Making circuit boards for medical device PCBA manufacturing is very important. These boards help power devices used to save lives. Each step focuses on safety and reliability. Medical circuit boards must work perfectly. Even small mistakes can cause problems with the device. Makers use special materials and methods to make strong boards. This helps medical tools work well in important healthcare settings.

Key Takeaways

Medical device PCBAs are important for safe and reliable tools.

Following rules like ISO 13485 and FDA is necessary for quality.

Using machines and new materials makes PCB making faster and better.

Careful testing finds and fixes problems early, keeping devices working.

Keeping records helps follow rules and solve problems quickly in production.

Overview of Medical Device PCBA

What Is Medical Device PCBA?

Medical device PCBA means making PCBs for medical tools. These PCBs are the main part of medical devices. They help the devices do important jobs. Medical PCBs need to be very accurate and dependable. They must follow strict rules for safety and quality. This ensures they work perfectly in life-saving situations.

Applications of Medical PCBs in Healthcare

Medical PCBs are very important in healthcare. They are used for many purposes, as shown below:

Application | Importance |

|---|---|

Helps create tools like MRI and CT scanners for better care. | |

Remote Monitoring | Wearable devices track health and allow remote checks. |

Implantable Technology | Used in devices like pacemakers to improve patients’ lives. |

Scientific Advancements | Needed for research tools to study diseases and learn more. |

Data-Driven Healthcare | Collects accurate data for better treatments and practices. |

Telemedicine | Supports online doctor visits when in-person care isn’t possible. |

Streamlined Operations | Helps manage patient records efficiently and reduces mistakes. |

These uses show how medical PCBs improve care, research, and healthcare systems.

Key Features of Medical Device PCBAs

Medical device PCBAs are made with special features for safety and reliability:

High Reliability: Tested carefully to avoid errors and keep patients safe.

Compliance with Standards: Certifications prove they meet strict safety and quality rules.

Durability: Made to last through tough conditions like cleaning and long use.

Miniaturization: Designed small to fit in tiny devices like wearables or implants.

Advanced Materials: Built with strong materials for good performance in hard environments.

These features make medical PCBs safe and reliable for healthcare needs.

Step-by-Step Medical Device PCBA Manufacturing Process

Design and Development

Making a medical PCB starts with knowing its purpose. You need to plan a clear design for the circuit. Picking safe and reliable parts is very important. For example, parts in implants must handle moisture and heat.

To save time, use tools to test designs virtually. These tools reduce the need for physical models. Adding backup systems keeps devices working if a part breaks. This is crucial for life-saving equipment.

Key goals during this step include:

Use parts that meet FDA and IEC 60601 rules.

Ensure signals are clear and power is steady.

Prevent overheating with good heat control.

Make small PCBs to fit tight spaces.

By following these steps, you create a safe and reliable design.

Material Selection and Procurement

Picking the right materials is key for medical PCBs. Implantable devices need materials safe for the body. Strong materials also make PCBs last longer and work better.

Buying parts from trusted suppliers is important. This ensures they meet IPC Class 3 and ISO 13485 rules. These rules check quality and traceability for medical devices.

Important quality checks include:

Quality Check | What It Does |

|---|---|

Ensures high performance and reliability. | |

Automated Optical Inspection | Checks PCB quality visually. |

Flying Probe Test | Tests electrical connections on PCBs. |

Solderability Test | Checks if solder sticks to PCB surfaces. |

Following these checks ensures materials meet strict medical standards.

PCB Fabrication and Prototyping

Fabrication turns the design into a real PCB. Layers of copper and fiberglass are used to build it. Advanced tools like lasers make the process more precise.

Prototypes are tested before making many PCBs. Each prototype goes through strict tests to ensure it works. Data shows how consistent the process is:

First Pass Yield (FPY) is usually 95% to 98%.

Defects Per Million Opportunities (DPMO) is often 500 to 1000.

Using SPC methods helps track and fix problems early. This ensures every PCB meets high-quality standards.

