When it comes to electric cars, safety is very important. A key part of this safety is the ISO 26262 compliant PCBA for EV. This special circuit board meets strict car safety rules. It lowers risks in important systems like batteries and power control.

ISO 26262 compliant PCBAs for EV help handle the tricky parts of EV electronics. They make sure every system works well, even in tough situations. By following these rules, companies can make EVs that are fast and safe to drive.

Key Takeaways

ISO 26262 rules are important for keeping electric cars safe. They make sure key parts like brakes and batteries work well.

Printed Circuit Board Assemblies (PCBAs) help control EV electronics. They stop problems that might cause accidents.

Following strict safety steps when designing and testing PCBAs lowers risks. It also makes electric cars work better.

Teams for design, making, and testing must work together. This helps meet ISO 26262 rules and create safe, good-quality PCBAs.

Using PCBAs that follow ISO 26262 builds trust with buyers. It also meets safety laws, making electric cars safer and more popular.

What Is ISO 26262-Compliant PCBA for EV?

Overview of ISO 26262 and its focus on functional safety

ISO 26262 is a worldwide rule for keeping car electronics safe. It helps find and fix problems that could cause system failures. These failures might harm passengers or other drivers. By following this rule, companies can make systems that spot issues early. These systems act quickly to stop accidents from happening.

The need for ISO 26262 is clear when looking at crash data. In 2022, car crashes caused about 40,000 deaths. Even with better car technology, 42,514 deaths happened in 2023. These numbers show why strong safety rules like ISO 26262 are still needed. They help solve the safety challenges of modern cars.

Role of PCBAs in electric vehicles

Printed Circuit Board Assemblies (PCBAs) are key parts of EV electronics. They control important systems like batteries, charging, and power flow. Without good PCBAs, these systems might fail. This would hurt both safety and performance.

In EVs, PCBAs are crucial for safety systems. For example:

They check sensors to make airbags work in crashes.

They process data for ADAS to help avoid accidents.

They improve braking and stability in ABS and ESC systems.

The table below shows how PCBAs help in safety systems:

Application | Role in Safety Protocols |

|---|---|

Airbags | Checks sensors to make airbags deploy during crashes. |

Advanced Driver-Assistance Systems | Processes data to warn drivers and prevent accidents. |

Anti-Lock Braking Systems | Helps brakes work better and keeps control during stops. |

Electronic Stability Control | Tracks steering and wheel speed to keep cars stable. |

Vehicle Communication Networks | Handles communication for different safety systems. |

Fuel Injection Control | Controls fuel use for better engine performance. |

Shock Load and Engine Vibration Management | Manages suspension to reduce engine shakes and impacts. |

Engine and Gear Control | Controls engine and gear shifts for smooth driving. |

By making sure these systems work well, PCBAs boost EV safety and reliability.

Key requirements for ISO 26262 compliance

To meet ISO 26262 rules, companies must follow strict steps. These steps ensure all parts, including PCBAs, meet top safety standards. The table below lists some key rules for compliance:

Compliance Requirement | Description |

|---|---|

ISO 26262 | |

Safety Aspects | Focuses on keeping car electronics safe on the road. |

Risk Mitigation | Reduces risks to protect passengers and other drivers. |

For EV PCBAs, meeting these rules involves several tasks:

High-voltage safety: Special materials keep insulation strong and prevent failures. Coatings are added to high-voltage areas for extra protection.

Thermal management: Cooling methods like copper-graphene layers manage heat better. This stops overheating and makes parts last longer.

Electromagnetic compatibility (EMC): Shields and frequency controls reduce interference. This ensures PCBAs work without affecting other systems.

Environmental durability: Water-resistant and corrosion-proof materials make PCBAs last longer. Tests are done to find weak spots and improve designs.

By following these steps, companies can make ISO 26262-compliant PCBAs. These PCBAs improve the safety, reliability, and performance of EVs.

Why Does ISO 26262 Matter for Electric Vehicles?

Keeping EV Systems Safe and Working Well

Electric cars need advanced electronics to work safely and smoothly. These systems manage things like batteries and motors. ISO 26262 makes sure these systems follow strict safety rules. This helps lower the chance of problems in key parts. It’s especially important for motor systems, where small issues can cause big dangers.

ISO 26262 finds risks early during design. It ensures systems like brakes and steering work in all conditions. For example, in motor control, it helps handle sudden speed or load changes safely. By following this rule, companies make cars that are safe and efficient for daily use.

