A printed circuit board (PCB) is the base of electronics, serving as a flat, non-conductive board that connects parts using conductive paths. In the realm of process control PCBA manufacturing, a PCBA (Printed Circuit Board Assembly) is a PCB with all parts attached and ready to work.

The difference between a PCB and a PCBA is simple but important. A PCB is the base, while a PCBA, created through process control PCBA manufacturing, works by adding parts like resistors and capacitors. Understanding this distinction helps you make better choices for design and production, ensuring your projects meet technical and functional needs with ease.

Key Takeaways

A PCB is the foundation of electronics. A PCBA is a PCB with parts added to work.

Picking good materials and designs makes PCB building easier and cheaper.

Making a PCBA is harder than making a PCB. It needs careful assembly and testing for good quality.

Knowing how each process works helps you choose the best method for your project.

Talking clearly with manufacturers avoids design mistakes and speeds up production.

What is a Printed Circuit Board (PCB)?

Definition and Overview of PCB

A printed circuit board (PCB) is the heart of electronics. It connects parts using copper pathways, pads, and features. These pathways let electricity move between parts to make devices work. Without PCBs, organizing electronic circuits would be very hard.

PCBs are used in phones, machines, and more. They are small, light, and dependable, making them ideal for electronics.

PCB Construction and Common Materials

Making a PCB requires careful steps. First, a base like fiberglass or resin is used. Copper layers are added to this base to create pathways. Special methods like imaging and etching shape the circuits.

Materials affect how well a PCB works. Copper conducts electricity well, while aluminum lasts in tough conditions. Below is a table showing key PCB materials and processes:

Aspect | Description |

|---|---|

Manufacturing Processes | Automated assembly, imaging, etching, and copper lamination. |

Material Selection | Copper and aluminum for strength and conductivity. |

Compliance Standards | Meets strict rules for military and aerospace use. |

Environmental Resistance | Handles heat, moisture, and shaking. |

Counterfeit Prevention | Certified methods to avoid fake parts. |

These materials and steps help PCBs work in many industries, like electronics and aerospace.