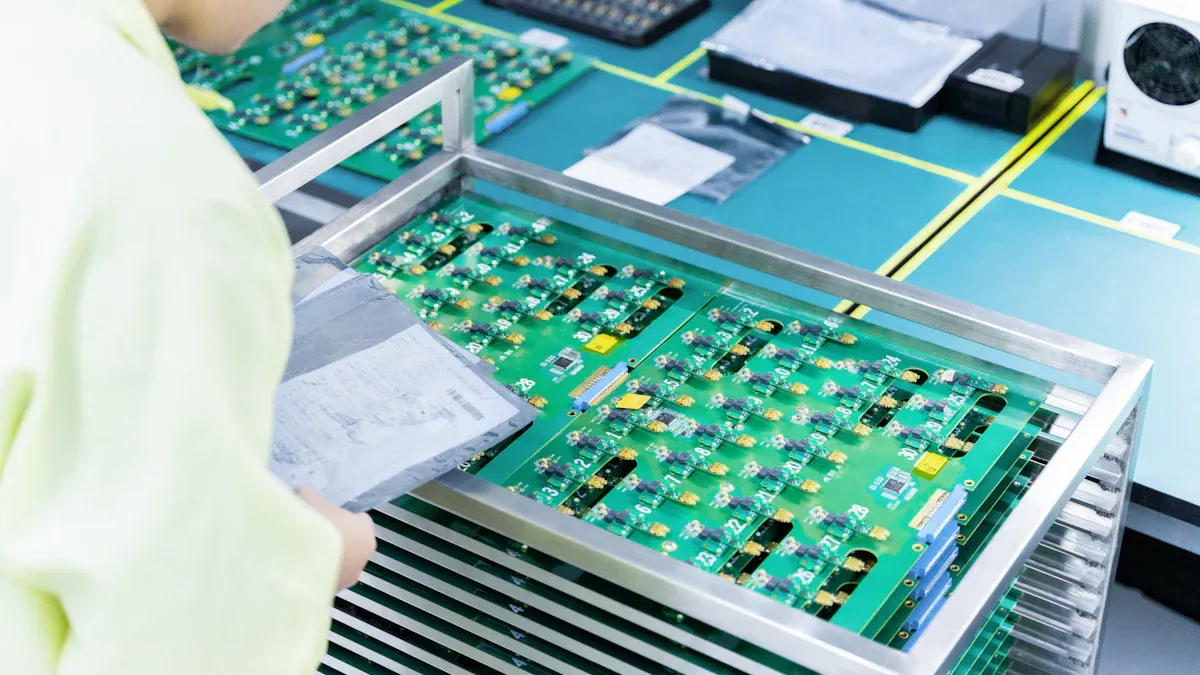

Assembly Using Surface Mount Technology (SMT)

SMT is very important for making medical PCBs. It places parts directly on the board’s surface. This method skips older through-hole techniques. SMT helps create smaller and lighter designs. These are needed for modern medical tools.

The process starts by adding solder paste to the board. A stencil ensures the paste goes in the right spots. Then, machines place parts on the board with great accuracy. These machines handle tiny parts, perfect for small medical devices.

After placing the parts, the board goes into a reflow oven. The heat melts the solder paste, connecting parts to the board. This step ensures the board works well. Afterward, the board is cleaned to remove leftover residue.

The medical field has increased the use of SMT. More advanced medical devices need compact and reliable boards. SMT helps make high-quality boards for tools like monitors and imaging machines. These improve healthcare and make operations smoother.

SMT has many benefits for medical PCBs:

Compact Designs: Makes small boards for wearable and implantable devices.

High Efficiency: Automated steps reduce mistakes and speed up production.

Enhanced Reliability: Strong connections make boards last longer in tough conditions.

Using SMT ensures medical PCBs meet strict safety and quality rules.

Inspection and Functional Testing

Checking and testing are key steps in making medical PCBs. These steps ensure the boards are safe and work well for medical use.

The first step is Automated Optical Inspection (AOI). Cameras check for problems like misplaced parts or bad soldering. AOI quickly finds issues early in the process.

Next is functional testing. This checks if the board works in real-life conditions. For example, a board for a patient monitor is tested for signal accuracy and power stability.

Testing also ensures the board meets ISO 13485 rules. These rules focus on safety, quality, and tracking. Following them ensures the board is safe and reliable.

Important testing methods include:

Flying Probe Testing: Checks electrical connections and circuits.

X-ray Inspection: Looks for hidden problems in solder joints and layers.

