In factories, choosing industrial network interface boards requires good performance and low cost. These boards facilitate communication between machines, ensuring they work efficiently. Fast and reliable connections are crucial, especially in environments like data centers, which demand smooth and uninterrupted data movement. The market for industrial network interface boards is expanding rapidly, projected to grow from $5.1 billion in 2023 to $10.8 billion by 2032. There is an increasing demand for cost-effective yet high-performing boards. Additionally, automation systems utilize these boards for IoT devices and robots, which have experienced a growth rate of 13% annually since 2018.

Key Takeaways

Industrial network boards help machines talk to each other easily. This keeps factories and data centers running smoothly.

Picking the right board means balancing price and performance. Think about speed, dependability, and how well it can grow with your system.

Boards with modular designs are easy to upgrade. They are great for businesses that want to expand later.

Choose boards that work with many protocols. This makes it easier to connect different devices and keeps systems working together.

Good-quality boards might cost more at first. But they save money over time with fewer repairs and better reliability.

Understanding Industrial Network Interface Boards

Purpose and Functionality in Industrial Systems

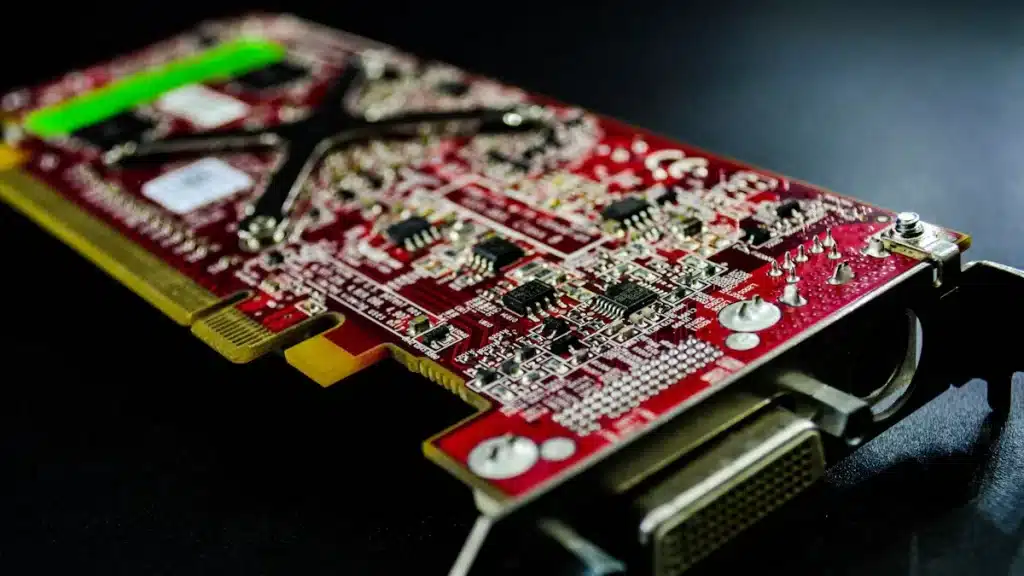

Industrial network interface boards help machines talk to each other. They act like bridges, making sure data moves smoothly between devices. These boards do important jobs like changing signals, adjusting voltage, and converting protocols. Signal translation changes signals from analog to digital so devices can understand. Voltage level shifting helps devices with different voltages work together. Protocol conversion lets devices using different systems communicate easily.

These boards also protect machines from electrical problems like noise or voltage spikes. They allow systems to grow by adding more devices or features. Customization is another benefit, letting boards be designed for specific tasks like running robots or special equipment.

Functionality | Description |

|---|---|

Signal Translation | Changes signals, like turning analog into digital. |

Voltage Level Shifting | Helps devices with different voltages work together. |

Connector Adaptation | Matches connectors so devices can connect easily. |

Protocol Conversion | Lets devices with different systems share data. |

Isolation and Protection | Protects machines from electrical noise or voltage spikes. |

Expansion and Integration | Adds more devices or features to a system. |

Customization | Designs boards for specific tasks, like automation or special tools. |

