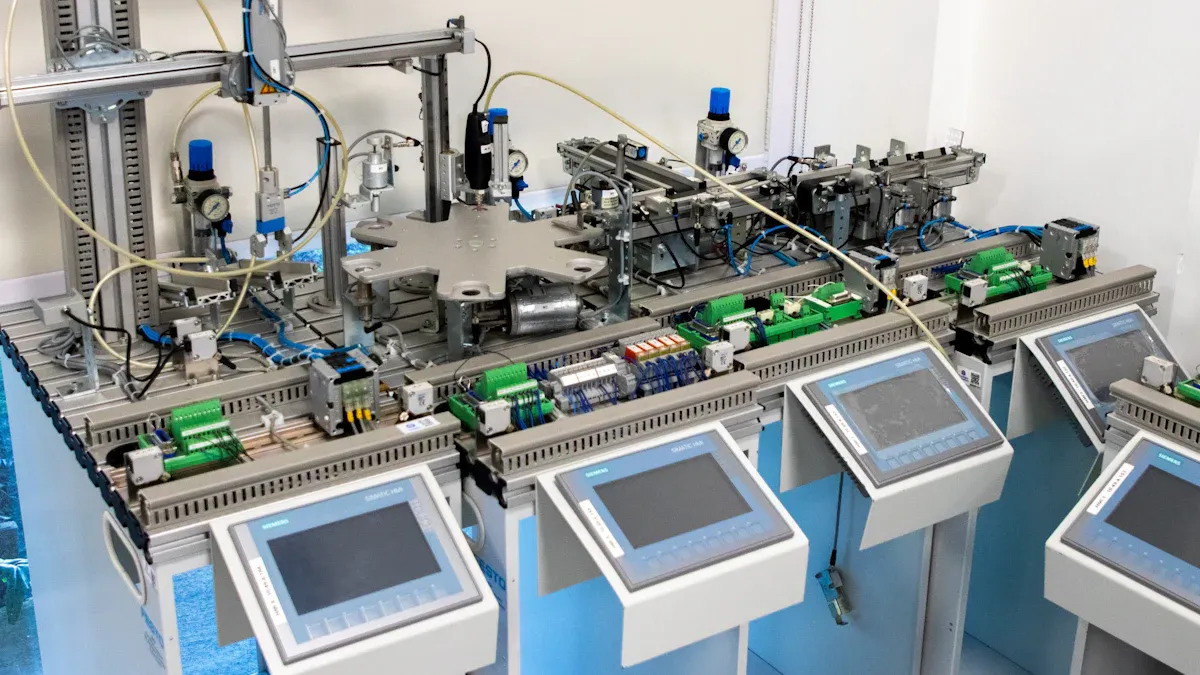

Industrial process control in PCB assembly utilizes advanced tools such as robots, IoT, and AI to enhance efficiency. These innovations accelerate tasks, correct errors, and ensure precise manufacturing. For instance:

Fast pick-and-place machines can add thousands of parts each hour, significantly reducing production time.

Robots in industrial process control PCB assembly manage complex tasks with greater accuracy and fewer mistakes.

Live data systems, like DIASPC, monitor for issues and resolve them promptly to maintain precision.

These cutting-edge tools not only expedite operations but also reduce costs by minimizing resource usage and decreasing the need for manual labor.

Key Takeaways

Using robots and IoT makes PCB assembly faster and better.

Automation can make production 30-60% quicker and cut mistakes by 20-40%.

Smart tools like AI find problems early, saving time and improving quality.

Teaching workers new tech skills helps them do better work with machines.

Green practices in PCB assembly save money and protect the planet.

What Is Industrial Process Control in PCB Assembly?

Definition and Core Principles

Industrial process control in PCB assembly uses smart tools to improve production. It helps make sure every step, like soldering and checking, meets high standards. Key ideas include collecting live data, predicting problems, and using machines. For example, IoT tools collect real-time machine data. Digital twin technology copies production to find possible issues. These methods make work faster and reduce mistakes.

Importance in Modern Manufacturing

Today, factories need process control to save time and money. Using these systems gives big benefits, such as:

Boosting productivity by 20-40%.

Shortening production times by 30-60%.

Lowering defect rates by 20-40%.

These changes make PCB assembly faster and better. A PwC study found 85% of factory leaders think advanced process control is key to staying competitive. This shows how important it is today.

Key Components of Process Control Systems

Good process control systems depend on key parts to work well. These include:

Metric | Description |

|---|---|

Counts defects per million chances, helping compare quality. | |

First Pass Yield (FPY) | Shows the percent of PCBs passing checks the first time. |

Rework Rate | Tracks the percent of PCBs needing fixes after assembly. |

Scrap Rate | Measures the percent of bad PCBs that can’t be used. |

Watching these numbers helps find problems and fix them. For example, checking the rework rate cuts waste and keeps PCB assembly up to standards.

