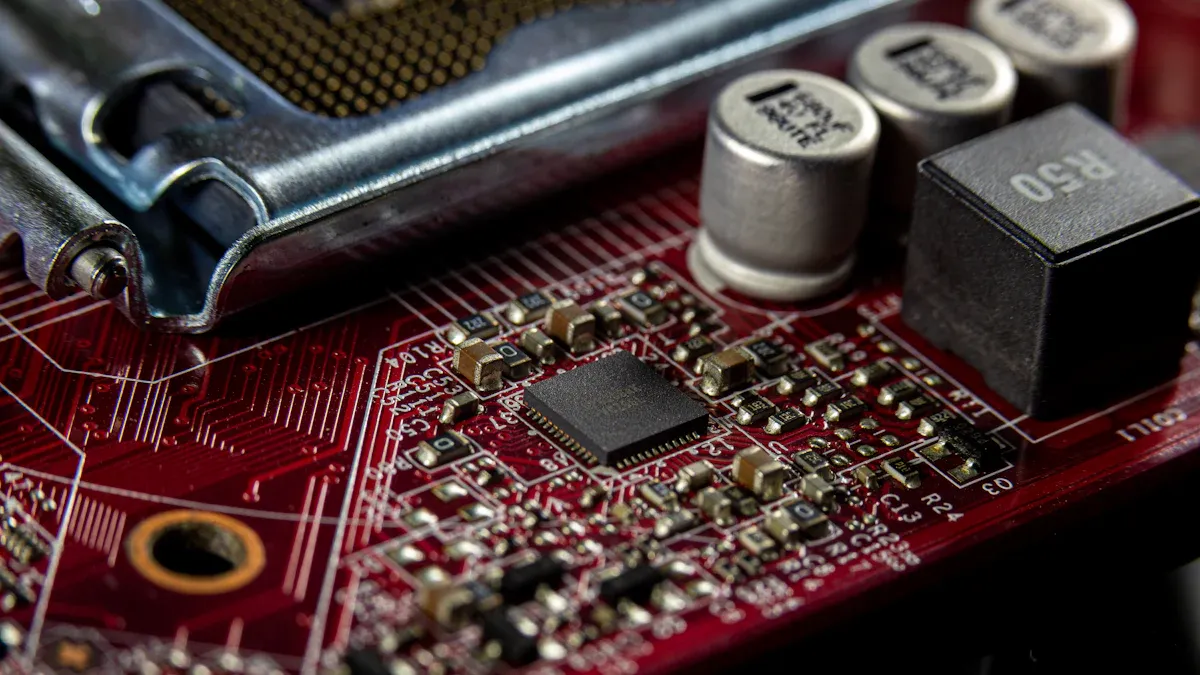

A PCB busbar is a part that moves power easily on a circuit board. It works like a main road, helping power flow smoothly in systems. Unlike regular wires, PCB busbars make connections simpler and less messy in high-power setups.

PCB busbars are very important in today’s electronics. They help get rid of heat, keeping parts from overheating. They also make devices work better by reducing electrical noise and being more reliable in tough conditions. These benefits make them key to modern electronic designs.

Key Takeaways

PCB busbars make it easier to share power on circuit boards.

They help control heat, stopping devices from getting too hot.

PCB busbars lower electrical noise, making electronics work better.

Copper and aluminum are often used, each with special uses.

PCB busbars are important in cars and green energy systems.

What Is a Bus Bar in PCB Design?

Definition and Concept of PCB Busbars

A PCB busbar is a flat piece that carries power on a circuit board. It works like a main road, moving electricity to different parts. Instead of using wires, PCB busbars are built into the board. This makes the design neat and saves space.

Here’s a table to explain what PCB busbars do:

Function | Description |

|---|---|

Conduction | Moves electricity from the power source to the devices. |

Distribution | Spreads power evenly to all parts of the device. |

Connection | Links devices to the main power source for smooth working. |

Flexibility | Makes it easy to add or remove parts. |

Heat Dissipation | Gets rid of heat to stop parts from overheating. |

Protection | Can include safety features like fuses to prevent damage. |

These features make PCB busbars important for managing power in electronics.

Differences Between PCB Busbars and Traditional Wiring

PCB busbars are different from regular wiring in many ways. They are built into the circuit board, so there’s no need for extra wires. This makes the design simpler and cleaner.

Aspect | PCB Busbars | Traditional Wiring Methods |

|---|---|---|

Structural Benefits | Makes the board stronger and stops it from bending. | Does not help the board stay strong. |

Thermal Management | Removes heat well, useful for things like LED lights. | Needs extra parts to handle heat. |

Cost Efficiency | Costs less because it’s simpler and needs no insulation. | Costs more due to extra wires and insulation. |

Fabrication | Made with machines for faster and easier production. | Needs more work to put together and insulate. |

PCB busbars also use thinner insulation than regular laminated busbars. This makes them lighter and cheaper but still safe. They are great for things like car power systems.

