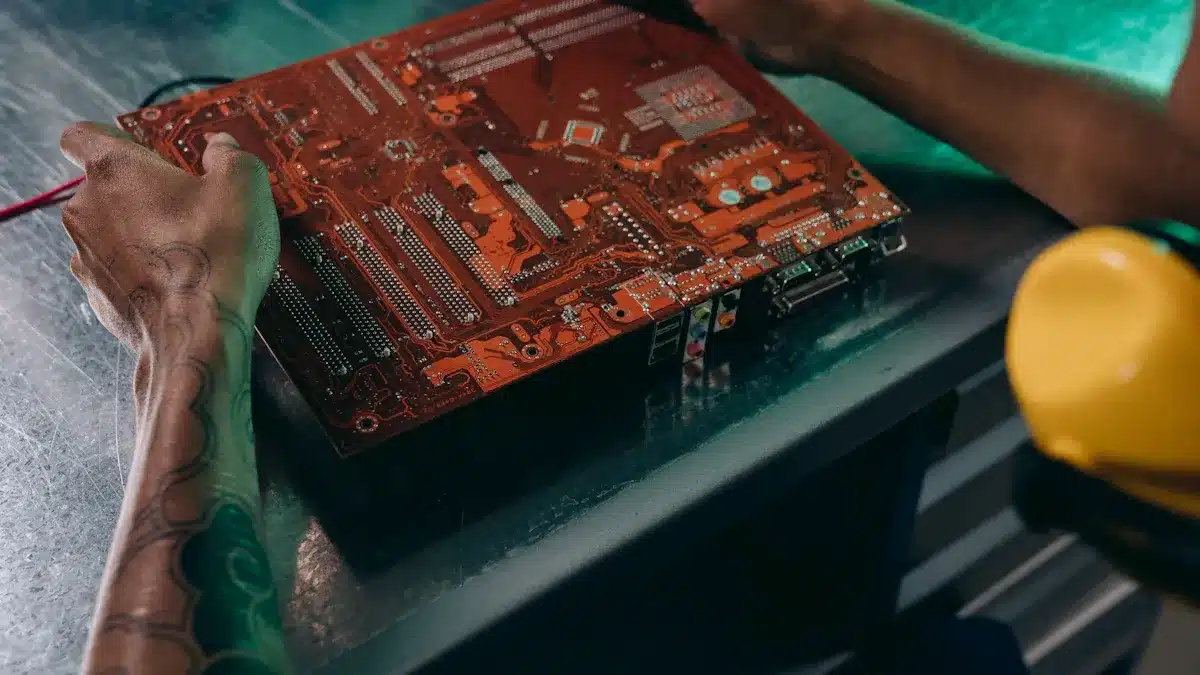

PC board assembly (PCBA) changes a plain pcb into a working device by adding parts like resistors and chips. PCBA uses careful steps to put and connect each part. This process is not the same as pcb fabrication, which makes the empty board. Putting parts and soldering them in the right places stops early device problems. Bad assembly, like weak joints or dirt, causes more failures in the first hours of use. Good assembly and strong quality checks help make pcba work well for daily electronics.

Key Takeaways

PC board assembly changes a plain board into a working device by putting on and soldering parts with care.

Doing each step in the assembly process makes sure devices work well and last longer.

Good quality control finds problems early and helps make safe, reliable electronics.

Different assembly methods like surface mount and through-hole fit different device needs.

PC board assembly is important for making everyday electronics and advanced industry products work right.

PC Board Assembly Basics

What is PC Board Assembly

PC board assembly changes a plain board into a working device. It does this by putting and soldering parts onto the board. The goal is to make a circuit that powers things like phones and cars.

The steps in assembly are very important. Each step helps make sure the board works well.

Design and Prototyping: Engineers make a design and build a test board.

Material Procurement: The team gets all the needed parts.

Stencil Production: A stencil helps put solder paste in the right spots.

Component Inspection: Workers check each part before using it.

Solder Paste Application: Solder paste goes where parts will be placed.

Component Placement: Machines or people put each part in its place.

Soldering: The board is heated to attach the parts.

Cleaning: Any dirt or extra paste is cleaned off.