Environmental Testing: Tests the board in extreme conditions like heat or humidity.

Testing and checking catch problems before the board is sold. This reduces failures and makes medical devices more reliable.

Quality and Regulatory Standards in Medical Device PCBA Manufacturing

Why ISO 13485 and FDA Rules Matter

Making medical PCBs needs ISO 13485 and FDA rules. These rules make sure devices are safe and high-quality. ISO 13485 focuses on managing quality systems. It helps create reliable and effective products. It also highlights reducing risks and improving processes.

FDA rules ensure medical devices are safe and work well. Testing, like functional and environmental tests, is very important. These tests check if devices work safely in real-life situations.

Not following these rules can cause big problems. It might lead to recalls, fines, or patient harm. By following ISO 13485 and FDA rules, your medical PCB stays safe and high-quality.

How Quality Assurance Reduces Risks

Quality assurance helps lower risks in making medical PCBs. A strong quality system ensures products are safe and work well. Checking and approving tools for production is very important. This includes making sure tools work properly at all stages.

Training workers is also a big part of quality assurance. Skilled workers make fewer mistakes during production. Keeping detailed records of how products are made is crucial too. These records show that rules and quality checks are followed.

Ways quality assurance helps manage risks:

Makes sure processes follow ISO 13485 rules.

Checks tools to keep quality steady.

Finds and fixes defects with careful testing.

Keeps records to meet regulatory rules.

Using these steps makes medical PCBs more reliable and safer.

Why Traceability and Records Are Important

Traceability means tracking every part and step in making PCBs. This ensures all rules are followed. Good traceability systems should start early in the process.

Keeping accurate records is just as important. Records help find problems quickly if something goes wrong. They should include details like orders, steps, and worker info. This ensures the PCB meets FDA rules.

Best ways to improve traceability and records:

Use lot numbers for parts and boards.

Keep Design History Files (DHF) and Device Master Records (DMR).

Switch to digital systems for easier data sharing.

Monitor processes in real-time to improve results.

These steps make tracking easier and build trust with regulators. They also ensure your medical PCB process is clear, efficient, and follows the rules.