Importance of PCB Busbars in Modern Electronics

PCB busbars are very useful in today’s electronics. They make circuit boards stronger, stopping them from bending or shaking. This helps devices last longer, even in tough conditions.

Copper PCB busbars are especially good at carrying electricity. They are perfect for circuits that need to handle a lot of power. Industries like cars, planes, and green energy use PCB busbars because they manage heat and power so well.

Key Functions of PCB Busbars

Power Conduction and Distribution

PCB busbars help move power across a circuit board easily. They act like main roads, letting electricity flow to all parts. Unlike regular wires, they carry more current without wasting energy. This makes them great for systems needing lots of power and reliability.

Studies show how well PCB busbars work for power flow. For example, the study “Optimization of Electric-Field Grading Plates in a PCB-Integrated Bus Bar” explains how they improve power movement and system performance. Here’s a summary:

Study Title | Focus |

|---|---|

Optimization of Electric-Field Grading Plates in a PCB-Integrated Bus Bar | Shows how PCB busbars improve power flow and efficiency. |

Using PCB busbars helps manage power better, especially in high-power systems.

Heat Dissipation and Thermal Management

Getting rid of heat is important in electronics, and PCB busbars do this well. Their flat shape spreads heat, stopping parts from overheating. This is key in systems with lots of current, where too much heat can cause damage.

Copper and aluminum are common materials for PCB busbars. Copper moves electricity and heat very well, while aluminum is lighter but still good at handling heat. Adding PCB busbars to your design helps control heat and makes devices last longer.

Reducing Electrical Noise and Inductance

Electrical noise and inductance can mess up electronic systems. PCB busbars reduce these problems by keeping current paths close together. This lowers inductance, cutting down voltage spikes and noise. The result is a smoother and more stable system.

In high-frequency circuits, less inductance means fewer disruptions. PCB busbars are perfect for systems needing precision, like power electronics and communication devices. They improve current flow while reducing noise and keeping systems efficient.

Materials Used in PCB Busbars

Copper: Properties and Benefits

Copper is a common material for PCB busbars. It carries electricity well, moving large currents with little energy loss. This makes it great for systems needing high power. Copper also spreads heat quickly, keeping the circuit board cool.

Copper is strong and doesn’t rust, so it lasts long. Its toughness helps stop damage from shaking or bending. These features make copper a top choice for reliable and efficient designs.

Aluminum: Properties and Benefits

Aluminum is another material often used for PCB busbars. It is light, which is helpful in cars and airplanes where weight matters. While not as conductive as copper, aluminum still works well in many systems.

Aluminum also handles heat well, keeping parts cool in high-power setups. It costs less than copper, making it a budget-friendly option without losing performance.

Comparison of Copper and Aluminum in PCB Busbars

Choosing between copper and aluminum depends on your needs. Copper is better for carrying electricity and heat, ideal for high-performance systems. Aluminum is lighter and cheaper, good for projects where weight and cost are key.

Both materials manage heat well, but copper works better in tough conditions. Special materials like Amodel® Supreme PPA can improve heat resistance and strength when used with these metals. This is useful in electric cars and green energy systems.

By knowing what each material does best, you can pick the right one for your design.

