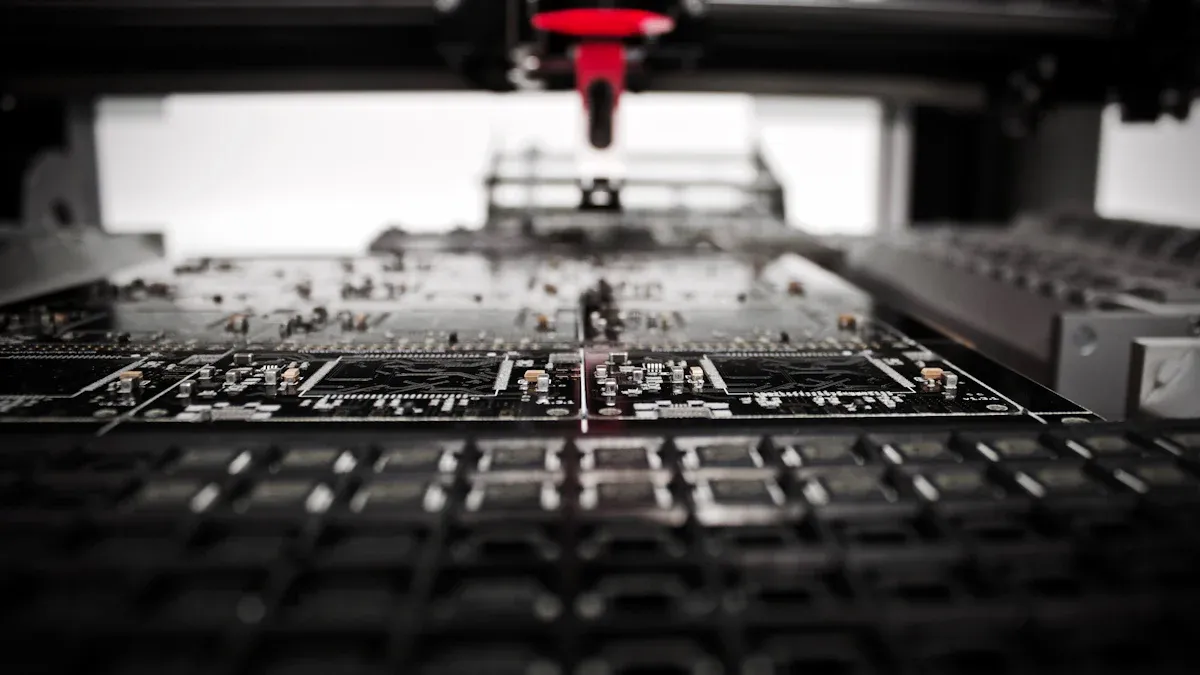

Low volume high mix PCBA services for industrial automation involve the manufacturing of many circuit boards in small quantities. This approach is crucial for industrial automation, where systems require custom solutions tailored for specific tasks. Such services are utilized across various sectors, including automotive, healthcare, and electronics. Automation plays a significant role in minimizing errors and enhancing operational efficiency.

The demand for low volume high mix PCBA services for industrial automation is rapidly increasing. Companies are seeking unique products to maintain a competitive edge in the market. This shift represents a transition from mass production of identical items to the adoption of low volume high mix methods. These methods are not only cost-effective and flexible but also facilitate the creation of customized products.

Key Takeaways

High mix low volume (HMLV) manufacturing makes many different products in small amounts to meet customer needs.

HMLV manufacturing is flexible, helping businesses adjust quickly to market changes and stay competitive.

Using automation and digital tools makes HMLV production faster, cheaper, and better in quality.

Customization is important in HMLV, allowing products to fit specific industrial automation needs.

Good supply chain management is key in HMLV to reduce waste and deliver materials on time.

What is High-Mix Low-Volume Manufacturing?

Definition and Characteristics

High-mix low-volume (HMLV) manufacturing means making many different products in small amounts. This method focuses on being flexible and creating custom items. It works well for industries like industrial automation. Unlike regular manufacturing, which makes lots of the same thing, HMLV changes to fit what customers and markets need.

HMLV manufacturing has key traits like being customizable, flexible, and using quick supply chains. These traits help make special products fast. But, switching setups often and managing supply chains can be tricky. Below is a table showing the main features of HMLV manufacturing:

Feature | Description |

|---|---|

Customizability | Makes products that match specific customer needs. |

Flexibility | Quickly changes designs and schedules using advanced tools. |

Agile Supply Chains | Cuts down wait times and costs while handling different products. |

Frequent Changeovers | Needs smart planning for setup costs and production changes. |

Supply Chain Complexities | Requires careful teamwork to keep things running smoothly. |

Waste Management | Focuses on using materials wisely to avoid waste. |

These traits show how HMLV manufacturing helps meet the growing need for low volume high mix PCBA services in industrial automation.

