Improving low volume high mix industrial PCB assembly enhances a business’s competitive edge.

It allows for faster product creation and earlier launches.

Producing small batches aids in quality checks and early problem resolution.

This guarantees that products meet high standards.

Low volume high mix industrial PCB assembly reduces initial costs for tools and machinery.

This approach is particularly beneficial for startups and small to medium-sized businesses.

By maintaining flexibility, ensuring quality, and managing costs, businesses can achieve greater success.

These strategies support low volume high mix industrial PCB assembly and facilitate future growth.

Key Takeaways

Making low volume high mix PCB assembly faster improves competition. It helps create products quickly and keeps quality high.

Using live tracking tools and many suppliers helps handle supply chain issues. This also lowers risks.

Adding machines and teaching workers increases speed and keeps quality steady in PCB assembly.

Using lean manufacturing ideas reduces waste and makes production better. This saves money.

Building good relationships with suppliers ensures on-time deliveries and good materials. These are important for success.

Key Challenges in Low Volume High Mix Industrial PCB Assembly

Supply Chain Complexities and Inventory Management

Handling the supply chain for low volume high mix PCB assembly is tricky. Inventory levels often change, and supplier delivery times can be unpredictable. Using real-time tracking tools and predictive systems helps you stay prepared. Having multiple suppliers can reduce risks from price changes or stock issues.

Here are some useful metrics to track inventory and supply chain:

Metric | Description |

|---|---|

Inventory Turnover | Tracks how often inventory is sold and replaced, showing how well inventory is managed. |

Days Inventory Outstanding (DIO) | Shows how many days it takes to turn inventory into sales, helping measure efficiency. |

Inventory Days of Supply | Tells how long current stock will last based on demand, ensuring enough supply. |

Inventory-to-Sales Ratio | Compares stock levels to sales, giving insights into inventory practices. |

Using these metrics can improve inventory control and speed up production times.

High Costs in Low Volume PCB Assembly

Making low volume PCBs costs more per unit. Setup costs spread over fewer units, raising the price per piece. Big production runs save money, but small ones offer flexibility and lower stock risks. This makes them great for special products or prototypes.

To save money, focus on cutting setup costs and improving processes. Automation and better tools can lower labor costs and boost efficiency in PCB assembly.