Inspection and Testing: Machines and people check for problems and test the board.

Final Assembly and Packaging: The finished board is packed for shipping.

Note: Every step in the pcb assembly process matters. Skipping a step can make the device not work right.

The materials used in printed circuit board assembly are very important. They help the board work well and last longer. The table below lists some common materials and parts:

Category | Examples/Components | Function/Role | Typical Application/Notes |

|---|---|---|---|

Base Materials | Dielectric materials, Prepreg, Core | Give insulation and hold layers together | Used in boards with many layers |

Protective Materials | Solder mask, Silkscreen ink | Stop short circuits and help with assembly | Used on all board surfaces |

Surface Finishes | HASL, ENIG, OSP, Immersion Silver/Tin, Gold plating | Help solder stick and stop rust | Used for many types of boards |

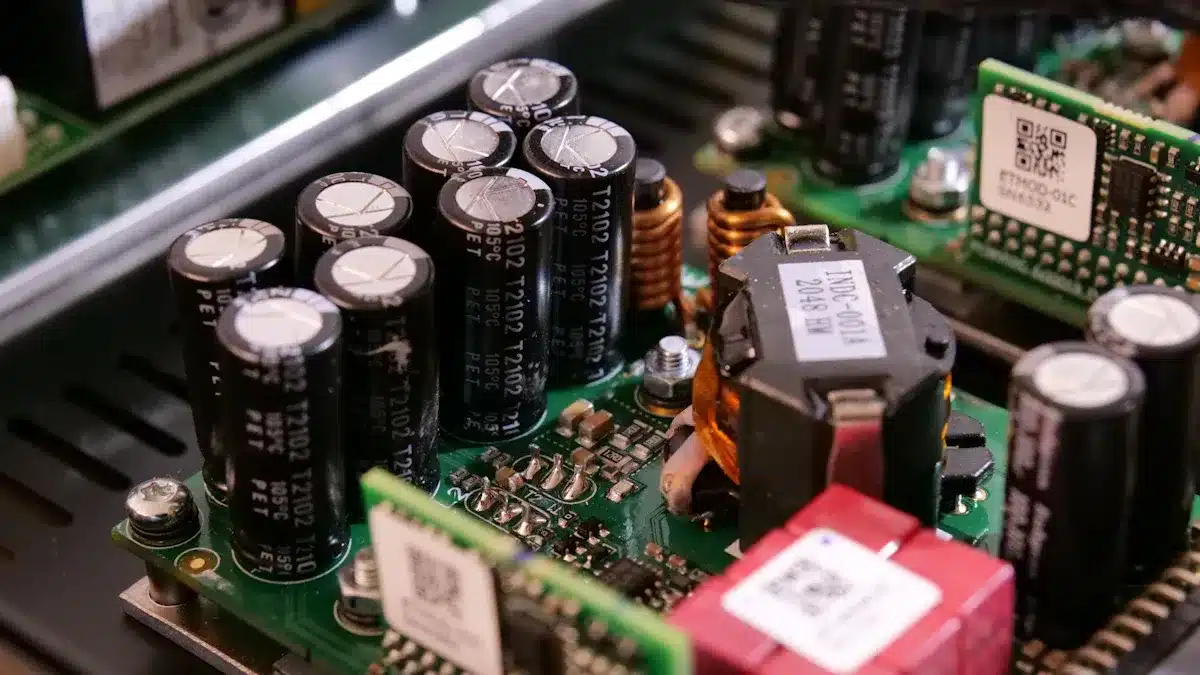

Passive Components | Resistors, Capacitors, Inductors | Control current and store energy | Used in basic circuits and for filtering |

Active Components | Diodes, LEDs, Transistors, ICs | Control signals and make logic work | Used for power, signals, and microcontrollers |

I/O Components | Connectors, Switches, Relays | Make connections and let people control things | Used for USB, HDMI, alarms, and timing |

Printed circuit board assembly uses two main ways to add parts. Surface-mount technology makes small and light devices. Through-hole technology gives strong support for bigger parts.

PCB vs. PCBA

A printed circuit board is a flat board with copper and insulation. It has lines called traces that connect different spots. But a plain board cannot do anything by itself. It is just the base for circuits.