Key Differences from Traditional Manufacturing

HMLV manufacturing is very different from traditional low-mix high-volume (LMHV) production. LMHV makes large amounts of the same product, while HMLV focuses on variety and flexibility. The table below compares these two methods:

Feature | Low Mix High Volume (LMHV) | |

|---|---|---|

Production Scale | Small batches of products | Large amounts of one product |

Flexibility | Easily adjusts to market changes | Stays the same for efficiency |

Product Diversity | Makes many types of products | Focuses on fewer, standard products |

Output per Product | Lower number of each product | Higher number of each product |

HMLV lets companies react quickly to market shifts and customer needs. LMHV works better for industries that need mass production. For example, HMLV faces challenges like frequent setup changes and waste control. LMHV focuses on saving money with long production runs.

Importance in Modern Industrial Applications

HMLV manufacturing is very important for today’s industries. As people want more unique and varied products, making large amounts of the same thing doesn’t work as well. HMLV helps by letting companies create products for specific needs.

This method is especially useful for low volume high mix PCBA services in industrial automation. It helps make custom circuit boards for special automation systems. HMLV also makes production flexible, allowing quick changes to setups. This is key for meeting changing market needs and keeping customers happy.

Benefits of HMLV in industries include:

Making different products to match market changes.

Creating ‘make-to-order’ items for happier customers.

Using automation to reduce mistakes and work faster.

Helping companies adjust to new products and technologies quickly.

Using HMLV manufacturing helps businesses stay ahead in industries needing precision, custom solutions, and flexibility.

Benefits of HMLV Manufacturing for Industrial Automation

Flexibility to Meet Different Needs

HMLV manufacturing is very flexible. It works well for industries needing custom solutions. You can easily adjust to market changes and customer needs. This is helpful in industrial automation, where specific parts are often required.

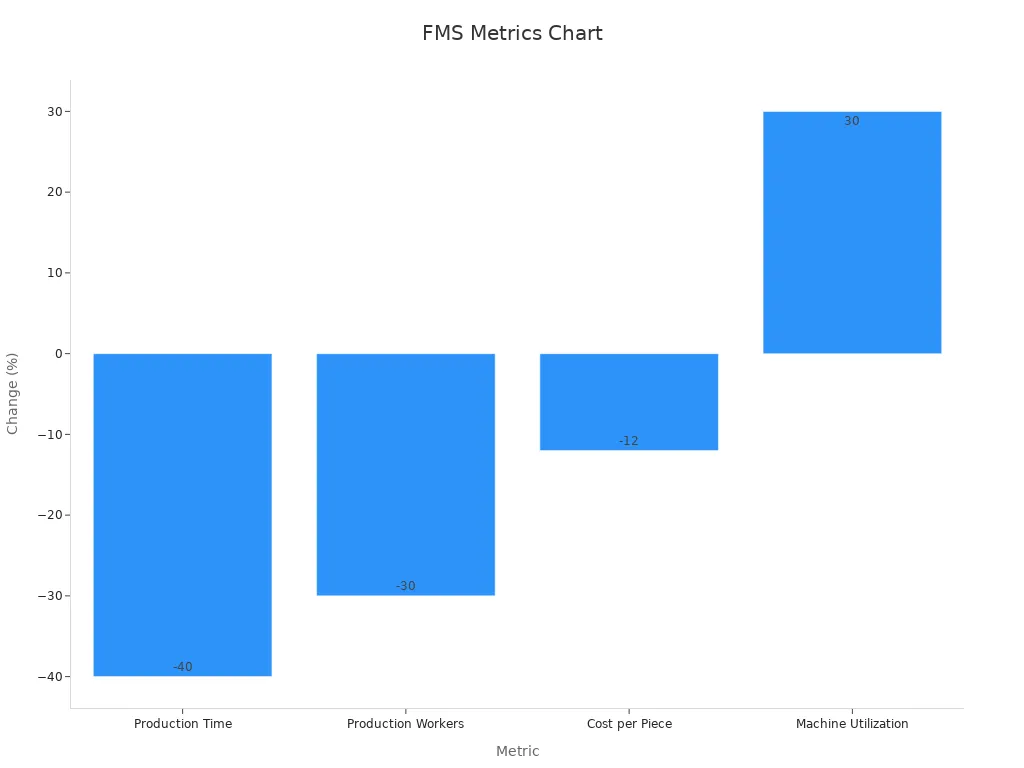

Flexible manufacturing systems (FMS) make this even better. They save time and money while using machines efficiently. For example, FMS can cut production time by 40% and costs per piece by 12%. Machine usage improves by 30%, making resources more effective.