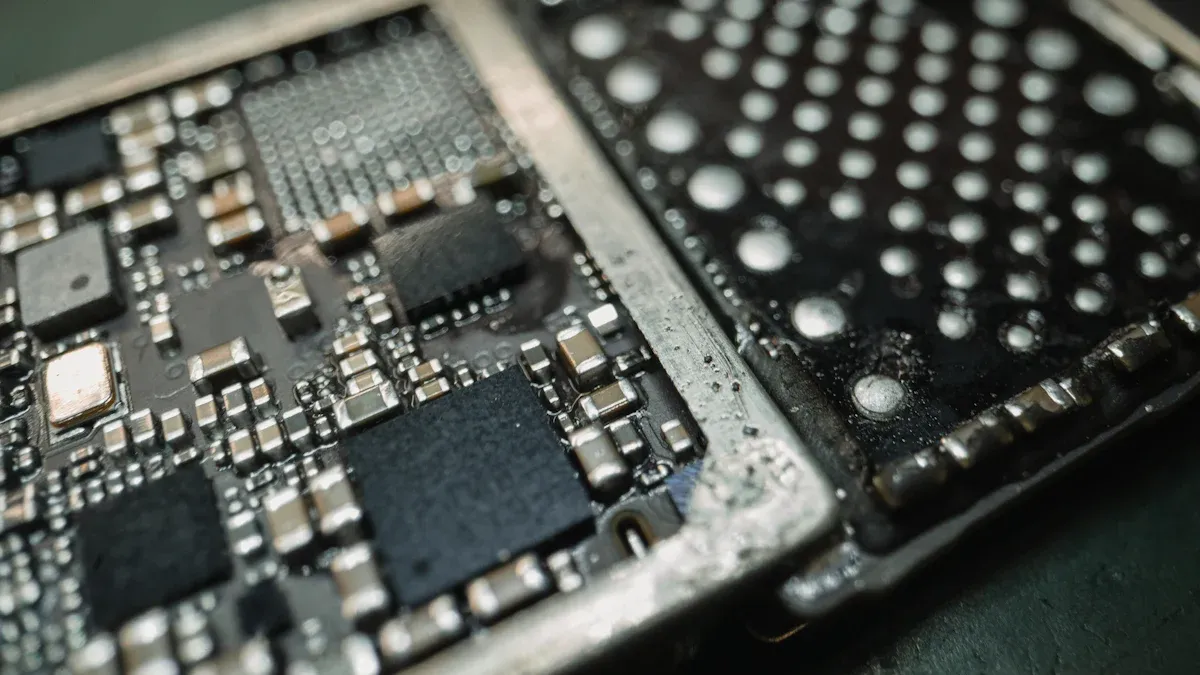

Maintaining Quality Across Diverse Products

Keeping quality high in low volume high mix PCB assembly needs extra care. Each product has different needs, making quality checks harder. Automated Optical Inspection (AOI) systems can find problems early and keep quality steady across designs.

Using the same parts and steps when possible can make production easier and reduce mistakes. Strong testing ensures every product meets high standards. By focusing on quality, you can earn customer trust and grow your reputation in PCB assembly.

Adapting to Frequent Design Changes

Design changes can slow production and raise costs. Adjusting setups for each change takes time and effort. These changes often happen because customers want updates or better features. To handle this well, you need smart strategies.

Review designs early to spot problems before production starts. This saves time and avoids expensive fixes later. Choices made during design affect how fast and smooth production goes. Frequent changes can stretch timelines and add costs. Fixing manufacturability issues early keeps things running better.

Flexible tools make adapting easier. PCB software with live simulations lets you test designs before making them. This lowers mistakes and helps when changes are needed. Good communication between design and production teams avoids confusion and keeps everyone on track.

Workforce Expertise and Training Gaps

Skilled workers are key for handling tricky PCB assembly jobs. But training gaps can make meeting goals harder. Workers might not know how to use advanced tools or handle different products.

Regular training programs can fix these gaps. Teach your team about new tools and methods in PCB assembly. Hands-on classes and certifications build their skills and confidence. Training workers for multiple roles adds flexibility and cuts downtime.

Support learning by offering online courses, webinars, and guides. This helps workers improve and boosts overall production. A trained team keeps quality high and works efficiently, even with tough tasks.

Strategies to Improve HMLV Manufacturing

Lean Manufacturing to Cut Waste

Lean manufacturing helps reduce waste and improve efficiency. In low volume PCB assembly, waste comes from extra materials, long setups, or unneeded steps. Removing these problems can save money and time.

First, check your production process. Find steps that don’t help the final product. For example, moving materials too much or repeating quality checks wastes time. Simplify these steps to work faster and use fewer resources.

Using just-in-time (JIT) inventory management is also helpful. This method orders materials only when needed, cutting storage costs and waste. Modular production lines can adjust quickly to design changes, making your process more flexible.

Lean manufacturing saves money and keeps quality high. By focusing on cutting waste, you can succeed in low volume PCB assembly.

Making Supply Chains More Flexible

A flexible supply chain is key for HMLV manufacturing. It helps you handle changes in demand or designs quickly. This is important because high-mix low-volume production often has changing needs.

To improve flexibility, work with several suppliers. This lowers the chance of delays or running out of materials. Having more suppliers also helps you get better prices and steady supplies.

Use tools to track inventory and supplier performance in real time. These tools show useful data to help you make smart choices. For example, you can see how much material you use and adjust orders as needed.

The table below compares HMLV manufacturing with traditional large-scale production, showing why flexibility matters:

Aspect | HMLV Features | Large-Scale Features |

|---|---|---|

Production Scale | Small, flexible runs; easy to adapt | Big, steady runs; fixed processes |

Flexibility | Great for custom products | Hard to change |

Setup Costs | Lower costs; modular setups | High costs; special equipment |

Production Costs | Higher per unit; more labor needed | Lower per unit; automated processes |

Quality Control | Careful checks for each item | Automated checks; standard rules |

Customization | Easy to customize and change | Limited changes allowed |

Market Focus | Niche markets; handles changing demand | Mass markets; steady demand |

By improving supply chain flexibility, you can handle design changes and meet customer needs better.

