A PCBA circuit board is the foundation of modern electronics. Essentially, it starts as a printed circuit board (PCB), which is a flat board made from non-metal materials like fiberglass. Copper lines on the board connect various components. However, a PCB by itself cannot function. It requires the addition of components such as resistors, capacitors, and chips. Once these components are attached, the PCB transforms into a printed circuit board assembly (PCBA), or simply, a PCBA circuit board.

The distinction between a PCB and a PCBA circuit board is straightforward but crucial. A PCB serves as the base, while a PCBA is a fully functional unit. Understanding this difference is key to making informed decisions. Innovations like flexible PCBs and multilayer boards are revolutionizing the industry. With approximately 70% of PCBs being utilized in gadgets, the significance of PCBA circuit boards in advancing technology is undeniable.

Key Takeaways

A PCB is a flat board that links electronic parts. A PCBA is a PCB with parts added, making it work.

Use a PCB for easy projects needing a basic board. Pick a PCBA if you need a ready-to-use circuit board.

Think about how complex your design is. Simple gadgets might need a single-layer PCB. Advanced devices often need multi-layer PCBAs.

Plan your budget by thinking about size, materials, and quantity. Ordering more boards can lower the cost per board.

Choose a trusted maker who does quality checks and has certifications. This ensures you get good boards.

What is a PCB?

Definition of a Printed Circuit Board

A printed circuit board (PCB) is the heart of electronics. It holds and connects electronic parts together. The board is made of fiberglass with copper lines on it. These copper lines let electricity flow between the parts. Without PCBs, building electronic devices would be very hard.

Rules like IPC-ESD-2020 and IPC-6010 make sure PCBs are safe and high-quality. These rules cover things like handling static electricity and soldering. By following these rules, companies make strong and reliable PCBs for many uses.

Structure and Materials of a PCB

A PCB has layers, and each layer has a job. The bottom layer, called the substrate, gives support. On top of that, copper lines carry electricity. A solder mask covers the copper to stop short circuits. Labels and markings are added with a silkscreen layer.

Most PCBs use fiberglass as the base material. But now, some companies are using eco-friendly materials. These new materials help reduce waste and save energy when thrown away.

Types of Printed Circuit Boards

PCBs come in different types for different jobs. Single-sided PCBs have parts on one side and are used in simple gadgets like calculators. Double-sided PCBs have parts on both sides and work for more complex devices. Multi-layer PCBs have many layers and are great for advanced circuits.

Here’s a table showing PCB types and their uses:

Type | Application | Vehicle Type | Region |

|---|---|---|---|

Single-Sided | Engine Control Units | Passenger Cars | Asia Pacific |

Double-Sided | Transmission Control Units | Commercial Vehicles | North America |

Multi-Layer | Anti-lock Braking Systems | Electric Vehicles | Latin America |

Rigid | Airbag Control Modules | Europe | |

Flexible | Infotainment Systems | Middle East & Africa | |

Rigid-Flex | Navigation Systems |

Each PCB type has a special use. Picking the right one is important for your project.

Role of PCBs in Electronics

Printed circuit boards (PCBs) are very important in electronics. They are the base of almost all electronic devices. Without them, making small and useful gadgets would be very hard. PCBs connect and organize parts so they work together smoothly.

PCBs are used in many industries. Here are some examples:

Consumer Electronics: HDI PCBs help make smartphones and tablets. These boards let devices do complex tasks while staying small.

Automotive Industry: PCBs power ADAS, which uses sensors to improve car safety.

Aerospace: Satellites and flight systems need strong PCBs to work in tough conditions.

Medical Devices: Machines like MRIs use precise PCBs that meet safety rules.

Industrial Automation: Robots and factory systems use tough PCBs for harsh places.

PCBs also make devices smaller. By organizing parts well, they help create portable products. This has changed industries like healthcare, communication, and entertainment.

PCBs are key to improving technology. They help make smarter, faster, and better devices that improve life.

What is a PCBA?

