Switching to a lead-free PCBA manufacturing process requires careful planning. It’s essential to understand the regulations, such as the EU’s 2006 lead ban. Selecting the right materials, including lead-free SnAgCu alloys, is crucial. These alloys have higher melting points compared to SnPb alloys, which necessitates adjustments in soldering techniques to prevent damage to components. Continuously enhancing the lead-free PCBA manufacturing process ensures efficient production while maintaining high quality. By adhering to regulations, choosing appropriate materials, and implementing necessary changes, you can establish a robust and environmentally friendly manufacturing process.

Key Takeaways

Changing to lead-free PCBA manufacturing follows global rules like RoHS. This helps you follow laws and sell in more markets.

Using lead-free materials, like SnAgCu alloys, makes products safer and stronger. This creates better circuit boards.

Training your team on lead-free rules lowers errors and improves product quality.

Testing and checking your process often finds problems early. This ensures your products stay high-quality.

Making lead-free steps the same for everyone saves time and helps teamwork. It also keeps quality steady in production.

Benefits of a Lead-Free PCBA Manufacturing Process

Following Environmental Rules

Using a lead-free PCBA process helps meet global rules. Laws like RoHS require removing harmful materials, such as lead, from electronics. Following these rules avoids fines and opens doors to global markets.

Compliance Area | Explanation |

|---|---|

Companies must limit harmful substances in their products. | |

Lead-Free Solder | Switching to tin-silver-copper (SAC) alloys is very important. |

Environmental Gains | Less pollution and easier recycling are big benefits. |

Following these rules shows you care about the planet. It also makes your company a trusted leader in the industry.

Safer and Stronger Products

Lead-free manufacturing makes circuit boards safer and stronger. New lead-free solder, like SnAgCu, works better under heat and pressure. This lowers the chance of solder problems and keeps products working well.

Global Standards: Meeting world rules builds customer trust.

Better Durability: Lead-free solder makes boards last longer.

Safer Workplaces: No lead means a healthier place for workers.

As Purdue’s Handwerker explains, new solder types can work better than old tin-lead ones. These changes improve how products are made and ensure top quality.

Staying Ahead in the Market

Switching to lead-free PCBA gives your business an advantage. People now prefer eco-friendly products, and lead-free practices meet this need. Big electronics companies have seen good results after switching.

The lead-free solder market is growing fast and worth billions.

Companies using lead-free methods gain better reputations and loyal customers.

Industry teamwork helps create new ideas and grow the market.

By going lead-free, your business can grow with these trends. This ensures success in a tough market.

Helping Sustainability Goals

Switching to lead-free manufacturing helps meet sustainability goals. Removing lead lowers harm to the environment and makes the planet safer. This change supports global efforts to cut waste and use eco-friendly methods.

Lead-free processes bring many benefits:

They lower harmful materials in electronics.

They make workplaces safer by avoiding lead exposure.

They improve recycling of circuit boards, helping the environment.

Tip: Using lead-free materials helps the planet and boosts your company’s image as eco-friendly.

The table below shows how lead-free PCBA helps sustainability:

Metric | Description |

|---|---|

Following rules | Meeting RoHS and other laws to remove harmful substances like lead. |

Less harmful materials | Switching to lead-free PCBs cuts dangerous substances in electronics. |

Better health and safety | Lead-free methods protect workers and users from lead risks. |

Easier recycling | Lead-free materials make PCBs easier to recycle, supporting eco-friendly goals. |

Using lead-free methods meets global standards for safer products. It keeps your circuit boards competitive in a market that values green practices. Every step toward sustainability helps your business lead while protecting the planet for the future.

Steps to Implement a Lead-Free Manufacturing Process

Understanding Regulatory Requirements

Before starting lead-free PCBA manufacturing, learn the important rules. These rules help your products meet global standards and avoid fines. The Restriction of Hazardous Substances (RoHS) rule is very important. It limits harmful materials like lead in electronics.

Check local laws and industry rules too. For example, the Waste Electrical and Electronic Equipment (WEEE) rule focuses on recycling electronics. Knowing these rules helps you follow legal and eco-friendly standards.

