The PCBA abbreviation means printed circuit board assembly. It is an important part of electronics. PCBA is the process of attaching electronic parts to a plain printed circuit board (PCB) to make it work. Without PCBA, devices like phones, computers, and smart gadgets wouldn’t work.

PCBA is very important in industries like cars, healthcare, and electronics. In 2023, the global PCB and PCBA market was worth $68.4 billion. It is expected to grow to $105.8 billion by 2032. This shows how much PCBA is needed for modern technology. From helping medical tools to improving smart devices, PCBA is key to the future of electronics.

Key Takeaways

PCBA means printed circuit board assembly. It makes electronics work.

The PCBA process includes adding solder paste, placing parts, soldering, and testing.

PCBA is important in many fields like electronics, cars, healthcare, and phones.

Using PCBA makes devices last longer, work better, and supports new tech.

Green methods in PCBA help cut waste and protect the environment.

What Is PCBA and How Does It Work?

PCBA Abbreviation and Its Meaning

PCBA means printed circuit board assembly. It is the process of adding electronic parts to a plain printed circuit board (PCB) to make it work. A PCB is just a base, but PCBA adds parts like resistors, capacitors, and chips to make it functional. Without PCBA, electronic devices like phones and computers wouldn’t work.

PCBA is very important in today’s electronics. It helps devices like laptops, smartphones, and medical tools work properly. The PCBA abbreviation is well-known in the electronics world because it helps create reliable and high-quality devices.

Overview of the PCBA Manufacturing Process

Making a PCBA involves many steps to ensure it works well. Each step is important for creating a good assembly. Here’s how it’s done:

Solder Paste Application: A stencil spreads solder paste on the PCB where parts will go.

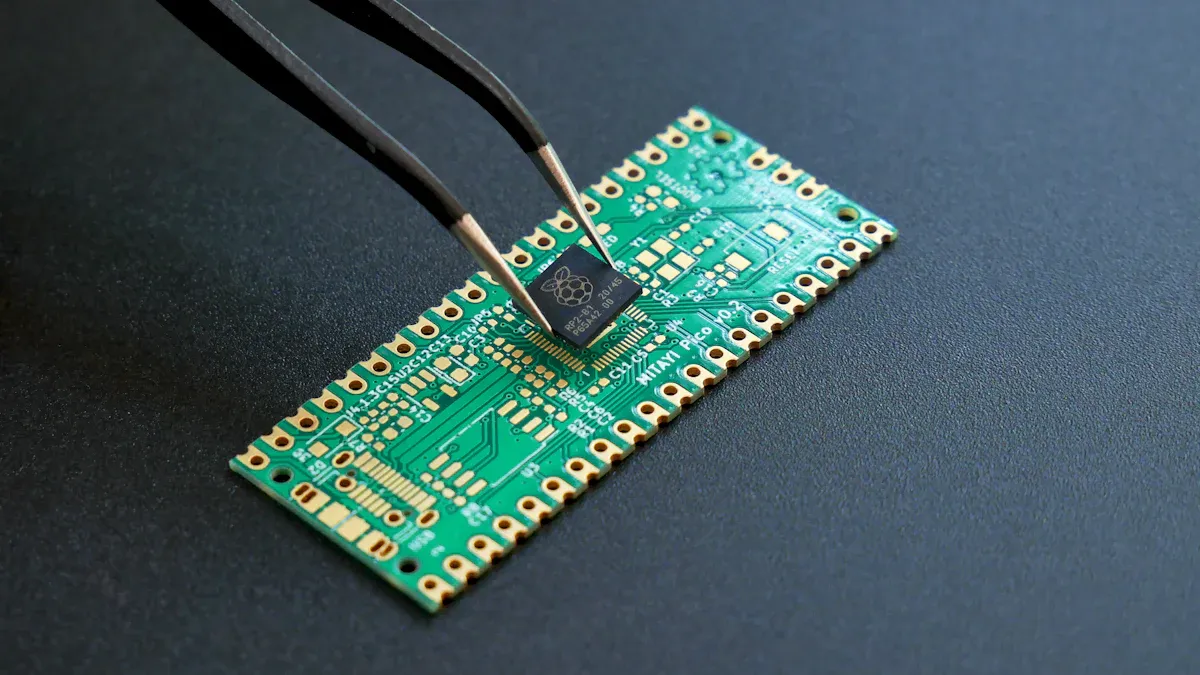

Component Placement: Machines place parts like resistors, capacitors, and chips on the board.