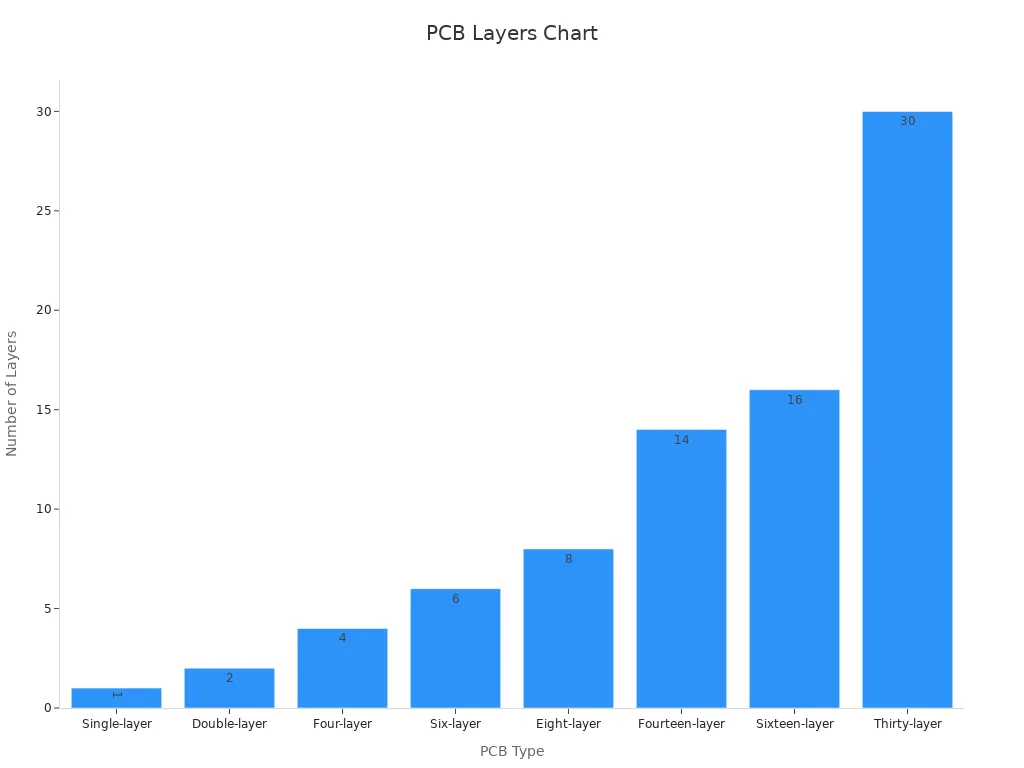

Types of Printed Circuit Boards

PCBs come in different types for various uses. Common ones are single-layer, double-layer, and multi-layer PCBs. Single-layer PCBs are simple and cheap. Multi-layer PCBs are more advanced and powerful. Below is a table comparing PCB types:

PCB Type | Number of Layers | Copper Layer Thickness | Insulating Layer Thickness | Minimum Track Width | Minimum Via Diameter |

|---|---|---|---|---|---|

Single-layer | 1 | 0.5 oz - 13 oz | 0.17 mm - 7.0 mm | 70 μm | 0.15 mm |

Double-layer | 2 | 0.5 oz - 13 oz | 0.17 mm - 7.0 mm | 70 μm | 0.15 mm |

Four-layer | 4 | 0.5 oz - 13 oz | 0.17 mm - 7.0 mm | 70 μm | 0.15 mm |

Six-layer | 6 | 0.5 oz - 13 oz | 0.17 mm - 7.0 mm | 70 μm | 0.15 mm |

Eight-layer | 8 | 0.5 oz - 13 oz | 0.17 mm - 7.0 mm | 70 μm | 0.15 mm |

Fourteen-layer | 14 | 0.5 oz - 13 oz | 0.17 mm - 7.0 mm | 70 μm | 0.15 mm |

Sixteen-layer | 16 | 0.5 oz - 13 oz | 0.17 mm - 7.0 mm | 70 μm | 0.15 mm |

Thirty-layer | 30 | 0.5 oz - 13 oz | 0.17 mm - 7.0 mm | 70 μm | 0.15 mm |

Knowing these types helps you pick the best PCB for your needs.

Applications of PCBs in Electronics

Printed circuit boards (PCBs) are key to modern electronics. They connect parts and allow smaller, smarter designs. You can find PCBs in almost every gadget, from phones to big machines.

Everyday Devices

PCBs are important in devices we use daily. Phones, laptops, and TVs depend on them for their small size and light weight. At home, appliances like fridges and washers use PCBs to work properly. These boards make sure your gadgets are reliable and accurate.

Advanced Applications

In healthcare, PCBs power tools like heart monitors and scanners. Cars use PCBs for engines, GPS, and safety systems. In space and defense, special PCBs handle tough conditions and critical tasks.

Tip: Think about your device's needs when designing with PCBs. For example, medical tools need to be very reliable, while car systems must handle rough conditions.

The Shift Toward AI

PCBs are changing as artificial intelligence (AI) grows. Before, PCBs were used in simple ways. Now, AI is making them smarter. The table below shows this change:

Year | Traditional Approaches (%) | AI Approaches (%) |

|---|---|---|

2004 | 100 | 0 |

2010 | 67 | 33 |

2022 | 49 | 51 |

This shows how PCBs now help with AI tech, like smart homes and self-driving cars. As AI expands, PCBs will stay important for new ideas.

From everyday gadgets to future tech, PCBs are everywhere. Knowing their uses helps you see why they matter in electronics.

What is a Printed Circuit Board Assembly (PCBA)?

Definition and Overview of PCBA

A printed circuit board assembly (PCBA) turns a plain PCB into a working unit. This happens by attaching parts like resistors and capacitors to the board. These parts are soldered on based on the design plan. The finished PCBA can power devices and make them work. It is very important for creating small and efficient gadgets today.

As more people use electronics, PCBA manufacturing has become crucial. Following strict rules ensures the products are safe and high-quality. Whether for home gadgets or industrial tools, PCBA is key to new technology.

The Process Control in PCBA Manufacturing

Process control keeps PCBA manufacturing reliable and consistent. Companies track things like First Pass Yield (FPY) and defect rates. A high FPY means most boards work on the first try, saving time and money. Below is a table showing important process control metrics:

Metric | Description |

|---|---|

Percentage of boards passing tests on the first try. | |

Defect Rate | Percentage of faulty boards; lower is better. |

Reliability Metrics | Measures how long products last without breaking. |

Process Capability Index | Checks if the process is stable and consistent. |

New tech like automation and Industry 4.0 improves process control. These tools make PCBA manufacturing faster, cheaper, and more accurate.