Definition of a Printed Circuit Board Assembly

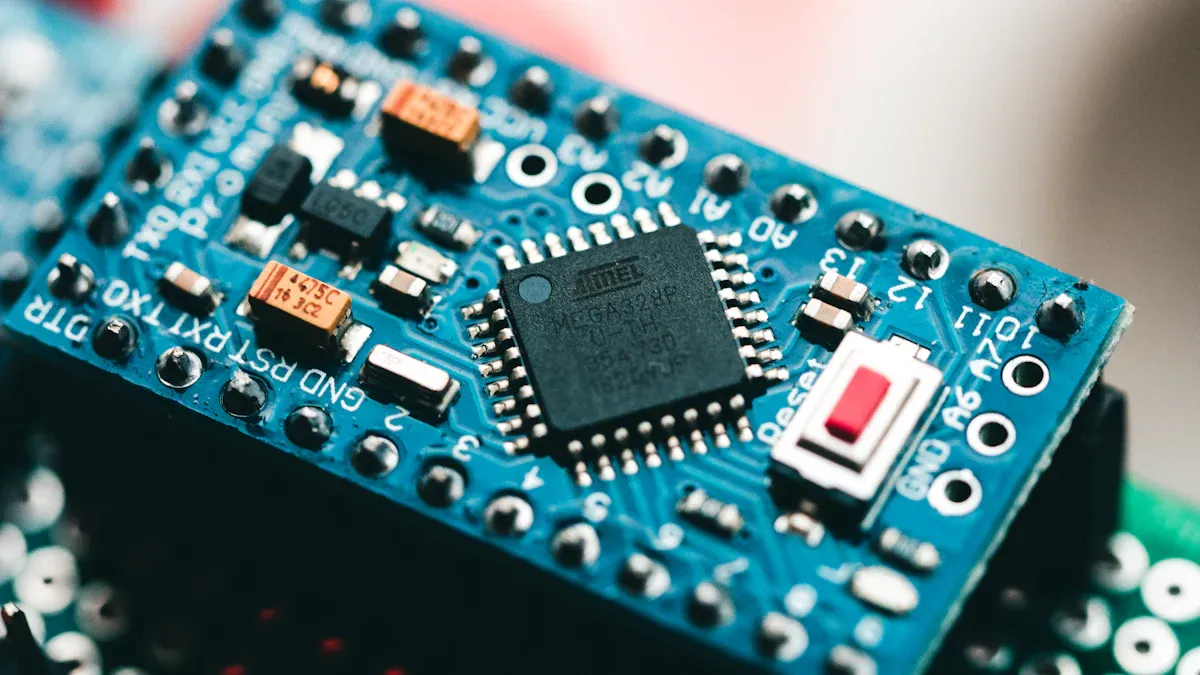

A printed circuit board assembly (PCBA) is a PCB with parts added. The PCB is the base, but the PCBA makes it work. Parts like resistors, capacitors, and chips are attached to the board. These parts allow the board to do specific jobs. Without them, the PCB is just an empty board. Knowing this difference is important for designing or making electronics.

To explain simply:

A PCB is like a blank sheet of paper.

A PCBA is like a finished drawing, ready to use.

This understanding helps you pick the right one for your needs.

The PCBA Assembly Process

Making a PCBA involves careful steps to ensure it works. Here’s a simple guide:

Solder Paste Application: Solder paste is added to the board’s pads.

Component Placement: Machines place parts like chips onto the board.

Reflow Soldering: Heat melts the solder paste, securing the parts.

Inspection and Testing: Machines check for mistakes to ensure quality.

This process uses skill and technology to create working PCBA boards.

Components Used in a PCBA

A PCBA has many parts, each with a job to do. Common parts include:

Resistors: Manage how much electricity flows.

Capacitors: Hold and release electrical energy.

Integrated Circuits (ICs): Handle tasks like data processing.

These parts work together to make the PCBA useful. The parts chosen depend on what the board will be used for, like gadgets, cars, or medical tools. Quality checks ensure the parts are reliable and work well.

Importance of PCBA in Electronics

Printed circuit board assemblies (PCBA) are crucial in modern electronics. They turn a plain PCB into a working system by adding parts like resistors, capacitors, and chips. This change helps devices do specific jobs, making PCBA essential in many industries.

PCBA improves how devices work. It uses advanced PCB designs with methods like surface mount technology (SMT) and through-hole technology (THT). SMT helps make smaller designs with more circuits. THT gives strong connections for tough uses. Hybrid technology, which mixes SMT and THT, adds flexibility and better performance.

PCBA is important in many fields. In consumer electronics, it helps make smartphones and smartwatches. Cars use PCBA for safety systems and navigation tools. Medical machines, like MRIs, need PCBA to meet strict rules. PCBA also supports factory automation and communication systems, keeping them running smoothly.

The need for better electronics shows why PCBA matters. In 2023, the global PCBA market was worth $36.86 billion. Consumer electronics made up $15 billion of this. By 2032, the market could grow to $50 billion, thanks to new PCB designs and better parts. PCBA costs can differ, but its role in advancing technology is clear.

