Building industrial wireless communication module assembly is important for modern factories. Following clear steps helps you assemble them correctly and avoid mistakes. Each step ensures a strong system for IoT, which shares data easily. A good plan makes work faster and improves wireless system performance. Knowing how to plan and build helps you connect modules well and skip common problems.

Key Takeaways

Get tools like screwdrivers, pliers, and a soldering iron first. Being ready saves time and avoids errors.

Keep your workspace clean and neat for safety and speed. A tidy space stops accidents and helps you find tools easily.

Test the module in real situations to check if it works well. This step ensures all parts work together properly.

Protect the module with covers and grounding to avoid damage. This makes it last longer and work better in tough conditions.

Update software often and check connections to keep it working. Staying updated prevents problems and improves how it functions.

Preparation for Industrial Wireless Communication Module Assembly

Essential Tools and Equipment

To build a wireless module, gather the right tools. Basic tools like screwdrivers, pliers, and wire cutters are needed. Use an anti-static wrist strap to stop static from damaging parts. A soldering iron and solder help connect pieces firmly. Keep a multimeter to check if wires are working. For software setup, use a computer with the right programs. Labeling tools, like markers or stickers, keep parts organized. Having these tools ready makes the job easier and faster.

Setting Up a Safe and Organized Workspace

A tidy workspace helps you work safely and quickly. Place tools and parts neatly on a surface that doesn’t conduct electricity. Use small trays to keep tiny parts separate. Good lighting helps you avoid mistakes while working. Keep the area clean to lower the chance of accidents.

Organized spaces improve safety. For example:

A factory lowered its accident rates by tracking safety data.

Reporting near-misses increased, showing better safety habits.

By staying organized, you can work safely and make fewer mistakes.

Safety Measures and Planning for Secure Installation

Safety is very important. Wear safety glasses and gloves to stay safe. Check tools for damage before using them. Don’t work near water to avoid electric shocks. Plan each step of the installation carefully. Make sure the module fits with your current system. This helps it work well with your IoT setup. Being careful keeps you and your tools safe.

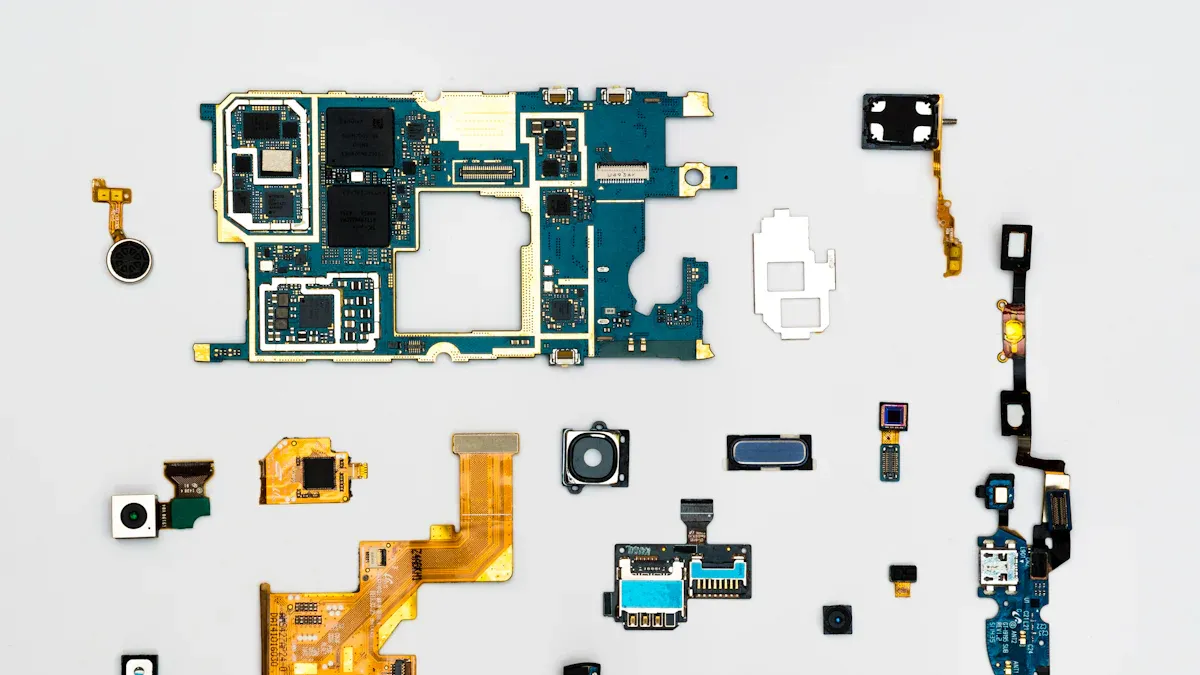

Understanding Wireless Communication Module Components

Key Parts of the Module and Their Functions

Wireless modules have important parts, each with a special job. For example, the nRF24L01 module sends data between devices. It adjusts power levels based on distance, making it useful for many tasks.