Importance of Printed Circuit Board Assembly in Electronics

PCBA is essential for making useful electronics. It helps create smaller, lighter devices. You’ll find PCBAs in phones, medical tools, and car systems. With the rise of IoT and 5G, PCBA is now used in smart homes, healthcare, and fast internet.

Note: Many companies now use eco-friendly materials and energy-saving methods. This helps make PCBAs better for the environment.

The flexibility of PCBA makes it important in many fields. From everyday gadgets to advanced tech, it supports modern electronics.

Uses of PCBAs in Different Industries

Printed circuit board assemblies (PCBAs) are crucial in many fields. They power devices that improve how we live and work.

Gadgets for Everyday Use

PCBAs are found in phones, laptops, and gaming systems. They help make small, light devices with cool features. About 70% of all PCBs are used in electronics, computers, and telecom. This shows how important they are for staying connected and having fun.

Cars and Vehicles

In cars, PCBAs run systems like engines, GPS, and airbags. The car PCBA market is growing fast. It could rise from $9.15 billion in 2023 to $13.39 billion by 2030. This growth comes from more electric cars and smart car tech.

Smart Devices and IoT

Smart homes, wearables, and factory IoT systems need PCBAs. These boards help devices talk to each other easily. In 2023, over 63 million U.S. homes had smart devices. By 2027, this number may reach 93 million. PCBAs are key to this tech boom.

Quick Facts Table

Here’s a table showing PCBAs’ role in industries:

Industry | Key Fact |

|---|---|

Consumer Electronics | 70% of PCBs are used in electronics, computers, and telecom. |

Automotive | Market may grow from $9.15 billion in 2023 to $13.39 billion by 2030 (5.6% yearly growth). |

IoT | 63 million U.S. homes had smart devices in 2023; 93 million expected by 2027. |

PCBAs are driving new ideas and are vital for shaping the future.

Comparing PCB and PCBA Manufacturing Processes

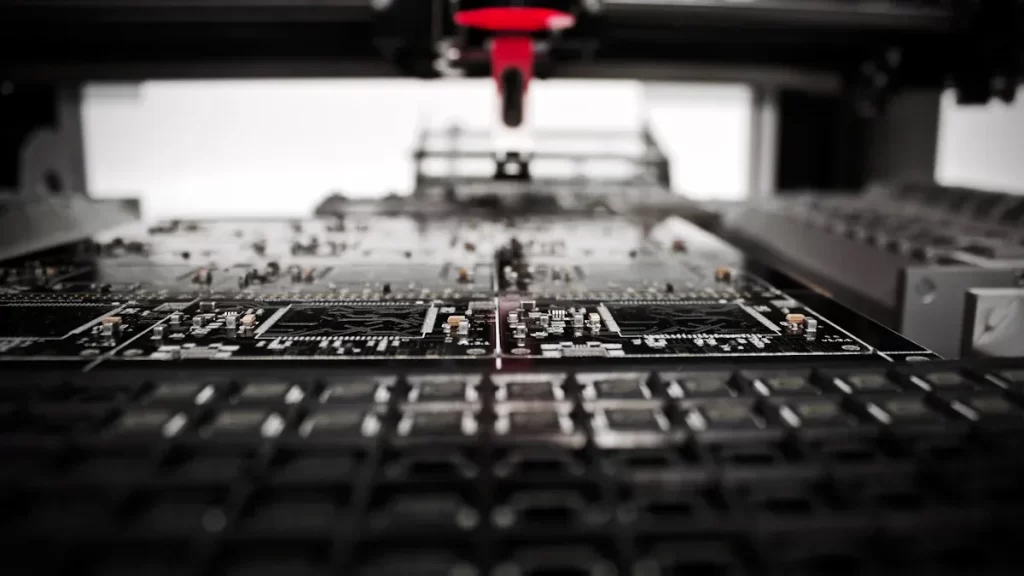

Key Steps in PCB Manufacturing

Making a PCB turns raw materials into an electronic base. This process has many steps to meet design and performance needs.

Design and Layout: First, a detailed design is made using special software. This shows where copper paths and parts will go.