Technology Type | Description | Impact on Functionality |

|---|---|---|

Surface Mount Technology | Small and efficient design | Adds more circuits and boosts performance |

Through-Hole Technology | Strong mechanical connections | Reliable for critical uses |

Hybrid Technology | Mixes SMT and THT benefits | Improves flexibility and device performance |

PCBA is the heart of electronics, making devices smarter and more reliable.

Key Technical Differences Between PCB and PCBA

Design and Manufacturing Differences

Making a PCB and a PCBA is very different. A PCB is a flat board made of fiberglass or polyimide. It is the base for electronic circuits. Copper lines and layers connect parts on the board. To make a PCB, steps like etching, drilling, and adding solder masks are used.

A PCBA is made by adding parts to the PCB. Resistors, capacitors, and chips are placed on the board. Methods like SMT or THT attach these parts securely. Reflow soldering uses heat to make strong connections. Finding mistakes early is very important. Studies show fixing late mistakes can cost $0.40 to $45.

Aspect | Details |

|---|---|

Focus | Predicting defects in PCBs using BGA package types |

Methodology | Uses data from SPI machines and machine learning models |

Key Findings | Models scored over 0.82 precision, 0.50 recall, and 0.62 f1 |

Cost Implications | Defect costs rose from $0.40 to $45 at later stages |

Importance | Early defect checks save money and reduce rework costs |

Cost and Complexity Comparison

The price and difficulty of making PCBs and PCBAs depend on many things. PCB costs depend on size, layers, and materials. A multi-layer PCB with gold connectors costs more than a simple one. Adding parts during assembly makes it more complex. More parts, testing, and placement increase costs.

Here’s a breakdown of factors:

Type of Report | Factors Affecting Costs and Complexity |

|---|---|

PCB Assembly Report Card | – One or two IR reflow passes |

Wave solder process

Manual or automatic part placement

Odd-shaped parts

Part quality level

Connector placement

Test coverage

Test diagnosability

Stress testing

Repair equipment compatibility | | Fabrication Report Card | – Board size and number per panel

Number of layers

Material used

Trace and space widths

Total holes

Smallest hole size

Solder mask and legends

Final finish

Gold edge connectors

Special design features |

Knowing these details helps you plan your budget better.

Functional Differences in Applications

PCBs and PCBAs do different jobs. A PCB is the base for circuits. It lets electricity flow but cannot work alone. Adding parts during assembly makes it functional. For example, a smartphone PCB works only after assembly.

Flexible circuits are useful for special devices. They can bend, fold, and twist, unlike rigid PCBs. This makes them great for wearables and small gadgets. Here’s a comparison:

Aspect | Printed Circuit Boards (PCBs) | Flexible Circuits |

|---|---|---|

Flexibility | Rigid, cannot bend | Can bend, fold, and twist |

Base Material | Usually FR4 (rigid) | Polyimide (flexible) |

Adhesive Requirements | Limited to chemical/thermal | Must allow bending |

Copper Type | Electro Deposited (ED) | Rolled Annealed (RA) |

Design Complexity | Standard tolerances | More complex due to flexibility |

Knowing these differences helps you pick the best option for your needs.