Reflow Soldering: The board goes through a hot oven. The solder paste melts and hardens, holding the parts in place.

Inspection and Testing: Special tools check for mistakes to ensure the board works. These tools can quickly check thousands of parts for accuracy.

Final Assembly: Extra parts like connectors or heat sinks are added by hand or machines.

Manufacturers try to make this process faster and better. For example, they aim for a 96% success rate and to cut production time by 20%. Companies that track these goals often improve efficiency by 15%.

Key Components in a PCBA

A PCBA has many parts that work together to do specific jobs. These parts include:

Resistors: Manage how much electrical current flows.

Capacitors: Hold and release electrical energy when needed.

Diodes: Let current flow one way but block it the other way.

Integrated Circuits (ICs): Work like the brain, doing complex tasks.

Connectors: Help different parts of the device communicate.

Transistors: Boost or switch electronic signals.

Each part has a special job to make the PCBA work well. The mix of parts shows how detailed and precise the PCBA process is.

PCBA vs. PCB: Understanding the Difference

What Is a PCB and Its Role?

A printed circuit board (PCB) is the base of electronics. It holds and connects electronic parts in an organized way. Think of it as the skeleton of an electronic device. A PCB has layers of copper for electricity and insulation to guide signals.

You can find PCBs in almost all devices, like phones and machines. They act as the backbone, helping parts work together. But a PCB alone cannot do anything. It needs parts like resistors and chips to function. This is where PCBA becomes important.

How PCBA Builds Upon PCB

PCBA turns a plain PCB into a working system. It adds parts to the PCB so it can do tasks. For example, in a phone, PCBA makes the screen respond and the camera work.

Making a PCBA needs careful steps and modern tools. Machines place parts on the PCB with precision. Then, the parts are soldered and tested to ensure they work. This process ensures the product is safe and high-quality.

Using FMEA in PCBA projects helps reduce risks. It also saves resources and creates safer, better products for the market.

This shows how PCBA improves the reliability and safety of devices.

Key Differences Between PCB and PCBA

Knowing the difference between PCB and PCBA is important. Here’s a simple table:

Aspect | PCB | PCBA |

|---|---|---|

Definition | A plain board with no parts. | A board with parts added. |

Functionality | Cannot do any task. | Fully works and ready to use. |

Manufacturing | Makes the board only. | Adds parts to the board. |

Applications | Acts as a base for parts. | Powers electronic devices. |

In summary, a PCB is just the start, while PCBA is the final product that powers devices. Without PCBA, industries like healthcare and telecom wouldn’t have advanced tools today.

Applications of PCBA in Different Industries

Consumer Electronics

PCBA is very important for consumer electronics. It powers gadgets like phones, laptops, and smartwatches. By adding parts like chips and resistors to a PCB, PCBA makes these devices work properly. For example, your phone’s touch screen or your laptop’s fast processor depends on PCBA to work well.

As technology improves, people want more advanced gadgets. Companies use PCBA to make small, reliable, and energy-saving devices. Without PCBA, modern gadgets wouldn’t have sleek designs or powerful features. This makes PCBA a key part of creating new technology in electronics.

Automotive Industry

PCBA is crucial for today’s cars. It helps run systems like engine controls, entertainment screens, and safety tools like airbags. These systems need PCBA to process data and work smoothly.

Electric cars (EVs) especially need PCBA. It helps control batteries, track energy use, and manage electric motors. As cars become electric and self-driving, the need for good PCBA grows. This technology makes cars smarter, safer, and better for the environment.

Medical Devices and Healthcare

PCBA is very important in medical tools and healthcare. It powers devices like pacemakers, ventilators, and testing machines. These tools need PCBA for accuracy and reliability.

Wearable health devices like fitness trackers and glucose monitors also use PCBA. These gadgets help people check their health anytime, making life better. PCBA is more than just a process—it’s the technology behind life-saving medical devices and healthcare solutions.