Material Preparation: A base material, like fiberglass, is chosen. A thin copper layer is added to make it conductive.

Imaging and Etching: A photo layer is placed on the copper. UV light transfers the design onto the board. Extra copper is removed, leaving only the needed paths.

Drilling and Plating: Holes are drilled to connect layers or hold parts. These holes are coated with conductive material for electricity to flow.

Solder Mask Application: A protective layer is added to stop short circuits and protect copper lines.

Silkscreen Printing: Labels and symbols are printed on the board to help with assembly and repairs.

Quality Testing: The board is tested to ensure it works and meets standards.

These steps make the PCB ready to support your electronic device.

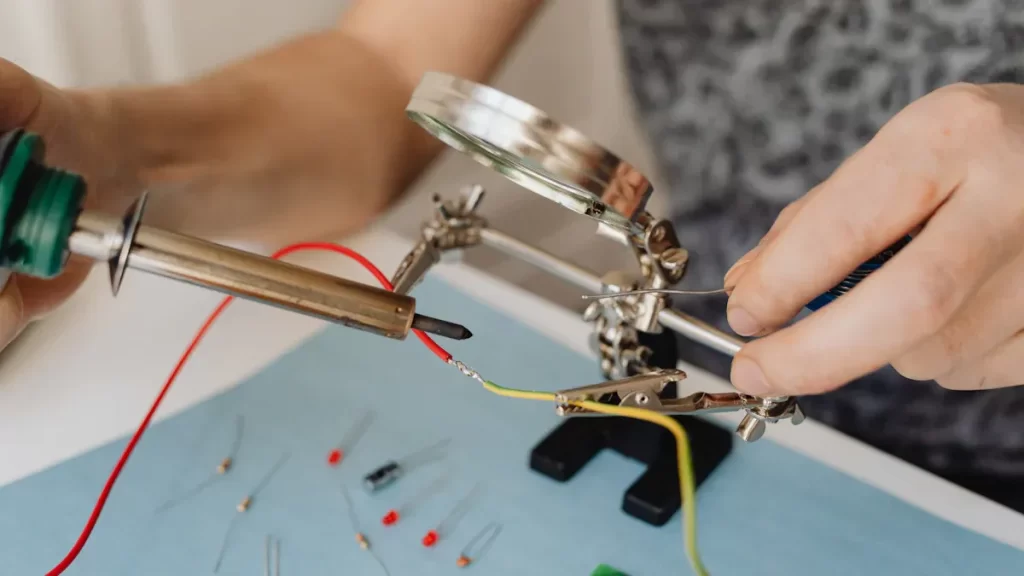

Key Steps in PCBA Manufacturing

Making a PCBA adds parts to a PCB to create a working unit. This process focuses on accuracy and dependability.

Component Sourcing: First, all needed parts, like resistors and chips, are collected. These parts must be high quality.

Solder Paste Application: A stencil spreads solder paste on the board’s pads. This paste holds parts in place during soldering.

Component Placement: Machines place parts on the board with great precision. Each part must match the design exactly.

Soldering: Surface parts are soldered in a reflow oven. Through-hole parts may need wave soldering.

Inspection and Testing: Tools like X-rays and cameras check for mistakes. Tests ensure the PCBA works properly.

Final Assembly: Extra steps, like adding connectors or cases, are done if needed. The PCBA is now ready to use.

This process turns a plain PCB into a fully working unit for your devices.

Differences in Process Complexity and Time

Making PCBs and PCBAs takes different amounts of time and effort. PCB manufacturing is simpler and faster. It focuses on making the board itself, with fewer steps and variables.

PCBA manufacturing is more complex. It includes sourcing parts, placing them, and soldering. Each step must be precise to avoid errors. Testing is stricter because the final product must work perfectly. This makes PCBA manufacturing take longer.

Tip: Plan ahead if your project needs PCBA manufacturing. Extra time and resources are needed, but good planning ensures quality and on-time delivery.

Knowing these differences helps you choose the best process for your needs. This ensures your project is efficient and reliable.

Quality Control in PCB vs. PCBA Manufacturing

Quality control is key to making sure PCB and PCBA are reliable. Both aim for high-quality results, but their methods differ. Knowing these differences helps you choose the right approach.

