Printed Circuit Board Assembly (PCBA) datasets are important for finding problems in circuit boards. These datasets have pictures and data showing different types of defects. They help you use smart tools like machine learning and computer vision to spot issues quickly.

For instance, the DsPCBSD+ dataset has 20,276 labeled defects from 10,259 pictures. It gives both a large amount of data and variety. Likewise, the PCBA-DET dataset offers many defect types with enough examples for good analysis. Using a PCBA dataset helps find defects faster and more accurately. This reduces mistakes and makes production better.

Key Takeaways

PCBA datasets help find problems in circuit boards faster and better.

Important parts of a PCBA dataset are clear pictures, correct labels, and many defect types to train detection tools well.

Keep your datasets updated and clean to match production needs and improve results.

Work with experts to make labeling better and adjust datasets for industry needs to find defects more easily.

Use both machine learning and computer vision to improve how well defects are found.

Overview of PCBA Datasets

What is a PCBA dataset?

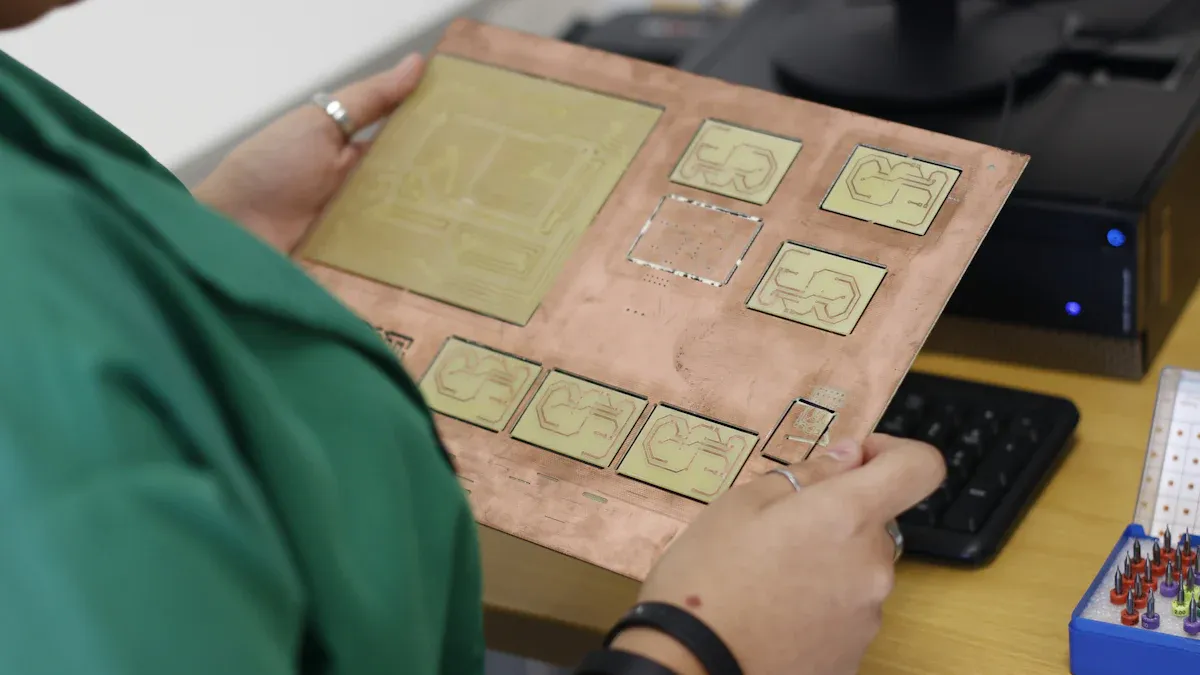

A PCBA dataset is a group of data made to find problems in circuit board assemblies. These datasets usually have pictures of boards, notes showing defects, and details about parts. They are used to train smart tools like machine learning to find defects better. For example, the FICS-PCB dataset has 9,912 pictures and over 77,000 parts with detailed notes like boxes around defects and extra details. The FPIC dataset also has advanced notes, like shapes, making it useful for many tasks.