Telecommunications

PCBA is important for keeping communication systems working. It helps devices like phones, routers, and satellites do their jobs. These devices use PCBA to handle signals, manage data, and keep communication smooth. Without PCBA, networks wouldn’t work well.

PCBA helps with fast data transfer and strong connections. For example, it’s used in 5G networks, which need accurate circuit assemblies. PCBA makes sure base stations and towers work together for faster internet and clearer calls. This makes PCBA a key part of modern communication.

PCBA also helps make smaller devices. It lets companies design compact gadgets that still work well. That’s why your phone is small but powerful. As technology improves, PCBA becomes even more important in telecommunications.

Aerospace and Defense

PCBA is crucial for reliable systems in planes and defense tools. It powers navigation, communication, and diagnostic devices used in tough conditions. These systems need to be precise and durable.

For example, PCBA is in flight controls, radar, and satellites. It ensures these tools work correctly under pressure. In defense, PCBA supports safety features in weapons and surveillance tools, making them dependable.

PCBA also helps create new technologies like drones and advanced missiles. It ensures these systems work properly, aiding national security and space missions. PCBA is vital for innovation in aerospace and defense.

Industrial Equipment and Automation

PCBA is key for running machines in factories. It powers robotic arms and conveyor belts, helping them work smoothly. PCBA makes sure these systems are accurate and efficient.

In factories, PCBA connects sensors, controllers, and communication tools. These parts monitor and control processes, reducing mistakes and boosting productivity. For example, PCBA helps engine controls optimize machinery performance.

PCBA also improves safety in factories. It powers systems that protect workers and prevent accidents. Smart systems powered by PCBA can adapt to changes, making automation better.

As industries use IoT and AI, PCBA becomes more needed. It drives innovation and helps factories work smarter and faster.

Benefits of PCBA in Electronics

Better Reliability and Strength

PCBA helps make devices strong and reliable. Advanced methods are used to build PCBAs that last. For example, medical PCBA in tools like ventilators must follow strict rules like ISO 13485. This ensures medical devices work safely and correctly, even in emergencies.

In cars and factories, PCBA helps systems work longer and better. Parts like resistors and capacitors are placed carefully to avoid problems. This makes devices tough for hard conditions. Whether for medical tools or factory machines, PCBA ensures safety and top performance.

Boosted Efficiency in Electronics

PCBA makes electronic systems work faster and better. By using materials wisely, manufacturers save money and time. Careful planning during PCBA design reduces waste and speeds up production. This means fewer mistakes and quicker results.

Modern PCBA uses robots and machines for better results. Robots cost a lot at first but save money later. They can handle different tasks quickly, cutting labor costs. This is very useful for medical PCBA, where accuracy matters most. Energy-saving machines also lower costs and improve work speed.

Helps Create New Technologies

PCBA helps invent new and advanced tools. In healthcare, PCBA is used in life-saving devices like diagnostic machines. These tools need medical PCBA to work safely and accurately. Following safety rules ensures these devices are trustworthy.

In other fields, PCBA helps make smaller, smarter gadgets. Tiny parts allow compact designs without losing power. For example, in factories, PCBA helps create smart machines that work better. By using quality PCBAs, companies can make new products that meet modern needs.

Cost-Effectiveness in Mass Production

PCBA helps lower costs when making many electronics. Machines do tasks like placing parts and soldering them on the PCB. This reduces the need for workers and saves money.

Making devices in large amounts lowers the cost per item. Buying materials like solder paste in bulk also costs less. Automated systems keep quality steady, reducing waste and fixing errors.

Tip: High-quality PCBA tools cost more at first but save money later by lowering running costs.

PCBA also uses fast testing tools to find problems quickly. This stops bad products from being sold. It helps deliver good devices to customers while keeping costs low.

Contribution to Miniaturization of Devices

PCBA has changed how small gadgets are made. It lets companies make tiny devices that still work well. Using surface-mount technology (SMT), parts go straight onto the PCB. This removes the need for big wires and connectors.

Tiny parts like microchips and small capacitors add more features in less space. For example, your phone has a camera, GPS, and processor in a slim body. PCBA makes this possible.