Metric | Change |

|---|---|

Production Time | 40% less |

Production Workers | 30% less |

Cost per Piece | 12% less |

Machine Utilization | 30% more |

Using HMLV production helps businesses stay quick and competitive. It ensures supply chains can handle changes easily.

Saving Money with Small Batch Production

HMLV manufacturing is a smart way to save money on small batches. While automation tools cost a lot upfront, they save money over time. Automation lowers labor costs and reduces wasted materials, cutting overall expenses.

A McKinsey study shows that low-volume, high-complexity manufacturers can increase yearly output by 5–20% with HMLV methods. Automation also keeps production running without stopping, speeding up processes. This helps meet demand while keeping quality high.

Main Cost Benefits of HMLV Manufacturing:

Less waste, saving materials.

Faster production, reducing delays.

HMLV manufacturing helps save money while staying flexible. It allows companies to make unique and varied products.

Better Customization for Automation Systems

Customization is key in HMLV manufacturing, especially for low volume high mix PCBA services. This method creates circuit boards and parts for specific industrial needs. Modular designs are made for high-mix, low-volume demands, making it easy to adapt to changes.

Feature | Benefit |

|---|---|

Designed for High Mix / Low Volume needs, improving customization. | |

Adaptability | Easily adjusts to changing manufacturing demands. |

Flexibility | Supports a responsive and adaptable production process. |

HMLV production allows quick design and setup changes. This keeps automation systems efficient and up-to-date with new technology and trends. By focusing on customization, businesses can meet client needs better, boosting satisfaction and loyalty.

Faster Time-to-Market for Innovative Solutions

Today, getting products out quickly is very important. High-mix low-volume (HMLV) manufacturing helps speed up this process. It focuses on being flexible and efficient to deliver products faster.

HMLV makes production smoother and quicker. Traditional methods need long setup times, but HMLV uses smart tools and agile supply chains. This helps reduce delays and respond to customer needs fast. For example, new technology can be added to designs without much downtime.

Modular designs also save time in HMLV manufacturing. These parts are easy to customize and assemble. They cut down on retooling and shorten the production cycle. This lets companies focus on creating new ideas instead of dealing with long schedules.

Automation is another way HMLV speeds things up. Machines handle tasks instead of people, reducing slowdowns. Automation keeps quality high while working fast, helping meet deadlines without problems.

HMLV also supports quick prototyping. Small batches of prototypes can be made fast and cheaply. This allows testing, improving, and finalizing designs much faster than traditional methods.

Challenges in High-Mix Low-Volume Manufacturing

Handling Supply Chain Issues

Managing supply chains in high-mix low-volume manufacturing is tricky. Many materials and parts are needed, making disruptions more likely. Working with many suppliers adds to the risk. Keeping extra parts in stock can cost more and lead to waste if unused. Scheduling production is also hard because frequent changes need flexible systems.

Here’s a table showing these challenges:

Challenge | Description |

|---|---|

Supply Chain Problems | Using many materials and suppliers increases disruption risks. |

Inventory Costs | Stocking extra parts raises costs and may cause waste. |

Scheduling Difficulties | Frequent changes make it hard to plan production efficiently. |

Quality Control Issues | Small batches need strong systems to ensure consistent quality. |

High Costs | Without large-scale production, labor and overhead costs are higher. |

To solve these problems, lean methods like Just-in-Time delivery can help. These strategies reduce waste and improve workflows.

Reducing Setup Costs and Boosting Efficiency

Switching setups often in high-mix low-volume manufacturing raises costs. This lowers production efficiency. To fix this, processes must be improved to reduce downtime. Tracking metrics like changeover time and idle hours helps find areas to improve.

Metric | Description |

|---|---|

All time available, including production and non-production periods. | |

Available Hours | Time ready for production, excluding planned downtime like maintenance. |

Downtime Hours | Time lost due to equipment issues or other disruptions. |

Idle Hours | Unused production time caused by inefficiencies or scheduling gaps. |

Changeover Hours | Time spent switching between production tasks, including setup and cleaning. |

Time Utilization (%) | Percentage of total hours used effectively for production. |

By cutting changeover time and using production hours better, efficiency improves, and costs drop.

