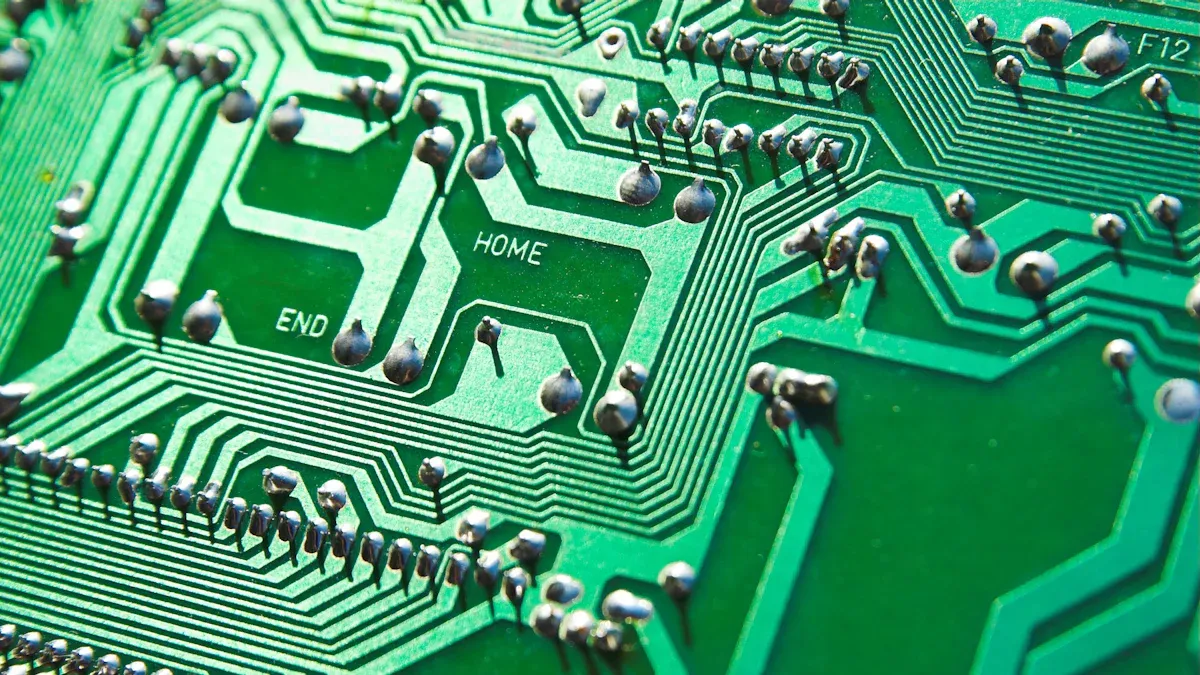

PCBA functional testing checks if a circuit board works properly. It ensures that all parts and connections work together correctly. By simulating real-life conditions, it helps identify problems early. With a PCBA functional tester, you can verify if boards meet standards. This step is crucial for creating better and more reliable products.

Functional testing protects devices from breaking, saving time and money later.

Key Takeaways

PCBA functional testing makes sure circuit boards work correctly by mimicking real-world use.

Catching issues early in production saves time, money, and avoids expensive recalls.

Good PCBs mean fewer complaints and help customers trust your brand.

Using smart tools like Automated Optical Inspection makes testing faster and more accurate.

Picking an experienced provider with proper certifications ensures good and reliable testing.

What is PCBA Functional Testing?

Definition and purpose

PCBA functional testing checks if a circuit board works right. It uses real-life conditions to test the board. The board is put in a setting like its real use. Signals and currents are used to see how it works. Problems like signal issues or timing mistakes are found. A computer program helps start and test the board. Results are checked against what is expected. This makes sure the board meets what customers want and works well.

Functional testing is key to checking design quality. It looks for making mistakes and checks the programming in chips. This makes sure the board does what it should without problems.

Role in verifying PCB functionality

PCB functional testing checks if a board works in different settings. It looks at things like heat, current, and frequency. For example, it checks if the board can handle heat and works at the right frequency. It also checks power, signal, and voltage levels. These tests find problems like wrong parts or missing pieces that can hurt how the board works.