Dataset Name | Number of Images | Number of Components | Annotation Types | Year Introduced |

|---|---|---|---|---|

FICS-PCB | 9,912 | 77,347 | Boxes, shapes, extra details | 2020 |

FPIC | N/A | 58,000 | Boxes, part types, shapes, extra details | 2022 |

These datasets help create strong systems to find defects fast and correctly.

Types of PCBA datasets

PCBA datasets are grouped by their use and setup. Some focus on certain problems, like bad soldering or parts not lined up. Others cover many kinds of defects. Some are made for specific industries, like cars or electronics.

Another way to group them is by how they mark defects. Some use boxes to show problems, while others use very detailed markings. The dataset you pick depends on what you need and how much detail is required.

Sources of PCBA datasets

You can get PCBA datasets from schools, free websites, or companies working together. For example, datasets like FICS-PCB and FPIC are free and used in research. Factories often make their own datasets using machines like SPI (Solder Paste Inspection). These machines collect data that can help predict problems.

Key Findings | Description |

|---|---|

SPI Data | Shows how SPI data helps predict problems. |

Dataset Variety | Explains why having different datasets gives better results. |

Precision Scores | Shows models reaching over 82% accuracy in finding defects. |

Feature Extraction | Talks about using Python TSFRESH to pull details from SPI data. |

Environmental Impact | Explains how finding problems early saves resources and helps the planet. |

By checking these sources, you can find a PCBA dataset that fits your needs.

Key components of a PCBA dataset

When using a PCBA dataset, you should know its main parts. These parts make the dataset helpful for finding defects and training smart tools. Here are the key parts:

Images of Circuit Boards

Clear pictures are the base of any PCBA dataset. These pictures show circuit boards from different angles and lighting. Good images help spot problems like bad soldering, misplaced parts, or missing pieces.Annotations and Labels

Annotations point out defects on the board pictures. These labels can be boxes, shapes, or masks. They show where the defect is and what type it is. This helps tools learn and find similar problems.Defect Categories

A strong PCBA dataset has many defect types. Common ones include bad soldering, wrong part placement, or dirty surfaces. This variety helps train tools for real-world problems.Metadata

Metadata gives extra details about the pictures and defects. It may include board type, date made, or inspection settings. This helps find patterns and improve defect detection.Ground Truth Data

Ground truth data makes the dataset trustworthy. Experts check this data to confirm defect details. It is key for training accurate smart tools.

By focusing on these parts, your PCBA dataset will be ready for finding defects.

Preparing PCBA Datasets for Defect Detection

Data cleaning and preprocessing

Before using a PCBA dataset, make sure it is clean. Raw data often has mistakes, missing parts, or errors. These problems can lower the accuracy of your results. Cleaning and preparing the data fixes these issues. This makes the dataset ready for tools like machine learning.

Tip: Use standard methods to improve data quality and results.

Key steps include removing duplicates, filling missing parts, and fixing outliers. Missing data can confuse models, while outliers may cause wrong predictions. Preprocessing also ensures all images and labels are consistent.

Preprocessing solves problems like:

Missing data and outliers that hurt analysis.

Making data accurate and reliable for better decisions.

By following these steps, your dataset will work well for finding defects.

Labeling defects in PCBA datasets

Good labeling is key for training defect detection tools. Labels show the truth that helps models learn and find patterns. Without clear labels, models may miss defects.

When labeling, focus on being clear and consistent. Use boxes, shapes, or masks to mark defects. Each label should describe the defect, like soldering issues or missing parts. Consistent labels make the dataset useful for many tasks.

Studies show how good labels improve results. For example, well-labeled datasets have better scores:

Metric | Value |

|---|---|

46.89% | |

F1-score | 63.84% |

These scores prove that clear labels make models more accurate. Spending time on good labeling improves defect detection systems.

Addressing imbalanced and missing data

Imbalanced and missing data are common problems in PCBA datasets. Imbalanced data happens when some defect types appear more than others. This can make models biased and less effective.