Tip: Make a list of all rules to stay compliant during the process.

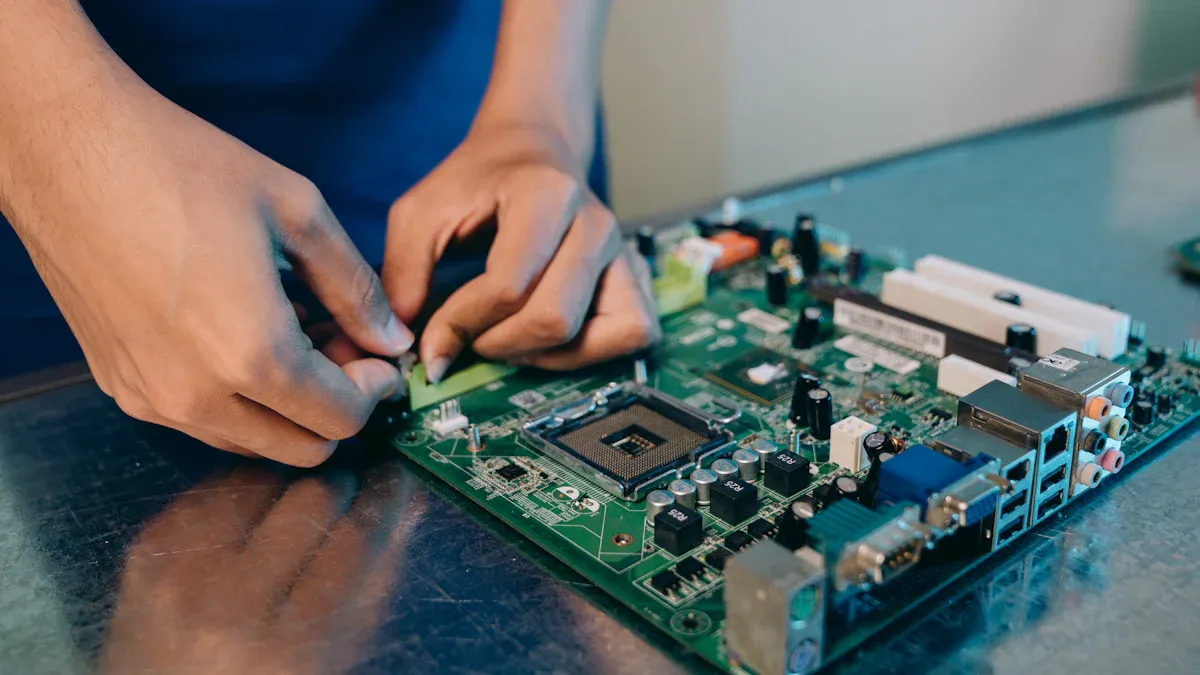

Selecting Lead-Free Materials and Components

Picking the right materials is key for success. Lead-free solder, like tin-silver-copper (SnAgCu) alloys, works well and is reliable. These materials melt at higher temperatures, making them good for modern boards.

Ensure components can handle lead-free soldering heat. Some parts may not work with higher temperatures. Work with suppliers to get materials that meet quality and rule standards.

Key points for choosing materials:

Solder Paste: Pick paste that fits lead-free soldering.

Component Durability: Check if parts handle higher heat.

Environmental Impact: Use materials that support eco-friendly goals.

Choosing the right materials improves board quality and strength.