Using Automation in HMLV Production

Automation is important for high-mix low-volume production. It boosts efficiency, reduces mistakes, and keeps quality steady. In PCB assembly, automation cuts downtime and speeds up work.

Advanced machines, like pick-and-place systems, can handle many designs easily. These machines adjust quickly to different needs, making them perfect for low volume PCB assembly. Automated Optical Inspection (AOI) systems also improve quality by finding problems early.

Here are some benefits of automation in HMLV manufacturing:

Faster production by reducing delays between steps

Fewer quality issues with better-trained workers

Quick process changes for faster production

Investing in automation improves efficiency and saves money. It helps you make prototypes quickly and meet tight deadlines without losing quality.

By using automation, you can solve challenges in low volume high mix PCB assembly and succeed in the long run.

Workforce Training for Specialized Skills

Your team is very important for HMLV PCB assembly. Workers need special skills to handle different designs and tools. Without these skills, mistakes can happen and slow things down. Training programs help workers learn and stay ready for challenges.

First, find out what skills your team is missing. For example, they might need to learn how to use pick-and-place machines or AOI systems. After finding the gaps, make a training plan. Workshops and certifications are great for teaching real-life skills. These methods help workers feel confident and capable.

Training workers for multiple jobs is also helpful. If workers can do more than one task, it reduces delays. For example, someone trained in assembly and quality checks can help where needed. This teamwork makes production smoother and faster.

Keep learning going by offering online classes and webinars. Websites like IPC EDGE or Coursera have PCB assembly courses. Helping workers grow their skills also makes them happier at work. A skilled team keeps quality high and handles HMLV challenges well.

Streamlining Design and Production Collaboration

Good teamwork between design and production teams is very important. If they don’t work well together, it can cause delays and mistakes. Better communication helps things run smoothly and improves results.

One way to improve teamwork is to involve production early in design. Manufacturing experts can check designs for problems and suggest fixes. This method, called Design for Manufacturability (DFM), makes assembly easier. For example, Apple includes its production team early in design. This helps them make products faster and better.

Using shared tools also helps teams work together. PCB software with live simulations lets both teams test designs. Real-time feedback avoids confusion and keeps everyone on the same page. Regular meetings also help solve problems quickly.

Many companies show how teamwork improves production. The table below lists examples of better design and production collaboration:

Company | Industry | Improvement | Evidence Link |

|---|---|---|---|

Tesla Motors | Automotive | Better designs improved production and product quality | |

Toyota | Automotive | Fewer parts and error-proofing boosted efficiency and quality | |

Apple Inc. | Consumer Electronics | Early production input simplified assembly |

These examples show how teamwork helps companies succeed. For instance, Toyota’s focus on fewer parts improved reliability. In 2022, Toyota ranked high in customer satisfaction studies. Apple’s teamwork helped them lead the smartphone market with great customer ratings.

By improving teamwork, you can avoid mistakes and make better products. Good communication between design and production teams is key for HMLV PCB assembly success.

Tools and Technologies for Low Volume PCB Assembly

Flexible Pick-and-Place Machines for Different Designs

Flexible pick-and-place machines are important for low volume PCB work. These machines can handle many parts and adjust to new designs fast. Unlike older systems, they don’t need big changes, saving time and reducing delays.

These machines place parts accurately, even on tricky boards. They can switch tasks easily, making them great for PCB assembly with changing designs. For example, one machine can make small prototypes and bigger batches without losing accuracy.

Using flexible pick-and-place machines makes work faster and reduces mistakes. This keeps your production process flexible, even with high-mix, low-volume needs.

PCB Design Software with DFM Tools

PCB design software with Design for Manufacturability (DFM) tools is very helpful. These tools find problems early in the design stage, saving time and money.

Here’s how DFM tools improve your designs:

They check for errors like wrong part sizes or spacing issues.

Teamwork tools help everyone share ideas and avoid mistakes.

Better designs mean faster production and quicker product launches.

With DFM software, your designs match manufacturing needs. This cuts down on costly fixes and makes low volume PCB assembly more efficient.

Automated Optical Inspection (AOI) Systems for Quality

Automated Optical Inspection (AOI) systems are key for checking quality in PCB assembly. These systems use cameras to find problems early, stopping bad products from being shipped.

