Choosing the right industrial HMI circuit board assembly service is crucial. Small mistakes in assembly can significantly increase costs later on. Problems can escalate from $0.40 to $45 if not addressed early. The service must align with your requirements for quality and expertise. Industries utilizing human-machine interfaces demand precision and adherence to standard regulations. Selecting a service that meets your needs minimizes risks and enhances efficiency.

Key Takeaways

Clearly explain what your project needs. Know the details and how it will be used to pick the best service.

Look for good quality checks. Choose companies with high success rates and proper certifications for dependable results.

Understand the costs. Watch out for hidden charges and compare total prices between companies.

Check how fast they work. Pick a service that meets your deadlines, especially for urgent jobs, without lowering quality.

Focus on helpful customer support. Go with companies that give strong guarantees and clear communication for lasting trust.

Define Your Requirements

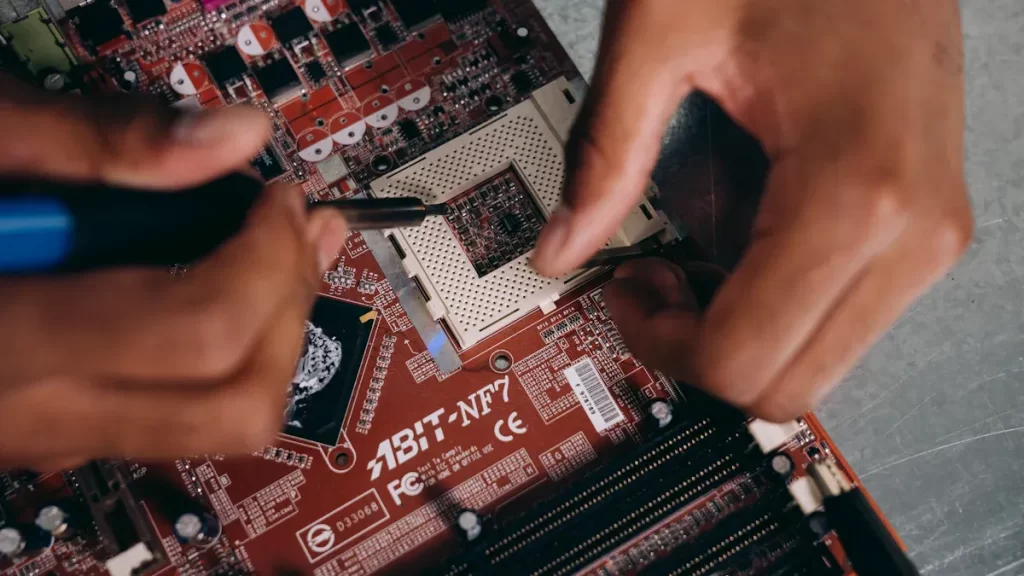

Identify Technical Specifications

The first step is to know what you need. Make sure the design and assembly fit your project’s goals. Important things to check include:

Keeping power schematics organized and in the right place.

Picking trace widths that handle current safely.

Separating analog and digital traces to avoid interference.

Placing ground planes under signal traces to block noise.

Leaving enough space between traces to stop short circuits.

Changing trace directions to lower electromagnetic interference.

Avoiding capacitive coupling for better signal quality.

Adding thermal vias and pads to manage heat.

Managing ground and power traces for steady performance.

Managing heat is very important. If heat isn’t handled well, the board can break or work poorly over time. By focusing on these details, you can create a strong and efficient HMI circuit board.

Understand Application Scenarios

How you use your HMI circuit board matters a lot. Many factories need real-time data and constant monitoring to keep products high-quality.

A good HMI design helps workers do their jobs better. It should work well in different settings. For example, if tasks change often, the interface should be easy to use. The design should also match the workers’ needs and work conditions.

By knowing how you’ll use the board, you can pick a service that fits your specific needs.

Consider Industry Standards and Compliance

Following industry rules ensures your HMI circuit board works well. Look for services that meet these certifications:

ISO9001: Ensures strong quality management systems.

ISO14001: Shows care for the environment.

Also, choose providers with strict quality checks beyond basic inspections. These rules not only meet standards but also make your boards last longer and work better.

By matching your needs with these rules, you can confidently pick a service that meets both legal and work requirements.

Evaluate Industrial HMI Circuit Board Assembly Providers

Check Quality Assurance Steps

Quality checks are key for good industrial HMI circuit boards. Make sure the provider has strong systems to ensure reliable results. Look for proof of their focus on quality. For example, a First-Pass Yield rate of 99.8% means most boards pass inspection the first time. Providers with a Quality Assurance Percentage of 100% aim for zero mistakes in production.

