Printed Circuit Board (PCB) assembly is crucial for industrial IoT PCB assembly. It ensures that IoT devices function effectively by meticulously integrating components. This careful assembly enables devices to communicate seamlessly and conserve energy. Additionally, PCBs facilitate compact designs, allowing IoT devices to fit into tight spaces while maintaining optimal performance.

PCB assembly is essential for the advancement and enhancement of IoT devices. These devices require wireless communication and energy-efficient components to operate efficiently in industrial settings. As industrial IoT continues to gain traction globally, improved PCB assembly will pave the way for innovative solutions and superior devices.

Key Takeaways

PCB assembly is key to making IoT devices work well. It connects parts and helps them communicate.

Smaller PCB designs make devices compact and efficient. This helps them fit in small spaces in industries.

Good power management in PCB assembly saves energy. This makes batteries last longer and lowers costs.

Strong testing and smart design make devices reliable. They work well even in tough industrial conditions.

Designers and manufacturers working together improve PCB assembly. This leads to better quality and faster production.

What Is PCB Assembly and Its Importance to IoT?

What PCB assembly means and how it works

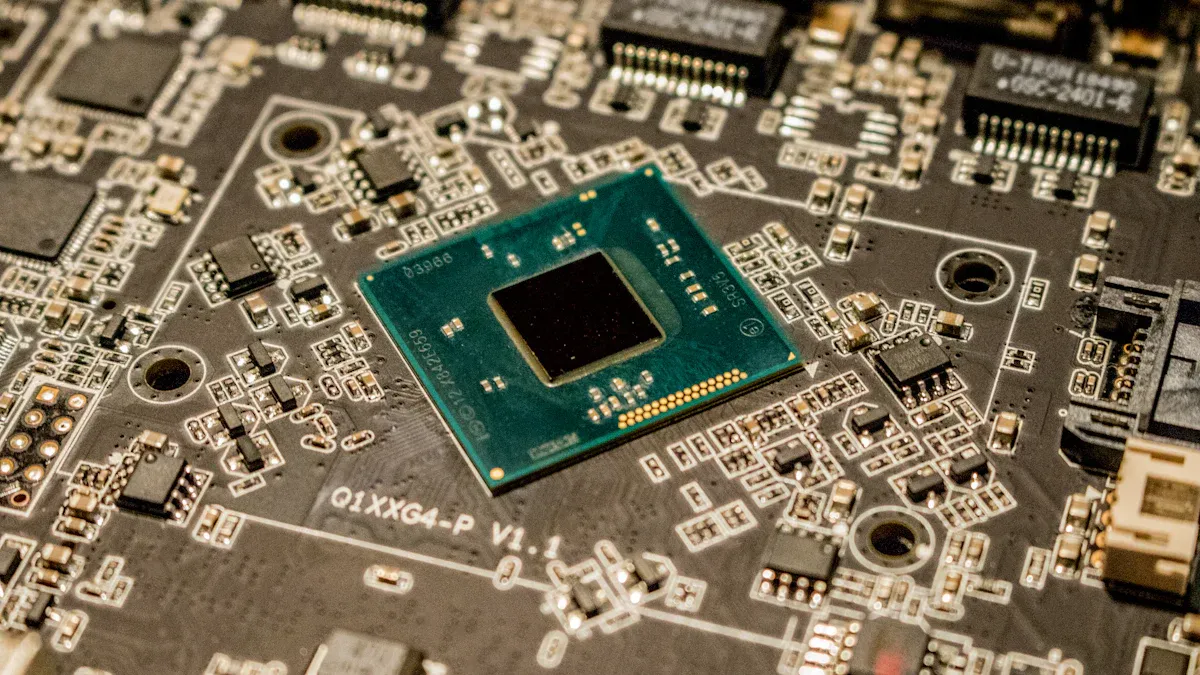

PCB assembly is the process of putting electronic parts on a printed circuit board (PCB) to make a working device. It acts like the backbone of modern gadgets, helping them do their jobs. The process has a few main steps:

Solder paste application: A thin paste is spread on the PCB pads using a stencil.