AOI systems have many benefits:

They spot physical issues, like bad soldering, before they cause trouble.

Data tools, like Pearson Correlation, link defects to failures, helping fix processes.

Early problem detection lowers waste and keeps quality steady.

The table below shows how AOI systems reduce defects:

Defects | Failures | |

|---|---|---|

10 | 5 | 0.8 |

20 | 15 | 0.9 |

30 | 25 | 0.95 |

Adding AOI systems improves quality checks and builds customer trust. This ensures your products meet high standards, even in low volume PCB assembly.

Material Resource Planning (MRP) Software for Efficiency

MRP software helps make PCB assembly more efficient. It ensures you have the right materials when needed. This prevents running out of parts or having too much stock. With MRP, your production stays on schedule.

Here are some benefits of MRP software:

It shows real-time inventory levels and tracks materials.

Alerts warn you when stock is low, so you can reorder.

It works with MES systems to manage quality and resources.

Reports help predict material needs for future projects.

The table below explains how MRP improves efficiency:

Evidence Type | Description |

|---|---|

Inventory records | |

Data collection | Records when and where materials are used. |

Utilization logs | Shows real-time use of resources. |

Level notifications | Alerts when stock is too low. |

MES integration | Links to MES for better planning and quality checks. |

Data analysis | Creates reports to predict future material needs. |

Inventory control | Reduces extra stock and helps plan better. |

Delivery timelines | Keeps production on time by avoiding material delays. |

Cost control | Saves money by reducing waste and improving timing. |

Using MRP software cuts waste and saves money. It helps you order only what you need, reducing extra stock. This keeps production smooth and costs low.

Real-Time Monitoring Tools for Production Optimization

Real-time monitoring tools improve PCB assembly by tracking every step live. They help find and fix problems quickly. With live data, you can make better choices to boost productivity and reduce delays.

Here’s how these tools help production:

They find bottlenecks and improve workflows.

Defect detection lowers errors and improves quality.

Energy tracking reduces power use and saves money.

Alerts warn about equipment issues to prevent downtime.

The table below shows real-world results from using these tools:

Case Study | Results |

|---|---|

Semiconductor Manufacturer | 9.3% higher yield, $15M more revenue yearly, 7.2% lower costs |

Automotive Manufacturer | 23% fewer defects, 15% faster work, 19% less downtime, $42M saved yearly |

2023 MESA Survey | 18.5% better productivity, 16.3% lower quality costs, 12.7% faster delivery, 24.2% quicker new product launches, 9.1% lower costs |

These tools improve production metrics like:

Raising daily output from 10,000 to 85,000 units.

Cutting defect rates from 2% to 0.02%.

Shortening new product launch time by 65%.

Lowering labor costs by 78% per unit.

Reducing energy use per unit by 42%.

Real-time monitoring tools make production faster, cheaper, and better. They help meet deadlines, keep quality high, and save money, making them essential for PCB assembly.

Best Practices for Keeping Quality High in HMLV Manufacturing

Focusing on Design for Easy Manufacturing (DFM)

Designing for easy manufacturing (DFM) makes production smoother. Fixing design problems early saves time and money. Including production teams during design helps spot and solve issues. For example, using simple layouts or standard part sizes speeds up assembly.

Flexible inspection plans are also helpful. These plans change based on the product and how much you’re making. This keeps quality steady. Modular quality checks let you adjust tests for different designs. This is important when making many types of products.

Good teamwork improves DFM even more. Sharing ideas and feedback keeps everyone on the same page. Keeping detailed records helps track changes and ensures consistency.

Using Standard Parts and Steps

Standardizing parts and steps makes production easier and more reliable. Using the same parts across designs reduces mistakes and keeps things simple. It also makes managing inventory easier since fewer unique parts are needed.

Following IPC standards ensures your PCBs are high quality and meet industry rules. These standards help you pick the right materials and improve production methods. For example, tests like heat cycling and electrical checks make products stronger and more reliable.

The table below shows why standardization is useful:

Benefit | Explanation |

|---|---|

Better Quality | IPC standards ensure PCBs work well in different uses. |

More Reliable | Following standards lowers the chance of failures, which is key for safety. |

Easier Production | Standards help choose good materials and improve production steps. |

Stronger Products | Tests like heat cycling and electrical checks make PCBs last longer. |

By using standard parts and steps, you can keep quality high and make production more efficient.