Here’s a simple list of key parts and what they do:

Key Component | Function |

|---|---|

Wi-Fi Technology | Sends data wirelessly and connects to the internet. |

Receiver Sensitivity | Decides how far signals can go and affects battery use. |

Power Amplifier (PA) | Makes signals stronger but uses more power and costs more. |

Digital Signal Processing (DSP) | Works with other parts to complete the signal system. |

Knowing these parts helps you pick the right module for your needs.

How Components Work Together for Optimal Performance

The parts of a wireless module work as a team to send data. Wi-Fi technology connects devices, while receiver sensitivity controls signal range and strength. The power amplifier boosts signals for long distances. Digital signal processing ties everything together for smooth operation.

Modules like the nRF24L01 show how teamwork works. They use pipes to move data between devices. You can change the amplifier’s power to match the distance. This teamwork makes communication reliable in industrial IoT systems.

Tip: Test the module in real situations to check if all parts work well.

Ensuring Compatibility with Existing Systems

Making sure a new wireless module fits your current system is key. Check hardware and software to avoid problems. Look at temperature limits to ensure it works in tough environments. Also, confirm it uses the same communication rules as your IoT setup.

Key Concept | Description |

|---|---|

Compatibility | Makes sure new tools work with old ones. |

Interoperability | Helps different systems talk to each other easily. |

By checking these things, you can avoid problems and keep your work running smoothly.

Step-by-Step Guide to Industrial Wireless Communication Module Assembly

Getting Components Ready and Powering the Device

Before starting, gather all parts and check the power setup. Preparing well helps avoid mistakes and keeps things running smoothly. Lay out the parts in the order you’ll use them. This makes the process faster and less confusing. For example, robots in factories often give parts in a set order, showing why arrangement matters.

Setting up the power correctly is just as important. Adjust the power supply to match the module’s needs. For example, tools like OnRobot™ Eyes need setup to identify parts properly. Wrong power settings can harm parts or cause problems. Always check the voltage and current before connecting the power.

Tip: Wear an anti-static wrist strap to stop static from harming the wireless sensor node.

Attaching Hardware and Placing the Antenna

Next, connect the hardware parts. Start by linking the wireless sensor node to the mainboard. Make sure all connections are tight and secure. Use a multimeter to check if the wires are working. This step ensures the module will work when powered on.

Where you place the antenna affects how well it works. Put the antenna at the PCB edges for better signals. Research shows edge placement improves signal strength and accuracy. The table below compares antenna placements:

Performance Metric | RF Modules Placement | Chipsets Placement |

|---|---|---|

Best Positioning | Edges of PCB | Center of PCB |

Time-to-First-Fix (TTFF) | Faster with edge placement | Slower in the center |

Signal Strength (C/N0) | Higher at edges | Lower due to interference |

Accuracy (CEP) | Better with edge placement | Standard performance |

Good antenna placement ensures strong communication, especially for industrial IoT where data sharing is key.

Setting Up and Configuring Software

After hardware assembly, install and set up the software. Load the firmware onto the wireless sensor node and set communication rules. Use a computer with the right tools for this step. Follow the maker’s instructions to avoid problems.