By fixing these problems early, testing makes sure the board meets rules and works well. This step is important for keeping quality in making boards.

How it differs from other testing methods

Functional testing checks the whole board’s performance using real-life settings. Unlike in-circuit testing (ICT), which checks parts and links, functional testing looks at the board as a whole. ICT uses a special tool to find making mistakes like shorts or wrong parts. ICT gives detailed problem info but doesn’t check if the board works right.

Functional testing makes sure the board works as planned. It might not find all making mistakes, but it ensures the board works in its real setting. This makes functional testing an important part of making boards.

How Does a PCBA Functional Tester Work?

Overview of the testing process

A PCBA functional tester checks if a circuit board works. The process starts by linking the board to test tools. These tools mimic real-world conditions like voltage and signals. The tester sends inputs and watches the outputs. If something is wrong, it finds the problem for fixing.

Testing has many steps. First, design tests check if the circuit works. Then, functionality tests confirm the board’s main features. Interoperability tests see if it works with other systems. Environmental tests check performance in heat or humidity. Compliance tests ensure it meets industry rules. Reliability tests look at long-term use. Usability tests focus on how users interact with it.

Type of Test | What It Checks |

|---|---|

Design | Makes sure the circuit design works |

Functionality | Confirms main features and system functions |

Interoperability | Tests if it connects with other systems |

Environmental | Checks if it works in heat or humidity |

Compliance | Ensures it follows industry rules |

Reliability | Tests how it works over time |

Manufacturing | Looks at how it’s made |

Usability | Focuses on how users interact with it |

Common techniques used in functional testing

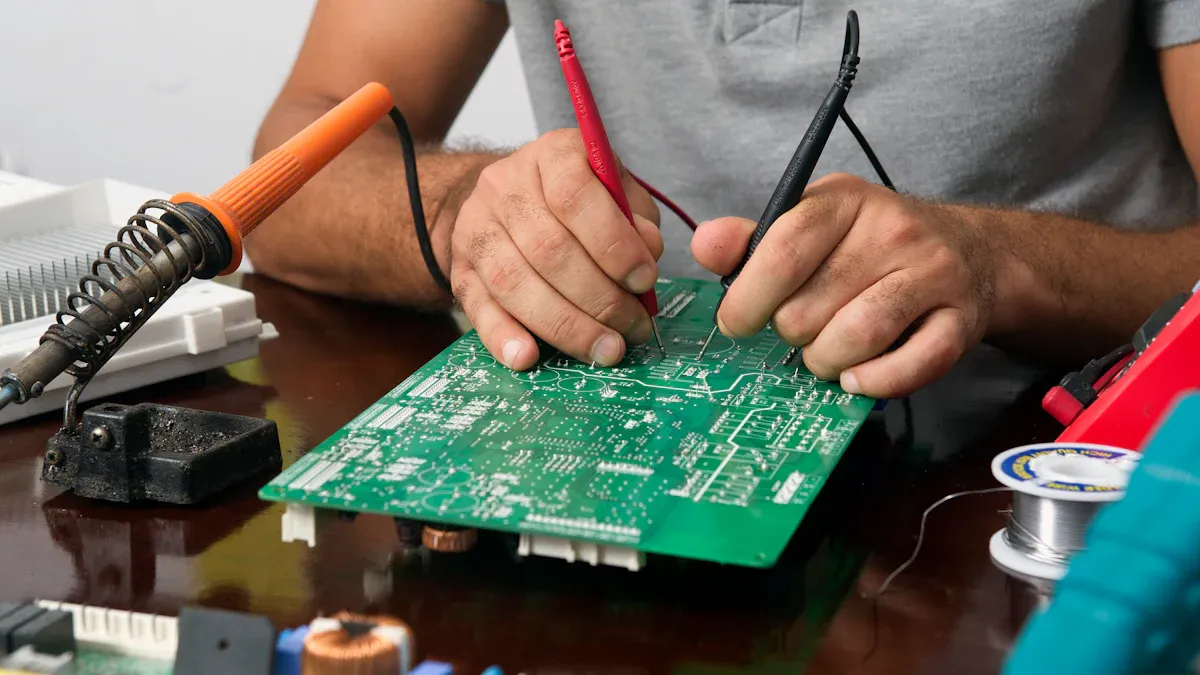

Functional testing uses different methods to check boards. One way is boundary scan testing, which checks connections. Another is automated optical inspection (AOI) that finds physical flaws. In-circuit testing (ICT) looks at parts for problems like shorts.

Software methods are also used in testing. Test case effectiveness shows how well tests find issues. Cycle time measures how long testing takes. Defect fixing time tracks how fast problems are fixed. Passed/failed test metrics show if the board is stable. These methods help find and fix problems early, improving quality.

Test Case Effectiveness: Shows how well tests find problems.

Cycle Time: Tracks how long testing takes.

Defect Fixing Time: Measures how fast issues are fixed.

Number of Defects: Counts problems to check software quality.

Defect Severity: Ranks problems by how serious they are.

Passed/Failed Test Metrics: Shows if the board works well.

Examples of input/output verification

Input/output checks are important in testing boards. The tester sends inputs and watches the outputs. For example, it might send voltage to a power circuit. If the output matches the expected value, it passes. It might also send a signal to a microcontroller to see if it responds.