Functional Differences and Use Cases

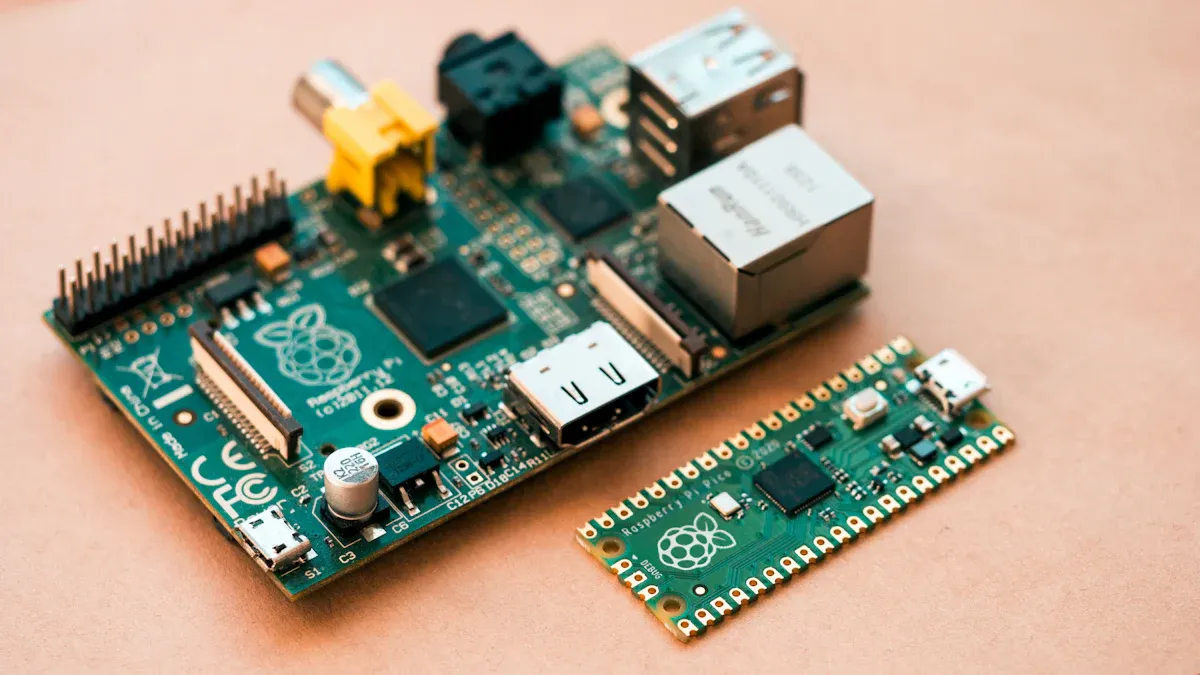

When to Use a PCB

Use a PCB when you need a basic board for circuits. It provides a stable base to connect electronic parts. PCBs are great for simple devices like calculators or remotes. They are also cost-effective for basic projects.

If you want to add parts later, a bare PCB is flexible. It lets you design and change as needed. This is helpful in research or testing, where adjustments happen often.

When to Use a PCBA

Choose a PCBA when you need a working circuit board. It has all the parts, like resistors and chips, already attached. This makes it ready to perform specific tasks.

PCBAs are best for advanced or reliable devices. Cars use them for engine controls and entertainment systems. Medical tools like pacemakers need PCBAs for safety and precision. They are also used in telecom for routers and base stations.

Common Applications of PCBs and PCBAs

PCBs and PCBAs are used in many industries. Here are some examples:

Consumer Electronics: PCBAs power phones, laptops, and smartwatches.

Automotive Electronics: PCBAs run safety systems and navigation tools.

Medical Devices: Machines like MRIs and pacemakers need reliable PCBAs.

Industrial Automation: PCBAs control factory machines and power systems.

Telecommunications: Routers and cell towers use high-performance PCBAs.

Aerospace and Defense: Aircraft and military systems rely on strong PCBAs.

These examples show why picking the right option matters. Whether you need a simple PCB or a complete PCBA, understanding their uses helps your project succeed.

How to Choose the Right Option

Understanding Project Needs

Deciding between a PCB and a PCBA depends on your project. First, figure out what your circuit board will do. If you only need a simple base for testing, a PCB works. But if you need a fully working board, go with a PCBA.

Think about how complex your design is. A basic device like a remote may need just one-layer PCB. However, advanced tools like medical machines or car systems often need multi-layer PCBAs. Testing early helps find problems and ensures your design works.

Also, consider where the board will be used. Flexible boards are great for wearables since they can bend. Testing them in real-life situations ensures they work well.

Budget and Cost Factors

Your budget is important when choosing. A simpler board design costs less. For example, fewer layers and bigger holes lower costs. Making more boards at once also saves money, so plan your orders wisely.

Here are some things that affect costs:

Board size and design. Bigger and complex boards cost more.

Parts used. Advanced parts make it pricier.

Order size. Larger orders lower the price per board.

Using design tools like Altium Designer can help you save money. These tools let you test your design and avoid mistakes.

Factor | Cost Impact |

|---|---|

PCB Material | |

Surface Finish | Basic finishes are affordable; advanced ones cost extra. |

Easy-to-Make Design | Simple designs save money. |

Knowing these details helps you balance cost and performance.