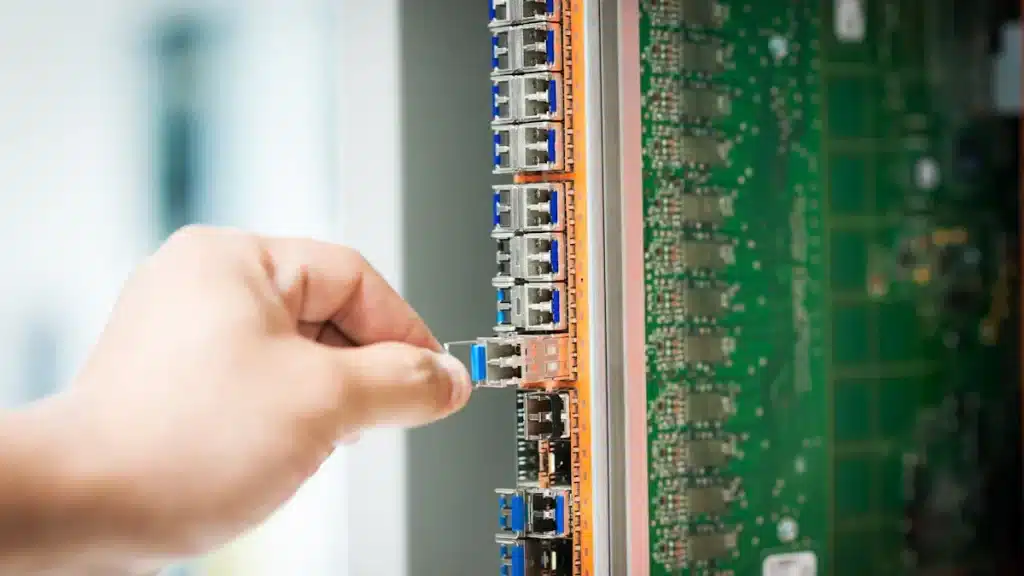

Importance in Data Centers and Automation

In data centers, these boards move data quickly and reliably. They are important for cloud computing and high-speed tasks. For automation, they help IoT devices and robots work better together. These boards are tough and work well in harsh conditions, making them essential for many industries.

Types of Industrial Network Interface Boards

There are different types of industrial network interface boards. Ethernet NICs are used for wired connections, offering speeds like 5-Base T, 10-Base T, and Gigabit Ethernet. Wireless NICs are for wireless setups, giving flexibility in networks.

By use, these boards work with devices like firewalls, hubs, and routers. They are also grouped by users, such as data centers or telecom companies. Boards are even made for specific regions, like North America or Europe.

Category | Types/Applications |

|---|---|

By Type | Ethernet NICs, Wireless NICs |

- 5-Base T, 10-Base T, 100-Base T, Gigabit Ethernet | |

By Application | Wireless Communication Devices, Wired Communication Devices |

- Firewalls, Bridges, Repeaters, Hubs, Switches, Routers, Telephones | |

By End User | Data Centers, Networking Service Providers, Telecom Operators, Enterprises/Corporates, Others |

By Region | North America, Latin America, East Asia, South Asia & Pacific, Western Europe, Eastern Europe, Central Asia, Russia & Belarus, Balkan & Baltic Countries, Middle East and Africa |

Evaluating Performance Metrics

Speed and Data Transfer Rates

Speed is very important for network boards to work well. Faster speeds help devices share data smoothly in busy places like data centers. You can check speed using these simple measures:

Metric | Description |

|---|---|

The most data a network can send in a time, measured in bps or Mbps. | |

Latency | The delay in sending data; lower is better. |

Round Trip Time (RTT) | Time for data to go to the receiver and back; shorter is better. |

Download Speed | How fast data is downloaded, measured in Mbps; higher is better. |

Upload Speed | How fast data is uploaded, measured in Mbps; higher is better. |

Packet Loss Rate (PLR) | Percent of lost data packets; high rates mean slower speeds. |

Bandwidth shows how much data can move at once. Low latency is also key for real-time tasks. Packet loss, though often ignored, can hurt performance a lot.

To get fast connections, boards need flexible designs. They should support different systems like Ethernet and RS-485. Programmable controllers also help by allowing updates for new systems.

Latency and Real-Time Communication

Latency means the time it takes to send data. Keeping it low is important for real-time tasks like robots and IoT devices. Different systems have different speeds:

Protocol | Sampling Rate | Processing Time |

|---|---|---|

Highest | Shortest | |

OPC-UA | Moderate | Moderate |

Ethernet/IP | Lowest | Longest |

Modbus is the fastest for quick tasks. Ethernet/IP is slower and not great for time-sensitive jobs. OPC-UA is a good middle option for many uses.