Another example is testing USB ports. The tester sends data through the port and checks if it works. These tests make sure the board works in real life. Finding problems early helps keep the boards reliable.

Why is PCB Functional Testing Important?

Lowering failure rates

PCB functional testing helps reduce failures during production. It uses real-world conditions to find problems early. This makes sure the PCB works properly before customers get it. For example, testing can spot wrong voltage levels or bad connections. Fixing these issues early avoids expensive recalls and improves quality.

It finds problems early, lowering the chance of recalls.

About 30% of recalls happen because of PCB problems, showing why testing matters.

Using functional testing reduces the risk of faulty products. This saves money and keeps your brand’s good name safe.

Making products reliable

Reliability is important for all electronics. PCB functional testing checks if boards handle heat, moisture, and electrical stress. Testing under these conditions ensures the board works well over time. For example, it can test if a power circuit gives the right output under different loads.

Reliable PCBs mean fewer complaints and longer-lasting products. Testing also finds weak spots in the design, so you can fix them before making many units. Reliable products build customer trust and help your brand stand out.

Following industry rules

Functional testing makes sure PCBs meet industry rules. This is very important for fields like cars, planes, and medical devices. These areas need high safety and quality standards. Testing confirms that boards work safely and correctly.

For example, testing checks if PCBs meet safety and performance rules. This helps your products pass inspections and avoid legal trouble. Meeting these rules improves quality and makes customers trust your products more.

Careful functional testing is key to making high-quality, reliable, and safe PCBs.

Benefits of Functional Testing Services

Finding problems early

Functional testing finds problems early in production. It uses real-world conditions to spot issues like wrong voltage, missing parts, or bad connections. Fixing these problems early saves time and money.

Metrics like defect detection rate and test case effectiveness show why early detection matters. For example:

Metric | What It Checks |

|---|---|

Defect Detection Rate | Shows how well tests find problems, ensuring good quality. |

Test Case Effectiveness | Checks how well test cases find issues, making testing better overall. |

Finding problems early avoids expensive recalls and keeps customers happy.

Saving money

Functional testing saves money by making testing faster and easier. Automated tools help test complex boards quickly. Many companies save a lot of money using these services. For example:

Benefit Description | Percentage Saved |

|---|---|

Time spent on test execution | |

Time spent creating and maintaining test scripts | Up to 70% |

Testing resources saved per year on one module | 35 days |

Total testing days saved per year across multiple modules | Over 200 days |

Automation can cut testing costs by 50% and hardware costs by 40%. This makes functional testing a smart choice for saving money.