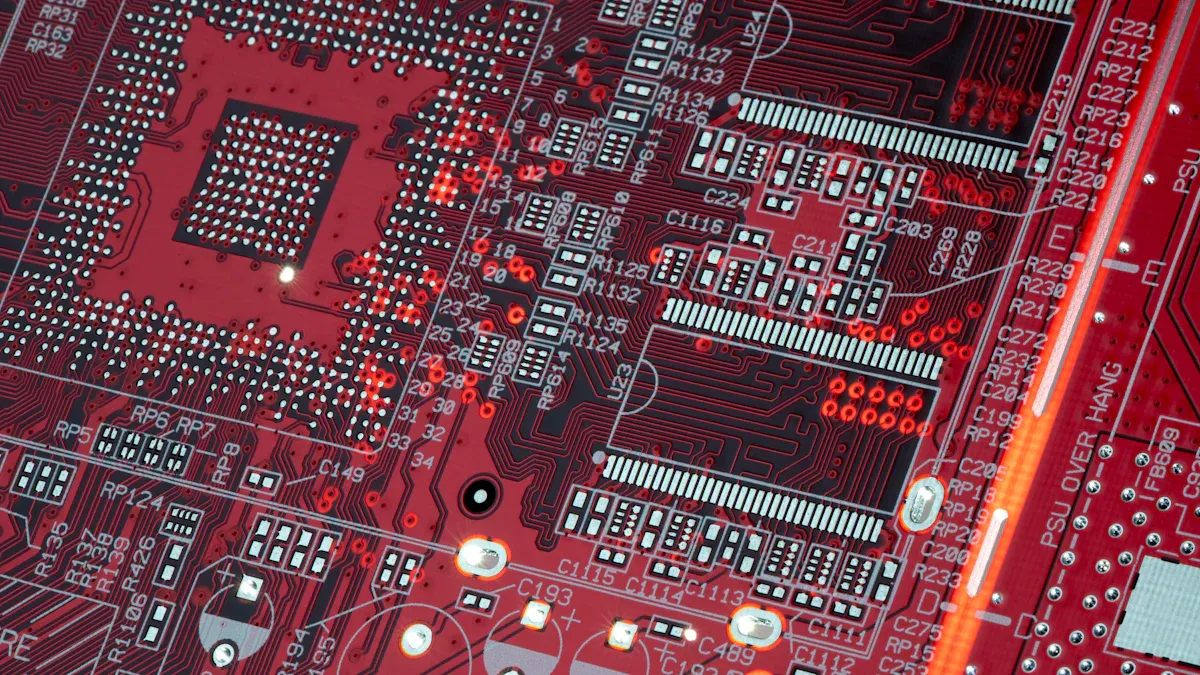

Types and Configurations of PCB Busbars

Solid PCB Busbars

Solid PCB busbars are widely used in electronics. They are made from one solid piece of metal, usually copper or aluminum. Their main job is to carry high currents without wasting energy. These busbars are found in systems needing strength and reliability, like power setups and industrial machines.

Their simple design makes them easy to add to circuit boards. The solid structure is strong and resists bending or breaking. If your project needs to handle high power and stay durable, solid PCB busbars are a great option.

Laminated PCB Busbars

Laminated PCB busbars are made by stacking layers of metal sheets. Insulating materials are placed between the layers to reduce electrical noise and inductance. This design works well for circuits needing precise power flow.

Laminated busbars are good for handling complex power needs. The layered design saves space and spreads heat better. They are used in advanced systems like green energy, electric cars, and airplanes. Their design ensures smooth power flow and less interference.

Custom Configurations for Specific Applications

Sometimes, regular busbars don’t fit a project’s needs. Custom busbars are made for specific uses to work perfectly. For example, you might need a special shape or thickness for tight spaces with high currents.

Custom PCB busbars often use thick copper layers, called heavy copper PCBs. These layers can be over 3 ounces per square foot. This design handles high currents and reduces resistance. You’ll find these in power converters and systems needing high reliability and efficiency.

Picking the right busbar type improves power flow, heat control, and device durability.

Advantages of PCB Busbars

Better Heat Control

PCB busbars help keep electronics cool and safe. Their flat shape spreads heat evenly across the board. This stops parts from getting too hot and breaking. Copper and aluminum are common materials for busbars. Copper is especially good at moving heat away from important areas.

Using PCB busbars improves how well your devices handle heat. This is very useful for systems with high power needs. Good heat control makes devices last longer and work better. PCB busbars are great for managing power and keeping electronics reliable.

Less Electrical Noise and Inductance

Electrical noise can cause problems in devices. PCB busbars reduce this by keeping current paths close together. This lowers inductance, stopping voltage spikes and noise. Your devices will run smoother and more efficiently.

In circuits with high frequencies, low inductance is very important. It keeps power steady and avoids interference. PCB busbars are perfect for systems needing accuracy and dependability. They help create a stable and clean electrical system.

Saves Space and Offers Flexibility

PCB busbars save space in your devices. They are built into the circuit board, so no extra wires are needed. This makes devices smaller, lighter, and more efficient.

You can design PCB busbars to fit your needs. They can be made in different shapes and sizes. This lets you create unique designs without losing performance. PCB busbars make power management easier and give you more design options.

Stronger and More Reliable Systems

When building electronics, you need them to last and work well. PCB busbars are better than regular cables for this. They are strong and designed to handle tough conditions without breaking.

A big plus of busbars is handling high currents easily. Cables can wear out or loosen, but busbars stay secure on the circuit board. This lowers the chance of power problems and keeps things running smoothly, even with vibrations or stress.

Busbars also resist damage from the environment. They are made from materials like copper or aluminum, which don’t rust or corrode. This makes them great for cars, planes, and other harsh settings. Using busbars means your devices last longer and need less fixing.

Their flat shape also helps stop overheating. This protects parts from heat damage and keeps systems working well. PCB busbars make your electronics more reliable and able to handle different challenges.