Printed circuit board assembly means the board has all its parts attached. Now the board can work in a device. The difference is like a blank canvas versus a finished painting.

Aspect | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

Definition | Plain board with paths for electricity | Board with all parts added and working |

Function | Holds parts and connects them | Does a job in an electronic device |

Components | No parts, just the board | Has all needed parts like resistors and chips |

Appearance | Flat board with lines and holes | Board with many parts on top |

Manufacturing | Makes the board with copper and coatings | Adds and solders parts onto the board |

Testing | Checks the copper lines for breaks | Tests if the board works right |

Stage | Just the base | Finished and working board |

Applications | Used for testing and early designs | Used in real products like phones and computers |

Making a PCB means building the board itself. This includes adding copper, making patterns, drilling, and coating. The board has no parts yet and cannot work. PC board assembly adds all the needed parts. This includes placing, soldering, cleaning, and testing. Only after assembly does the board become ready for use.

Tip: Remember, a PCB is just the start. After assembly, it becomes a working part in your favorite devices.

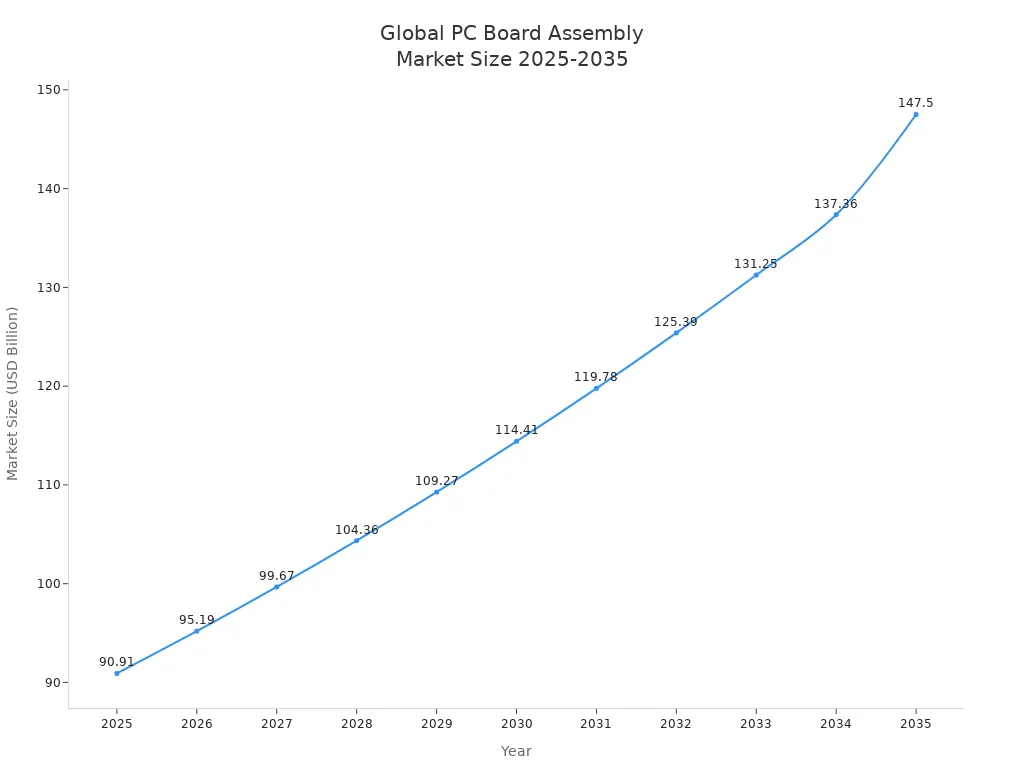

The market for printed circuit board assembly is getting bigger. In 2025, it may reach about $90.91 billion. By 2035, it could grow to $147.5 billion. Asia-Pacific is the biggest market, with over 60% share. Phones, cars, and 5G help this market grow.

Printed circuit boards and printed circuit board assemblies are the base of modern electronics. Knowing the difference between making and assembling boards helps you see how simple boards become complex devices.