Certifications are also important for quality. Providers with ISO 9001:2015 and ISO 14001:2015 certifications show they follow strict rules for management and the environment. Compliance with RoHS and REACH ensures safe materials are used. Certifications like UL Safety and standards like IPC-A-600 and IPC-A-610 prove they make high-quality boards.

Here’s a summary of key metrics:

Metric | Value |

|---|---|

First-Pass Yield | 99.8% |

Quality Assurance Percentage | 100% |

ISO 9001:2015 Certification | Yes |

ISO 14001:2015 Certification | Yes |

RoHS Compliance | Yes |

REACH Compliance | Yes |

UL Safety Certification | Yes |

IPC-A-600 Standards | Yes |

IPC-A-610 Standards | Yes |

Choose providers who meet or exceed these standards. This ensures your HMI circuit board works well in tough conditions.

Confirm Certifications and Experience

Certifications and experience are vital for picking the right service. Providers with ISO 9001 and ISO 14001 certifications follow global rules for quality and sustainability. These certifications show they have systems to keep standards high.

Experience in industrial HMI circuit board assembly adds trust. Providers with years of work in this field know the challenges of your industry. They can spot problems early and offer solutions that fit your needs. For example, experienced providers handle tricky designs, connect parts smoothly, and meet tight deadlines.

Ask about their past work in your industry. Providers with a record of delivering high-quality PCB assembly for similar projects are more likely to meet your needs. Their knowledge of industry rules ensures good performance and compliance.

Look at Reviews and Case Studies

Customer reviews help you learn about a provider’s reliability. Look for comments about their pcb board assembly, like accuracy, durability, and meeting deadlines. Positive reviews show they deliver the best HMI solutions.

Case studies give real examples of their skills. These stories explain how they solved problems. For instance, a case study might show how they improved heat control or reduced signal interference. These examples prove their technical knowledge and focus on quality.

Pay attention to common themes in reviews and case studies. Praise for quality, communication, and support shows a provider you can trust. Complaints about delays or poor work should be a warning.

Tip: Talk to past clients if you can. Direct feedback gives a clearer idea of the provider’s strengths and weaknesses.

Compare Costs and Turnaround Times

Understand Pricing and Hidden Fees

Knowing how pricing works is very important. Look at both upfront costs and the Total Cost of Ownership (TCO). TCO includes all costs, like buying, using, and maintaining the product. This helps you find hidden fees, such as maintenance or disposal costs.

Watch out for these hidden fees:

Fulfillment fees, which can be 25-35% of each order.

Extra charges for onboarding, storage, or delivery zones.

Higher costs for faster services or special customizations.

By knowing the full cost, you can compare providers better. Some may seem cheaper at first but have hidden fees that add up. Always ask for a detailed cost list to avoid surprises.

PCB assembly pricing can differ a lot. Some providers include all services in one price. Others charge for each step separately. A full cost review helps you pick a service that fits your budget and needs.

Check Production and Delivery Times

How fast a provider works is very important. Quick production means you can launch your product faster. But not all providers work at the same speed. Here’s a quick look at typical delivery times:

PCB Type | Turnaround Time |

|---|---|

Simple 2-layer | Same day |

8-layer board | 3-5 days |

Quick-turn PCB | 5-10 working days |

Traditional cycle | Weeks to months |

If you need fast results, quick-turn PCB services are best. They focus on speed without lowering quality. For less urgent or complex projects, traditional cycles may work better. Always check if the provider can meet your deadlines, especially for big orders.

Also, ask about their ability to handle delays. Providers with good systems and automation often deliver faster. Reliable providers will have backup plans for unexpected problems.

Tips for Saving Money

Negotiating can help you save money on PCB assembly. Here are some tips:

Ask for discounts when ordering in large amounts.

Get better payment terms to manage your budget.

Request guarantees to avoid paying for rework.

Advanced methods like cost analysis can also help. For example:

Cost-Regression Analysis: Finds areas where you can save by renegotiating.

Factor-Cost Analysis: Looks at cost details to improve deals with suppliers.

Strategy | Description |

|---|---|

Cost-Regression Analysis | Finds savings by studying cost patterns and renegotiating. |

Factor-Cost Analysis | Breaks down costs to improve supplier deals. |

Effective Supplier Negotiations | Uses research and planning to get better contract terms. |

Not negotiating can cost you a lot. Studies show businesses lose 63.3% of income when they skip negotiations. This shows why it’s important to negotiate for better deals.

When negotiating, aim for a long-term partnership. Good relationships with providers can lead to lower prices and better service. Always go into talks with clear goals and a strong understanding of your needs.

