Industrial protocol converter PCB assembly is crucial for efficient operations. These converters facilitate communication between machines and systems that operate on different “languages.” Without industrial protocol converter PCB assembly, machines may struggle to work together, leading to delays and reduced production efficiency. Evaluating these converters allows you to select the best option for your specific requirements, ensuring that your work processes are smoother, faster, and more interconnected.

Choosing the right industrial protocol converter PCB assembly enhances connections and accelerates tasks.

Key Takeaways

Industrial protocol converters let machines talk, making PCB assembly faster.

Picking the right protocol, like Ethernet/IP or EtherCAT, boosts speed and cuts delays.

It’s important the converter works with both old and new systems.

Real-time communication keeps things running smoothly; TSN and EtherCAT are great for this.

Choose converters that can update and handle new tech in the future.

Understanding Industrial Protocol Converters

What Are Industrial Protocol Converters?

Industrial protocol converters help machines talk to each other. They translate data between systems using different communication methods. These devices make sure machines, controllers, and networks share information smoothly. In factories, they connect old systems with newer technologies. For example, a converter can change Modbus data into Ethernet/IP so devices can work together.

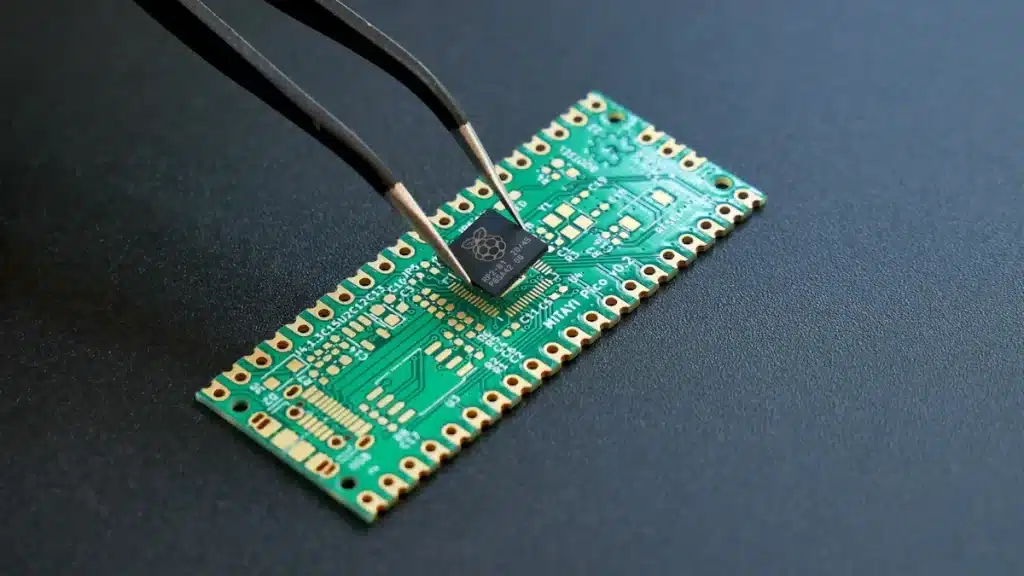

These converters often have parts you can swap out. This lets them work with protocols like CAN, RS-485, or Ethernet. Programmable controllers make them flexible by allowing updates for new protocols. Testing ensures they work well with many industrial devices, making them dependable for various tasks.