Doing Strong Quality Tests

Testing is very important to keep quality high in HMLV manufacturing. Careful tests make sure every product meets high standards before it’s sent out. Automated Optical Inspection (AOI) systems are great for finding problems early.

Tracking important numbers, called KPIs, helps improve testing. The table below lists some key KPIs:

KPI | What It Measures |

|---|---|

First Pass Yield (FPY) | Percentage of products passing all tests the first time without fixes. |

Defect Rate | Percentage of bad products made, showing where to improve. |

Cycle Time | Total time to make one product, showing how fast production is. |

Throughput | Number of products made in a set time, showing production capacity. |

Using data to watch these KPIs helps find patterns and fix problems early. For example, checking defect rates can show repeated issues to address. Regularly checking equipment and improving processes also keeps results consistent.

By focusing on strong quality tests, you can make customers happy and build trust in your manufacturing.

Building Strong Supplier Relationships

Good supplier relationships are very important for PCBA success. Reliable suppliers deliver materials on time, keeping production on schedule. Late deliveries can mess up your work and raise costs. Trusting your suppliers helps avoid these problems and keeps things running smoothly.

Working well with suppliers also ensures you get good materials. This is key to keeping your products high quality. Strong partnerships make suppliers more likely to prioritize your needs. They may even give you better deals or faster service during busy times.

Here are some benefits of strong supplier relationships:

On-time deliveries prevent delays.

Fewer supply chain problems.

Better deals save money.

High-quality materials ensure good products.

To build strong relationships, talk often with your suppliers. Share your plans and needs so they can prepare better. Treat them as partners, not just sellers. This builds trust and long-term teamwork.

Continuously Evaluating and Improving Processes

Improving processes is key to staying competitive in PCBA work. Checking your workflows often helps find problems and areas to improve. Small changes over time can boost efficiency and lower costs.

Start by studying how things are done now. Look for slow steps or repeated tasks that waste time. Use tools like live tracking systems to find issues. For example, checking how long tasks take can show where to improve.

Ask your team for ideas. Workers know what works and what doesn’t. Their suggestions can lead to useful changes. Also, compare your performance to industry standards to stay ahead of others.

Regular checks help your processes adjust to new needs. They also fix problems early to keep quality high. By focusing on improvements, you can succeed in PCBA manufacturing for the long term.

Solving problems in low volume high mix PCB assembly is key. It helps improve work speed and cut costs. By using the tips and tools shared, you can make better PCBs while keeping quality high.

Using machines and training workers makes handling mixed orders easier. Better supply chain planning ensures quick deliveries and enough materials. These steps not only improve your production but also help your business grow and stay strong in a tough market.

FAQ

What is the hardest part of low volume high mix PCB assembly?

The hardest part is managing the supply chain. Inventory levels change often, and deliveries can be late. Design changes also happen a lot. Real-time tracking tools and planning systems help you stay ready and lower risks.

How can costs be lowered in low volume PCB assembly?

Focus on reducing setup costs and working more efficiently. Machines like pick-and-place tools save on labor costs. Simplifying steps and using common parts also cut expenses while staying flexible.

Why is training workers important in HMLV manufacturing?

Trained workers keep quality high and work faster. Training teaches them to use advanced tools and handle different designs. Cross-training lets workers do many jobs, which reduces delays and boosts productivity.

What tools help improve PCB assembly quality?

Tools like Automated Optical Inspection (AOI) systems and design software with DFM features are key. AOI systems find problems early, and DFM tools make designs easier to build. These tools keep quality steady and reduce mistakes.

How do you manage frequent design changes well?

Get production teams involved early in the design stage. Use PCB software with live testing to check designs before making them. This reduces mistakes, speeds up changes, and makes updates smoother.

See Also

Essential Strategies to Enhance PCB Assembly Productivity

Best Practices for Achieving Quality and Efficiency in PCBA

Ten Professional Suggestions for Cost-Effective PCBA Assembly

Ways to Enhance Workflow Efficiency in PCBA Production

Key Strategies for Overcoming Obstacles in PCBA Manufacturing