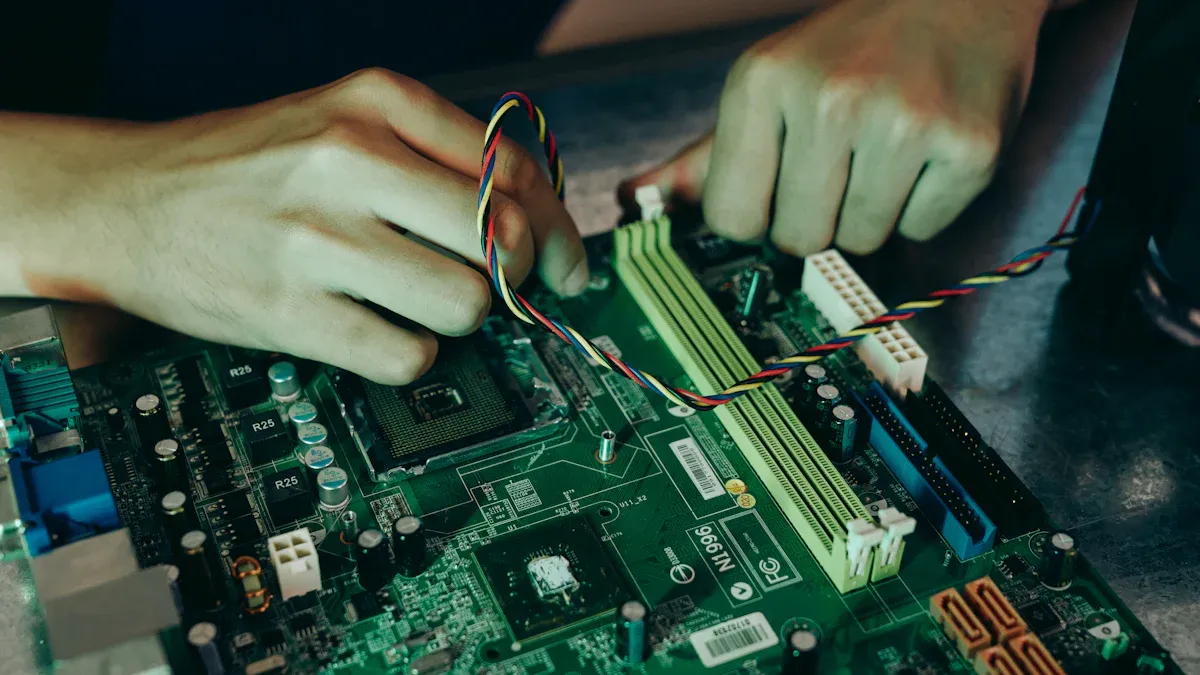

Upgrading Equipment for Lead-Free Soldering

Lead-free soldering needs better tools to handle higher heat. Old machines may not work well with lead-free processes. Upgrading tools ensures fewer mistakes and better results.

Here’s how to improve your equipment:

Material Selection: Use machines that work with lead-free solder.

Solder Paste Optimization: Match paste with lead-free needs.

Temperature Control: Keep soldering heat steady to avoid damage.

Pad Design: Change pad designs for strong solder joints.

Quality Control and Testing: Check solder quality carefully.

Training and Operating Procedures: Teach workers lead-free soldering steps.

Equipment Maintenance: Fix machines often to keep them working well.

Transition Management: Plan changes to avoid problems and delays.

Note: Buying better reflow ovens and wave soldering tools can make lead-free assembly faster and easier.

Upgrading tools and following these tips will improve your lead-free PCBA process.

Optimizing the PCB Manufacturing Process for Lead-Free Solder

Making the PCB process work with lead-free solder needs changes. Lead-free solder melts at higher temperatures, which affects circuit boards. You must adjust each step to handle these differences.

Here are some ways to improve your process:

Adjust Reflow Profiles: Lead-free solder needs more heat. Set your reflow oven to match SnAgCu alloy melting points. Watch the temperature to avoid damaging parts.

Improve Solder Paste Application: Use paste made for lead-free soldering. Apply it evenly to stop weak joints or solder bridges.

Enhance PCB Design: Change pad sizes and layouts for lead-free soldering. This helps prevent defects and makes solder joints stronger.

Focus on Cleaning: Lead-free solder leaves more residue. Clean boards well to keep them reliable.

Test and Validate: Check boards often for problems like cracks or voids. Use tools like X-rays to ensure solder joints are strong.

Tip: Work with suppliers to get materials and tools for lead-free soldering. This teamwork can improve your results.