Quality Control in PCB Manufacturing

In PCB manufacturing, quality checks focus on the board’s design and pathways. The goal is to make sure the board works well as a base for parts. Common methods include:

Manual Visual Inspection: People look for scratches or misplaced lines. It’s simple but only finds surface problems.

Automated Optical Inspection (AOI): Machines scan boards for broken lines or wrong sizes. This is faster and more accurate than manual checks.

Thermography: Finds heat issues, like hotspots, that show conductivity problems.

Acoustic Microscopy: Looks inside layers for cracks or gaps without damaging the board.

Radiography: Uses X-rays to see inside the board and find hidden flaws.

Quality Control in PCBA Manufacturing

For PCBA, quality checks are more detailed. They ensure parts are placed correctly, soldered well, and work properly. Key methods include:

Solder Joint Inspection: Checks if solder connections are strong and free of cracks.

Functional Testing: Makes sure the board works as it should in real conditions.

X-ray Inspection: Finds hidden problems in solder joints, especially in crowded boards.

Multi-sensor Fusion: Combines data from different tools to find defects better.

Comparing Quality Control Metrics

The table below shows how quality control methods differ for PCB and PCBA:

Use in PCB Manufacturing | Benefits | Limits | |

|---|---|---|---|

Manual Visual Inspection | Basic PCBs | Easy and cheap | Only surface issues |

Automated Optical Inspection (AOI) | Basic PCBs | Faster and more precise | Misses flaws in layered boards |

Thermography | Both basic and advanced | Finds heat problems | Needs specific conditions |

Acoustic Microscopy | Both basic and advanced | Checks inside without damage | Hard to understand results |

Radiography | Both basic and advanced | Sees inside layers | Expensive and needs experts |

Multi-sensor Fusion | Both basic and advanced | Better defect detection | Complicated setup and analysis |

Tip: For PCBA, use advanced methods like X-rays and functional tests. These ensure the board works perfectly.

By learning the quality control needs for PCB and PCBA, you can improve your process. This makes your products reliable and efficient.

Cost and Lead Time Considerations

Cost Factors in PCB Manufacturing

The cost of making a PCB depends on several things. The type of PCB, materials used, and how many are made all affect the price. For example, single-layer PCBs cost less than multi-layer ones because they are simpler. Materials like fiberglass are cheaper than ceramic or aluminum.

How many PCBs you make also matters. Making a few prototype PCBs costs more per board due to setup fees. But making many spreads the cost, lowering the price per board. The table below compares prototype and production PCBs:

Feature | Prototype PCBs | Production PCBs |

|---|---|---|

Quantity | Low (e.g., 1-10 units) | High (e.g., 100+ units) |

Per-Unit Cost | High | Lower |

Setup Costs | Significant | Distributed over volume |

Lead Time | Often Faster | Can vary with volume |

Customization | High flexibility | Less flexibility |

Ideal For | Testing and validation | Large-scale deployment |

Cost Drivers | Initial tooling and setup | Raw material prices, labor, and efficiency |

For testing, speed and flexibility may matter more than cost. For large production, focus on saving money and being efficient.

Cost Factors in PCBA Manufacturing

Making a PCBA costs more because it involves extra steps. One big factor is the cost of parts. High-quality or rare parts can be expensive. Using machines for assembly saves labor costs but needs costly equipment upfront.

The design of the board also affects the price. Boards with many parts or complex layouts take longer to assemble and check. Soldering methods, like reflow or wave soldering, also change costs based on the parts used.

When planning a PCBA, balance cost and quality. Spending more on good parts and careful assembly makes a better product, even if it costs more at first.

Lead Time Differences Between PCB and PCBA

Making a PCB is faster than making a PCBA. PCB production has fewer steps. Once the design is ready, the process focuses on building the board. This makes PCBs good for quick prototypes or small projects.

PCBA production takes longer because it’s more detailed. Parts need to be ordered, placed, and soldered carefully. Testing and quality checks add more time, especially for critical uses like medical tools or aerospace.

If your project has a tight deadline, plan ahead. PCBs can be made quickly, but PCBAs need extra time. Knowing these time differences helps you avoid delays and stay on schedule.

Balancing Cost and Efficiency in Manufacturing

Balancing cost and efficiency in PCB and PCBA manufacturing takes smart planning. You must think about materials, production methods, and design choices. Here’s how to manage this balance effectively.