Fun Fact: Old computers filled rooms, but PCBA now fits that power in your pocket! 📱

Miniaturization helps fields like healthcare and space. Pacemakers and satellites use small PCBAs for important jobs. As tech improves, PCBA will keep making electronics smaller and better.

The Future of PCBA in the Electronics Industry

New Trends in PCBA Technology

PCBA technology is changing and improving electronics. Flexible printed circuit boards (FPCBs) are becoming common. They can bend and fit into small devices. These boards may grow by 8% yearly until 2030. Industries like aerospace, cars, and healthcare use them a lot. Automation and digital tools are also helping PCBA grow. Industrial PCBA applications may rise by 5% from 2022 to 2030.

North America leads in PCBA advancements. In 2021, its PCB market was worth $6 billion. By 2030, it is expected to grow much more. This growth comes from AI, machine learning, and robotics. As these technologies improve, PCBA will help make smarter and better devices.

How PCBA Helps IoT and AI

PCBA is very important for IoT and AI. High-density PCBs allow smart sensors to work well. These designs help IoT devices process data and connect easily. For 5G, advanced PCBs handle faster speeds and better communication.

In cars, PCBA supports electric vehicles and safety systems. High-density PCBs combine many functions in small spaces. This makes cars safer and smarter. PCBA also helps wearable gadgets and smart home devices. These need small, powerful designs to work well.

Sector | How PCBA Helps |

|---|---|

IoT | Makes smart sensors and connected devices work with detailed circuits. |

5G Technology | Handles fast data and high frequencies for smooth communication. |

Automotive Industry | Supports electric cars and safety systems with small, multi-use PCBs. |

Consumer Electronics | Helps create small, high-performing gadgets like wearables and smart home devices. |

Eco-Friendly Changes in PCBA

PCBA manufacturing is becoming greener. Companies now use eco-friendly methods to cut waste and save energy. For example, lead-free solder and recyclable materials are used to protect the environment. Energy-saving production also reduces pollution.

Recycling old PCBAs is growing too. Valuable materials like copper and gold are reused. This saves resources and lowers costs. These changes help both the planet and the industry. In the future, PCBA will keep improving while staying eco-friendly.

PCBA is key to making modern electronics work well. It helps devices like smartphones and tablets run smoothly. In cars, PCBA powers electric vehicles and safety systems. Healthcare depends on PCBA for accurate medical tools that save lives. The car PCBA market may grow from $8.87 billion in 2023 to $13.58 billion by 2031. As technology gets better, PCBA will keep improving gadgets and shaping the future of electronics.

FAQ

What is the difference between SMT and THT in PCBA?

Surface Mount Technology (SMT) puts parts directly on the PCB surface. Through-Hole Technology (THT) places parts into drilled holes. SMT is quicker and helps make smaller devices. THT gives stronger connections, good for tough conditions.

Tip: Pick SMT for small gadgets and THT for strong setups.

How do you ensure PCBA quality?

Factories use machines to check for mistakes and test functions. These steps find problems early and make sure PCBAs work well. Using good materials and careful assembly also improves quality.

Note: Look for factories with ISO certifications for trusted quality.

Can PCBA be repaired if damaged?

Yes, broken PCBAs can often be fixed. Experts replace bad parts or repair soldering. But fixing depends on the damage and board design. Sometimes, replacing the PCBA is cheaper than fixing it.

Why is PCBA important for IoT devices?

PCBA makes IoT devices work by adding sensors, processors, and connectors. It helps them process data and stay connected. Without PCBA, devices like smartwatches or smart home gadgets wouldn’t function.

Fun Fact: IoT devices need tiny PCBAs for small designs and cool features.

How does PCBA contribute to sustainability?

PCBA uses green methods like lead-free solder and recycling. Factories also save energy and cut waste. These actions help protect the environment and meet global green goals.

Reminder: Choose brands that use eco-friendly PCBA to support the planet.

See Also

Exploring PCBA: Its Definition and Importance in Electronics

Defining PCBA and Its Significance in Electronic Devices

Understanding PCBA: Meaning and Its Function in Electronics

An Overview of PCBA: Definition and Explanation

PCBA Explained: Key Definitions and Applications in Electronics