To fix this, use methods like data augmentation or oversampling. Augmentation creates new samples by changing existing ones, like flipping images. Oversampling copies rare defect types to balance the dataset. These methods help models learn all defect types.

Missing data can also hurt your analysis. Fix this by filling missing parts with similar data or removing incomplete entries. Both ways keep your dataset strong.

By solving these problems, you can build a complete and balanced dataset for finding defects.

Improving data quality for better results

Making your data better is key to finding defects correctly. Good data helps your tools learn well and give accurate results. Here are simple ways to improve your PCBA dataset:

Keep Image Quality Consistent

Clear images are important for spotting defects. Use good cameras and even lighting to take sharp pictures. Avoid shadows or glare that hide problems. Keeping images the same makes your dataset more reliable.Check Annotations Carefully

Make sure all labels in your dataset are correct. Wrong or messy labels can confuse your tools and lower accuracy. Use tools to fix labels easily. Work with experts to ensure defect labels are clear and useful.Add Variety to Your Dataset

A mix of images helps your tools work in different situations. Include pictures of boards with various designs, lighting, and defect types. This variety helps your tools handle real-world challenges better.Remove Extra Data

Too much repeated data can confuse your tools. Check your dataset often to find and delete duplicates. This step improves quality and saves computer power during training.Use Data Augmentation

Create new images from old ones using tricks like flipping or rotating. You can also change brightness to mimic different conditions. These methods grow your dataset without needing new pictures.

Tip: Test your dataset after changes. Use a small part of it to see how updates affect your tool’s performance.

By following these steps, you can make your PCBA dataset much better. Good data is the base for building strong and accurate defect detection tools.

Techniques for Finding Defects Using PCBA Datasets

Machine learning methods

Machine learning has changed how we find PCB defects. By training models with PCBA datasets, machines learn to spot flaws. This makes inspections faster and reduces human mistakes. Common algorithms include random forests, neural networks, and support vector machines.

Old manual inspections often fail due to outside factors. This lowers the success of finding defects. Machine learning has improved this process a lot. For example, Wang et al. made a tool that finds 2 mm pinhole defects in 10 seconds. Yuk et al. used random forests and special features to locate defect areas. This greatly improved accuracy. Deep learning and convolutional networks now lead in defect detection. They are fast and reliable.

These tools handle hard tasks better than old methods. Using them means quicker and more accurate defect detection.