Importance in PCB Assembly Applications

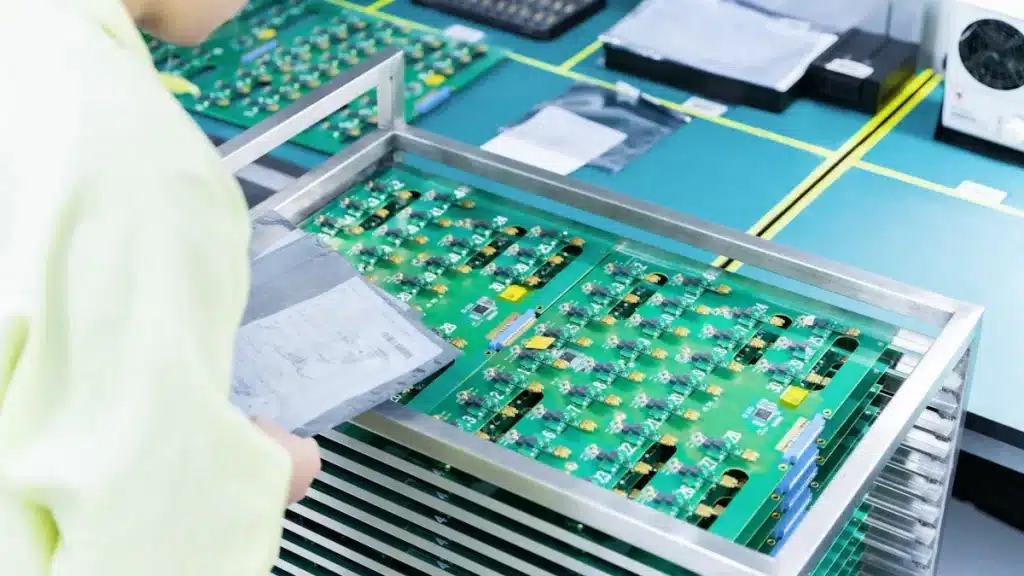

In PCB assembly, these converters keep machines working together without problems. They help machines on the production line communicate, even if they use different systems. This is important for faster and more efficient automation. Without them, delays and mistakes could slow down production.

The industrial internet of things (IIoT) depends on these converters to link devices. For example, they allow real-time data sharing between assembly machines and monitoring tools. This helps make better decisions and reduces downtime. Strong designs, like grounding and shielding, ensure they work well in tough environments.

Using these converters in PCB assembly improves connections and prepares your systems for the future. They connect old and new technologies, making them essential in modern industries.

Key Protocols for PCB Assembly

Modbus: Features, Limitations, and Applications

Modbus is a common industrial communication protocol used worldwide. It helps devices share data through serial lines or Ethernet. Its simple design and open-source nature make it popular in PCB assembly. Modbus connects devices like sensors and programmable logic controllers (PLCs) easily.

Features:

Works with serial (RS-232/RS-485) and Ethernet communication.

Simple to use and affordable.

Compatible with many industrial devices.

Limitations:

Slower data transfer compared to newer protocols.

Weak security, making it prone to cyber risks.

Applications:

In PCB assembly, Modbus links old machines to modern systems. For instance, it connects older pick-and-place machines to new monitoring tools. This ensures smooth data sharing on production lines.

Profibus: Features, Limitations, and Applications

Profibus is a strong protocol for fast communication in factories. It works well in tasks needing precise control and quick data sharing. It’s especially helpful in complex PCB assembly setups.

Features:

Fast data transfer, up to 12 Mbps.

Handles both regular and occasional data sharing.

Performs reliably in tough factory conditions.

Limitations:

Needs special hardware, raising setup costs.

Not ideal for very large networks.

Applications:

Profibus is used in automated PCB assembly lines for speed and accuracy. It helps soldering machines, inspection tools, and conveyors work together smoothly.

Ethernet/IP: Features, Limitations, and Applications

Ethernet/IP is a modern protocol using Ethernet for automation. Its flexibility and ability to grow make it great for PCB assembly.

Features:

Fast data sharing and supports large networks.

Handles real-time tasks efficiently.

Connects easily with IT systems for better analysis.

Limitations:

Costs more to set up than older protocols.

Needs a strong network to avoid delays.

Applications:

In PCB assembly, Ethernet/IP connects advanced tools like reflow ovens and AOI systems. It allows real-time control and monitoring, improving efficiency.

Did you know? The global in-circuit test market, which uses protocols like Modbus, Profibus, and Ethernet/IP, may reach $1.5 billion by 2030, growing at 3.7% yearly.

Emerging Protocols: TSN and EtherCAT

New protocols like TSN and EtherCAT are changing PCB assembly. They help machines share data faster and work better together. These methods improve automation and make production smoother.