Check Reliability and Support

Why Good Customer Service and Communication Matter

Good customer service and clear communication are very important. Pick a provider who cares about quality at every step. They should make sure their work meets high standards. This directly affects how well your final product works.

Here’s what to look for:

Using automation reduces mistakes and makes work more consistent.

Well-trained workers handle automated tools and screens easily.

Quality checks, like measuring during work and tracking data, ensure good results.

A provider with clear updates will keep you informed. They should quickly fix problems and answer questions. This openness builds trust and keeps your project on schedule.

Look at Warranty and Support After Assembly

Warranties and support show how much a provider values quality. Choose one that offers strong warranties to cover unexpected costs. This protects you if something goes wrong.

Other things to check include:

How often problems are fixed remotely to save time.

How quickly they solve issues to avoid long delays.

Providers with remote monitoring can spot problems early. They also offer maintenance to prevent breakdowns. This keeps your circuit boards working longer.

Think About Long-Term Partnerships

A good provider should be more than just a seller. They should work with you to improve processes and cut costs. They should also help keep quality steady as your business grows.

Signs of a strong partnership include:

Knowing how to design for easier and faster production.

Being flexible to meet changing needs and share resources.

Creating a positive working relationship that benefits both sides.

To avoid supply problems, pick providers who plan for future parts needs. They should also give you all design files for easy updates later.

By focusing on these points, you can find a partner who helps your business grow and keeps your circuit boards reliable.

Make a Smart Choice

Focus on Key Factors

To pick the best service, look at key points. First, check the provider’s quality checks. High first-pass yield rates and ISO 9001 show they care about quality. Next, think about their experience with industrial HMI circuit board assembly. Experienced providers can give solutions that fit your needs.

Cost and speed are also important. Choose providers with clear pricing and no hidden fees. Quick-turn services are great for urgent jobs, while slower cycles work for less rushed tasks. Lastly, check their reliability. Good customer support, strong warranties, and post-assembly help ensure your boards work well for a long time.

Match the Service to Your Industry

The service you choose should fit your industry’s needs. For example, if accuracy is very important, pick a provider with advanced tools. The table below shows how different alignment tools improve performance:

Alignment Tool | Performance Boost | What It Does |

|---|---|---|

X-Series Laser Shaft Alignment | Less need for rough alignment | Uses dual beams for better precision. |

AT-300 Digital Line Laser | Better machine alignment | Shim Simulator shows shim effects instantly. |

XT950 Bore Alignment System | Accurate straightness checks | Measures bore sizes for engines and gearboxes with high accuracy. |

By matching the provider’s tools to your needs, you can make sure your HMI circuit boards work well in tough conditions.

Steps to Seal the Deal

Once you find the right provider, follow these steps to finalize:

Check the Contract Carefully: Make sure costs, timelines, and warranties are clear.

Ask for Long-Term Perks: Talk about bulk discounts, flexible payments, and quality guarantees.

Get Design Files: Ask for all design documents and codes for future updates.

Plan Communication: Set up regular updates and ways to solve problems quickly.

These steps help create a smooth working relationship. A good agreement saves money and ensures high-quality boards that meet your needs.

Doing good research is very important when picking an industrial HMI circuit board assembly service. By checking providers carefully, you can avoid problems and get better results for your projects.

Main things to think about include:

Quality: Check for certifications and strong quality checks.

Cost: Learn about pricing and watch out for hidden charges.

Technical Capabilities: Make sure they can handle your specific needs.

Turnaround Time: Pick a service that meets your schedule.

Reliability: Choose providers with great support and solid warranties.

🛠️ Tip: Match the service to your industry’s special needs. This helps your HMI circuit boards work well in tough conditions.

By focusing on these points, you can choose wisely and help your industrial projects succeed.

FAQ

Why is picking the right PCB assembly service important for HMI?

Choosing the right service keeps your HMI working well. A reliable provider makes high-quality boards that follow industry rules. This prevents problems like broken circuits or keypad issues, saving time and money.

How can you check if the provider meets your needs?

Look at their certifications, skills, and quality checks. See if they focus on HMI designs and can handle tricky layouts. Ask for examples of past work to prove their experience.

What affects the cost of PCB assembly services?

Costs depend on how complex the design is, materials used, and order size. Extra fees like faster delivery or special designs can add up. Always ask for a full price list to avoid surprises.

How do fast turnaround times help urgent projects?

Quick production keeps your project on track. Providers with fast prototyping and production help meet deadlines without lowering quality. Good communication also avoids delays.

Why is support after assembly important for long-term use?

Warranties and maintenance keep your boards working longer. Providers with remote monitoring and quick fixes stop problems early. This ensures your HMI stays reliable and efficient over time.