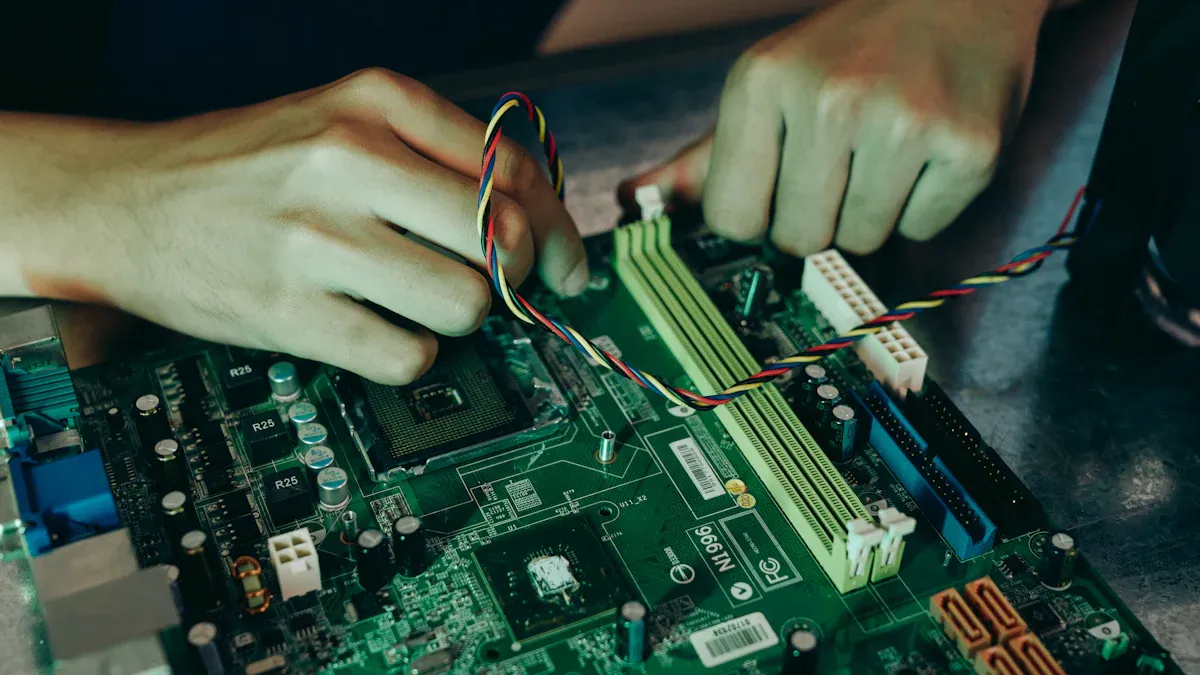

Picking the Right Manufacturer

Choosing a good manufacturer is key for quality boards. Find suppliers who focus on quality checks. They should test their boards to ensure they work well.

Look for certifications like ISO 9001 for quality and ISO 14001 for eco-friendly practices. Also, check if they offer guarantees for customer satisfaction.

High-quality boards make your final product better. Always choose manufacturers with good reviews, experience, and fair prices.

Reputation is important. Read reviews and ask for samples before placing big orders. Testing their boards first can prevent problems later.

Knowing the difference between a PCB and a PCBA helps you choose wisely for your projects. A PCB is just the base, while a PCBA has all the parts to make it work. Each has its own steps and uses, as shown here:

Aspect | PCB Maker | PCB Assembler |

|---|---|---|

Focus | Making empty PCBs | Adding parts to PCBs |

Key Processes | – Designing PCB layout | – Getting the needed parts |

– Building PCB layers | – Applying solder paste | |

– Sticking layers together | – Placing components | |

– Drilling holes | – Using soldering methods | |

– Coating with solder mask | – Checking for quality | |

– Cutting the board to shape | – Testing how it works | |

Decision Criteria | Decide if you need just a PCB or a full PCBA | Think about whether you need assembly services |

or a company that does both |

Pick the right option based on how complex your project is. Talk to skilled makers or assemblers for advice. Their knowledge ensures your boards are high-quality and work well.

FAQ

What is the difference between PCB and PCBA?

A PCB is an empty board for circuits. A PCBA has parts like resistors and chips added, making it work.

Why is PCB testing important?

Testing checks if the PCB works properly and meets standards. It finds problems early, saving time and money during production.

Can you reuse a PCB?

Yes, if the PCB is not damaged, it can be reused. But taking off and reattaching parts might lower its performance.

How do you choose the right PCB type?

Think about your project needs. Simple devices use single-sided PCBs. Complex projects may need multi-layer or flexible PCBs.

What are the steps in the PCB manufacturing process?

Steps include designing, adding copper layers, drilling holes, and applying solder masks. Testing ensures the board works as planned.

See Also

Uncovering Key Distinctions Between PCBA and PCB

Benefits of Overmolded PCBA Compared to Other Methods

Essential In-Circuit Testing Tools for PCBA You Should Know