TSN: Features and Benefits

TSN uses Ethernet to send real-time data quickly. It keeps timing accurate and reduces delays, which is important for PCB assembly. TSN helps machines and controllers work in sync, cutting mistakes and downtime.

Key Features:

Shares data fast with little delay.

Reliable for important tasks.

Works with current Ethernet setups.

TSN is great for jobs needing exact timing. For example, it can match pick-and-place machines with soldering systems. This makes production faster and more efficient.

EtherCAT: Features and Benefits

EtherCAT is another fast protocol for factory automation. It connects many devices without slowing down. You can use EtherCAT to control tools with speed and accuracy.

Key Features:

Sends data extremely fast.

Handles big networks easily.

Controls devices for real-time tasks.

EtherCAT works well with advanced PCB assembly tools. For instance, it links reflow ovens, inspection machines, and conveyors. This creates a connected system that improves productivity.

Why These Protocols Matter

TSN and EtherCAT fix problems with older protocols like Modbus and Profibus. They offer quicker speeds, better timing, and room to grow. Adding them to your setup can prepare your systems for the future.

Tip: Upgrade to TSN or EtherCAT if your current system struggles with timing or large networks.

Protocol Comparison for PCB Assembly

Data Rate and Transmission Speed

When picking a protocol converter for PCB assembly, speed matters. Faster data sharing helps machines work without delays. This keeps production lines running smoothly. Different protocols have different speeds, so choose one that fits your needs.

For instance, Modbus RTU is a common protocol. It works at speeds up to 115 Kbps using RS-232 or RS-485. This is fine for simple tasks but too slow for fast PCB assembly. Modbus TCP, which uses Ethernet, can reach 100 Mbps or more. This makes it better for modern systems needing quick data sharing.

Here’s a simple speed comparison:

Protocol | Maximum Speed | Communication Media |

|---|---|---|

Modbus RTU | 115 Kbps | RS-232, RS-485 |

Modbus TCP | 100 Mbps+ | Ethernet-based communication |

Other protocols like Profibus and Ethernet/IP are also fast. Profibus can go up to 12 Mbps, great for precise tasks. Ethernet/IP handles big networks and real-time jobs well. Newer protocols like TSN and EtherCAT are even faster. They are perfect for advanced PCB assembly with low delays.

Tip: For fast production lines, use Ethernet/IP or EtherCAT.

Compatibility with PCB Assembly Systems

Compatibility is key when choosing a protocol for PCB assembly. Machines often come from different brands and use different systems. Protocol converters help these machines connect and share data easily.

Modbus works well with older machines. It lets them connect to newer systems, making it popular for mixed setups. Profibus is reliable for tasks needing exact timing between machines. Ethernet/IP connects easily to modern systems and supports advanced monitoring.

New protocols like TSN and EtherCAT work with IIoT devices. They allow switching between systems like CAN, Ethernet, and RS-485. This makes your setup flexible and ready for future upgrades.

Note: Check if your machines and protocol can work together before deciding.

Network Size and Topology

The size of your network affects which protocol to use. PCB assembly lines often have many devices. You need a protocol that handles large networks without slowing down.

Modbus RTU is simple and cheap but best for small networks. Profibus supports up to 126 devices, good for medium setups. Ethernet/IP can handle hundreds of devices, making it great for big networks.

EtherCAT and TSN are excellent for large, complex networks. EtherCAT processes data quickly without delays. TSN keeps devices in sync, even in big setups.

Callout: For large PCB assembly lines, use Ethernet/IP or EtherCAT for strong connections and low delays.

Real-Time Communication Capabilities

Real-time communication is crucial for PCB assembly. It helps machines share data instantly, keeping production smooth and fast. Without it, delays can cause mistakes and slow down work.

Why Real-Time Communication Matters in PCB Assembly

In PCB assembly, timing is very important. Tasks like placing parts, soldering, and checking boards need perfect timing. Real-time communication keeps these steps in sync. For example, a machine placing parts needs quick feedback from a camera system. If feedback is slow, parts might be placed wrong, causing bad boards.