1. Choose the Right Materials

Picking the right materials helps control costs. Strong materials like copper and fiberglass last long but can be pricey. To save money:

For Prototypes: Use cheaper materials like FR-4 for testing.

For High-Performance Needs: Pick advanced materials like ceramic for heat resistance.

Tip: Match materials to your project’s needs. Avoid spending on unnecessary features.

2. Produce in Larger Batches

Making more units lowers the cost per item. Bulk production spreads setup costs across all units, saving money.

Production Type | Cost Per Unit | Best Use Case |

|---|---|---|

Small Batch | High | Testing and small projects |

Large Batch | Low | Big orders and commercial products |

For prototypes, keep batches small to save. For final products, make more to cut costs.

3. Use Automation When Needed

Automation makes production faster and cheaper. Machines like pick-and-place tools help with precise assembly. But automation costs more upfront.

Use Automation: For big orders or complex designs.

Skip Automation: For small orders or simple designs.

Note: Check your project size and design before automating. It’s not always the cheapest option.

4. Simplify Your Design

A simple design saves time and money. Fewer layers and parts mean less material and faster assembly.

Keep It Simple: Only include what’s needed for the design to work.

Use Standard Parts: Common parts are easier and cheaper to get.

Pro Tip: Work with your manufacturer early. They can suggest ways to save money.

5. Focus on Quality Checks

Skipping quality checks can lead to costly mistakes. Test your PCBs and PCBAs to ensure they work well.

For PCBs: Look for broken lines or misplaced layers.

For PCBAs: Check that parts are soldered correctly and work properly.

Good quality control costs more upfront but prevents expensive fixes later.

6. Plan for Reasonable Lead Times

Faster production often costs more. If you have time, choose standard schedules to avoid rush fees.

Reminder: Share your deadlines with your manufacturer early. This avoids delays and extra costs.

Final Thoughts

Balancing cost and efficiency takes careful planning. Use the right materials, produce in bulk, and simplify your design to save money. Always invest in quality and plan ahead—it pays off in the end.

Emoji Insight: 🛠️ Smart planning = 💰 Savings + 📈 Efficiency

Practical Applications and Industry Use Cases

Real-World Examples of PCB Applications

PCBs are important for modern devices. In medical tools, special PCBs handle high heat. These boards make small, reliable devices like implants work better. In factories, these PCBs help motor drives last longer in hot places. This reduces repairs and saves money. Telecommunication devices use these PCBs to improve signals and reduce noise. This makes routers faster and keeps customers happy.

Industry | Example |

|---|---|

Medical Devices | Small, reliable PCBs improve implantable devices. |

Industrial Equipment | Heat-resistant PCBs make motor drives last longer. |

Telecommunications | PCBs improve router signals and reduce noise. |

These examples show how PCBs are useful in many industries.

Real-World Examples of PCBA Applications

PCBAs turn plain PCBs into working units. They add parts like chips and resistors. Phones, laptops, and gaming consoles use PCBAs for small designs and cool features. Cars need PCBAs for engines, GPS, and airbags. Electric cars use PCBAs even more now. Smart homes and wearable gadgets also depend on PCBAs to connect devices easily.

PCBAs are key for making devices that work well and improve daily life.

Industry-Specific Use Cases (e.g., Automotive, Medical, Consumer Electronics)

PCBs and PCBAs are used in many industries. Cars use simple PCBs for lights and electronics. Medical tools need high-quality PCBs for accuracy and safety. Double-sided PCBs are common in gadgets and control systems because they handle complex designs.

Industry | PCB Uses | Features |

|---|---|---|

Automotive | Car lights and basic electronics | Single-sided and double-sided PCBs for simple tasks |

Medical | Tools like monitors and scanners | High-quality PCBs for safe and precise healthcare devices |

Consumer Electronics | Phones, communication tools, and control systems | Double-sided PCBs for advanced designs |

In North America, PCBs are popular in cars, healthcare, and telecom. As electronics grow, the need for good PCBs increases. Knowing these uses helps you choose the right PCB for your project.

Design Workflow and Manufacturing Challenges

Designing for Printed Circuit Board Manufacturing

When making a PCB, focus on a good layout. Pick materials that match your device’s needs. For example, FR-4 is great for regular electronics, while ceramic handles heat better. Use design tools to draw copper paths wide enough to carry current safely.