Advanced Manufacturing Techniques for Medical Devices

Automation and Robotics in PCBA Production

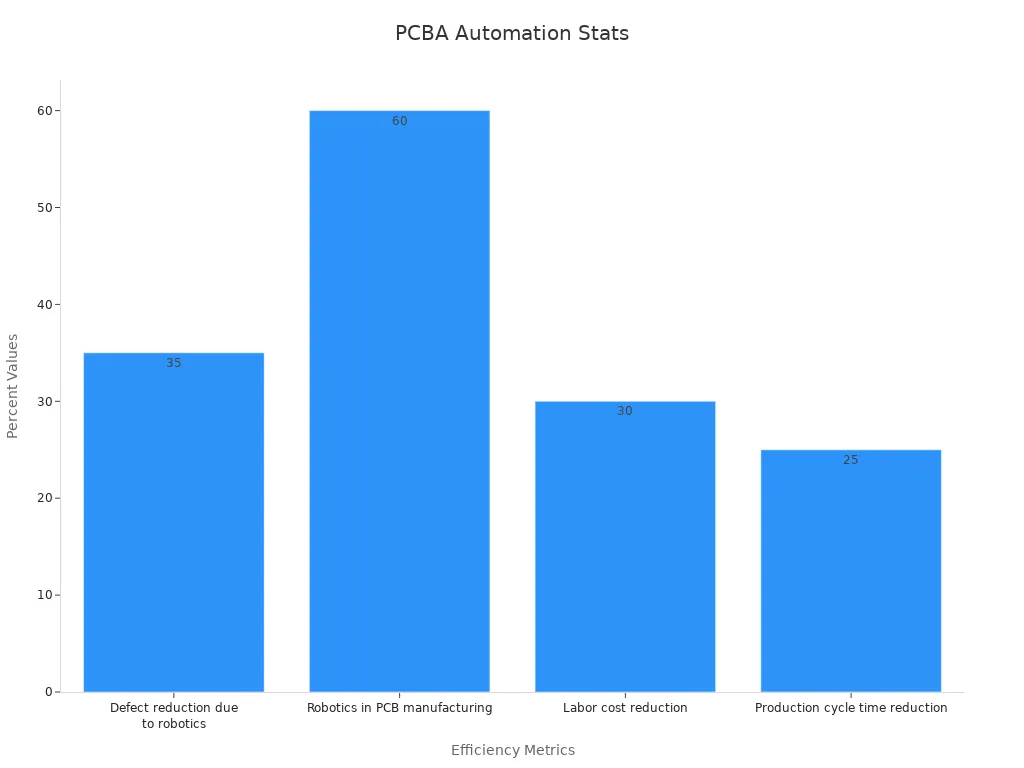

Automation and robots have changed how PCBs are made. These tools make work faster, reduce mistakes, and improve accuracy. Robots do tasks like placing parts on boards. This keeps quality steady and lowers defects by 35%. Precision improves by over 90% with these methods. Automation also speeds up production by 25%, delivering PCBs faster.

Costs are lower too. Automated systems cut labor costs by 30%. Most companies see savings within 18 months. Real-time inventory checks and automated quality tests make the process smoother. These tools help meet strict rules while keeping track of every step.

Use of Flexible Substrates and Advanced Materials

Flexible materials are key in medical PCB assembly. They make devices more reliable by reducing mechanical parts. Fewer parts mean fewer errors. These materials are light, perfect for small devices like wearables. They also resist heat, shocks, and chemicals, making them tough.

Performance Advantage | Description |

|---|---|

Reliability | Fewer mechanical parts mean fewer errors. |

Weight Reduction | Lightweight materials allow smaller device designs. |

Thermal Management | Handles heat and temperature changes well. |

Impact Resistance | Stands up to shocks and vibrations. |

Chemical Resistance | Resists damage from chemicals and UV light. |

Adaptability | Flexible for creating smaller, smarter devices. |

Using these materials helps make strong, adaptable medical devices that meet tough standards.

Enhancing Precision with Laser Direct Imaging

Laser Direct Imaging (LDI) makes PCB production very precise. It creates tiny details, keeping signals clear for high-tech devices. LDI is 99.9% accurate in aligning layers, which is vital for complex designs.

“Laser Direct Imaging improves precision, which is critical for medical devices. Even small errors can affect safety.” – MDIC Advanced Manufacturing Report

LDI also reduces alignment mistakes and improves solder mask accuracy. This lowers the chance of short circuits. It ensures medical PCBs meet strict quality needs and work reliably.

Precision Improvement | Description |

|---|---|

Micron-level resolution | Creates details smaller than 5 μm for advanced uses. |

Via registration accuracy | Aligns layers with 99.9% accuracy for complex designs. |

Solder mask precision | Defines solder mask openings exactly, avoiding short circuits. |

Using LDI helps make high-quality PCBs for modern medical tools.

Making medical device PCBAs ensures medical tools are safe and reliable. The process is detailed and follows strict rules to meet healthcare needs.

Tests like heat and stress checks prove PCBAs can handle tough conditions.

New trends, like wearable devices, improve how PCBAs are made.

AI and IoT are changing production, making devices smarter and more useful.

These changes, along with better materials, are shaping the future of medical PCBAs. The industry is expected to grow a lot because it helps healthcare improve.

FAQ

What makes medical PCBs special compared to regular PCBs?

Medical PCBs are made for important medical uses. They follow strict rules like ISO 13485 for safety. These boards use strong materials to handle tough conditions and work reliably in life-saving tools.

Why is tracking important in making medical PCBs?

Tracking helps follow every step and part in production. It ensures rules are followed and problems are found quickly. This builds trust and keeps medical devices safe.

How does automation help make medical PCBs?

Automation makes production faster and reduces mistakes. Robots place parts accurately, improving quality and saving money.

What tests are done on medical PCBs?

Tests include functional testing, flying probe testing, and X-rays. These check how well the board works, solder quality, and strength in tough conditions.

Can medical PCBs be made for specific devices?

Yes, medical PCBs can be designed for special needs. Experts use tools to create boards that fit the device’s size, job, and reliability.

See Also

Key Phases In The PCBA Production Workflow

Detailed Instructions For The PCBA Manufacturing Procedure

An In-Depth Overview Of PCBA Assembly Stages