Works with other testing methods

Functional testing works well with other testing methods. It checks the board’s performance after parts are tested. Automated optical inspection finds physical problems, while functional testing ensures the board works in real-life settings.

Using different testing methods together improves quality. It increases testing coverage to 80% and accuracy by 90%. This helps your board meet rules and work reliably.

Functional testing improves quality and works well with other tests, making it a great tool for production.

Challenges in Functional Testing

Common challenges (e.g., cost, time, complexity)

Testing circuit boards has many problems. These can slow work and hurt quality. One big problem is slow testing methods. They cause delays and mistakes, making it hard to finish on time. Another issue is handling data well. Without good data, it’s tough to check results and decide what to do. Watching tests in real-time is also key. Finding problems early keeps products reliable, but many systems can’t do this.

Challenge | Description |

|---|---|

Slow testing methods | Current ways are slow, causing delays and mistakes. |

Need for better data handling | Better data use is needed for good checks and choices. |

Importance of real-time monitoring | Finding problems early is important for keeping products good. |

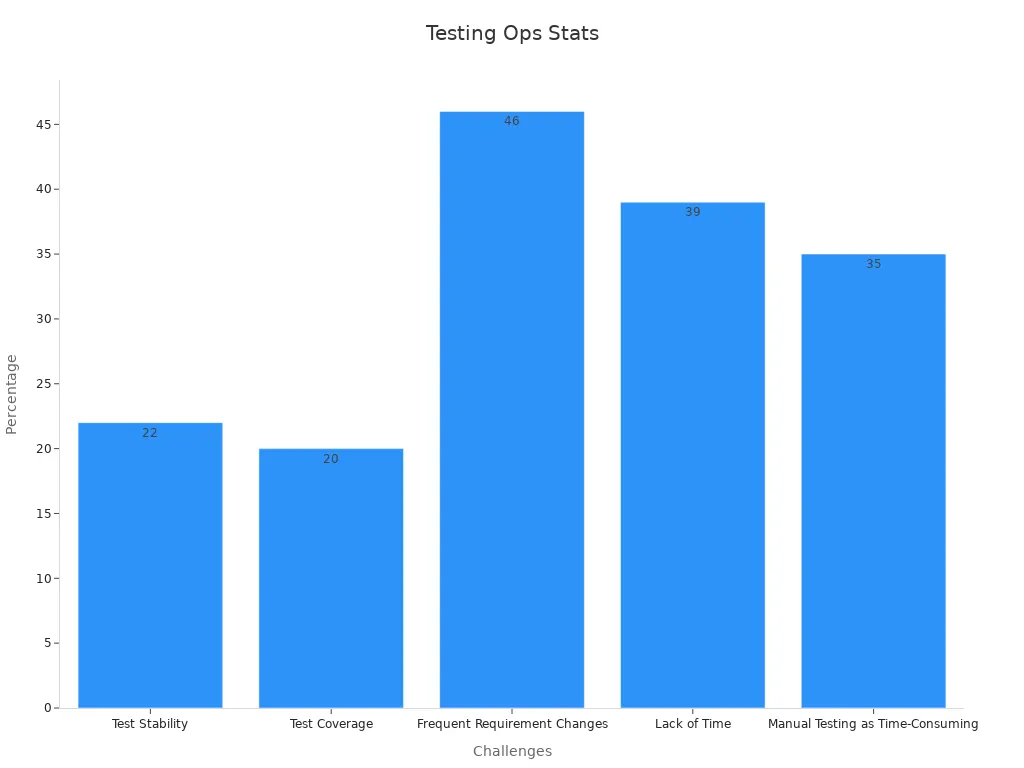

Statistics show more problems. Many companies have issues like test stability, small test areas, and changing needs. These make testing harder and take more time.

Challenge | Percentage of Companies Reporting |

|---|---|

Test Stability | |

Test Coverage | 20% |

Frequent Requirement Changes | 46% |

Lack of Time | 39% |

Manual Testing as Time-Consuming | 35% |

Misconceptions about functional testing

Many people get functional testing wrong. Some think it’s only for hard designs. Others believe it replaces other tests. But, it works with other tests like in-circuit testing. It checks if the board works in real life. Some say it’s too costly. While it costs money, it saves by stopping failures and recalls.