Place vias and pads carefully. Bad placement can weaken the board or cause problems with signals. Add a solder mask layer to protect copper paths and stop short circuits. Follow design for manufacturability (DFM) rules to avoid mistakes during production. Talk to your PCB supplier early to spot and fix issues quickly.

Tip: Keep your design simple. Complicated layouts cost more and can cause errors.

Designing for Process Control in PCBA Manufacturing

Making a PCBA needs careful planning. Choose parts that are easy to find and fit your PCB design. Create a bill of materials (BOM) to list all parts and check their quality. Place parts smartly to avoid signal problems and make assembly easier.

Only apply solder paste where parts will go. This keeps the soldering process clean and smooth. Work with your PCBA maker to use tools like automated optical inspection (AOI) and testing. These steps ensure fewer mistakes and better results.

Note: Using DFM services can make production faster and easier, saving time and effort.

Challenges in Transitioning from PCB to PCBA

Switching from PCB design to PCBA production can be tricky. Balancing speed and quality is a big challenge. Rushing can lead to mistakes. Complex designs with tight spaces need extra care to keep signals strong and reduce noise.

Prototyping can also be hard. Testing parts too much might cause failures that don’t match the design’s real strength. To solve these problems, try these tips:

Work with PCB suppliers to fix common issues early.

Get stencils from your PCB maker for easier assembly.

Use special tests like HALT/HASS to check reliability in tough conditions.

By solving these problems early, you can move smoothly from PCB to PCBA and create a great product.

Tips for Simplifying the Design-to-Production Process

Making the design-to-production process simple saves time and money. It also helps create better products. Follow these tips to avoid problems and improve results.

1. Make Your Design Easy to Build

Keep your design simple to speed up production. Use fewer layers in your PCB and pick standard board sizes. Choose parts that are easy to find to avoid delays. Wider paths and more space between them improve success rates. Through-hole vias and standard copper thickness make production faster.

2. Use Modern Software

New ECAD tools help designers and manufacturers work together. They reduce the need for many prototypes and improve quality with feedback. These tools also find ways to save money and make switching to large-scale production easier.

3. Add Process Control Steps

Regular checks and process controls keep production consistent. Certifications like IPC show strong assembly skills. Sample checks ensure finished PCBAs meet standards. Tracking part life cycles and fixing defects improve reliability even more.

Tip: Test tools and write clear instructions early to avoid mistakes later.

4. Plan for Reliability and Supply

Add backup circuits to make devices more reliable. Test PCBAs under tough conditions with methods like HALT/HASS. Plan ahead for key parts and have backup options ready. Keep detailed records to handle future updates smoothly.

5. Work Closely with Manufacturers

Talk to your manufacturer early to fix design issues. Share your design files and needs clearly to avoid confusion. Regular communication between design and production teams reduces mistakes and keeps everyone on the same page.

By using these tips, you can make production faster, cheaper, and more reliable.

Knowing how PCB and PCBA differ helps in making smart choices. A PCB is the base, while a PCBA makes it work. Their production steps vary in difficulty, price, and time. Understanding these differences helps meet your project’s needs and budget.

Think about both PCB and PCBA steps for your next project. This will save time and ensure your product works well.

FAQ

1. What is the main difference between PCB and PCBA?

A PCB is just the board with copper lines. A PCBA has parts like resistors and capacitors added to it. The PCB is the base, and the PCBA makes it work.

2. Can you reuse a PCB after assembly?

You can’t reuse a PCB if parts are soldered on. Taking off parts might break the board or make it stop working. Plan your design well to avoid wasting materials.

3. How do you choose the right PCB type for your project?

Think about what your device needs. Simple designs use single-layer PCBs. Complex circuits need multi-layer PCBs. Pick materials like FR-4 for regular use or ceramic for heat resistance.

4. Why does PCBA manufacturing take longer than PCB manufacturing?

PCBA takes more time because it adds parts, soldering, and testing. These steps need careful work and checks, which make it slower than PCB production.

5. What tools help ensure quality in PCB and PCBA manufacturing?

Machines like AOI check PCB mistakes. X-rays look at PCBA solder joints. Functional tests make sure the product works. These tools help avoid errors and improve reliability.