By improving your PCB process, you can make strong and reliable boards that meet industry rules.

Training and Educating Staff on Lead-Free Standards

Your team is key to making lead-free PCBA work. Training them on lead-free rules helps them understand what’s needed. Skilled workers make fewer mistakes and work faster.

Here’s how to train your team well:

Provide Hands-On Training: Teach workers to use lead-free tools. Let them practice with new materials and equipment.

Explain Regulatory Requirements: Show your team rules like RoHS and WEEE. Help them see why following these rules matters.

Highlight Process Changes: Explain how lead-free soldering is different. Focus on higher heat and handling materials safely.

Use Visual Aids: Use charts or videos to explain hard ideas. These tools make learning easier.

Encourage Continuous Learning: Offer workshops or online classes often. Keep your team updated on new trends and ideas.

Note: Reward workers who do well with lead-free methods. This inspires others to do their best.

Training your team ensures smooth PCBA production. A skilled team can solve problems and keep your products high-quality.

Addressing Challenges in Lead-Free Manufacturing Processes

Handling Higher Soldering Temperatures

Lead-free solder melts at higher temperatures, which can cause problems. These high temperatures may harm delicate parts during assembly. Adjust your soldering process to keep components safe and working.

Start by fine-tuning your reflow oven settings. Lead-free solder, like SnAgCu alloys, melts at about 217–220°C, unlike tin-lead solder at 183°C. Heat the circuit boards slowly to avoid sudden temperature changes. Use accurate temperature controls to ensure even heating for all batches.

Choosing the right components is also important. Pick materials that can handle high heat without breaking down. Work with suppliers to find durable, heat-resistant parts that meet your needs.

Tip: Check solder joints often for cracks or gaps from heat stress. Finding problems early saves time and lowers repair costs.

Managing Costs of Lead-Free Materials

Using lead-free materials can raise production costs. These materials, like lead-free solder and heat-resistant parts, cost more than traditional ones. To control costs, you need a smart plan.

Several things make costs harder to manage:

Limited Information: Suppliers may not share full cost details, making analysis tough.

Skill Gaps: Teams may lack training to handle complex cost reviews.

Complicated Buying Processes: Dealing with many suppliers and pricing systems adds challenges.

Price Differences: Costs vary between suppliers, making savings hard to find.

Train your team to improve cost analysis skills. Simplify buying processes to compare suppliers easily. Build strong supplier relationships to get better deals and steady quality.

Note: Review costs regularly to find ways to save money without lowering quality.

Keeping PCBAs Strong and Reliable

Making sure circuit boards stay strong and reliable in lead-free processes takes effort. Lead-free solder joints can be weaker and crack under stress. Take steps to make them more dependable.

Improve your soldering methods. Use tools like X-rays to spot hidden joint problems. Change PCB designs to fit lead-free solder better. For example, use bigger pads to make stronger connections.

Environmental factors also matter. Lead-free solder can rust, weakening joints over time. Store materials in dry, controlled spaces to protect them from air and moisture.

Callout: Work with engineers to test boards in real-world conditions. Simulating stress and temperature changes helps find weak spots before production.

By solving these issues, you can make products that meet industry rules and work well for a long time.

Preventing Component Damage During Assembly

Stopping damage to parts during assembly is a big challenge in lead-free PCBA. Higher heat and brittle lead-free solder can cause problems. Careful assembly steps can protect parts and keep them working well.

Reduce Stress on PCBAs

Stress during assembly can harm solder joints and parts. Lead-free solders, like SnAgCu, are more brittle than tin-lead ones. This makes them easier to break under stress. Bending or twisting the board too much can make it worse.

Don’t bend or twist the board too much.

Use tools to check for stress during assembly.

Add supports to keep the board steady while working.

Tip: Watch your assembly steps often to stop stress problems early.

Manage Soldering Heat

Lead-free soldering needs more heat, which can hurt delicate parts. High heat can also weaken the board’s materials, causing problems like conductive anodic filaments (CAFs). To avoid this:

Set your reflow oven to match lead-free solder heat levels.

