A functional circuit test (PCBA FCT) checks if your circuit board works right. This test looks at how the board performs in real-life-like situations. It finds design or manufacturing mistakes early, avoiding expensive fixes or returns.

Testing helps makers create boards with 99.9% no defects.

PCBA FCT in real-life-like conditions ensures the board works well.

Better product quality makes customers happy and builds trust.

Using these tests, including PCBA FCT, makes sure your electronics are reliable and high-quality.

Key Takeaways

Functional Circuit Testing (FCT) checks if circuit boards work well. It tests them in real-life situations to find problems early.

FCT makes products better, which makes customers happy and improves your brand’s image.

Finding problems early with FCT saves time and money. It lowers the chance of expensive recalls or warranty issues.

FCT ensures products follow rules, making them safe, reliable, and good for the environment.

Spending on special tools and trained workers makes FCT faster and more accurate. This improves how well products are made.

Why PCBA FCT Is Important

Functional circuit testing (FCT) is key to making sure your printed circuit board assembly (PCBA) works well. It checks if your circuit boards function properly and perform as they should. This helps you create reliable products that customers can trust. Let’s see why FCT matters so much.

Ensuring PCB Quality and Reliability

Your PCBs need to work perfectly in real-world situations. FCT lets you test how your boards act in conditions like their actual use. This testing finds and fixes design or production mistakes before the boards leave the factory. For example, it checks if electrical performance, signals, and power meet strict rules like IPC-2221 and IPC-A-610.

Mistake-free PCBs work better and last longer. This builds customer trust and lowers complaints. The table below shows how FCT helps improve PCB quality and reliability:

Role of FCT in PCB Quality and Reliability | Description |

|---|---|

FCT tests boards in real-use conditions, catching errors early and ensuring only good boards are shipped. | |

Check PCB Performance and Durability | Boards without errors work well and last longer, reducing failures. |

Keep Customers Happy | Testing ensures high-quality boards, avoiding complaints and keeping trust. |

Finding Problems Early

Finding problems early saves time and money. FCT spots issues before boards are sent to customers. This early check lets you fix designs quickly without spending too much. For example, automated test equipment (ATE) can find problems in big batches, while manual testing works for smaller orders.

Here are some benefits of finding problems early with FCT:

It stops expensive recalls by fixing issues during production.

It makes your PCBs better, meeting what customers expect.

It lowers the chance of failures, improving your brand’s image.

Meeting Industry Rules

Following industry rules is important for your PCBA to succeed. FCT makes sure your boards meet standards like RoHS, which limits harmful materials. In fields like aerospace and medical devices, stricter tests ensure safety and reliability.

The table below shows how FCT helps meet rules in different industries:

Industry Sector | Evidence |

|---|---|

Aerospace & Defense | Needs custom FCT solutions to meet strict safety and rule requirements. |

Environmental Compliance | FCT follows the EU’s RoHS rules, promoting eco-friendly testing. |

Market Trends | Semiconductor testing market expected to hit $10 billion by 2025 due to more rules. |

By following these rules, your products stay safe, reliable, and eco-friendly. This not only meets legal needs but also boosts your reputation in the market.

How Functional Circuit Test Works

Functional Circuit Testing (FCT) is important in making PCBs. It checks if circuit boards work as planned and meet design needs. Let’s look at the tools, steps, and processes used in FCT.