Modern protocols like Ethernet/IP, TSN, and EtherCAT are great for real-time communication. They send data quickly and on time, which is key for fast assembly lines. Even tiny delays can hurt productivity.

Comparing Protocols for Real-Time Performance

Different protocols handle real-time communication differently. Here’s a table showing their market stats:

Protocol | Market Stats |

|---|---|

Market Size | USD 21.9 billion in 2023, growing to USD 29.0 billion by 2028 |

Modbus | 49% market share |

BACnet | 25 million devices worldwide |

DLMS | 533 million smart meters by 2025 |

CANopen | 25 million nodes in industries |

PROFIBUS | 38% Fieldbus market share in 2018 |

DeviceNet | 10 million nodes in car factories |

Ethernet/IP | Growing at 12.7% yearly until 2028 |

Ethernet/IP and EtherCAT are great for big networks with low delays. TSN is perfect for exact timing jobs, like robotic arms in PCB assembly.

Key Features Enabling Real-Time Communication

To work in real-time, converters need special features:

Modular Communication Interfaces: These let converters switch between systems like CAN, Ethernet, and RS-485. This makes them work with many devices.

Programmable Controllers: Updates allow converters to support new systems, keeping them ready for the future.

EMI/EMC Design Strategies: Shielding and grounding stop interference, ensuring data stays accurate in tough conditions.

These features help PCB assembly systems stay efficient and ready for new technology.

Benefits of Real-Time Communication in PCB Assembly

Real-time communication has many benefits:

Better Efficiency: Machines react quickly, reducing downtime and speeding up work.

Improved Quality: Instant feedback helps fix problems fast, lowering defects.

Scalability: Protocols like TSN and EtherCAT handle big networks, making them good for growing factories.

Tip: If your assembly line has delays or timing issues, try upgrading to EtherCAT or TSN. These protocols are fast and reliable for modern factories.

Real-time communication is now essential for PCB assembly. Picking the right protocol and features can improve your production and keep you ahead in the industry.

Choosing the Right Industrial Protocol Converter

Evaluating Application Requirements

Picking the right industrial protocol converter starts with knowing your needs. Think about what tasks the converter will do. Will it link old machines to new systems? Or will it handle fast communication in a busy production line? Understanding these details helps you find the right converter.

Check the communication protocols your machines use. Older devices may need Modbus or Profibus support. For newer systems, Ethernet/IP or newer protocols like TSN and EtherCAT might work better. Also, consider the environment. Factories often have strong electromagnetic interference. A converter with good EMI/EMC design, like shielding, ensures it works well.

Look for converters with modular communication interfaces. These let you switch between protocols like CAN, RS-485, and Ethernet. This makes the converter work with many devices and ready for upgrades. Testing it with common industrial devices is also important. It ensures everything connects smoothly.

Tip: Write down all the devices and protocols in your system first. This helps avoid problems later and saves time.

Scalability and Flexibility

Scalability and flexibility are key when choosing a converter for PCB assembly. Your production might grow, so the converter should handle more devices. Scalable converters, like Ethernet/IP and EtherCAT, can manage large networks easily.

Flexibility is also important. Converters with programmable controllers can add new protocols through updates. This keeps your system ready for future changes. Modular interfaces let you switch between communication methods, making your setup adaptable.

Think about the converter’s physical design too. Strong connectors and durable PCBs are better for tough environments. These features help the converter work in extreme conditions like heat, humidity, or vibration.

Callout: If you plan to grow your production or add IIoT devices, pick a converter with future-ready hardware. This ensures it can handle new protocols later.

Cost and Budget Considerations

Cost matters when picking a protocol converter. Cheaper options might save money now but could cost more later. A reliable converter reduces downtime and works better long-term.

Break costs into purchase, setup, and maintenance. Converters with strong EMI/EMC design may cost more upfront but prevent failures in noisy environments. Modular converters might seem pricey but support many protocols, saving money over time.