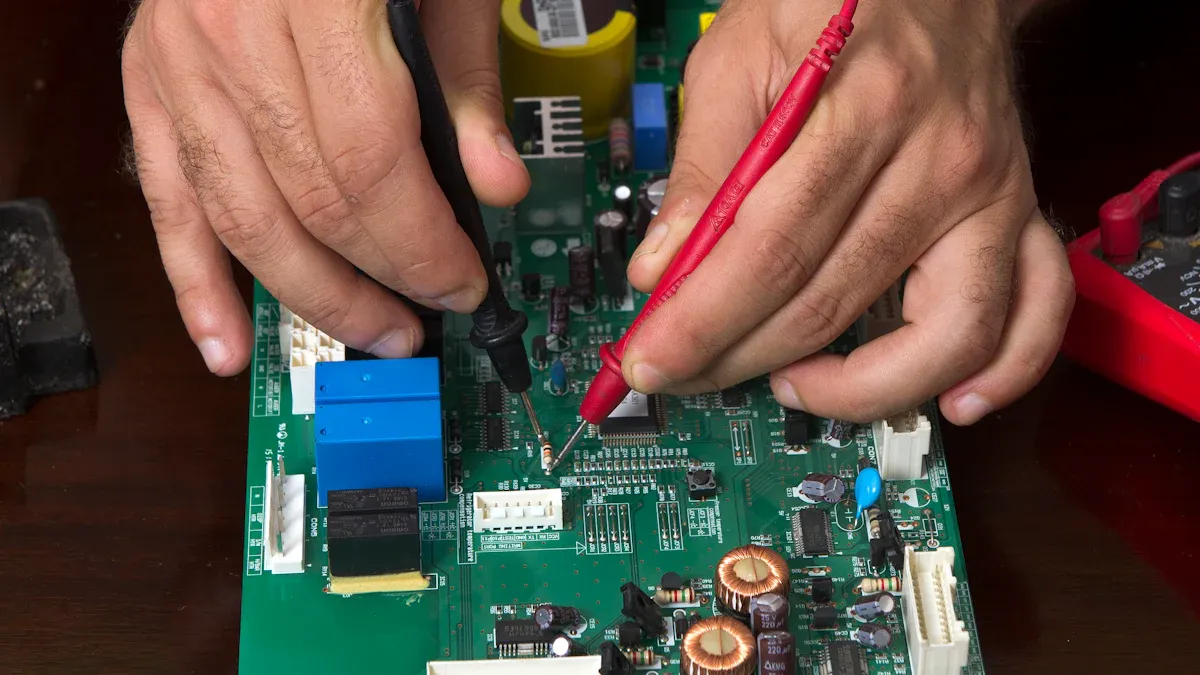

Computer vision for defect detection

Computer vision is key for spotting problems on circuit boards. It uses images to find issues like bad soldering or missing parts. This technology automates inspections and improves accuracy.

Studies show computer vision works very well. For example, advanced systems have great results:

Metric | Value |

|---|---|

Detection Accuracy | 94.69% |

F1-Score | 99% |

Average Precision | Improved |

Average Recall | Improved |

These results prove computer vision helps find defects better. It ensures fewer mistakes and better quality control.

Role of manual inspection

Even with smart tools, manual checks are still important. Humans can confirm results and find rare defects machines miss. Skilled inspectors notice small problems and give helpful insights.

Manual checks also back up automated systems. When machines flag defects, humans can double-check them. Combining human skill with technology gives the best results.

Using both manual and advanced methods creates a strong defect detection process.

Combining techniques for better accuracy

Using different methods together can make defect detection much better. Each method has its own strengths. When combined, they fix each other’s weaknesses. This helps find even tricky or small defects more easily.

One good way is to mix machine learning with computer vision. Machine learning finds patterns in data. Computer vision looks at images to spot problems. Together, they make a strong system that finds defects with great accuracy.

Tip: Try tools like YOLO (You Only Look Once) to improve defect detection. These tools are quick and work well for real-time tasks.

New ideas show how mixing methods works well. For example:

Using YOLOv5 with Res2Net finds tiny, hard-to-see defects better.

The YOLO-pdd tool is faster and more accurate than older YOLO models.

On the PKU-Market-PCB dataset, YOLO-pdd gets higher recall and F1-scores.

Combining methods boosts accuracy, speed, and precision.

These examples show that using mixed methods improves results and saves time. This is very important for industries needing both speed and accuracy.

You can also mix machines with human checks. Machines find possible defects fast. Humans then check and confirm them. This teamwork reduces mistakes and catches all defects. Skilled workers can also notice things machines might miss.

To get the best results, focus on:

Picking methods that work well together: Use tools that handle different parts of defect detection.

Testing combinations: Try different mixes to see what works best.

Using advanced tools: Choose modern tools like YOLO-pdd for top performance.

By combining methods, you can create a system that is accurate and reliable. This not only finds defects better but also improves the quality of your PCBA production.

Tools and Software for PCBA Dataset Analysis

Tools for data preprocessing

Preprocessing tools are key to getting PCBA datasets ready. They clean, organize, and improve data for better results. These tools remove duplicates, fix missing values, and make formats consistent. This ensures the dataset works well with machine learning models.

Python libraries like Pandas and NumPy are great for large datasets. Pandas helps you manage data easily, while NumPy speeds up math tasks. For image editing, use OpenCV or Pillow. These tools resize, crop, and adjust images to make them clearer.

Tip: Use tools like TSFRESH to quickly pull features from raw data. This saves time and keeps things consistent.

With these tools, you can create a clean dataset that improves defect detection.