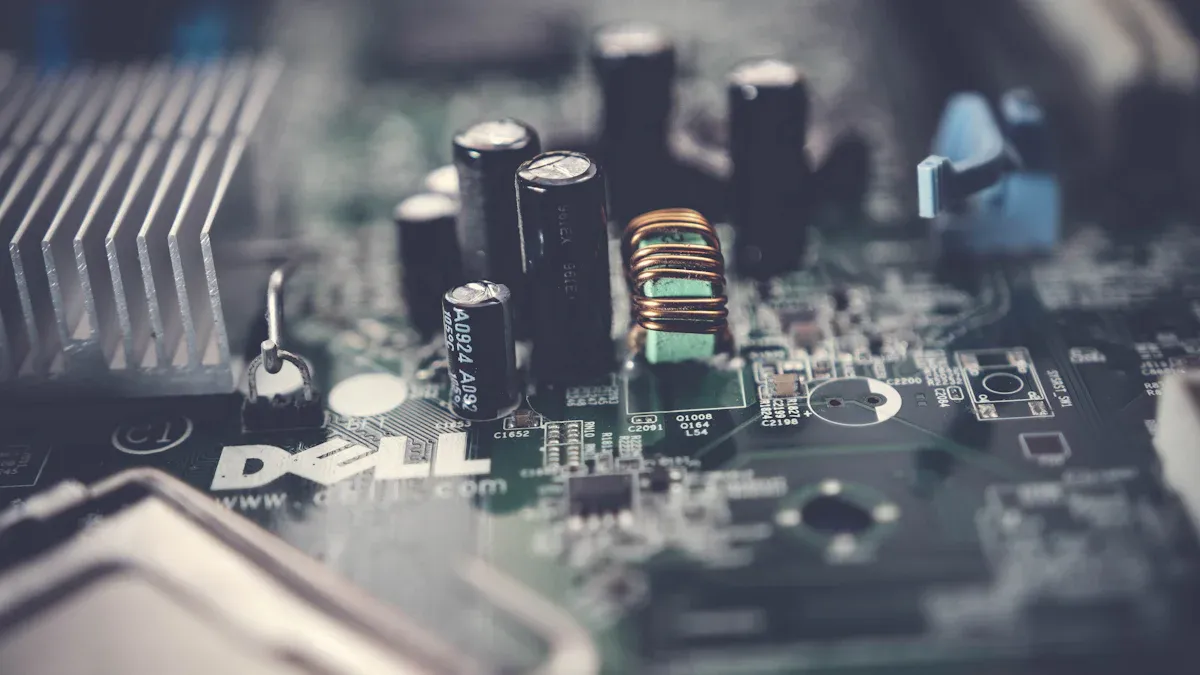

Technologies Driving Automation in PCB Assembly

Automation in PCB assembly has changed how factories work. It makes production faster, more accurate, and saves money. Using tools like IoT, AI, and robots helps improve processes and quality.

IoT and Smart Factory Integration

IoT turns regular factories into smart ones. It connects machines, sensors, and systems to share data instantly. This helps spot problems, plan repairs, and avoid delays.

For example, Bosch’s factory in Germany cut delays by 25% with IoT. Siemens’ factory improved work speed by 20% using IoT and augmented reality. McKinsey says predictive maintenance can reduce delays by 30-50%, keeping things running smoothly.

Study/Company | Improvement Type | Percentage |

|---|---|---|

Bosch (Germany) | Downtime Reduction | 25% |

Siemens (Germany) | Productivity Increase | 20% |

Predictive Maintenance (McKinsey, 2022) | Downtime Reduction | 30-50% |

Quality Issues Prevention (Quality Magazine, 2022) | Early Issue Detection | 75% |

Analytics Usage | Efficiency Improvement | 17% |

Analytics Usage | Mistake Reduction | 21% |

Adding IoT to PCB assembly helps track work in real time. It finds problems early and makes production better.

AI and Machine Learning in Process Optimization

AI and machine learning are powerful tools for improving PCB assembly. They study lots of data to find patterns, predict results, and make smart choices. AI systems check quality better and reduce mistakes, ensuring good products.

Volkswagen uses AI to check machines and plan repairs. AI design tools make production faster and cheaper. Machine learning systems find defects better than people. They check parts early and accurately.

AI also improves soldering by adjusting oven settings for tricky parts. These tools show how automation boosts efficiency and reliability.

