Achieving excellent results in PCB assembly requires strong teamwork.

Collaborating closely with PCBA manufacturers allows for early problem-solving.

Early cooperation between design and manufacturing teams helps prevent errors.

This collaboration streamlines the process, making it faster and more efficient.

The PCB industry continues to evolve with innovations like compact designs and 5G technology.

Partnerships with PCBA manufacturers enable the adoption of new technologies and enhance supply chain efficiency.

Companies that foster collaboration often experience smoother assembly processes and superior outcomes.

Effective communication and thorough planning are essential for success.

Key Takeaways

Work with PCBA manufacturers early to fix issues before production.

Follow DFM rules to make designs simple and avoid mistakes.

Choose good-quality parts from reliable suppliers for better performance.

Use strong testing and checks to find problems early and keep quality high.

Talk clearly and set goals with manufacturers to boost teamwork and work faster.

Understanding the Basics of Working with PCBA Manufacturers

What is PCB Assembly and Why It Matters

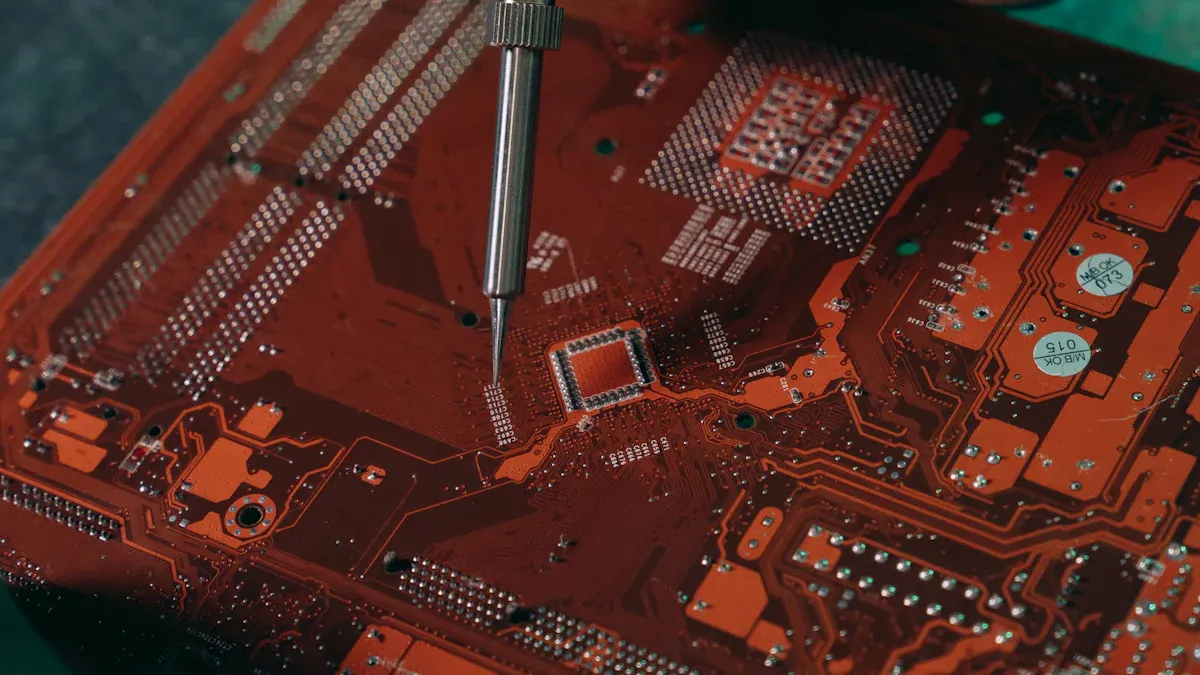

PCB assembly turns a plain circuit board into a working device. This process is very important in making modern electronics. It helps create gadgets that are smaller, lighter, and work better. Techniques like Surface Mount Technology (SMT) and Through-Hole Technology (THT) make designs compact and speed up production. These methods help meet the rising need for advanced electronics.

PCB assembly also improves signal quality and reduces interference. This is crucial for devices like medical tools and communication systems that need to work reliably. Knowing how this process works helps you understand its value in electronics manufacturing.

The Role of High-Quality PCB Manufacturers in the Process

Good PCB manufacturers are key to successful assembly. They bring knowledge, advanced tools, and strong quality checks. Their focus is on fewer mistakes, better efficiency, and on-time delivery. This directly improves how well your devices perform.

For instance, quality checks include testing before, during, and after production. This ensures every product meets high standards. Top PCB manufacturers also manage supply chains well. They solve problems like part shortages and reduce delays, keeping production smooth.

Metric | How It Helps Production |

|---|---|

PCB Production Efficiency | Cuts costs and lowers mistakes |

PCB Quality Control Metrics | Speeds up delivery and improves product quality |

Financial KPIs | Saves money and reduces spending |

Operational KPIs | Supports new ideas and eco-friendly efforts |

Overall Efficiency Improvement |

Common Challenges in PCB Assembly Services

Working with PCBA manufacturers can have problems. Shortages of parts, long wait times, and poor communication can slow things down. These issues may cause delays and raise costs. To fix this, work closely and communicate well with your manufacturers.

Another issue is choosing good-quality parts. Bad parts can cause errors and make devices less reliable. Buying from trusted suppliers helps avoid this. Using automation in assembly also fixes problems and makes production smoother.