Component placement: Parts like resistors and chips are placed on the paste by machines or by hand.

Reflow soldering: The board is heated so the paste melts and connects the parts.

Inspection and testing: The finished board is checked to make sure it works well.

These steps help IoT devices stay connected, save power, and handle tough conditions. Rules like IPC-A-610 set the quality standards needed for industrial IoT use.

How PCB assembly helps IoT devices work

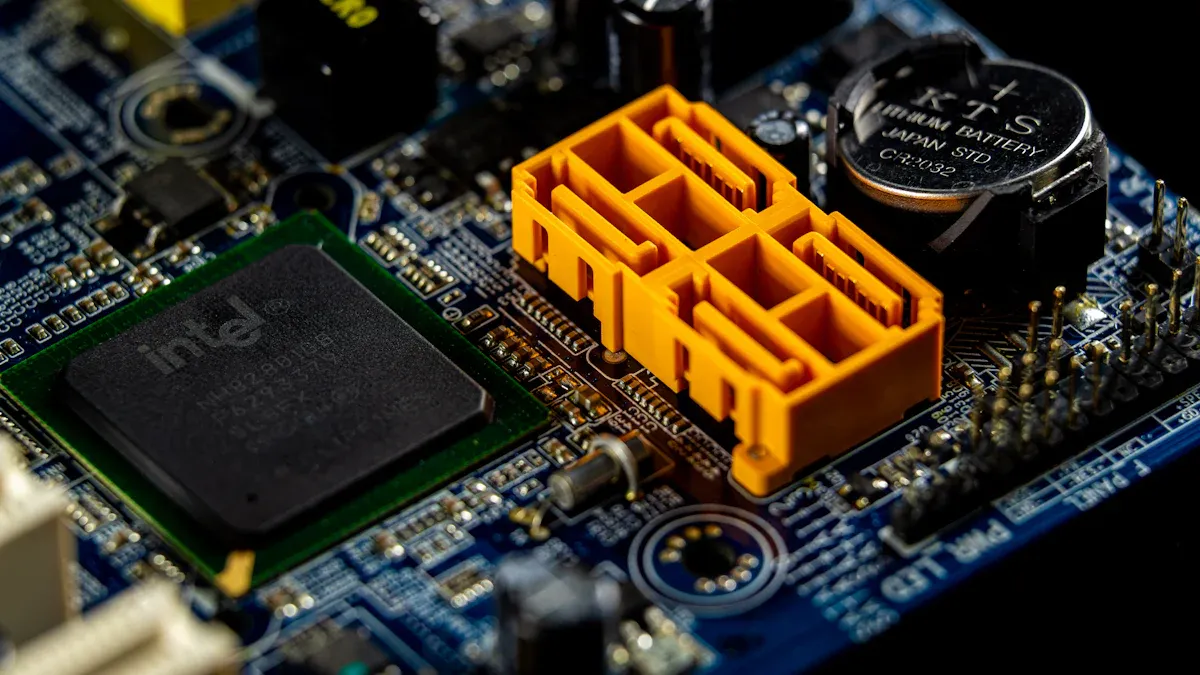

PCB assembly is key to making IoT devices work smoothly. It links parts together so they can share data and communicate. For example, connections using Bluetooth, Zigbee, or WiFi need well-made PCBs. Small designs, made with advanced methods, keep IoT devices tiny but still powerful.

Managing power is also very important. IoT PCBs are designed to save energy, which helps devices like fitness trackers last longer. Careful checks make sure the devices are strong and can handle hard tasks.

Why IoT PCB assembly matters in industries

IoT PCB assembly is even more important in factories and industrial areas. These devices often face tough conditions like high heat, moisture, or strong interference. For example, industrial IoT gateways use strong PCBs with special coatings to stay reliable.

It also helps industries grow by making it easier to produce many devices. Using smart tools and good design methods, manufacturers make PCBs that are strong and efficient. This makes IoT PCB assembly a must-have for industries wanting to use IoT on a big scale.