Machine learning frameworks

Machine learning frameworks make training defect detection models easier. They offer ready-made tools and algorithms to boost accuracy. Popular ones include TensorFlow, PyTorch, and Scikit-learn.

TensorFlow and PyTorch are best for deep learning tasks. They handle neural networks that find complex patterns in PCBA datasets. Scikit-learn is better for simpler models like decision trees or support vector machines.

Here’s how different models perform in defect detection:

Model Type | Mean Average Precision (mAP) | Inference Speed (FPS) |

|---|---|---|

One-stage models | N/A | |

Two-stage model | Competitive | Longer time for inference |

Image processing techniques | 1.0% | N/A |

One-stage models are faster, but two-stage models are more precise. Pick a framework based on what you need.

Computer vision software

Computer vision software changes how defects are found in PCBA datasets. These tools study images to spot problems like soldering mistakes or missing parts. Advanced tools like YOLO (You Only Look Once) and OpenCV detect issues in real-time.

Studies show how helpful computer vision tools are:

Evidence Description | Key Insights |

|---|---|

Advances in computer vision software | |

Importance of imaging systems | Good imaging systems are key for reliable detection. |

Best practices in design | Following best practices boosts efficiency and results. |

AI-powered vision systems reduce the need for human checks. They find small defects people might miss, improving quality control. These systems also learn from past data to get better over time.

Note: Combining computer vision tools with machine learning frameworks can improve both accuracy and speed.

Using the right tools makes defect detection effective and scalable.

Industry-specific tools for PCBA defect detection

Tools made for certain industries help find defects in PCBA. These tools are built to fit the needs of different fields. They make production better and processes more efficient.

Specialized Inspection Systems

Many industries use Automated Optical Inspection (AOI) systems to spot PCB defects. These systems have sharp cameras and smart programs to find problems like bad soldering or missing parts. For fields like aerospace or medical devices, AOI ensures strict quality rules are followed.

Solder Paste Inspection (SPI) machines are also very important. They check how thick and aligned the solder paste is on PCBs. This is crucial for industries like car manufacturing, where small mistakes can cause big safety issues.

Software Solutions for Analysis

Special software helps analyze data from inspection tools. Programs like Siemens Valor and Mentor Graphics are made for electronics factories. They show defect patterns and help improve production. These tools also connect with factory systems for live updates and reports.

Market Dynamics and Trends

The need for industry-specific tools is growing fast. A recent study shows key market trends:

Aspect | Details |

|---|---|

Market Dynamics | Focus on automating quality checks and assurance. |

Challenges | Lack of skilled workers in manufacturing plants. |

Industry Focus | Aiming to increase good products while reducing defective ones. |

Trends | More use of automation to keep product quality high. |

These trends show why advanced tools made for your industry are important. Using these tools can help find defects, cut waste, and improve efficiency.

Tip: Pick tools that match your industry’s needs. This will give you better results and long-term success in finding defects.

Best Practices for Using PCBA Datasets

Keeping data quality high

Good data is key to finding defects correctly. Clean and clear datasets help tools learn better and make fewer mistakes. Start by taking sharp, clear pictures of circuit boards. Use good cameras and bright lighting to show all details. Avoid blurry or dark images, as they can hide problems.

Labels are also very important. Check all labels to make sure they match the defects. Wrong labels confuse tools and lower accuracy. Work with experts to confirm labels and keep them consistent.

Better data gives better results. For example, improving dataset quality can raise recall by 10.90% and mAP by 12.87%. Models like YOLOv4, trained on good data with extra samples, can reach 98.6% mAP using 19,029 images. This shows why spending time on data quality matters.

Improvement Metric | Increase (%) |

|---|---|

Recall | 10.90% |

mAP Value | 12.87% |

Updating and checking datasets often

Datasets need updates to stay useful. Circuit boards and how they’re made change over time. Old datasets might miss new defect types, making detection less accurate. Update your dataset often to match current production needs.

Checking your dataset is also important. Test it regularly to see if it still works well. Use a small part of the data to check model accuracy and recall. If results drop, look for missing or outdated data.

