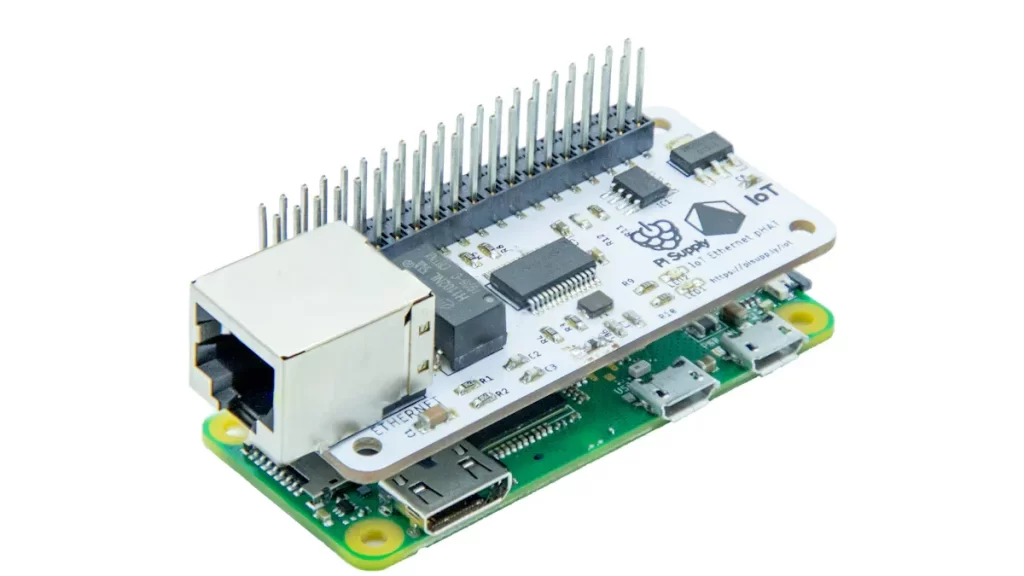

Product 5: Power over Ethernet (PoE) PCB Assembly

PoE PCBs send both power and data through one cable. This clever setup makes networks simpler and cheaper to install. They are used in things like security cameras, Wi-Fi devices, and sensors.

Benefits of PoE PCBs:

Simplified Cabling: One cable for power and data saves time and space.

Cost Efficiency: Combining power and data lowers setup costs.

Enhanced Scalability: Adding new devices is easier with PoE PCBs.

These PCBs are tough and work well in hard conditions. They are built to block electromagnetic noise, keeping signals clear.

PoE PCBs follow many Ethernet rules, so they work with lots of devices. Their modular design makes upgrades simple, keeping your network ready for the future.

Did You Know? PoE can send up to 100 watts of power, enough for LED lights.

Comparing Leading PCB Assembly Service Providers

Provider 1: Jabil Circuit

Jabil Circuit is a top company in PCB assembly. They are experts in modular designs that support multiple protocols like Ethernet, CAN, and RS-485. Their programmable controllers make firmware updates easy, keeping up with new standards.

Jabil focuses on quality with certifications like ISO 9001 for quality management and ISO 14001 for environmental care. They use grounding, shielding, and filtering to reduce electromagnetic interference. Their strong PCBs and connectors work well in tough conditions.

Tip: Choose Jabil Circuit if you want hardware ready for the future.

Provider 2: Sanmina Corporation

Sanmina Corporation is known for its wide range of PCB services. They design PCBs for industries like aerospace, cars, and medical devices. Their protocol conversion solutions connect old systems to modern Ethernet networks.

Sanmina has certifications like AS9100 for aerospace and IATF 16949 for cars, showing they meet strict standards. They test their PCBs to ensure they work with many industrial devices. This keeps your network running smoothly.

Their designs include differential signaling and opto-isolation to block noise. They also test PCBs in extreme heat, humidity, and vibrations to ensure durability.

Did You Know? Sanmina ensures strong signals even in noisy environments.

Provider 3: Benchmark Electronics

Benchmark Electronics offers custom PCB services that are flexible and scalable. Their modular designs allow easy upgrades and expansions. They also create hardware with enough power for future protocol updates.

Benchmark has certifications like ISO 13485 for medical devices and ISO 9001 for quality management. These show their commitment to high-quality PCBs for different industries. They use advanced grounding and shielding to ensure reliable performance.

Benchmark works closely with customers to meet specific needs. They balance cost, performance, and durability in their designs. Their PCBs are tested to handle tough industrial conditions.

Note: Benchmark Electronics is great for custom and scalable solutions.

Certification | Industry Focus | Importance |

|---|---|---|

ISO 9001 | General Quality | Ensures overall quality management |

ISO 14001 | Environmental | Focuses on eco-friendly practices |

IATF 16949 | Automotive | Ensures quality in car manufacturing |

ISO 13485 | Medical Devices | Ensures safety in medical device production |

AS9100 | Aerospace | Ensures quality in aerospace and defense |

These certifications show the providers’ ability to meet various industry needs. When picking a provider, check their certifications to match your requirements.

Provider 4: Flex Ltd.

Flex Ltd. is a top company for PCB assembly services. They create high-quality solutions for industrial Ethernet needs. Their focus on new ideas keeps networks efficient and ready for the future.

Why Pick Flex Ltd.?

Flex designs PCBs for tough jobs in modern industries. Their designs are strong and work well in hard conditions. They use special materials to make PCBs last longer and perform better. Multi-layer designs help signals stay clear and manage heat better.

Flex makes scalable PCBs that grow with your business. Modular designs let you expand networks without replacing old parts. This saves money and time as your needs change. Their PCBs work with many protocols, like Ethernet and CAN, for easy device connections.

