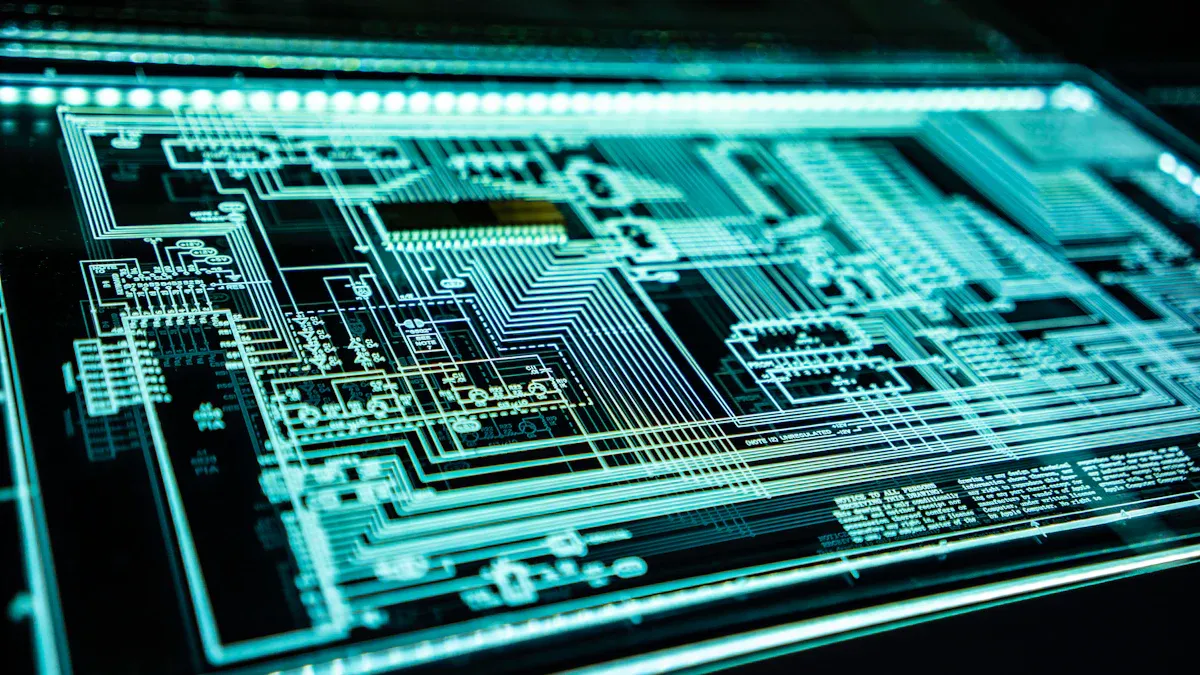

Machine condition monitoring in PCB manufacturing is essential for achieving accuracy and efficiency. Monitoring the health of machines ensures they operate optimally, reducing delays and enhancing product quality. Advanced technologies, such as predictive analytics and connected systems, are revolutionizing how machine performance is assessed. These innovations enable early detection of issues and streamline production processes. By adopting these advancements in PCB manufacturing, businesses can implement smarter and more sustainable practices. This shift is driving the industry toward greater reliability, cost savings, and the ability to meet modern demands.

Key Takeaways

Watching machines closely makes PCB production faster and better.

Smart tech like AI and IoT spots problems early to save time.

Live data checks help machines work well and fix issues fast.

Using robots reduces mistakes, makes machines last longer, and work better.

Green methods in PCB making protect nature and cut expenses.

AI and IoT in Machine Condition Monitoring for PCB Manufacturing

AI-Driven Predictive Maintenance

AI is changing how machines are maintained in PCB factories. It studies large amounts of data to predict machine problems. This helps stop unexpected breakdowns and expensive fixes. For example, vibration sensors in pumps find early signs of damage. These sensors let you fix problems before they stop production. Factories create a lot of data daily, but only 10% is used well. AI helps use this data to make production better and lower repair costs.

IoT-Enabled Interconnected Monitoring Systems

IoT, or the Industrial Internet of Things, links machines and sensors. This connection gives real-time updates on machine performance. In PCB factories, IoT systems check equipment all the time. This reduces downtime by fixing machines only when needed. For example, IoT systems in steel plants stop leaks before they cause big problems. In PCB factories, IoT sensors save resources and improve safety. They also help follow industry rules and keep workers safe.

Benefits of AI and IoT Integration in PCB Manufacturing

Using AI and IoT together has many benefits for PCB factories. It makes production faster and uses resources more wisely. It also saves energy and finds defects early to ensure quality. For example, AI and IoT-powered lines work faster and waste less material. The table below shows some key benefits:

Benefit | Impact on PCB Manufacturing |

|---|---|

Faster production | Big improvements |

Better resource use | More efficiency |

Energy savings | Less power used |

Smarter material use | Less waste |

Easier automation | Smoother processes |

Better quality checks | Fewer defects |

Lower costs | Save money on materials and labor |

Eco-friendly | Less waste and pollution |

By using these tools, PCB factories can stay modern and work smarter, safer, and greener.