Overcoming these challenges

You can beat these problems by using smart ways. Start by setting clear goals and getting enough test info. Good test management keeps things running well. Automation helps a lot too. Automated tools cover more and cut down on manual work. For example:

Coverage Level | Description |

|---|---|

Basic coverage | |

Good coverage | 80-90% line coverage |

High coverage | 90%+ line coverage |

Other ways include watching tests live and using data better. These help find problems early and make testing smoother. By fixing these issues, testing becomes better and more trustworthy.

Choosing the Right Provider for Functional Testing Services

Why expertise and experience matter

Pick a provider with strong skills and experience in PCB testing. Skilled providers know how to find problems quickly. Experienced teams have faced many challenges before. This helps them handle special testing needs better. Their knowledge ensures your PCB is tested well, lowering the chance of defects.

Providers with good past results often give better service. Choose companies that have worked in your industry. For example, if you make medical devices, pick a provider who knows those strict rules. This makes sure your PCB works well and meets all standards.

Using advanced testing tools

The best providers use modern tools for accurate testing. Tools like Automated Optical Inspection (AOI) and X-Ray Inspection (XRI) are very helpful. They find problems that people might miss during manual checks.

AOI and XRI help find defects and improve quality.

Automated tools give quick data for fast fixes during production.

Early problem detection avoids costly mistakes later.

Modern tools not only make testing more accurate but also speed up production. This ensures your PCB works well in real-life situations.

Checking provider certifications

Certifications show a provider’s skill and trustworthiness. They prove the provider follows global rules and good practices. Look for certifications like CMMI, ISTQB, and ISO. These show the provider can deliver top-quality testing services.

Certification | What It Means | Why It Matters |

|---|---|---|

CMMI | Shows mature processes | Ensures high-quality results |

ISTQB | Tests staff skills | Confirms testing knowledge |

ISO | Follows global standards | Ensures best practices |

Certifications like ISO/IEC 17025:2017 also prove the provider can do accurate tests. Providers with these certifications are more reliable. They help ensure your PCB meets all industry rules.

Picking a provider with the right skills, tools, and certifications ensures your PCB gets tested thoroughly and reliably.

PCBA functional testing is key to making quality products. It finds problems early, helping you avoid expensive recalls. This testing also ensures your products follow industry rules, making them safer and more reliable.

Tip: Spend on functional testing now to avoid future problems.

Focus on functional testing in your production steps. It boosts product performance and builds trust in your brand. Good testing brings better results and lasting success.

FAQ

What is the main goal of PCBA functional testing?

The main goal is to check if your PCBA works properly. It tests parts and connections to ensure they meet quality rules. This makes sure the product works well in real-life situations.

How does functional testing differ from in-circuit testing?

Functional testing checks how the whole board works in real life. In-circuit testing looks at single parts and their connections. In-circuit testing finds building mistakes, while functional testing ensures the board works as planned.

Can functional testing detect all types of defects?

Functional testing finds problems with how the board works. But it might miss physical issues like bad soldering or missing parts. Using functional testing with other methods like AOI helps find all problems.

Is functional testing suitable for all industries?

Yes, functional testing works for many industries like cars, planes, and medical tools. It ensures PCBs follow industry rules and work well in important jobs. This makes it a useful and needed testing method.

How can you choose the right functional testing provider?

Choose providers with skills, good tools, and certifications like ISO. Experienced providers know industry needs and give accurate testing. They help make sure your PCBs are safe and high-quality.

Tip: Check a provider’s certifications and past work before choosing them.

See Also

Innovative PCBA Testing Methods for Enhanced Electronics Production

Understanding PCBA Testers: Functionality and Operation Explained

Enhancing Accuracy Through Automation in PCBA Testing Procedures

The Essential Role of PCBA Test Fixtures in Manufacturing

Significance of PCBA Test Jigs in Today’s Electronics Manufacturing