Key Contributions of Industrial IoT PCB Assembly

Miniaturization for compact and efficient designs

Making things smaller is important in industrial IoT PCB assembly. It helps create tiny devices that still work well. By shrinking parts and arranging them smartly, more features fit into small spaces. This is crucial in industries like cars and planes, where space and weight matter a lot.

Smaller PCBs have many advantages:

They are stronger and less likely to break.

They can do more tasks in a smaller size.

They save space, making gadgets easier to carry.

They weigh less, which is great for moving devices.

They cost less to make because they use fewer materials.

By focusing on making PCBs smaller, you can build IoT devices that are tiny, useful, and affordable. This makes them perfect for factories where space and strength are very important.

Power management for energy-efficient operations

Good power use is key for IoT devices to save energy. Industrial IoT PCB assembly uses smart ways to make devices last longer without needing frequent charging.

New power-saving tools, like the MIPI I3C, help a lot:

The MIPI I3C uses much less energy than older methods.

It moves data fast while keeping power use low.

It lets devices rest in low-power modes when not in use.

Adding energy management systems (EPMS) to IoT devices helps even more. These systems use AI to watch energy use and predict problems. This keeps devices running smoothly and saves energy.

By focusing on power-saving in PCB assembly, you can make IoT devices that use less energy and work better. This lowers costs and helps the environment.

Reliability in harsh industrial conditions

Factories can be tough places for IoT devices, with heat, moisture, and stress. To make sure devices last, industrial IoT PCB assembly includes strong testing and smart designs.

Tests for reliability include:

Thermal Cycling Tests: Check how PCBs handle changing temperatures.

Environmental Stress Testing: Test durability under real-life conditions.

HAST Tests: Ensure PCBs stay strong in tough environments.

These tests make sure IoT devices are safe and work well. Strong PCBs stop breakdowns, cut repair costs, and last longer. This is very important in industries like medicine, cars, and planes, where safety matters most.

By focusing on strength, you can make IoT devices that work well even in hard conditions. This makes industrial IoT PCB assembly a key part of modern factories.

Signal integrity for smooth communication

Signal integrity is key for IoT devices to work well. In factories, devices face high-frequency noise and tough conditions. Keeping communication smooth is very important. Bad signal integrity can cause data loss or device issues. Using good PCB assembly methods can fix these problems.

The PCB layout design is crucial for signal integrity. A smart layout reduces interference and helps signals move easily. Follow these tips to avoid common signal problems:

Use fewer vias to keep signals strong.

Keep fast and slow signals apart to stop interference.

Reference planes are also very helpful. Connecting signal layers to a clear reference plane gives signals a good path back. This lowers noise and improves communication. Large planar capacitance reduces AC impedance at high frequencies. This keeps signals steady. Routing fast signals between planes cuts electromagnetic radiation, which is vital in factories.

Advanced tools help keep signal integrity strong. For example, time-domain modeling checks how your PCB handles frequencies. Checking common-mode current shows how interference might affect devices. These tools help find and fix problems early.

By using these methods, IoT devices can communicate well, even in tough places. Strong signal integrity improves performance and helps IoT grow in industries.

Challenges in IoT PCB Assembly for Industrial Applications

Managing high component density in compact designs

Industrial IoT devices need small designs to fit tight spaces. But packing many parts into small areas can cause problems. Too many components can lead to overheating or poor performance. Careful placement of parts is needed to avoid these issues.

Here are ways to solve these problems:

Use fans to move air and lower heat.

Apply copper layers to spread heat away from hot spots.

Place heat-making parts apart to stop overheating.

These methods help IoT devices work well and last longer. This is very important in factories, where devices must handle tough conditions.

Ensuring signal integrity in high-frequency environments

Good signals are needed for IoT devices to share data. In factories, high-frequency noise can cause signal problems. Bad signals can lead to errors or device failure. To fix this, you must stop issues like reflection and crosstalk.