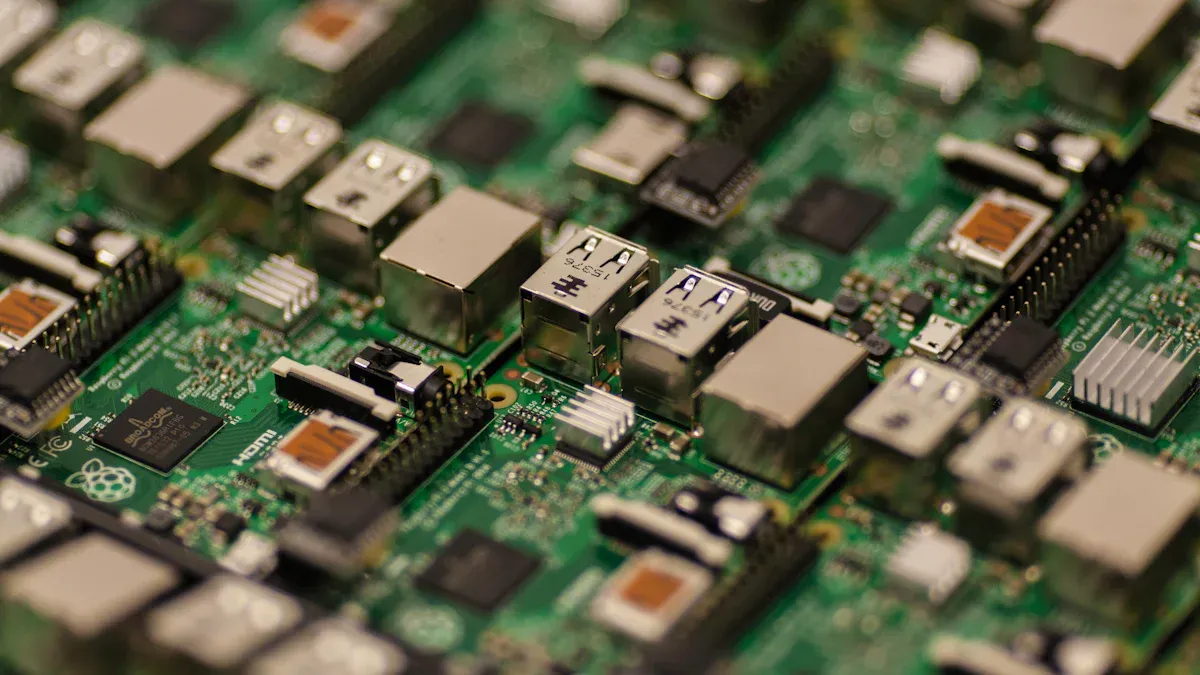

Robotics for Precision and Speed

Robots are key to automated PCB assembly. They handle tasks like placing parts, soldering, and checking quality. Robots work fast and reduce human errors.

Pick-and-place machines can add thousands of parts each hour. Robotic soldering applies solder evenly, lowering defects. Automated checks ensure quality and allow quick fixes.

Metric | Description |

|---|---|

Cycle Time Reduction | Cuts cycle times by 50-70% compared to manual work. |

Repeatability | Keeps precision within ±0.01mm. |

Speed | SCARA robots move up to 3,000 mm/s. |

Throughput Improvement | ABB’s IRB 930 SCARA robot boosts output by 10%. |

Using robots in PCB assembly ensures accuracy and speed. This leads to better products and faster production.

How Industrial Process Control Improves PCB Assembly Efficiency

Faster Production and Better Workflow

Industrial process control speeds up PCB assembly. It automates repeated tasks, making production faster and smoother. For example, pick-and-place machines in SMT PCB assembly can place thousands of parts each hour. These machines reduce the need for manual work, letting workers focus on other important tasks.

Automation also removes delays in workflows. Tasks like soldering, testing, and inspection can happen at the same time or quickly one after another. This reduces waiting time and keeps production moving. Many manufacturers use these systems to meet deadlines without lowering quality.

Improved Precision and Quality

Precision is very important in PCB assembly. Industrial process control uses advanced tools to improve accuracy and quality. Automated Optical Inspection (AOI) systems find problems like misplaced parts or soldering mistakes. Pick-and-place machines also help by placing parts exactly where they belong.

Technology | How It Helps with Quality |

|---|---|

Automated Optical Inspection (AOI) | Finds issues like misaligned parts or soldering errors. |

Pick and Place Machines | Places parts accurately, improving assembly precision. |

These tools catch mistakes early, reducing the need for fixes later. This saves time and materials while keeping high standards. It ensures every PCB meets customer needs.

Saving Money by Using Resources Wisely

Industrial process control helps save money by using resources better. It reduces waste by choosing the right parts and designing efficient layouts. For example, using fewer types of parts and avoiding rare ones makes assembly easier and cheaper.