Testing is needed to make sure boards work with other devices. Using special techniques like differential signaling reduces noise and keeps latency low.

Reliability in Harsh Environments

Reliability means the boards work well even in tough places. They must handle heat, moisture, and shaking without breaking.

Strong hardware designs help boards last longer and stay reliable. Tough connectors and strong PCBs make them good for hard conditions.

Electromagnetic interference (EMI) can cause problems. To stop this, designers use grounding, shielding, and filters. Testing ensures the boards work well even in bad conditions.

By focusing on reliability, boards can keep working fast and steady, even in the hardest environments.

Compatibility with Industrial Protocols

Industrial network boards must work well with different protocols. This ensures devices can communicate without problems. When checking compatibility, think about conditions, data safety, and your system’s needs.

Protocols like Modbus, Ethernet/IP, and OPC-UA are common in factories. Each has its own benefits. Modbus is simple and great for basic tasks. Ethernet/IP is fast, perfect for handling lots of data. OPC-UA is flexible and supports features like encryption and cross-platform use.

Here’s a simple table to explain key factors:

Factor | Description |

|---|---|

Operating Conditions | Protocols must handle tough conditions like heat, shaking, and moisture. |

Packet Loss Rate | Some protocols reduce data loss, which is vital for important tasks. |

Throughput | Simple tasks need less data speed; big tasks need more. |

Real-time/Deterministic | Some jobs need instant data delivery, so timing matters. |

Network Range, Load & Architecture | The network's setup affects how well it works under heavy use. |

Security | Strong security stops threats that could harm people or systems. |

Scalability & Extensibility | Adding or removing devices should be easy for future growth. |

Pick a protocol based on what your system needs most. For fast data, choose low-latency protocols. For secure systems, pick ones with strong safety features. Matching the protocol to your needs improves performance and reliability.

Scalability for Expanding Systems

Scalability means the network can grow without losing quality. Boards with scalable designs let you add devices easily. This keeps your system ready for the future.

Look for boards with modular designs. These let you add parts without stopping the system. Ethernet-based boards are great for this. They handle many devices and large data loads well.

Boards that work with multiple protocols, like Modbus and Ethernet/IP, are more flexible. They allow new devices to join, even if they use different systems.

Scalability also depends on the board’s hardware and software. Boards with programmable controllers let you update or add features. This saves money and makes the system last longer.

Test the board to see how it handles more devices and data. Choose a scalable board to prepare your network for the future and save costs over time.

Cost-Effectiveness in Industrial Applications

Initial Investment and Hardware Costs

When picking industrial network boards, the starting cost matters a lot. This includes the board’s price and extra parts for setup. Advanced boards like SmartNICs cost more than regular ones. Smaller businesses might avoid them because they seem too expensive at first.

But spending more on good boards can save money later. Boards with modular designs, like those supporting Ethernet and RS-485, are flexible. You can update them for new systems without replacing everything. Programmable boards also save money by allowing updates instead of buying new ones.

To get the best value, compare different boards’ features and durability. Pick one that balances cost and performance for the best deal.

Tip: High upfront costs can lead to long-term savings with less maintenance and better reliability.

Maintenance and Operational Expenses

After buying the board, you’ll need to think about upkeep. This includes repairs, software updates, and power use. Boards made for tough environments last longer and need fewer repairs. They work well even in heat or vibrations.

Energy-efficient boards save money on electricity and produce less heat. This helps your equipment last longer. Good EMI/EMC designs, like grounding and shielding, protect boards from damage, lowering repair costs.

Choose boards that allow easy upgrades to keep costs low. Modular designs let you add features or replace parts without stopping work. Regular checks can catch problems early and save on big repairs.

Long-Term Scalability and Upgrades

Scalability means your system can grow without losing quality. Boards with scalable designs let you add devices easily. Ethernet-based boards are great for handling more data and devices.

Look for boards that work with old and new systems. Multi-protocol boards make adding new devices simple. Programmable boards help by allowing updates for new systems.

Upgrading should be quick and easy. Modular boards let you change parts without much downtime. This saves time and money. Scalable boards prepare your system for the future, keeping it efficient and cost-effective.

Note: Scalability isn’t just about adding devices. It’s about balancing cost, performance, and reliability as your system grows.

Balancing Cost and Performance for Value

Picking industrial network interface boards needs a balance of cost and performance. The board should work well without costing too much. To do this, you must know your system’s needs and what trade-offs are involved.