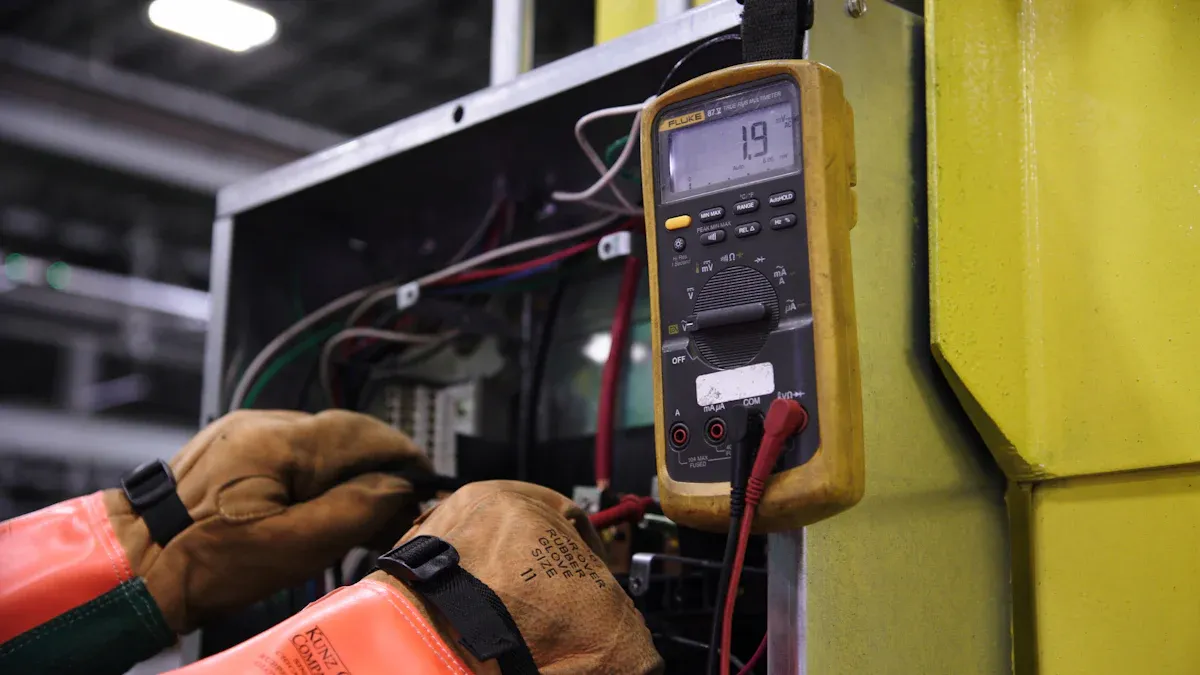

Overview of FCT Equipment

FCT tools mimic real-world conditions for testing PCBs. They measure things to ensure the board works properly. These tools test electrical performance, signals, and power. For example, voltage checks confirm power levels are correct. Microcontroller tests make sure memory and processors work well.

Here’s a simple table about FCT tools:

Specification | Description |

|---|---|

Voltage Validation | Checks if power levels are correct when turned on. |

Microcontroller Programming | Confirms memory and processors are working right. |

Communication Buses | Tests how different parts of the board talk to each other. |

These tools also test things like current, power, and even temperature. Using them ensures your PCBs follow strict rules like IPC-2221 and IPC-A-610.

Testing Processes and Parameters

FCT uses steps like automated and manual testing to check boards. Automated tools are great for big batches because they are fast and accurate. Manual testing works better for small or custom orders.

FCT checks these things during testing:

Parts and circuits to see if they match the design.

Inputs and outputs to confirm they work correctly.

Chips to find hardware or software problems.

Performance in different conditions like heat or humidity.

Here’s a table of common tests and their uses:

Testing Method | Description |

|---|---|

Voltage Testing | Checks if voltage levels are correct on the board. |

Load Testing | Tests how the board works under normal use. |

Quality Control Testing | Makes sure the board is made well and works reliably. |

These steps help find and fix problems early, saving time and money.

Role of Fixtures in FCT Testing

Fixtures are tools that hold PCBs during testing. They connect the board to the test equipment. Good fixtures, like those from SEMIKI, are made for complex boards. They are customized to fit specific testing needs.

Why fixtures matter in FCT:

They keep the board steady during testing.

They fit different board sizes and designs.

They make testing faster and easier.

For example, a good fixture can test many boards at once. This saves time and ensures tests are consistent. Using the right fixtures improves test accuracy and helps make reliable PCBs.

Benefits of FCT Testing in PCBA

Lowering Failure Rates

Functional Circuit Testing (FCT) helps lower failure rates in PCBA. It finds problems early during production, stopping bad boards from shipping. Fixing issues early avoids costly repairs or throwing away faulty boards. For example, automated test equipment (ATE) checks large batches fast, keeping quality consistent.

FCT also ensures your PCBs follow strict rules like IPC-2221 and IPC-A-610. These rules check electrical performance, signals, and power. Following them means your products work well in real-life use. This lowers failure rates and improves your brand’s reputation for quality.