Real-Time Data Analytics in PCB Manufacturing Trends

Improving Machine Performance with Real-Time Data

Watching machines in real time helps them work better. By checking data as it comes in, you can spot problems fast. For example, deep learning tools can predict issues with high accuracy. They achieve an RMSE value of 33.17 µm, much better than 119.36 µm in other methods. This accuracy keeps machines running smoothly, cutting downtime and boosting efficiency.

Tip: Using real-time data can catch small problems, like odd vibrations, before they become expensive fixes.

How Data Analytics Helps PCB Manufacturing

Data analytics has changed how PCB factories work. Companies like Daeduck Electronics use it to save time and money. For instance, combining sensor data in one system found a vibration problem in a factory. Fixing it made production faster and better.

Other uses include:

Stopping machine failures with predictive maintenance.

Catching bad materials early with quality checks.

Tracking worker training to lower mistakes.

These examples show how data analytics improves both speed and quality in PCB production.

Solving Problems in Real-Time Data Use

Using real-time data in PCB factories can be tricky. There are over 100 process types and many data formats to handle. Factories also track more than 800 quality checks for millions of units each month. Tools like MES Lite and Traceability Apps make this easier. They create digital twins and connect all data, so you can watch everything in real time.

Note: Tracking details like machine settings and inspection pictures helps find problems fast and ensures everything is traceable.

By solving these issues, factories can use real-time data fully. This leads to smoother work and better products.

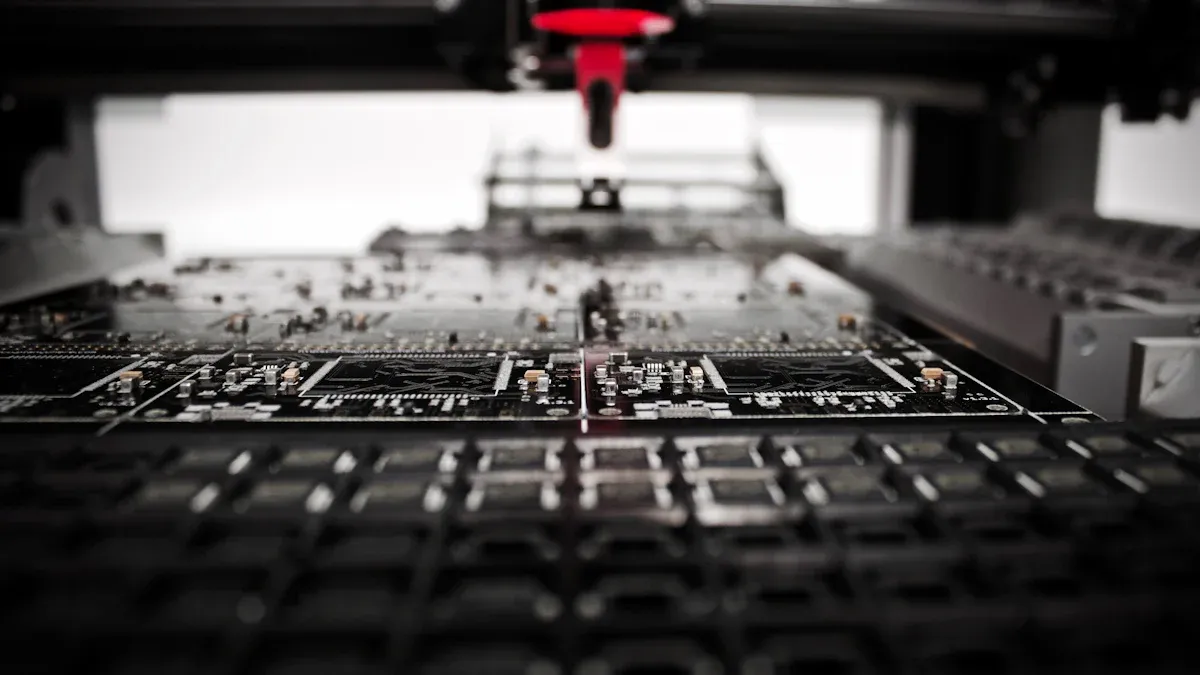

Automation and Machine Reliability in PCB Manufacturing

Reducing Human Error with Automated Monitoring

Automation helps reduce mistakes by replacing manual work with smart tools. In PCB factories, automated systems watch machines all the time. They find problems early, keeping machines running well and avoiding delays. For example, sensors can spot high temperatures or strange vibrations. This lets you fix issues before they get worse. Using automation removes guesswork and makes production more reliable.

Tip: Automation improves accuracy and lets workers focus on important tasks.

Examples of Automation in PCB Production

Automation has changed how PCBs are made. Tools like BluePrint work with EDA systems to handle documents. They use PCB CAD data to update files quickly, saving time. Simulation tools also check designs to avoid mistakes during production. These tools make work faster and improve the quality of PCBs.