PCB Assembly Process

Design and Components

The pcb assembly process begins with a good design. Engineers pick the right parts and decide where to put them. Smart choices help control heat and keep signals clear. They also make building the board easier. Putting decoupling capacitors near chips lowers noise. Leaving space between traces stops signals from mixing. The way parts are placed affects how easy it is to build and test the board. Planning early helps avoid problems like bad heat flow or hard-to-reach parts.

Some common problems at this stage are:

Bad design, like putting parts in the wrong spot or not handling heat well

Trouble finding good parts

Assembly Methods

The pcb assembly process uses different ways to attach parts. Surface Mount Technology puts small parts right on the board. This lets makers fit many parts and build boards quickly. Through-hole assembly pushes part leads through holes and solders them underneath. This makes strong connections and works for parts that get hot or stressed. Many new devices use both methods to handle tough jobs.

Assembly Method | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

Fits many parts, quick, saves money | Not as strong, harder to fix | Phones, computers, small devices | |

Through-Hole Assembly | Strong, easy to fix | Slower, uses more space | Industrial, automotive, prototyping |

Soldering Steps

Soldering is an important part of pcb assembly. The steps are:

Get the soldering iron ready and tin the tip.

Clean the board to get rid of dust.

Put parts on, starting with the smallest ones.

Heat the joint with the iron.

Add solder to the joint, not the iron.

Let it cool and check for a shiny look.

Cut off extra leads and clean away leftover flux.

Good soldering stops problems like weak joints, solder bridges, and open spots. Skilled workers and good supplies help make the finished pcba better.

Quality Control

Quality control is very important in pcb assembly. Checks find problems early and help make sure the product works well. Automated Optical Inspection uses cameras to spot parts that are not lined up, solder mistakes, and missing pieces. AOI is faster and more exact than checking by hand, especially for boards with lots of parts.

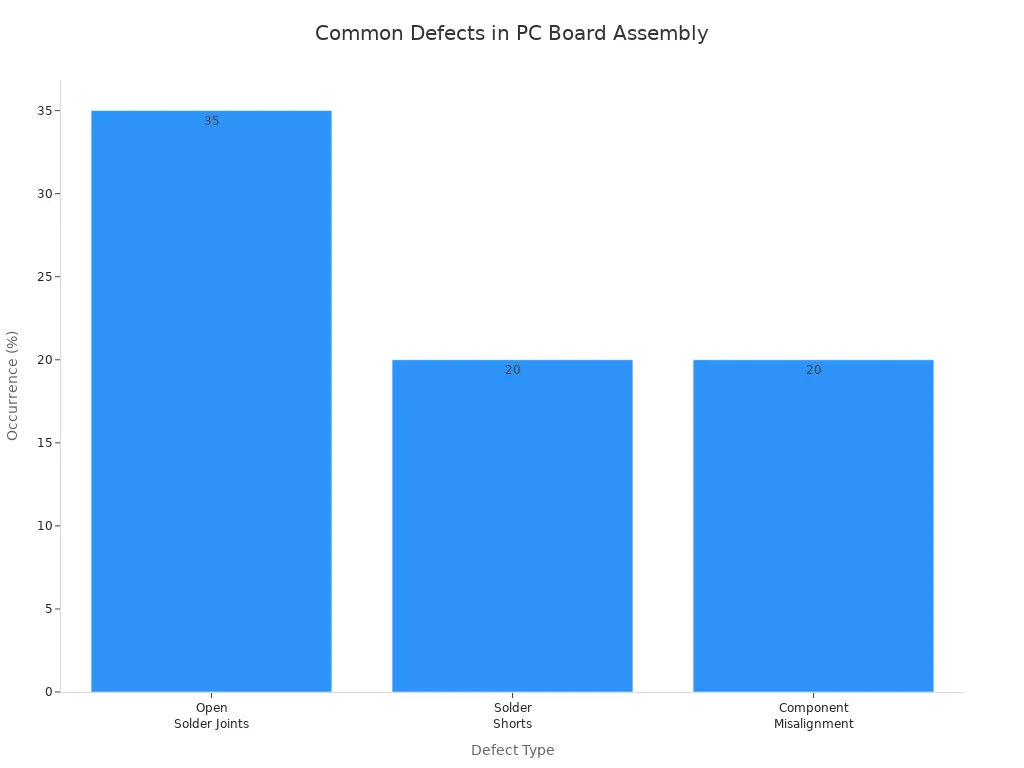

Industry rules help guide quality control in printed circuit board assembly. IPC and ISO rules set standards for soldering, cleaning, and checking boards. Regular checks, in-circuit tests, and worker training help keep quality high. Common problems are open solder joints, solder shorts, and parts not lined up. These checks make sure pcba manufacturing gives safe and reliable products.