Decision-Making Strategies

Tools can help you choose the right board. Decision trees show different choices and their possible outcomes. They make hard decisions easier by showing clear paths to follow.

Decision Trees | Description |

|---|---|

Visual Representation | Shows choices and their possible results clearly. |

Evaluation of Complex Scenarios | Helps predict outcomes and make smarter decisions. |

Another tool is break-even analysis. It finds the point where the board’s benefits match its costs. This helps you see the least performance needed for the board to be worth the money.

Break-Even Analysis | Description |

|---|---|

Financial Viability | Finds when benefits equal costs. |

Minimum Performance | Shows the lowest performance needed to be worth it. |

Optimizing Resource Allocation

Using resources wisely gives you the best value for your money. Boards with modular designs, like those using Ethernet, save time and money. You can upgrade them without replacing everything.

Resource Allocation | Description |

|---|---|

Optimization Framework | Helps use money, time, and manpower better. |

High Returns Identification | Focuses on projects that give the best results. |

Choose boards that are reliable in tough conditions. Boards with strong EMI shielding and durable parts last longer. They need fewer repairs and work better in hard environments.

Balancing Performance and Cost

For the best value, pick boards that are scalable and reliable. Ethernet-based boards handle big data and many devices well. Modular boards let you add features without stopping work.

Spending more on a good board can save money later. Reliable boards need fewer repairs and last longer. Boards that work with many protocols are flexible for future upgrades.

Tip: Spending more upfront on a quality board can save money and improve reliability later.

By using tools and managing resources well, you can pick a board that balances cost and performance. This keeps your system efficient, scalable, and within budget.

Comparative Analysis of Industrial Network Interface Boards

Overview of Leading Brands and Models

Knowing top brands helps you pick the right industrial network interface boards. Companies like Intel, Broadcom, and Mellanox make boards with advanced features. Intel boards are fast and reliable, perfect for data centers. Broadcom boards are flexible, working with protocols like Ethernet and RS-485. Mellanox boards have low latency, great for quick tasks like automation.

Each brand has its strengths. Intel boards are best for high-speed needs. Broadcom boards are ideal for growing systems. Mellanox boards work well for real-time jobs. Understanding these differences helps you choose the right board for your needs.

Side-by-Side Comparison of Features and Costs

Comparing boards side by side shows their features and prices. Here’s a simple table:

Brand | Key Features | Cost Range ($) | Best Use Case |

|---|---|---|---|

Intel | Fast data transfer, reliable | 200–500 | Data centers |

Broadcom | Flexible design, multi-protocol | 150–400 | Growing systems |

Mellanox | Low latency, quick communication | 250–600 |

Intel boards cost more but are very reliable. Broadcom boards are cheaper and flexible. Mellanox boards are expensive but great for fast tasks.

Performance vs. Cost Trade-offs

Balancing performance and cost is important. Spending more on a good board can save money later. Ethernet boards handle lots of data and need less maintenance. If your system doesn’t need high speed, cheaper boards might work fine.

Think about your system’s needs. For data centers, pick boards with high bandwidth and reliability. For automation, choose boards with low latency and strong EMI protection. Modular boards save money by letting you upgrade instead of replacing.

Tip: Buying a reliable board now saves repair costs and keeps your system running smoothly.

User Reviews and Industry Feedback

User reviews and expert opinions can help you pick the right board. They show how boards perform, how reliable they are, and if they’re worth the cost.

Many users like modular boards because they are flexible. These boards let you upgrade systems without replacing everything. For example, people in data centers say modular boards make scaling easier. Boards that work with many protocols, like Ethernet, are also popular. They connect different devices without problems.

Experts often talk about durability. Boards made for tough conditions get good reviews. They handle heat, moisture, and shaking well. Automation users say these boards keep working even in hard environments.

Some reviews mention downsides. High-performance boards work great but can be expensive. Users suggest checking your needs to avoid spending too much. If you don’t need fast data speeds, cheaper Ethernet boards might be enough.

Good customer support is also important. Brands with quick help and regular updates get better ratings. This keeps boards working with new systems and protocols.

By reading reviews and feedback, you can find boards that fit your needs and budget. These tips help you avoid mistakes and choose a board that lasts a long time.

Recommendations for Specific Use Cases

Boards for High-Speed Data Centers

For high-speed data centers, pick boards made for fast data transfer. These boards help manage large amounts of data smoothly. Choose boards that support advanced Ethernet types like 10-Gigabit or 25-Gigabit Ethernet. These handle heavy tasks well.