The table below shows key signal problems:

Signal Problem | What It Does |

|---|---|

Reflection | Causes signal loss due to mismatched paths. |

Crosstalk | Creates noise from nearby lines, causing errors. |

Delay | Slows signals, messing up timing. |

Impedance Matching | Keeps signals strong and reduces loss. |

To keep signals clear, use smart PCB designs. Avoid sharp angles, use fewer vias, and separate fast and slow signals. These steps help IoT devices communicate well in busy factory settings.

Addressing thermal management in industrial settings

Managing heat is very important for IoT devices in factories. Too much heat can damage parts and cause failures. Cooling systems are needed to keep devices working well.

Here are ways to manage heat:

Use heat sinks and fans to cool parts.

Add copper layers to move heat away.

Spread out heat-making parts to stop hot spots.

Hot spots happen in circuits with lots of power or parts. Fixing these hot spots helps devices last longer. Good heat control makes IoT devices stronger and more reliable. This is very important in factories, where devices work nonstop in tough conditions.

By learning how heat affects PCBs, you can make better designs. This helps IoT devices stay strong and work well in factories.

Overcoming supply chain challenges for specialized components

The supply chain for specialized components in industrial IoT PCB assembly has unique problems. These issues come from the growing complexity of IoT devices and the need for custom designs. If you work on IoT devices, you must solve these problems to meet performance and reliability goals.

One big challenge is making devices smaller. IoT gadgets are shrinking, which makes it harder to fit parts on PCBs. Finding parts that are both small and functional can be tough. Also, adding wireless features like antennas and transceivers makes things more complicated. This increases pressure on the supply chain.

Tip: Work with suppliers who focus on small and wireless parts to solve these problems.

Customization adds more challenges to the supply chain. Industrial IoT devices often need parts designed for specific conditions, like high heat or moisture. Finding these special parts can take time and cost more. You need to team up with suppliers to get these parts without slowing down production.

Global supply chain problems make things worse. Events like COVID-19 have shown the need for strong supply chain plans. Here are some reasons for supply chain struggles:

Custom parts are harder to find and take longer to get.

Wireless features need extra components, adding complexity.

To fix these problems, you need to plan ahead. Create a good supply chain strategy. This means managing part details and improving sourcing methods. Keeping your Bill of Materials (BOM) updated is also very important. By checking the BOM often, you can spot part shortages early and adjust your designs.

Follow these steps to handle supply chain issues:

Check your BOM often to find sourcing problems early.

Build strong ties with many suppliers to avoid relying on one.

Use smart tools to predict demand and manage inventory better.

By using these strategies, you can avoid delays and keep a steady flow of parts. This will make your PCB assembly process smoother and improve the reliability of your IoT devices.

Note: Keep up with market trends and new tech to stay ahead in solving supply chain problems.

Innovations and Best Practices in IoT PCB Assembly

Advanced manufacturing techniques for precision

Precision is very important for IoT devices to work well. New assembly methods help place parts exactly where they belong. This improves how IoT systems perform. Automation and surface mount technology (SMT) are great tools for this. Automation makes production faster and reduces mistakes. SMT helps fit more parts into smaller spaces.

Other methods, like lean manufacturing and poka-yoke, also help. Lean manufacturing cuts down waste and improves processes. Poka-yoke uses smart ways to stop errors during assembly. Reflow soldering is another helpful method. It melts solder paste carefully to make strong connections.

The table below shows some useful techniques:

Technique | What It Does |

|---|---|

Automation | Uses machines to improve accuracy and speed in PCB assembly. |

Lean Manufacturing | Reduces waste and makes processes better for higher precision. |

Poka-Yoke | Stops mistakes by using error-proofing methods during production. |

Fits more parts into small spaces and improves electrical performance. |

Using these advanced methods helps make IoT devices that are reliable and work well.

Quality control measures for reliability

Testing is key to making sure IoT PCBs are reliable. Following rules like IPC-A-610 and IPC-2221 keeps quality high. These rules help manufacturers make strong and long-lasting PCBs.