Warm the board slowly to avoid sudden heat changes.

Use parts that can handle higher temperatures.

Callout: Test soldering to make sure joints are strong and reliable.

Improve PCB Design and Layout

Good PCB design helps stop part damage. Bad layouts can cause uneven heating and weak solder joints.

Make pads bigger to strengthen solder joints.

Spread out parts for even heating during soldering.

Keep sensitive parts away from hot areas.

Smart designs lower risks and make boards last longer.

Do Regular Inspections

Checking your work often helps catch problems early. Use special tools to check how well your assembly is done.

Use X-rays to find hidden solder joint cracks or gaps.

Check for misplaced parts or solder bridges with optical tools.

Test boards in real-life conditions to find weak spots.

Note: Finding problems early saves time and money on fixes.

Train Your Team on Good Practices

Your workers are key to stopping part damage. Training helps them understand lead-free assembly challenges.

Teach them to handle boards carefully without bending or dropping them.

Show them how to set and keep the right soldering heat.

Stress the need to check solder joints and parts during assembly.

A well-trained team makes fewer mistakes and keeps quality high.

Key Practices Summary

Problem | Solution |

|---|---|

Stress on solder joints | Test for stress and avoid bending boards. |

High soldering heat | Adjust oven settings and use heat-safe parts. |

Weak solder joints | Test soldering and improve PCB design. |

Hidden flaws | Use X-rays and optical checks often. |

By following these tips, you can stop part damage and make great lead-free PCBAs. Careful planning and attention to detail will help you succeed in lead-free manufacturing.

Best Practices for Optimizing Lead-Free PCBA Manufacturing

Regular Testing and Process Audits

Testing and audits are key to making great PCBAs. They help find problems early and stop defects. Tests like Environmental Stress Screening (ESS) check how strong your boards are. These tests show weak spots before they cause big issues.

Audits ensure you follow industry rules. Use IPC guidelines to pick materials, inspect parts, and adjust processes. Audits improve product quality and build trust in your company.

Tip: Plan regular audits and tests to stay efficient and eco-friendly.

Evidence Description | Key Points |

|---|---|

IPC Standards Impact | Focus on materials, testing, and inspections for lead-free PCBAs. |

Environmental Practices | Use lead-free materials and save energy during production. |

Quality Control Methods | ESS checks if PCBs can handle real-world conditions. |

Using Advanced Quality Control Tools

Modern tools make your PCBA process better. They track production and catch problems early. For example, control charts show changes in the process. Fixing these changes quickly reduces defects and boosts efficiency.

Top companies using these tools have fewer quality issues. Their cost of poor quality (COPQ) is about 1%, while others face 5% or more. Tools like X-rays and automated optical inspection (AOI) check solder joints and parts. This saves time and money by avoiding rework and recalls.

Callout: Quality tools lower costs and make customers happier with reliable products.

Top companies have a COPQ of around 1%, much lower than others.

Control charts spot problems early, keeping products high-quality.

Using these tools improves production and reduces mistakes.

Partnering with Reliable Suppliers

Good suppliers are vital for lead-free manufacturing. They provide top-quality materials that meet rules. Check their performance by looking at order accuracy, delivery speed, and timing. These factors affect your production and product quality.

Strong supplier relationships help you get better prices and steady supplies. Working with trusted suppliers lowers risks and keeps customers happy.

Note: Review supplier performance often to keep your supply chain smooth.

Delivery Metrics: Check order accuracy, speed, and on-time delivery.

Order Accuracy: Avoid problems by ensuring correct orders.

Lead Time: Faster deliveries help production stay on track.

On-Time Delivery: Meeting deadlines keeps operations running well.

Staying Informed on Industry Innovations

Keeping up with industry changes is very important. The electronics world changes fast with new materials and ideas. Staying updated helps your lead-free PCBA process stay competitive and follow rules.