Enhancing Machine Lifespan with Automation

Automated tools help machines last longer. Condition monitoring ensures machines get care when needed. This stops damage and avoids expensive repairs. For example, lubrication systems keep machines working smoothly. Predictive tools also find parts that might fail soon. These steps save money and keep production running without problems.

Note: Spending on automation now saves money and improves reliability later.

Sustainable Monitoring Technologies in PCB Manufacturing

Eco-Friendly Sensors and Energy-Saving Systems

Eco-friendly sensors and energy-saving systems are changing PCB monitoring. These tools help the environment and make production better. For example, RGB cameras can spot tiny defects in real time. They are affordable and great for quality checks in PCB making. When paired with machine learning, these sensors improve recycling accuracy and speed.

Energy-saving systems are also important for sustainability. Tools like automatic oiling systems use less energy. Low-power devices also cut energy use and save money. These systems meet the need for greener practices in the industry.

Following Rules with Sustainable Methods

Rules like the ROHS directive promote eco-friendly PCB production. These rules push for safer materials and better recycling. By following them, factories can improve and help the planet. For instance, many now use lead-free solder and recyclable parts. These changes meet rules and lower harm to the environment.

Long-Term Gains from Green Technologies in PCB Making

Using green technologies has many long-term benefits. As people care more about the planet, green methods are in demand. Recyclable materials and energy-saving processes keep factories ahead. For example, dry etching and low-heat soldering may grow 20% by 2033. These methods are cheaper and better for the earth. Additive manufacturing and biodegradable parts are also becoming popular.

By using these tools, factories can cut waste and save money. They also meet the needs of eco-friendly buyers. These changes help the planet and ensure business success.

5G and Connectivity in Machine Condition Monitoring PCB Manufacturing

Faster Data Transmission with 5G

5G is changing how machines are monitored in PCB factories. It sends data instantly, helping make quick decisions to improve work. For example, many cameras can send live videos to one system. This setup finds problems fast and fixes them quickly. 5G allows more cameras to work together without slowing the network. Using this technology makes machines work better and reduces delays.

Tip: Use 5G systems to speed up data and fix issues faster.

Remote Monitoring and Diagnostics with Advanced Connectivity

5G makes remote monitoring easier and more dependable. Teams can check live data from anywhere and solve problems faster. This means you don’t need to be on-site to manage work. AI tools also help by checking every PCB for quality. Predictive maintenance with 5G lowers costs by using fewer workers and avoiding recalls. These features make remote monitoring important for today’s PCB factories.

Benefits of 5G-enabled remote monitoring:

Quick access to live factory data.

Faster fixes for defects to avoid bad parts.

Less waste and better use of resources.

Future Possibilities with 5G-Enabled Monitoring Systems

5G will shape the future of PCB production. It adds complexity but opens doors for new ideas. Factories using 5G will stay ahead in the industry. For example, linking IIoT devices with 5G creates smarter production lines. These systems use predictive tools to keep machines running their best. Fixing defects faster stops bad parts from being made, saving resources and helping the environment.

Note: Using 5G makes your factory a leader, ready for future challenges.

New trends are changing how PCBs are made. AI, IoT, and 5G make work faster, reduce waste, and improve quality. By 2025, these tools will transform the industry.

PCB design software will take 65% of the market. AI and cloud tools drive this growth.

Programs like Autodesk Fusion 360 save 40% of design time. This helps factories work faster.

Smaller designs and faster signals meet today’s needs.

Using these tools keeps factories modern, eco-friendly, and ready for the future.

FAQ

1. What is machine condition monitoring in PCB manufacturing?

Machine condition monitoring checks how well machines work in PCB factories. It uses tools like sensors to find problems early. This keeps machines running smoothly, avoids delays, and makes better products.

2. How does AI improve machine condition monitoring?

AI studies big sets of data to spot machine problems early. It finds unusual patterns and helps fix issues before breakdowns. This saves money on repairs and keeps production steady.

3. Why is IoT important for PCB manufacturing?

IoT links machines and sensors to share live updates on performance. It lets you check systems from anywhere, use resources wisely, and stay safe. IoT also helps follow industry rules.

4. Can 5G really make a difference in PCB production?

Yes! 5G sends data faster, helping you make quick decisions. It allows remote checks and fixes, cutting delays. With 5G, more devices can connect without slowing the system.

5. Are sustainable technologies cost-effective for PCB factories?

Yes! Green sensors and energy-saving tools cut waste and save money. They also meet eco-rules, attract green-minded buyers, and prepare your factory for the future.

See Also

Emerging Innovations in PCB and PCBA Design Processes

Investigating Testing Strategies for Modern PCBA Production

Proven Approaches to Perform PCBA Failure Assessments

Essential Strategies to Overcome PCBA Manufacturing Obstacles