Outsourcing some tasks to experts can also cut costs. This avoids the need to build in-house skills, saving money for other needs. Tools for testing designs before production help find problems early, preventing expensive mistakes.

Here are ways to save resources:

Pick flexible parts to avoid waste.

Design layouts to use space wisely.

Use parts and methods that lower repairs and downtime.

Test designs early to spot risks.

Outsource tasks to reduce extra costs.

By following these tips, manufacturers can save money while keeping production efficient. Automation not only improves speed and accuracy but also offers long-term cost benefits.

Challenges in Using Industrial Process Control

High Starting Costs and ROI Worries

Using industrial process control for PCB assembly costs a lot upfront. Buying advanced machines like pick-and-place or inspection tools can be expensive. Adding these tools to current SMT assembly setups also costs more. But looking at long-term savings can help. Automation lowers labor costs and reduces mistakes. This means faster production and better quality.

Problem | Solution |

|---|---|

High starting costs | Do a cost-benefit study |

Hard to set up | Focus on saving labor over time |

Need for careful planning | Check for fewer mistakes and faster work |

The high costs may seem scary at first. But thinking about future benefits can make the expense worth it. Better production and less waste often make up for the big initial spending.

Mixing New Tools with Old Equipment

Adding new process control tools to old machines can be tough. Many factories struggle to connect new tech with older systems. For example:

Mixing new tools with old ones is a big challenge.

42% of factories have trouble linking new and old systems.

Different network types, like HTTP and Modbus, make it harder.

Old machines are the second biggest problem in smart factories.

These problems can slow down new PCB assembly methods. To fix this, check your current tools and plan upgrades slowly. This way, changes happen smoothly without stopping production.

Training Workers and Fixing Skill Gaps

Using automation and smart tools needs skilled workers. Your team might not know how to use new machines or read IoT data. Training programs are key to solving this. Teaching your workers helps them use modern SMT assembly tools well.

Skill gaps can cause delays and lower quality. For example, using machines wrong can lead to mistakes. To stop this, focus on hands-on training and give support. A trained team keeps production smooth and makes high-quality products.

Future Trends in Industrial Process Control PCB Assembly

Smarter AI and Predictive Tools

AI and predictive tools are changing PCB assembly. They study live data to spot problems before they happen. For example, AI watches machines and plans repairs early. This cuts downtime and keeps work running smoothly. AI also finds patterns in data to improve processes and quality.

The factory automation market may grow to $399.12 billion by 2029. This shows how important AI is for better PCB assembly. Using these tools helps you stay competitive and keep quality high.

Growing Smart Factory Systems

Smart factories are changing how PCBs are made. IIoT connects machines, sensors, and systems to share data. This helps find problems and fix them quickly. Self-driving vehicles can move materials, saving time.

Cobots, or helper robots, work with people to improve workflows. They are great for small businesses because they save money. As smart factories grow, PCB assembly will get faster and more accurate.

Eco-Friendly Manufacturing Ideas

Green manufacturing is now a big focus in PCB assembly. It aims to cut waste, save energy, and use safer materials. For example, energy-saving machines and recycling programs help the planet and save money.

New ideas include using biodegradable materials and lead-free solder. These changes make PCBs safer for the environment. By going green, you can meet global goals and still make top-quality products.

Industrial process control changes how PCBs are made in factories. It makes work faster, more accurate, and produces better products. Starting costs and setup can be hard, but the benefits are worth it. You can save time, cut waste, and get more done.

New tools like AI, IoT, and eco-friendly methods will lead the way. Using these ideas helps you stay ahead and meet new needs. It takes work to start, but the results are important for today’s factories.

FAQ

What is the main benefit of industrial process control in PCB assembly?

The biggest benefit is better efficiency. Automation cuts mistakes, speeds up work, and keeps quality steady. It saves time and materials while making reliable PCBs that meet high standards.

How does IoT improve PCB assembly?

IoT links machines and systems to share live data. This helps spot problems early, track progress, and improve workflows. It keeps things running smoothly and reduces delays.

Is industrial process control expensive to implement?

Yes, starting costs are high. But it saves money later by cutting waste, boosting productivity, and lowering labor costs. A cost-benefit study can show its long-term value.

Can older factories adopt industrial process control?

Yes, but it takes planning. You can slowly add new tools to old systems. Start small and check compatibility to avoid problems.

How does automation affect workers in PCB assembly?

Automation reduces simple tasks, letting workers do skilled jobs. Training programs help workers learn new tools and improve their skills.

See Also

Essential Strategies for Enhancing PCB Assembly Productivity

Ways to Optimize Workflow in PCBA Production Processes

The Role of PCBA in Advancing Today’s Electronics

Ten Professional Suggestions for Cost-Effective PCBA Assembly