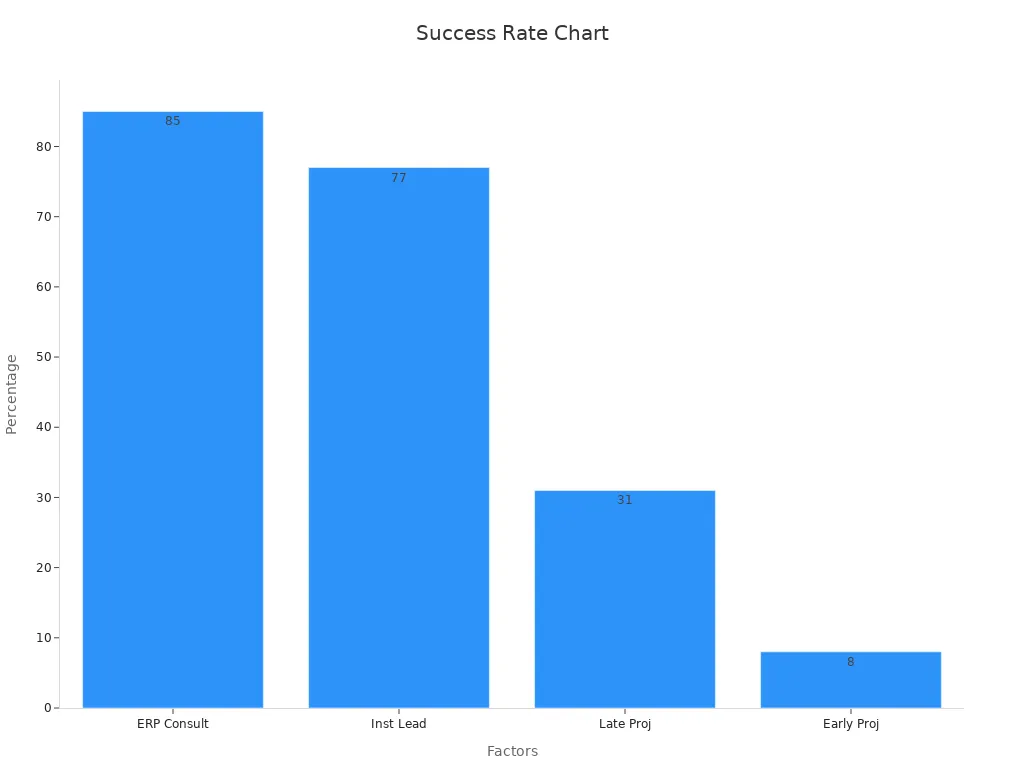

Correct software setup is very important for success. For example, companies using software experts for ERP systems see an 85% success rate. The chart below shows more stats about software setup success:

Test the module in real-life conditions during setup. This ensures it works well with your current system. A well-set module improves the whole assembly’s reliability and performance.

Note: Save your settings to avoid losing data during updates or fixes.

Securing the Module for Industrial Use

Keeping your industrial wireless communication module safe makes it work better. It also protects it from damage and cyber risks. Harsh conditions in factories can harm the module. Using the right methods keeps it strong and secure.

Physical Protection of the Module

Protect the module from physical harm first. Use special covers made for factories. These covers keep out dust, water, and heat. For example, IP-rated covers offer different levels of protection. Pick one that fits your factory’s needs.

Attach the module tightly to stop shaking or falling off. Use screws or brackets to hold it firmly. Loose parts can break the module or stop data flow. A steady setup helps it work well for a long time.

Tip: Mark all wires clearly to make repairs easier and faster.

Adding Security Modules

Security modules make the system safer. They check and protect data from start to finish. You can add them to old systems without changing how they work. This method adds extra safety layers.

Update security keys often to block hackers. Old keys can be unsafe and easy to crack. Managing keys well keeps devices talking securely.

Security Measure | Benefit |

|---|---|

Adding security modules | Protects data and ensures safe communication. |

Extra safety layers | Improves security without changing old systems. |

Updating keys regularly | Stops hackers and keeps data safe. |

Grounding and Shielding the Module

Grounding and shielding stop electrical problems. Connect the ground wire to a safe spot. This lowers the chance of static shocks and noise.

Use metal covers or special coatings to block interference. Electrical noise can mess up wireless signals. Shielding keeps signals clear and strong.

Testing for Safety and Strength

Test the module after securing it. Pretend it’s in real factory conditions to find problems. Check if signals stay strong and data is correct. Fix any issues quickly to keep it reliable.

Note: Write down your test steps and results. This helps you fix problems later and track progress.

Following these steps makes your module safe and reliable. A secure module works better and lasts longer in tough factory environments.

Testing and Troubleshooting Wireless Communication Modules

Testing for Functionality and Signal Stability

Testing makes sure the module works properly. First, turn it on and check if all parts respond. Use a multimeter to see if the voltage is correct. Then, test if it can send and receive data. This step ensures it works well in real situations.

Signal strength is also important. Move the module to different spots and measure signals. Tools like spectrum analyzers help find weak signals or interference. For industrial IoT, strong signals are needed for smooth communication. Test the module in tough conditions like heat or humidity. This ensures it works in harsh environments.

Tip: Write down test results to track performance over time.

Identifying and Resolving Common Issues

Problems can happen even with careful assembly. Weak signals, data loss, or broken parts are common issues. To fix them, check each part one by one. For weak signals, look at the antenna’s position and connections. Moving the antenna often solves signal problems.