Applications of PCB Busbars in Modern Electronics

Power Electronics and High-Current Systems

PCB busbars are important in power electronics and high-current systems. They move large currents with little energy loss. Their flat shape and good conductivity make them perfect for many uses, like:

Electrical panels use them to safely share power.

Switchgear depends on them for strong and lasting connections.

Data centers and factories use them for better power control.

A study shows PCB busbars can be soldered, inlaid, or built into boards. This makes them flexible for different high-power needs. They also resist wear, making them reliable for power systems.

Application Area | Description |

|---|---|

Electrical Panels | Help share power safely and efficiently. |

Switchgear | Provide strong and lasting power connections. |

Industrial Facilities | Control power in machines and data centers. |

Automotive Industry: Electric Vehicles and Battery Systems

PCB busbars are key in electric cars and battery systems. They help manage power in e-Mobility systems. Picking the right busbar improves cooling and saves energy in electric vehicles (EVs). Reports show they meet electrical and heat needs for battery systems.

Copper busbars are common in EVs because they carry power well and stay cool. They work well under high-power conditions. Busbars also make DC link systems more reliable, cutting energy loss in powerful setups.

Renewable Energy: Solar Inverters and Wind Turbines

Solar inverters and wind turbines need PCB busbars for power sharing. These systems make lots of energy, so they need parts that handle heat and high currents. Copper busbars are great for this.

In solar inverters, copper busbars keep power flowing smoothly and reduce noise. In wind turbines, they move energy between parts, making the system work better. They are tough and handle bad weather, making them perfect for renewable energy systems.

Industrial and Aerospace Applications

PCB busbars are very important in factories and aerospace systems. These areas need parts that work well in tough conditions. They must handle high currents, strong vibrations, and changing temperatures. PCB busbars are used where reliability and efficiency matter most.

Industrial Applications

In factories, PCB busbars help share power in big machines. They carry high currents without getting too hot. This makes them great for:

Robotic arms: They deliver power smoothly for accurate movements.

Power converters: They transfer energy with little waste.

Factory automation systems: They cut down electrical noise, improving performance.

Tip: Adding PCB busbars to machines can save money. They last longer and need less fixing.

Aerospace Applications

In aerospace, weight and strength are very important. PCB busbars are light but strong, making them a good choice. They are often used in:

Avionics systems: They give steady power to navigation and communication tools.

Satellite systems: They manage power well in small, high-tech designs.

Aircraft power systems: They handle high currents and resist heat and shaking.

Aerospace parts must survive harsh conditions. PCB busbars made of copper or aluminum work well here. Their flat shape spreads heat, keeping systems running during long flights or space missions.

Note: Picking the right material, like copper for better power flow or aluminum for less weight, can improve how well PCB busbars work in aerospace systems.

Using PCB busbars makes industrial and aerospace systems more reliable. They help these systems work better, even in tough environments.

PCB busbars are crucial in today’s electronics. They boost power use, cut heat, and make systems more reliable. They handle large currents and lower electrical noise. This makes them essential for industries like cars, green energy, and planes.

In the future, their use will grow with clean energy systems. Laminated busbars help solar and wind power work better and last longer.

Key Market Insights:

Rules to lower CO2 increase the need for efficient energy.

Used in batteries and everyday electronics.

With smart designs, PCB busbars will meet the power needs of new technologies.

FAQ

What is a bus bar PCB, and why does it matter?

A bus bar PCB is a part of a circuit board. It helps share electrical power in a neat and reliable way. It replaces messy wires and handles high currents well. This makes it important for keeping power steady in modern electronics.

How do busbars help with heat control?

Busbars are flat, so they spread heat evenly. This stops parts from getting too hot and breaking. Materials like copper and aluminum help remove heat better. This makes busbars great for systems that use a lot of power.

Do busbars lower electrical noise?

Yes, busbars cut down electrical noise. They keep current paths close, which lowers inductance. This stops voltage spikes and makes devices work smoothly. They are especially helpful in circuits with high frequencies.

What materials are used to make busbars?

Copper and aluminum are the main materials for busbars. Copper carries electricity well and spreads heat quickly. Aluminum is lighter and costs less. Both are strong and work well in many industries, like cars and green energy.

Where are bus bar PCBs found?

Bus bar PCBs are used in cars, green energy, and airplanes. They help share power in electric cars, solar panels, wind turbines, and planes. They handle high currents and tough conditions, making them very useful.

See Also

Understanding PCBA: Its Importance in Electronic Circuits

Exploring PCBA: Significance in the Electronics Sector

Defining PCBA: Its Function in Electronic Equipment

PCBA Services Explained: Their Importance in Electronics Production

PCB Design Explained: Its Significance in Electronic Devices