Updated datasets improve results. For example, the T-YOLOv5 model shows how fresh data helps. It has a recall of 99.24% and mAP/IoU of 99.15%, proving that updated and checked data makes a big difference.

Model | Accuracy | Recall | mAP/IoU |

|---|---|---|---|

T-YOLOv5 | 98.37% | 99.24% | 99.15% |

Focusing models on specific defects

Not all defects are alike. Some are easy to find, while others need special tools. Train your models to focus on the defects you want to detect. For example, if soldering problems are common, use more examples of soldering defects in training.

Add variety to your data with tricks like flipping or rotating images. This helps your model find defects in different situations. These steps make sure your model works well in real-life tasks.

Special models like YOLOv4 do better with focused datasets. By training on specific defect types, you can get higher accuracy and faster results. Tailoring your model makes it fit your production needs perfectly.

Working with domain experts

Working with domain experts can greatly improve how you find defects. These specialists know a lot about PCBs and how they are made. Their knowledge helps make your PCBA datasets better and improves detection accuracy.

Why work with domain experts?

Skilled in spotting defects

Experts know the small details of PCB problems. They can find tiny issues that machines might miss. Their help ensures your dataset covers all important defect types.Better labeling accuracy

Experts can help create clear and correct labels for your dataset. Good labels are key for training accurate machine learning tools. For example, they can tell the difference between similar problems like cracks and voids in soldering.Custom solutions for industries

Different industries have different needs. Experts can help adjust your system to fit these needs. For example, aerospace PCBs need stricter checks than regular electronics.

How to work well with experts?

Involve them early

Bring in experts when starting your dataset. They can help take clear pictures and decide on defect types.Use their skills for checking

Ask experts to review your dataset and results. Their checks make sure your system works well in real situations.Learn from their experience

Hold training sessions with experts. These sessions teach your team about tricky defect patterns.

Tip: Talk to domain experts often to keep up with new trends and defect types.

By teaming up with domain experts, you can create a strong defect detection system. Their knowledge connects technology with real-world needs, leading to better outcomes.

PCBA datasets are important for finding problems in circuit boards. They help train smart tools to inspect faster and more accurately. For example, the PCBA-YOLO model, based on YOLOv5, reaches 97.3% precision on the PCBA-DET dataset. It uses special methods like large kernel convolution and SIoU loss to work better and faster.

Using the right tools and steps makes defect detection even better. Here are some key points:

Evidence Type | Description |

|---|---|

Solder Joint Quality | Strong solder joints make PCBA products last longer. |

Production Mistakes | Most problems happen during production, so checks are needed. |

AI vs Old Methods | AI is more accurate and reliable than older inspection methods. |

By keeping data clean and working with experts, you can create a strong system to find defects. These actions save time, improve results, and make production more reliable.

FAQ

How should I start using a PCBA dataset?

First, learn how the dataset is organized. Look at the images, labels, and extra details. Use tools to clean the data and make it consistent. Begin with a simple model to check if the dataset works well before doing more.

What can you do about uneven defect data?

Try methods like data augmentation or oversampling. Augmentation makes new images by flipping or rotating old ones. Oversampling copies rare defect types to even out the dataset. These steps help your model understand all defect types better.

Can PCBA datasets work without machine learning?

Yes, they can. You can use manual checks or simple image tools to study the data. But machine learning is faster and more accurate, especially for big production tasks.

How often should a PCBA dataset be updated?

Update it when production changes or new defects appear. Regular updates keep your models accurate and useful. Test the dataset often to find and fix missing or outdated parts.

What tools are needed for PCBA dataset analysis?

You’ll need tools for cleaning data, machine learning, and image analysis. Good choices include Python tools like Pandas, TensorFlow, and OpenCV. Special software like Siemens Valor helps improve production quality too.

See Also

Innovative PCBA Testing Methods for Modern Electronics Production

Enhancing PCBA Testing Through Automation for Optimal Precision

Understanding PCBA: Its Importance in Electronic Equipment

The Importance of PCBA Functional Testing for Quality Assurance