Modular designs are important for data centers. Boards with multi-protocol support, like Ethernet and RS-485, work with different systems easily. Programmable controllers let you update for new protocols, keeping your system ready for the future. Testing for compatibility ensures the boards work with most industrial devices, avoiding communication issues.

Durable boards are a must. Look for ones with strong EMI/EMC features like grounding and shielding. These reduce electromagnetic interference, common in busy computing areas. Features like differential signaling and opto-isolation improve noise resistance, ensuring steady performance under heavy loads.

Tip: Spending more on quality boards now can save money later by reducing downtime and repairs.

Boards for Reliable and Durable Operations

In tough industrial settings, boards need to be strong and reliable. They must handle extreme heat, moisture, and shaking. Pick boards tested for these conditions to ensure they work well. These tests check for problems and improve designs.

Reliable boards are built to last. Methods like predictive analysis check how long a board will work. Boards made with failure prevention in mind are stronger. For example, rugged connectors and tough PCBs make them great for hard environments.

Good EMI/EMC designs are also key. Grounding and shielding lower electromagnetic interference. Signal tests check if communication stays clear in bad conditions. Features like opto-isolation and differential signaling make boards even more dependable.

Note: Strong boards cut down on unexpected breakdowns and improve system performance, making them worth the cost.

Boards for Cost-Sensitive Industrial Projects

For projects with tight budgets, pick boards that balance cost and features. Advanced boards like SmartNICs are powerful but may cost too much. Instead, choose modular boards that support Ethernet and other common systems. These let you upgrade parts without replacing the whole board.

Energy-saving boards are a smart choice. They use less power, cutting down on electricity costs. Boards with good EMI/EMC designs, like grounding and shielding, last longer and need fewer repairs.

Tools like break-even analysis help find the best value. This shows when a board’s benefits are worth its price. Decision trees can also help you decide between performance and cost.

Tip: Spending a bit more on a reliable board now can save money later by lowering repair and upgrade costs.

Boards for Systems That Can Grow and Change

To build a system that grows easily, choose scalable boards. These boards let you add devices without losing speed or reliability. They also save money over time by staying useful as technology changes.

Look for boards with modular designs. Modular boards let you swap parts without stopping the system. For example, you can add faster processors or more ports when needed. This makes them a smart choice for businesses that plan to expand.

Boards that support many protocols are also important. They work with systems like Modbus, OPC-UA, and Ethernet. This lets different devices connect and share data smoothly. It’s helpful for industries where tools and systems change quickly.

Scalable boards handle more data as your system grows. Ethernet boards are especially good for managing big data and many devices. They keep working well even with heavy use.

Pick boards that allow software updates and firmware upgrades. This lets you add new features without buying new hardware. Make sure the boards work with both current and future devices.

By choosing scalable boards, you prepare for growth while saving money. These boards adapt to new needs and keep your system running smoothly, making them a great choice for modern networks.

Picking the right industrial network board means balancing cost and performance. Look for features like speed, reliability, and growth potential. Boards using Ethernet are flexible and handle big data well. Choosing a board within your budget ensures good value and quality.

Think about how you’ll use the board. For fast tasks, pick boards with advanced Ethernet features. For tight budgets, modular boards save money and allow upgrades. Match the board to your needs to get the best mix of performance and cost.

FAQ

What do industrial network interface boards do?

These boards help machines share information in industrial systems. They make sure data moves smoothly and works well, even in tough conditions. You can use them for jobs like automation, managing data, and linking devices with systems like Ethernet.

How can you pick the best board for your system?

First, figure out what your system needs. Think about things like speed, dependability, and if it works with your current setup. For example, if your system handles a lot of data, pick a board that supports Ethernet for fast communication.

Are modular boards a good choice?

Yes, modular boards are very useful. You can change or upgrade parts without buying a whole new board. This saves money over time and keeps your system ready for future changes.

What makes a board strong for tough conditions?

Strong boards are made with durable materials and smart designs. Features like EMI shielding, grounding, and opto-isolation stop interference and damage. These boards work well in heat, moisture, and vibrations.

Can one board work with different systems?

Yes, many boards can handle multiple systems like Ethernet, Modbus, and OPC-UA. These boards let devices using different systems connect easily, which is great for complex setups.