Keeping Quality High for Different Products

Making sure all products meet quality standards is tough. Strong quality control systems are needed to catch problems early. Methods like statistical process control focus on improving processes, not just final products. This ensures reliability and reduces mistakes.

Advanced quality checks lower defects and improve efficiency.

Statistical tools find problems early, making products more reliable.

CAPA (Corrective and Preventive Actions) fixes root causes to improve quality.

Skilled workers and automated inspections also help maintain high standards. These steps make low-volume manufacturing both reliable and cost-effective.

Meeting Technology and Workforce Needs

Modern factories need smart tools and skilled workers. This helps handle the challenges of making many different products in small amounts.

Digital tools are very helpful. They make work easier and cut costs. These tools help manage information better and reduce waste. For example, connecting sales orders to production keeps inventory accurate and avoids delays.

Flexible systems also solve worker challenges. Dynamic Cell Manufacturing cuts setup times by 65%. It also makes machines work 35% better. Rapid Response Cells help semiconductor makers switch tasks faster. Changeover times dropped from 45 minutes to 8 minutes, improving results by 25%. These systems help workers adjust quickly and work more efficiently.

Reorganizing work into flexible groups can also help. A furniture company cut lead times by 50% and made customers 30% happier. Flexible groups let workers focus on tasks, reducing mistakes and boosting output.

Training is key for workers to use new tools well. Teaching workers new skills improves productivity and sparks new ideas. This helps businesses stay ahead in making small batches of custom products.

Solutions to Overcome Challenges in HMLV Manufacturing

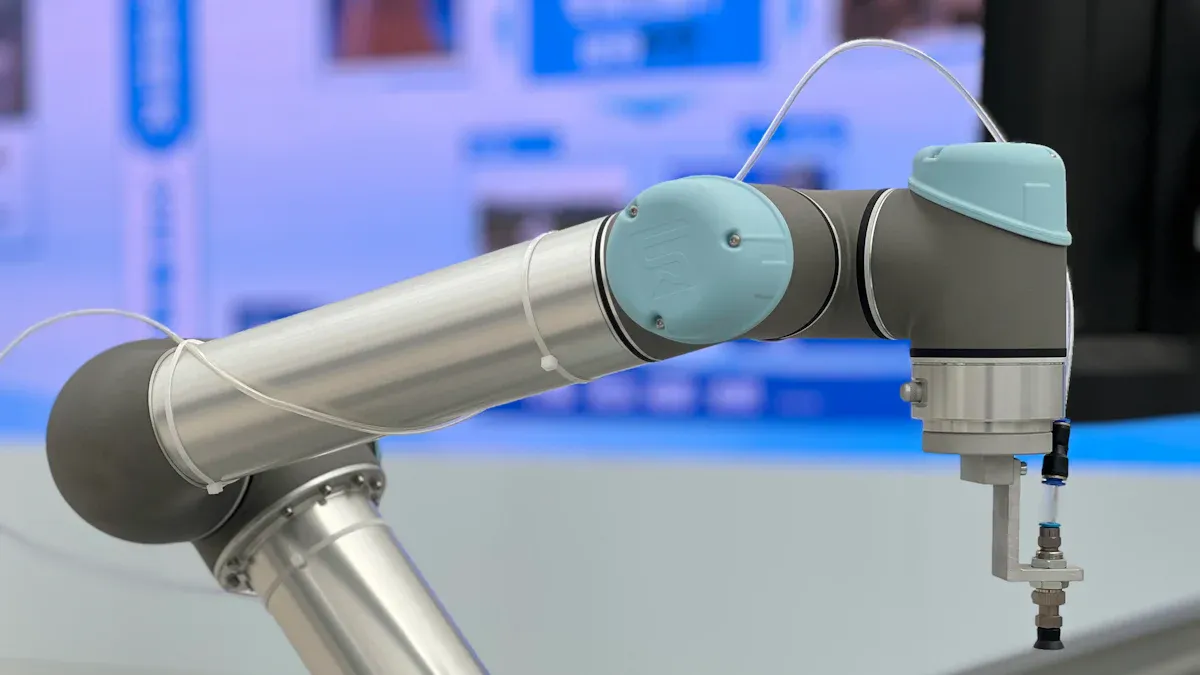

Using Automation and Robots

Automation and robots can make HMLV manufacturing faster and better. Advanced technology helps reduce mistakes and improve processes. For example:

A study shows 45% of tasks can be automated. This cuts processing time by 30% and errors by 40%.

Collaborative robots (cobots) increase productivity by over 25% in most companies, says the International Federation of Robotics.