Concept | Explanation |

|---|---|

Definition | PCBA manufacturing means adding electronic parts to a PCB to make it work. |

Technologies | SMT and THT are used, with SMT making smaller designs and faster production. |

Quality Control Measures | Steps like testing before, during, and after production ensure high quality. |

Supply Chain Management | Managing parts and solving delays keeps production running smoothly. |

Importance of Automation | Automation makes production faster and more reliable, helping create better electronics. |

By solving these problems, you can get better results and build stronger relationships with your PCBA manufacturers.

Key Tips for Ensuring Quality in PCB Assembly

Design for Manufacturability (DFM) Principles

DFM helps make the PCB assembly process easier. Designing with manufacturing in mind reduces mistakes and boosts efficiency. Keep your design simple to avoid problems during assembly. Use common parts and leave enough space between them. This prevents soldering issues and ensures smooth production.

Work with your PCBA manufacturers early in the design stage. Their knowledge can help spot problems before production starts. For instance, they might suggest changes to speed up assembly or cut down on waste. Using DFM principles saves time, lowers costs, and improves product quality.

Selecting High-Quality Components and Sourcing

Picking good parts is key for reliable PCB assembly. High-quality components last longer and work better. Always buy from trusted suppliers. Check their defect rates, delivery times, and if they meet standards.

Metric | Description | Importance |

|---|---|---|

Percentage of faulty products. | Low rates mean better quality; high rates show problems. | |

Compliance | How often parts meet agreed standards. | Consistency ensures smooth production and good quality. |

Keep an eye on supplier performance often. This ensures parts arrive on time and meet quality needs. Reliable sourcing reduces risks and keeps production running smoothly.

Testing and Quality Control Best Practices

Testing is vital to ensure high-quality PCB assembly. Use tools like automated optical inspection (AOI) to find defects early. Functional testing checks if the product works as it should.

Set up strong quality systems like ISO 9001 to improve processes. Methods like Six Sigma help maintain consistent quality and reduce errors.

Tip: Review your testing methods regularly. This helps find weak spots and ensures your products meet customer needs.

By following these steps, you make your PCBs more reliable and cut down on rework costs. Testing and quality control are smart investments for better products.

Strategies for Improving Efficiency with PCBA Manufacturers

Clear Communication and Teamwork

Good communication with your PCBA manufacturers makes assembly better. Misunderstandings can cause delays, mistakes, and higher costs. Research shows 86% of workplace problems come from poor teamwork. On the other hand, clear communication can raise productivity by 25%.

Statistic | Value |

|---|---|

Workplace failures caused by poor teamwork | 86% |

Productivity boost from clear communication | 25% |

Leaders who think communication helps productivity | 64% |

Workers who agree | 55% |

To work better together, set clear goals and check in often. Use tools to track tasks and solve problems quickly. This keeps things running smoothly and improves results.

Shortening Lead Times in PCB Assembly

Shorter lead times are key for faster assembly. Long waits can delay deliveries and raise costs. By cutting lead times, you can deliver quicker and make customers happier.

Metric | Before Changes | After Changes | Improvement |

|---|---|---|---|

Average Lead Time | 6-7 weeks | 4-5 weeks | 30-35% shorter |

On-Time Delivery Rate | 85% | 97% | 12% better |

Customer Satisfaction Scores | Baseline | +25% | Big improvement |

Overall Production Costs | Baseline | -15% | Lower costs |

Work with your manufacturers to fix slow steps and improve processes. Using methods like Just-In-Time (JIT) production can save money and speed things up.

Using Technology and Automation in PCB Assembly

Technology and automation are important for modern PCB assembly. Automated tools find problems early, reduce downtime, and improve quality. For example, Automated Optical Inspection (AOI) spots defects, and In-Circuit Testing (ICT) checks if products work.

Faster Production: Automation speeds up assembly.

Less Downtime: Real-time data helps prevent breakdowns.

Better Quality: Automated tools make products more reliable.

Lower Costs: Automation cuts labor and assembly expenses.

Flexibility: Automated systems adjust to new needs easily.

By using these tools, you can keep quality high and costs low. Work with your manufacturers to add advanced technology and improve your processes.

Getting great results in PCB assembly needs smart planning and teamwork. Use DFM rules, check quality often, and communicate clearly. These steps stop problems, make products better, and lower mistakes.

Work with manufacturers early to find better designs and materials.

DFM checks make production easier and increase success rates.

Talking to assemblers during design helps avoid assembly mistakes.

Talk to skilled PCBA manufacturers for advice. Look at your process to find ways to improve. These steps will make assembly smoother and boost product quality.

FAQ

What is the difference between PCB manufacturing and PCB assembly?

PCB manufacturing makes the empty board. PCB assembly adds parts to make it work. Manufacturing builds the board’s shape, while assembly makes it functional.

How can you ensure high-quality PCB assembly?

To ensure quality, use trusted suppliers and follow DFM rules. Test thoroughly and work with skilled manufacturers to fix problems early.

Why is testing important in PCB assembly?

Testing checks if the PCB works and meets standards. It finds problems early, saves money, and improves reliability. Tools like AOI and ICT make testing faster and better.

What role does automation play in PCB assembly?

Automation makes production quicker and reduces mistakes. It keeps quality steady and handles tricky designs well. Automated systems also adjust easily to new needs.

How do you choose the right PCB manufacturer?

Pick a manufacturer with good experience, advanced tools, and strong quality checks. Choose one with clear communication, reliable delivery, and knowledge of your industry.

See Also

Essential Tips for Selecting a Reliable PCBA Supplier

Finding the Perfect PCBA Manufacturer for Business Growth

Enhancing Workflow Efficiency in PCBA Production Processes

Investigating PCBA Testing Methods for Superior Electronics Production

Understanding PCBA Services and Their Importance in Electronics