Solving Special EV Problems Like High Voltage and Batteries

Electric cars have challenges that regular cars don’t face. High voltage, battery management, and self-driving features need extra care. ISO 26262 gives a plan to handle these risks.

High-voltage systems use designs that keep working if one part fails.

Self-driving systems depend on data and sensors. ISO 26262 ensures these systems stay safe and reliable.

Battery systems deal with fast charging, heat, and energy flow. The rule ensures they work without overheating or breaking.

ISO 26262 checks every step, from design to testing. This makes sure both technical and management processes meet top safety levels. By solving these problems, the rule helps make EVs safe and dependable.

Following Rules and Gaining Trust

As electric cars grow popular, meeting safety rules is a must. Governments and groups require ISO 26262 for safety certifications. This shows your car meets high safety standards. It also builds trust with buyers who want safe, reliable cars.

Some regions demand ISO 26262 for cars sold there. Following this rule avoids legal trouble and shows your brand cares about safety. It also helps you compete in a market where safety matters most.

Designing and Manufacturing ISO 26262-Compliant PCBAs

Principles of functional safety in PCBA design

Making a printed circuit board assembly (PCBA) for electric cars needs strict safety rules. These rules make sure safety parts work well in all situations. To meet ISO 26262 rules, follow these steps:

Component Selection: Pick strong parts that last in car conditions.

Design for Reliability: Add backup circuits and use durable materials.

Testing and Validation: Test parts for stress and electrical performance.

Manufacturing and Quality Control: Use top standards and check everything carefully.

Documentation and Compliance Reporting: Keep detailed records to prove safety.

Safety testing starts during design. You must find risks, spot dangers, and fix them early. This makes sure the PCBA meets safety levels and global standards.

Testing and validation for ISO 26262 compliance

Safety testing is key to proving ISO 26262 compliance. Tests check if safety parts work as planned. The table below shows important test methods:

Methodology | Description |

|---|---|

Fault Injection | Adds faults to test how systems handle problems. |

Measures how well safety features work. | |

Mutation Testing | Combines with fault tests to improve safety checks. |

Random hardware failure tests are also needed. Simulators add faults to check safety systems. Formal checks sort faults and study their effects on safety. These tests find and fix problems before production.

Collaboration across design, manufacturing, and testing teams

Meeting ISO 26262 rules needs teamwork between design, manufacturing, and testing groups. Each group helps meet safety goals. Designers make layouts with good insulation and heat control. Manufacturers use strong materials and follow strict rules. Testers check the PCBA with tough safety tests.

Good communication helps teams meet safety standards. For example, devices can spot insulation leaks, and heat tests improve cooling designs. By working together, teams create safe and reliable PCBAs for electric cars.

Benefits of ISO 26262-Compliant PCBAs in EVs

Better safety and fewer risks

ISO 26262-compliant PCBAs help make electric cars safer. They ensure systems like brakes, steering, and batteries work well in all conditions. By following strict safety rules, they lower the chance of system failures that could cause accidents. For example, special coatings and insulation monitoring stop electrical problems. These features keep insulation strong and quickly find leaks, offering extra protection.

Testing is also very important for safety. Fault injection and diagnostic tests check how systems handle real-life problems. These tests find risks and make sure systems respond correctly. Because of this, ISO 26262-compliant PCBAs greatly reduce the chances of dangerous failures in car electronics.

Stronger reliability and better performance

Reliability is key for ISO 26262-compliant PCBAs. They go through tough tests to prove they can handle the challenges of electric cars. Tests include checking for heat, cold, vibrations, and electromagnetic interference. These tests show that PCBAs can work well even in extreme conditions.

Key Performance Features:

Following IATF 16949 and SAE J2980 ensures strong designs and builds.

Advanced cooling methods, like copper-graphene layers, manage heat better and last longer.

Multi-layer shields cut down interference, keeping electronics working smoothly.

These features make EV systems more reliable and improve how they perform. For example, better cooling lowers heat by up to 25°C. Shields stop interference, helping parts communicate better. This makes driving safer and smoother for you.