Robotic process automation (RPA) handles repetitive tasks, letting workers focus on harder jobs. Predictive tools and machine learning cut downtime by 15%. The cobot market is expected to grow to $7.72 billion by 2026. Investing in automation is a smart move for small-batch production.

Using Digital Tools to Improve Processes

Digital tools are key to making production better. Lean manufacturing can boost productivity by 15% to 25%. Automation systems lower changeover times by 10%, and quality-related downtime drops by 56%.

Evidence Type | Improvement Metrics |

|---|---|

Lean Manufacturing Strategies | Productivity boost of 15% to 25% |

Automation Systems | 10% shorter changeover times |

Quality-Related Downtime Reduction | 56% less downtime from quality issues |

Line Utilization | 20–30% better line usage |

These tools help keep quality steady and improve efficiency. Linking sales orders to production systems avoids delays and waste. Digital solutions make small-batch manufacturing smoother and more reliable.

Working with Expert Manufacturers

Teaming up with expert manufacturers can solve HMLV production challenges. These specialists know the industry and have advanced skills. They simplify supply chains by creating templates for base models and easily adding variations.

Step | Description |

|---|---|

1 | Make a template process for the product’s base model. |

2 | Add variations by copying the template quickly. |

3 | Adjust steps or settings that differ from the template. |

4 | Template changes apply to all linked steps, except for adjusted ones. |

Experts also help with demand forecasting, improving material orders and timing. They understand product differences, which helps with planning. By partnering with them, you can focus on creating new ideas while keeping operations smooth.

Making Supply Chains Work Better

Good supply chain management is key for HMLV manufacturing. Materials must arrive on time to avoid waste and delays. Fixing these processes boosts productivity and lowers costs.

Simulation tools can help improve workflows. They show the best batch size and production order. For example, a palletizer’s process was improved using simulation. This cut waiting times and increased output. Similar methods can make supply chains more efficient.

Working closely with suppliers is also important. Strong partnerships ensure steady delivery of quality materials. Suppliers can help create templates for base models. These templates make adding variations easier and faster. This reduces complexity and speeds up production.

Automation and digital tools make supply chains even better. Advanced systems track inventory in real time. This prevents having too much or too little stock. Linking sales orders to production schedules uses resources wisely. These tools also improve accuracy, which is vital for industries like aerospace and healthcare.

Streamlining supply chains has clear benefits. It makes production flexible, customizable, and cost-effective. Below is a table showing these advantages:

Benefit | Explanation |

|---|---|

Flexibility | Adjusts easily to different project needs. |

Customization | Perfect for industries needing special parts in small amounts. |

Advanced Automation | Robots and AI boost productivity and ensure consistent quality. |

Cost Efficiency | Saves resources and reduces waste, even for small batches. |

Precision | Delivers accurate results, crucial for aerospace and medical industries. |

Using these strategies helps solve supply chain problems. It also prepares businesses for long-term success.

High mix low volume PCBA manufacturing gives great flexibility and customization. It helps save money and ensures systems meet exact needs. This makes it very useful for industries needing special solutions.

Using tools like robots, automation, and digital systems is important. These tools solve problems like supply chain issues and quality checks, keeping things running smoothly.

As industries change, HMLV manufacturing will become more important. By using new technology and smart methods, you can stay ahead and handle market changes easily. 🚀

FAQ

What is high-mix low-volume manufacturing?

High-mix low-volume manufacturing makes different products in small amounts. It focuses on being flexible and creating custom items. This method is great for industries needing special solutions, like industrial automation.

How does HMLV manufacturing help industrial automation?

It helps make custom solutions for automation systems. Flexibility allows quick changes to meet new needs. This method also cuts waste and boosts efficiency for small-batch production.

What problems can happen in HMLV manufacturing?

You might deal with tricky supply chains and higher setup costs. Frequent changes and keeping product quality steady can also be hard without good systems.

How does automation help HMLV manufacturing?

Automation makes work faster and reduces mistakes. Robots and digital tools improve efficiency, lower costs, and keep quality steady. These tools also make custom production quicker and easier.

Why is customization important for industrial automation?

Customization makes sure automation systems fit specific needs. It boosts efficiency and reliability while allowing fast updates for new tech or market changes.

See Also

Why PCBA Manufacturing Skills Matter in Electronics Development

Enhancing Workflow Productivity in PCBA Manufacturing Processes

Achieving Quality and Efficiency in PCBA Production Techniques

A Comprehensive Guide to PCBA Manufacturing and Assembly

Choosing Advanced PCBA Manufacturing Services for Optimal Results