Think about scalability costs too. A scalable converter avoids frequent replacements as your production grows. This saves money and keeps your system running smoothly. Easy-to-use converters with plug-and-play features also save time and labor costs.

Note: Match your budget to your needs. Spending a bit more on a good converter can save money in the future.

Additional Factors to Consider

Security and Data Integrity

Keeping data safe and accurate is very important. Protocol converters should protect sensitive information and send data correctly. Look for converters with strong security features to block unauthorized access. Tools like user controls and activity logs help track changes and keep data reliable.

Modern converters often include firewalls and tools to detect cyber threats. These features protect your system from hackers. Regular checks, like those by NIST, ensure your system meets safety rules. Self-checks can also find weak spots and make your system stronger.

For extra security, use converters that work with tools like DDS. DDS splits networks into sections and watches data in real time. It handles large data transfers and connects different systems smoothly. This makes it great for complex factory setups.

Tip: Pick converters with features like data checks and user controls to keep your system secure.

Future-Proofing and Industry Trends

Choosing the right protocol now can save you trouble later. The rise of IIoT is changing how machines connect. Ethernet and wireless systems are becoming more popular. Systems need to grow and adapt as technology improves.

New control systems use cloud storage to collect and analyze data. Converters with modular parts and programmable updates can keep up with these changes. Firmware updates let them support new protocols, keeping your system modern.

EtherCAT and TSN are great for future needs. They send data fast and work in real time, perfect for advanced PCB assembly. By choosing converters with strong hardware, you’ll be ready for future upgrades.

Callout: Stay prepared by picking converters that match IIoT trends and support cloud systems.

Ease of Integration and Maintenance

Easy setup and upkeep are key for smooth operations. Protocol converters should connect easily to old and new systems. Modular designs make switching between protocols like CAN, Ethernet, and RS-485 simple.

Strong designs, like tough connectors and durable PCBs, help converters last in harsh conditions. These features handle heat, moisture, and vibrations well. Grounding and shielding improve signal quality and reduce interference.

Converters that are easy to maintain save time and money. Plug-and-play options allow quick setup and fixes. Regular checks can spot problems early. Choosing converters with these features keeps your production running smoothly.

Note: Choose converters tested to work with common industrial devices for better compatibility.

Picking the right protocol converter helps machines work together easily. It also makes production faster and more efficient. Think about what your system needs before choosing. Look at things like how well it fits, how it can grow, and if it works quickly. These features make sure the converter fits your needs and keeps your system ready for upgrades.

Choose protocols that match your assembly line’s size and speed. Pick converters with strong builds and parts you can swap. These options lower delays and make your system more dependable. Getting the right converter boosts your work speed and keeps you ahead in changing industries.

FAQ

1. What does an industrial protocol converter do?

An industrial protocol converter helps machines “talk” to each other. It changes data so systems with different protocols can connect. This makes processes like PCB assembly faster and with fewer mistakes.

Tip: Use a converter to link old machines to new ones for smoother operations.

2. How can you pick the right protocol converter for PCB assembly?

First, check what communication protocols your machines use. Think about speed, compatibility, and how easily it can grow with your system. Choose converters with modular parts and strong designs to handle tough factory conditions.

Note: Always test the converter with your machines before deciding.

3. Are TSN and EtherCAT better than older protocols?

Yes, TSN and EtherCAT are faster and more precise. They work well for advanced PCB assembly. But older protocols like Modbus might still be fine for simpler tasks.

Callout: Switch to TSN or EtherCAT if your system needs exact timing or handles many devices.

4. Can protocol converters make production faster?

Yes! Protocol converters help machines share data quickly and without errors. Real-time communication keeps tasks like soldering and inspections on track, improving productivity.

Emoji Insight: ⚡ Faster data sharing = better production flow!

5. How can you prepare your system for the future?

Pick a converter with parts you can update or change. This lets you add new protocols as technology improves. Strong hardware is also important for handling IIoT and cloud systems.

Tip: Future-proofing saves money and keeps your system ready for new tech.