Using eco-friendly materials and smart technologies like 5G and AI can improve your work. These tools make production faster and meet customer and rule demands. The table below shows key trends shaping the industry:

Trend Description | Importance |

|---|---|

Helps meet rules and stay competitive in the market | |

Adding advanced tech like 5G and AI | Boosts innovation and improves manufacturing practices |

Moving to sustainable materials | Meets rules and public demand for greener products |

Focusing on sustainability is also very important. Using recyclable materials and lead-free soldering matches environmental rules and customer needs. These steps cut harmful waste and protect the planet. The table below highlights trends in sustainable PCB manufacturing:

Trend Description | Importance |

|---|---|

More focus on sustainability in PCB making | Matches environmental rules and customer expectations |

Using lead-free soldering methods | Cuts harmful waste and lowers environmental damage |

Choosing recyclable materials | Reduces waste and supports green efforts |

Tip: Read industry news, go to trade shows, and join groups to learn about new ideas. Staying informed helps your process stay modern and ready for the future.

Standardizing Lead-Free Manufacturing Processes

Making your lead-free processes the same everywhere improves quality and teamwork. A clear plan reduces mistakes and helps teams work better together.

Standardization makes work faster. Using the same data lets you automate tasks and track progress. This finds problems quickly and improves production. It also helps your team fix issues faster, keeping products high-quality.

Here are some benefits of standardizing processes:

Better Efficiency: Automation and tracking make workflows smoother.

Stronger Quality Control: Clear rules help spot and fix problems fast.

Improved Teamwork: Shared data reduces confusion and boosts teamwork.

Smarter Predictions: Predicting repairs and needs becomes easier, saving resources.

Callout: Write down your steps and train your team to follow them. This keeps everyone on the same page, lowers mistakes, and improves results.

By standardizing your lead-free processes, you can work faster, make better products, and stay ahead in the changing electronics market.

Switching to lead-free PCBA manufacturing is crucial to compete today. It helps follow global rules, makes products safer, and supports eco-friendly goals. For example, Europe has strict laws like the WEEE Directive. In North America, the Department of Defense bans lead-based soldering. Not following the EU’s RoHS Directive can block access to a $2.1 trillion market. The table below shows how regions are adopting lead-free practices:

Region | Key Details |

|---|---|

Europe | EU laws like EPR and WEEE push companies to comply. |

North America | U.S. Defense rules ban lead solder, affecting contractors. |

Emerging Markets | Brazilian companies spend 15-20% of budgets on lead-free rules for exports. |

APAC | Investments in new solder reduce defects and boost adoption. |

Global | RoHS non-compliance blocks entry to a $2.1 trillion market. |

Using a clear plan helps improve processes, lower risks, and make greener products. Start now to stay ahead in innovation and sustainability.

FAQ

What is the main difference between lead-free and traditional PCBA manufacturing?

Lead-free PCBA uses solder without lead, like SnAgCu alloys. These alloys need higher heat, so processes must change. Traditional PCBA uses tin-lead solder, which melts at lower heat but harms health and the environment.

How can you ensure quality in lead-free PCBA manufacturing?

To ensure quality, test often with tools like X-rays and ESS. Use AOI machines to find problems early. Reliable suppliers also help by providing good materials.

Tip: Regular checks keep products reliable and meet rules.

Are lead-free materials more expensive?

Yes, lead-free materials cost more because they are special. But, working closely with suppliers can lower costs. Using lead-free methods avoids fines and saves money over time.

What are the common challenges in lead-free soldering?

Higher heat can harm parts, and lead-free joints are weaker. Fix this by adjusting heat settings and using stronger materials. Better PCB designs also help make joints last longer.

Note: Training your team reduces mistakes during assembly.

Why is lead-free PCBA manufacturing important?

Lead-free PCBA follows rules like RoHS and protects the planet. It makes workplaces safer and meets demand for green products. Switching to lead-free also helps your business stay competitive.

Callout: Lead-free practices support the planet and build customer trust.

See Also

Best Practices for Achieving Quality and Efficiency in PCBA

Enhancing Workflow Efficiency in PCB Assembly Processes

Essential Strategies for Overcoming PCBA Manufacturing Challenges

Improving Quality Control Measures in PCB Assembly Operations