Certifications and Testing

Flex has certifications like ISO 9001 and ISO 14001 for quality and eco-friendly practices. They test PCBs to handle heat, shaking, and electromagnetic noise. These tests ensure reliable performance in tough places.

Tip: Flex Ltd. is a great choice for reliable and innovative PCB assembly.

Provider 5: Celestica Inc.

Celestica Inc. is another leading name in PCB assembly services. They focus on quality and custom designs for industries needing special solutions.

Why Choose Celestica?

Celestica makes PCBs that fit your exact needs. Their designs are flexible, so networks can adapt easily. Modular parts make upgrades simple and affordable. You can swap parts to improve performance or add features.

Their PCBs follow strict standards like IEEE 802.3 and IEC 61850. This ensures smooth communication and compatibility with your devices.

Durability and Reliability

Celestica tests PCBs to work in tough conditions. They use strong materials to resist heat, moisture, and shaking. Features like grounding and shielding block electromagnetic noise.

Celestica holds certifications like ISO 13485 and AS9100, showing they meet top industry standards. Their focus on quality ensures long-lasting and reliable PCB performance.

Did You Know? Celestica’s PCBs are popular in aerospace and medical industries for their precision and strength.

Real-World Use Case Scenarios

Use Case 1: Fast Data Transfer in Factories

Factories today need fast data transfer to work smoothly. Industrial Ethernet PCBs help machines share data quickly and reliably. For example, in automated factories, these PCBs allow real-time data sharing. This improves production speed and reduces delays.

These PCBs are built to lower delays and boost data flow. Features like smart signal paths and multi-layer designs make them work better. EtherCAT technology is often used because it handles data quickly with low delays. This keeps networks steady and fast, even in busy factories.

Tip: Pick strong PCBs to handle fast factory systems.

Use Case 2: Tough Work Environments

Some workplaces expose PCBs to heat, water, and shaking. To work well, PCBs must handle these tough conditions.

Important features include IP ratings like IP65 or higher, which block dust and water. For areas needing strong cleaning, IP69K-rated PCBs are best. Shielded cables are also key because they stop signal problems from electromagnetic or radio interference.

Feature | What It Does |

|---|---|

IP Ratings | Protects against dust and water; IP69K for strong cleaning. |

Shielded Cabling | Stops signal issues from interference. |

EtherCAT Technology | Works well in tough spots with great diagnostics. |

Network Reliability | Keeps systems running safely and without interruptions. |

Choosing PCBs with these features ensures your network works well, even in hard environments.

Use Case 3: Big Industrial Automation

Big automation systems need PCBs that handle complex tasks and growth. Industrial Ethernet PCBs built for flexibility and efficiency are ideal.

Protocols like PROFINET and EtherCAT are popular here. PROFINET is great for precise tasks like motion control and process automation. EtherCAT is perfect for robots and fast machines because it processes data quickly with low delays.

Protocol | Popularity | Key Benefits | Uses |

|---|---|---|---|

PROFINET | Most Used | Real-time data, precision, synchronization | Motion control, process automation |

EtherCAT | Growing Fast | Low delays, high precision | Robotics, fast automation |

Factory automation boosts production and lowers costs.

Process automation improves monitoring and makes operations smoother.

Transport systems use real-time data to avoid delays.

Energy grids need reliable communication for smarter systems.

Choose modular PCBs for easy upgrades. This helps your network grow as your business expands.

Use Case 4: Custom Solutions for Special Applications

Some industries need unique PCB designs for specific challenges. Standard options don’t always work. Custom PCBs are made to fit these special needs, helping systems work better in tough environments.

For example, medical devices need safe and reliable PCBs. Custom designs can include small layouts and strong signal isolation for tiny devices. In aerospace, PCBs must handle heat and shaking. Using strong materials and layered designs makes them last longer.

Factories with special machines also benefit from custom PCBs. These designs fit perfectly with unique equipment. Modular parts and programmable controllers make upgrades simple. This keeps systems running smoothly as needs change.

Tip: Share your exact needs with the maker. This helps them design a PCB that works best for you.

Key advantages of custom PCBs:

Precision: Designed to match your exact needs.

Scalability: Easy to expand when needed.

Reliability: Built with strong materials for long use.

Custom PCBs are also great for special uses like underwater robots or high-speed communication. These jobs need designs that resist water or keep signals clear.

Choosing a custom PCB improves system performance and lowers repair costs. A design made just for you ensures better results and reliability over time.

Picking the right industrial Ethernet PCB needs careful thought. Look at things like how well it works, how long it lasts, and how strong it is. These features help your network run smoothly, even in tough conditions. Always choose a product that fits your specific needs. For example, if the environment is harsh, pick PCBs that can handle heat, water, or shaking.

Think about what matters most to you. If speed and performance are key, choose a PCB with advanced tools. If you need to save money, find one that offers good value. Custom PCBs are great for solving special problems. By matching your choice to your needs, you can create a strong and flexible network.

FAQ

What is a PCB, and why does it matter for industrial Ethernet?

A PCB, or printed circuit board, links electronic parts together. It helps devices in industrial Ethernet networks share data smoothly. Its design affects how well it works and lasts.

How can you pick a PCB for tough environments?

Choose PCBs tested to handle heat, water, and shaking. Strong materials and shielding make them more reliable in hard conditions.

Can PCBs be customized for special industrial tasks?

Yes, you can get custom PCBs for unique needs. Ask for modular designs or software tweaks to improve how they work.

Why are modular PCB designs useful?

Modular PCBs are easy to upgrade or expand. You can swap parts or add features without replacing the whole board.

How do certifications improve PCB quality?

Certifications prove that PCBs meet important industry rules. They ensure safety, strength, and that they work well with your devices.