More trust and meeting rules

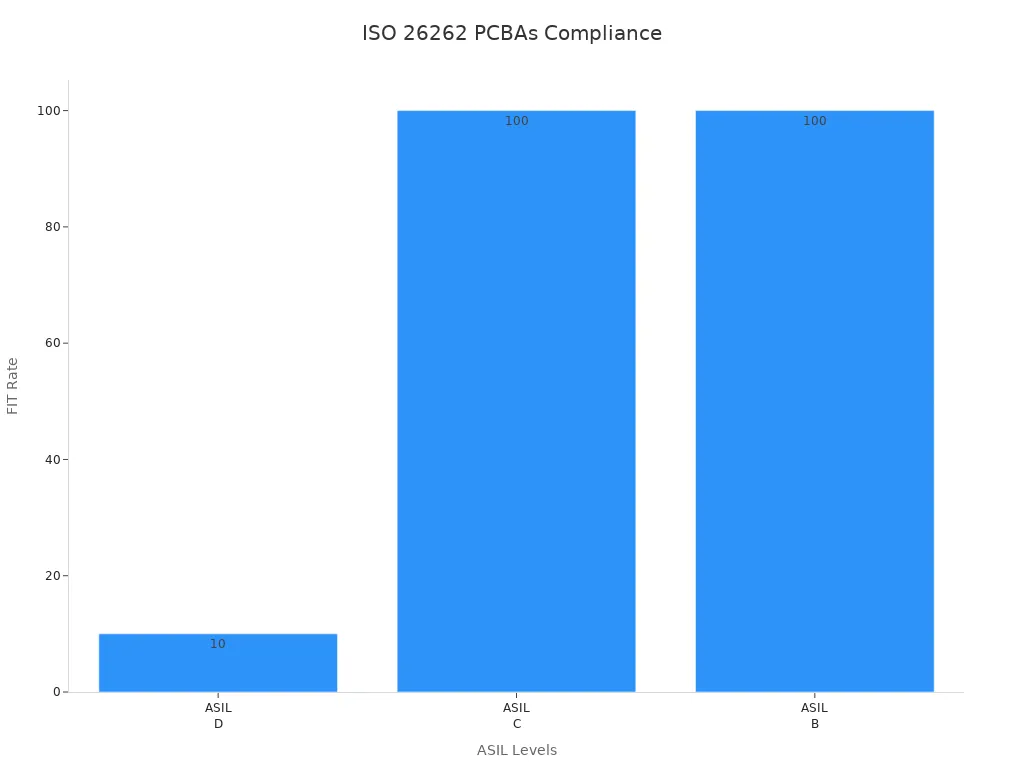

Using ISO 26262-compliant PCBAs shows a focus on safety and quality. This builds trust with buyers who care about safe and reliable cars. It also meets important rules like ASIL, which sets limits for hardware failures.

ASIL | PMHF Requirement | Note |

|---|---|---|

D | < 1E-08/hr (10 FIT) | Required |

C | < 1E-07/hr (100 FIT) | Required |

B | < 1E-07/hr (100 FIT) | Recommended |

A | – | No requirement |

Meeting these rules helps companies stay on track with designs and deadlines. It also boosts their reputation and speeds up the use of electric cars in the market.

ISO 26262-compliant PCBAs are important for safer electric cars. They help systems like batteries, brakes, and sensors work well. This lowers risks and makes EVs perform better. Following these safety rules builds trust in EVs and helps more people use them.

As electric cars improve, safety rules stay important.

Strong safety steps reduce risks and make people trust EVs.

Solving problems with high-voltage parts and sensors makes cars safer.

Sticking to ISO 26262 rules helps create new ideas while keeping EVs safe.

FAQ

What is ISO 26262 for car electronics?

ISO 26262 is a safety rule for car electronics. It makes sure systems like brakes and sensors work safely in all conditions. Following these rules helps lower risks and keeps cars safer.

How do PCBAs help keep EVs safe?

PCBAs manage key systems in electric cars, like batteries and power flow. They make sure these systems work well and stay safe, even in tough conditions.

Why does functional safety matter in car design?

Functional safety stops system failures that could cause accidents. It ensures every part of the car works properly to protect people inside and outside the car.

How are ISO 26262 PCBAs tested?

Tests include adding faults, checking safety features, and stress tests. These tests make sure PCBAs can handle real-world problems without failing.

Can ISO 26262 make EVs more reliable?

Yes, it ensures strong designs and careful testing. This improves how electric cars perform and makes them safer for daily use.

See Also

Exploring PCBA Concepts and Their Importance in Electronics

Defining PCBA and Its Significance in Electronic Systems

Benefits and Drawbacks of Flexible PCBA in Today’s Electronics

Understanding PCB Busbars and Their Function in Electronics

Grasping PCBA Definitions and Their Essential Uses in Electronics