Software issues can also cause trouble. Make sure the firmware is updated and matches the module. If it doesn’t connect to other devices, check if they use the same communication rules. Fixing these problems helps the module work better.

The table below shows key testing metrics and why they matter:

Metric | Description | Importance |

|---|---|---|

Pass Percentage | Shows how many tests passed. | Tells if the software is reliable. |

Fail Percentage | Shows how many tests failed. | Points out problems to fix. |

Test Efficiency | Finds defects during testing. | Helps improve testing and save resources. |

Defect Density | Counts defects compared to code size. | Shows where the code needs improvement. |

Mean Time to Repair | Time taken to fix a problem. | Shorter times mean less disruption. |

Using these metrics helps find and fix weak spots in the module.

Ensuring Seamless Integration with Other Systems

The module must work well with your current systems. First, check if its communication rules match your IoT setup. This ensures devices can share data easily.

Next, test how it works with the whole system. Pretend it’s in real situations to find problems. For example, see if it handles data from many devices at once. This step ensures the system stays stable under heavy use.

Lastly, focus on security. Use encryption to keep data safe from hackers. Update the firmware often to fix security holes. A secure and well-matched module improves your IoT system’s performance.

Note: Save a backup of your system settings. This helps restore it quickly if something goes wrong.

Best Practices for Efficient and Reliable Assembly

Tips for Making the Assembly Process Easier

Making the assembly process easier saves time and avoids mistakes. Start by keeping your workspace neat using the 5S method: sort, organize, clean, standardize, and maintain. This keeps tools and parts easy to find, reducing delays. Lean manufacturing methods also help by cutting waste and improving speed. For example, Kanban boards can track inventory and stop overproduction.

Using Six Sigma principles lowers errors and improves quality. Check your workflow often to find slow steps or wasted effort. Value stream mapping is a great way to see processes and find ways to improve. These methods boost productivity and give better results for customers.

Technique | Benefits |

|---|---|

Lean Manufacturing | Cuts waste, speeds up work, and adds value for customers. |

Six Sigma | Reduces errors, improves quality, and increases customer happiness. |

Value Stream Mapping | Shows processes, finds slow spots, and improves efficiency. |

Clear records of your setup help others repeat your process. This ensures consistent results every time.

Improving Long-Term Strength and Performance

To make the module last longer, focus on quality at every step. Use strong materials that can handle tough factory conditions. Grounding and shielding protect the module from electrical problems that can mess up signals. Tighten all connections to avoid wear and damage over time.

Test the module during and after assembly to check its performance. Try it in real-world conditions, like high heat or humidity, to see if it works well. This ensures the module stays reliable for IoT tasks.

A test is reliable if another team gets the same results using the same tools. Accurate measurements are key for this.

Taking Care of the Module After Assembly

Taking care of the module helps it last longer. Clean it often to remove dust that could cause problems. Check connections and parts for damage. Replace broken parts quickly to avoid bigger issues.

Update the module’s software regularly to improve its features and security. This is very important for IoT systems, where old software can be unsafe. Keep a record of maintenance to track the module’s condition. This careful approach keeps the module working well and safely.

Follow six key steps for reliable testing. These steps ensure high-quality results and accurate experiments.

Learning to build industrial wireless modules needs good planning and focus. Step-by-step instructions help you work correctly and quickly. Testing the module well makes sure it works in real life. Keeping your workspace clean and securing the module improves how it works and lasts longer.

By following these steps, you can build modules that connect easily with IoT systems. This method makes wireless communication better and reduces mistakes, saving both time and effort.

FAQ

What does an industrial wireless communication module do?

It helps devices share data without wires. This module is key for IoT systems. It makes machines talk to each other easily. This improves work speed and cuts down on wiring.

How can the module survive tough conditions?

Protect it with special covers to block dust and heat. Grounding stops electrical problems. Test it in hot or wet places to check if it works well.

Can old module parts be used again?

Yes, you can reuse parts if they still work. Make sure they fit the new system. Test them to see if they meet your IoT needs.

Why does antenna placement matter?

Where you put the antenna changes how signals work. Putting it at PCB edges makes signals stronger. It also reduces interference for better communication.

How often should the software be updated?

Update the software often to add new features. Updates keep the module safe from hackers. They also make sure it works with new IoT systems.

See Also

Grasping The Essentials Of PCBA Manufacturing And Assembly

Essential Strategies To Enhance PCB Assembly Productivity

Ten Professional Suggestions For Cost-Effective PCBA Assembly