Printed Circuit Board Assembly Importance

Device Reliability

Printed circuit board assembly helps devices work well and last longer. Engineers carefully attach parts to the pcb using exact steps. There are rigid, flex, and rigid-flex pcb assemblies. Flex and rigid-flex types make phones and wearables strong and small. Picking the right assembly type makes devices more reliable. Special tests check if pcba can handle heat and tough conditions. These tests help keep people safe and build trust. Devices can break early if companies use old pcbs or skip steps. Problems like delamination and corrosion can make devices stop working and cause safety risks.

Performance Impact

Good pcb assembly helps devices work better. Engineers test boards to check voltage, current, and noise. They also run tests to see if the board does what it should. Aging and stress tests show how long a pcba will last. Boards are tested with heat, water, and shaking to see if they can survive. Machines look for soldering mistakes and parts in the wrong place. X-rays check for hidden problems in solder joints. All these steps help make sure printed circuit board assembly gives strong performance.

Test Type | Fault Identified | Impact on Device Performance | Outcome of FET Action |

|---|---|---|---|

Continuity Test | Open circuit in trace | Device fails to power on | Fault detected and board rewired |

Solder Joint Check | Cold solder joint | Poor electrical connection, component inactive | Reflow soldering repairs joint |

Component Placement Check | Misplaced capacitor | Incorrect device functionality | Components repositioned and re-soldered |

Short Circuit Test | Short between components | Potential operational failure | Fault detected and components replaced |

Scalability

Scalability means making lots of devices quickly and easily. Contract manufacturers use machines to build many boards fast. Robots work all day without getting tired. Automated placement of parts makes fewer mistakes. Advanced inspection systems help check quality. Robots can switch to new products fast. These things help companies make millions of printed circuit boards every day. Fast work and flexible plans help companies grow and invent new things.

Bad assembly can make devices less reliable and unsafe. It can cost more to fix broken devices. Devices might have short circuits, get too hot, or break. Companies can get in trouble or have to recall products if they do not care about quality in pcba manufacturing.

PCBA Applications

Everyday Electronics

PCBA is very important in things people use daily. Homes have many products that need printed circuit board assembly. Phones, tablets, and smartwatches all use advanced pcb assembly. Computers and laptops need printed circuit boards for their parts. TVs, game consoles, and stereos use pcba for fun and music.

Many appliances at home now have smart features. Fridges, microwaves, and coffee makers use printed circuit assembly. They help control heat, time, and safety. Smart locks, switches, and speakers use pcb assembly too. These devices connect to other things and the internet. More connected products help the Internet of Things (IoT) grow. PCBA manufacturer teams make boards that fit in small spaces. They build boards that last through daily use.

Devices with pcba include:

Phones and tablets

Computers and laptops

TVs and monitors

Appliances like ovens and fridges

Smart home devices and lights

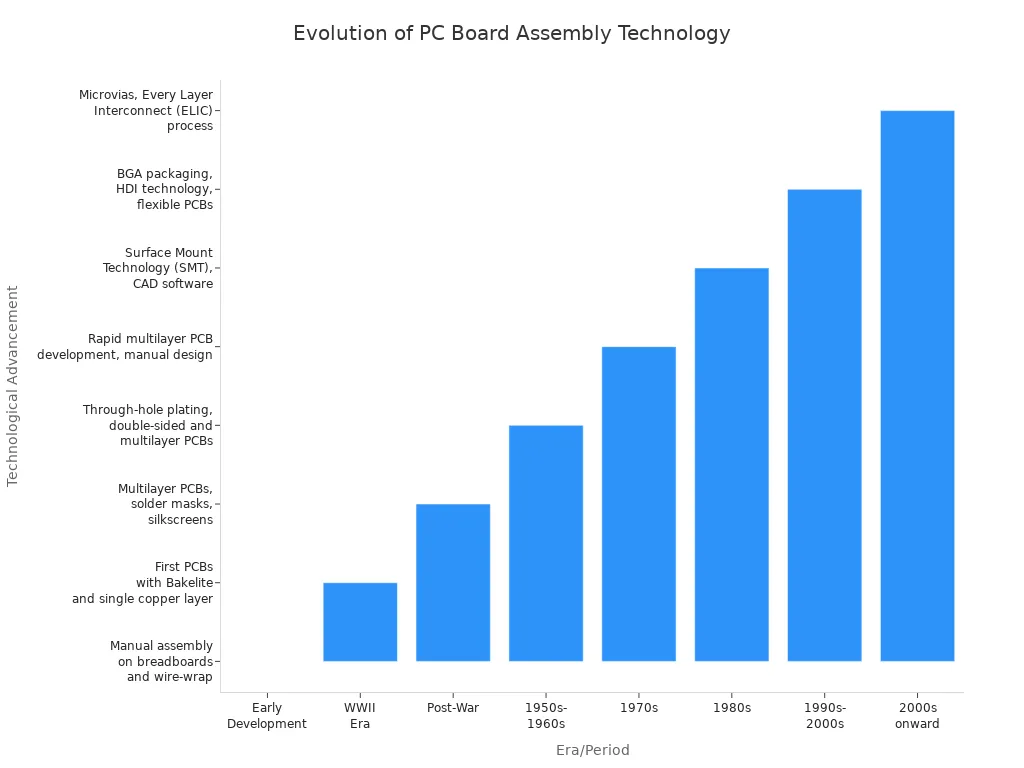

PCBA technology has changed a lot over the years. Old printed circuit boards were simple. Now, the pcb assembly process uses new methods. Surface mount technology and dense designs let devices have more features.

Industry Uses

Many industries need pcba manufacturing for their products. Cars use printed circuit assembly for safety, engines, and entertainment. Modern cars need strong pcb for sensors and cameras. PCBA manufacturer teams follow strict rules for quality and strength.

The medical field also needs printed circuit board assembly. Pacemakers, MRI machines, and surgical robots use safe pcb assembly. PCBA manufacturer experts use special materials and clean rooms. These steps help keep patients safe and make devices work well.

Factories use printed circuit boards for control and automation. Strong pcba helps machines work safely. The pcb assembly process helps new ideas in robots, energy, and smart factories.

PCBA helps make products smaller, stronger, and better. Skilled pcba manufacturer teams help technology move forward.

Printed circuit board assembly changes a plain board into something useful. It uses steps like putting parts on, soldering, and testing. These steps help devices last longer and work well. Printed circuit board assembly helps make new things like tiny phones and smart watches. If you learn about the pcb assembly process, you can see how it makes safe and reliable products. Knowing about pc board assembly helps people understand the cool ideas in today’s technology.

FAQ

What is the difference between pcb assembly and pcb fabrication?

PCB fabrication makes the plain board with no parts. PCB assembly puts electronic parts onto the board. Fabrication builds the base for circuits. Assembly changes it into a device that works.

Why does quality control matter in printed circuit board assembly?

Quality control looks for mistakes during assembly. It helps devices stay safe and last longer. PCBA testing finds problems before they get worse. Good checks stop failures and protect users.

How do manufacturers test printed circuit boards after assembly?

PCBA teams use visual checks, AOI machines, and x-rays. PCBA testing finds bad solder joints and wrong parts. These steps help boards work the way they should.

What are common methods used in the pcb assembly process?

Surface mount technology and through-hole assembly are both used. SMT puts small parts on top of the board. Through-hole puts leads through holes in the board. Both ways help make many different devices.

Can pc board assembly be used for medical devices?

Yes. PC board assembly helps make safe medical devices. PCBA manufacturing uses clean rooms and special materials. Printed circuit board assembly makes pacemakers, monitors, and robots work well.

Tip: PCBA fabrication and assembly steps help devices follow strict safety rules in many industries.

See Also

Understanding PCBA And Its Importance In Electronics

The Definition Of PCBA And Its Key Significance

Exploring PCBA Services And Their Role In Manufacturing