Tools like automated optical inspection (AOI) and in-circuit testing (ICT) are very useful. AOI uses cameras to find problems early. ICT checks if each part works correctly. Functional testing goes further by testing the PCB in real-life situations.

Here are some tips to improve reliability:

Train your team often to stay updated on new rules.

Keep good records for audits and reviews.

Work with groups like IPC to follow the latest standards.

By using these steps, you can make IoT devices that work well in tough environments.

Role of IoT PCB manufacturers in driving innovation

IoT PCB manufacturers do more than just make PCBs. They help create new ideas and better designs. For example, they make flexible PCBs for wearables and special PCBs for 5G networks.

The table below shows trends and their effects:

Trend/Impact | What It Means |

|---|---|

Advanced PCBs | Help IoT devices handle complex tasks in many industries. |

Automation | Speeds up production, lowers costs, and improves quality. |

IoT Growth | Increases the need for PCBs that handle more data and connections. |

Flexible PCBs | Important for small devices like wearables that need to bend or fold. |

5G Technology | Needs special PCBs for fast wireless communication and data transfer. |

By working with manufacturers, you can use these new ideas to make better IoT devices. Their skills in modern assembly methods keep your devices ahead in a fast-changing market.

Working Together for Better IoT PCB Solutions

When designers and manufacturers work together, they make better IoT PCBs. This teamwork ensures designs match what factories can produce. It also helps avoid mistakes and delays during assembly.

One important area is Design for Manufacturability (DFM). Sharing design ideas early lets manufacturers suggest helpful changes. For example, they might adjust part placement to make assembly easier. These changes save time, cut costs, and keep quality high.

Another key area is data-based improvements. Manufacturers use data to track how production is going. Sharing this data with designers helps find problems and fix them. This makes IoT devices work better and reduces errors.

Tip: Talk often with your manufacturing team to solve issues early.

Here are two companies that succeeded by working closely together:

Company | Focus Area | Results |

|---|---|---|

Company D | Design for Manufacturability (DFM) | Faster production, lower costs, better quality, quicker market launch |

Company E | Data sharing and improvements | Faster processes, fewer defects, happier customers, better efficiency |

These examples show how teamwork leads to success. Involving manufacturers early makes production smoother and devices more reliable. This partnership improves quality and helps meet market needs quickly.

By working together, you can improve your PCB process and stay ahead in the IoT industry.

PCB assembly helps IoT devices work by connecting sensors, power circuits, and wireless parts. It makes designs small and efficient. This allows devices to talk to each other easily and stay strong in tough places like factories. Fixing problems like heat control and signal issues makes IoT devices more reliable.

Using new ideas like bendable circuit boards and smart building methods helps make special designs for different uses. These ideas save money and improve how devices work. As IoT grows bigger, PCB assembly will help create smarter and better-connected systems for industries.

FAQ

What does a PCB do in IoT devices?

A PCB links all parts in IoT devices, helping them work. It spreads power evenly and supports wireless tech like WiFi or Bluetooth. Without a PCB, IoT devices can’t do their jobs properly.

How does PCB assembly make industrial IoT devices stronger?

PCB assembly uses tough materials and smart methods to improve strength. It helps parts survive heat, moisture, and shaking in factories. Good assembly lowers failures and makes devices last longer.

Why is good signal quality important in IoT PCBs?

Good signals help IoT devices share data smoothly. Bad signals can cause errors or lost data. A smart PCB design stops interference, keeps signals strong, and helps devices talk easily in factories.

What problems happen with small PCB designs for IoT?

Small designs can overheat or have signal problems. Crowded parts need careful placement and cooling systems. New methods solve these issues, making IoT devices work well and stay reliable.

How do makers check PCB quality for IoT use?

Makers use machines like AOI and ICT to check PCBs. They follow strict rules like IPC-A-610 to keep quality high. Regular tests make sure PCBs work well in tough factory conditions.

See Also

Exploring The Processes Behind PCBA Manufacturing And Assembly

Essential Strategies For Enhancing PCB Assembly Productivity

Key Uses And Advantages Of PCBA In Today’s Electronics