Boosting Product Quality

FCT improves the quality of your PCBA by checking every circuit board. It makes sure all parts work as they should. This builds trust with customers and meets their expectations. For instance, FCT tests how boards handle heat or humidity. This ensures your products stay reliable in tough conditions.

FCT also removes the need for extra system tests by covering all PCB areas. This thorough testing finds and fixes errors, ensuring no mistakes are missed. You can confidently ship high-quality products that meet industry standards and customer needs.

Saving Time and Money in Production

FCT saves time and money during manufacturing. It catches defects early, avoiding expensive fixes or extra testing later. This makes production faster and cuts labor costs, using resources better. The table below shows how FCT saves money:

Benefit | Description |

|---|---|

Finds issues early, avoiding costly repairs or wasted boards. | |

Fewer Warranty Issues | Reduces failures and warranty claims, saving money and reputation. |

Faster Production | Speeds up testing, lowering labor costs and increasing output. |

Better Product Reliability | Ensures boards work before shipping, cutting future repair costs. |

FCT also speeds up product development by testing boards before launch. This shortens the time it takes to bring products to market. By using FCT, you save time, cut costs, and make customers happier.

Challenges and Needs for FCT Testing

Importance of Custom Fixtures and Tools

Custom tools and fixtures are very important for FCT. They hold PCBs securely and connect them to test machines. Without these tools, testing can take longer and be less accurate. For example, using custom fixtures for a welding robot cut weld time from 8 hours to 45 minutes. This shows how special tools can save time and improve work.

Custom fixtures also make part changes faster during checks. Quick changes mean less waiting and better accuracy, keeping quality high. These tools may cost more at first, but they reduce mistakes and boost productivity over time.

Time and Planning in Testing

FCT needs good planning to avoid slowing production. Testing each PCB includes setting up tools, running tests, and checking results. Automated tools (ATE) help test big batches quickly, but small orders often need manual testing. Balancing both methods takes careful scheduling.

Testing for extreme conditions adds more steps. You must check if PCBs work in heat, cold, or vibrations. These tests make sure products stay reliable but need extra time and effort. Good planning helps avoid delays and keeps production moving smoothly.

Skilled Workers for Proper Testing

FCT needs trained workers to do it right. Experts must know PCBA details and how to use test machines. They ensure boards meet strict rules like IPC-2221 and IPC-A-610. Careful checks confirm the PCB works as planned and meets all needs.

Skilled workers also find problems with parts and signals. Their knowledge prevents delays and fixes, making production easier. Hiring trained staff improves product quality and reliability, helping your business succeed.

Functional Circuit Testing (FCT) helps make sure PCBs work well. It finds problems early so only good boards are used. This test sets clear rules for passing or failing. It checks fixes and gives tips to make boards better. It also keeps track of mistakes, showing you care about quality.

FCT is important for making things right. It lowers errors, saves time, and follows industry rules. By improving how you make boards, you can make them last longer and work better. FCT also creates reports to track and improve your work.

In the end, FCT makes sure your electronics meet customer needs. It helps you make strong, high-quality products that people trust. By focusing on this step, you can succeed in the busy electronics world.

FAQ

What is FCT in PCBA?

FCT means Functional Circuit Test. It checks if a PCB works right. It mimics real-life use to test how it performs. This makes sure the board meets design needs and works well.

How is FCT testing different from other tests?

FCT checks if a PCB works in real-life conditions. Unlike defect checks, it tests how the board functions, including its parts and software.

Why is PCB functional testing needed?

PCB functional testing ensures boards meet rules and customer needs. It finds problems early, lowers failure rates, and makes products more reliable. This step helps create high-quality electronics.

What does automated functional testing do in FCT?

Automated testing checks many PCBs quickly and accurately. It gives steady results, avoids mistakes, and saves time during production.

Can FCT testing help save money in production?

Yes, FCT testing saves money by catching problems early. It stops costly recalls, reduces waste, and lowers warranty claims. It also makes production faster and more efficient.

See Also

Understanding PCBA: Its Definition And Importance In Electronics

The Significance Of PCBA In The Electronics Industry

Exploring The Meaning Of PCBA In Electronics Today