PCBA manufacturing and assembly mean making and putting together printed circuit board assemblies (PCBAs). These PCBAs are the main part of modern electronic devices. This process adds electronic parts to a PCB, turning it into a working assembly. Knowing these steps helps you make high-quality electronics that follow industry rules.

This knowledge is important because the global electronics market is growing fast. By 2029, it might reach $797 billion, which is 58% more than in 2022. The PCB market is also growing, from $70 billion in 2022 to over $86 billion by 2026. Companies now spend a lot on better testing and inspection tools to make products more reliable. This is because today’s electronics are more complex. Learning PCBA manufacturing and assembly helps you keep up with these changes and create better products.

Key Takeaways

Check designs early for making and assembling problems. This saves money and makes products better.

Pick good materials and trusted suppliers for parts. This helps PCBAs work well and last longer.

Do careful quality checks when making PCBs. Use tools like AOI to find mistakes early and make them reliable.

Follow clear steps in SMT and THT processes. Good soldering and placing parts right make strong connections.

Keep PCBs clean and label them properly. This removes dirt, makes them easy to track, and helps them last longer.

Preparations in the PCBA Manufacturing Process

Design for Manufacturability (DFM) and Design for Assembly (DFA) Checks

Before making PCBAs, check if the design is ready. This means doing DFM and DFA checks for the PCB. These checks find problems that might make production harder. DFM makes sure the PCB design can be made without mistakes. DFA focuses on making assembly easier and faster.

Good DFM and DFA checks save money and reduce mistakes. They also improve PCBA quality and follow industry rules, making products more reliable.

Think about what increases PCB costs. Design to save money and keep costs low. This step helps make the manufacturing process smooth and efficient.

Material Procurement and Component Sourcing

After finalizing the design, gather the needed materials and parts. Use high-quality materials to make the PCBA strong and work well. This includes picking the right PCB base, solder paste, and electronic parts.

Smart design helps in choosing the right materials.

Check materials carefully to avoid fake parts.

Work with trusted suppliers to ensure good quality.

Getting the right materials affects how well the PCBA works. Delays in getting parts can slow down the whole process.

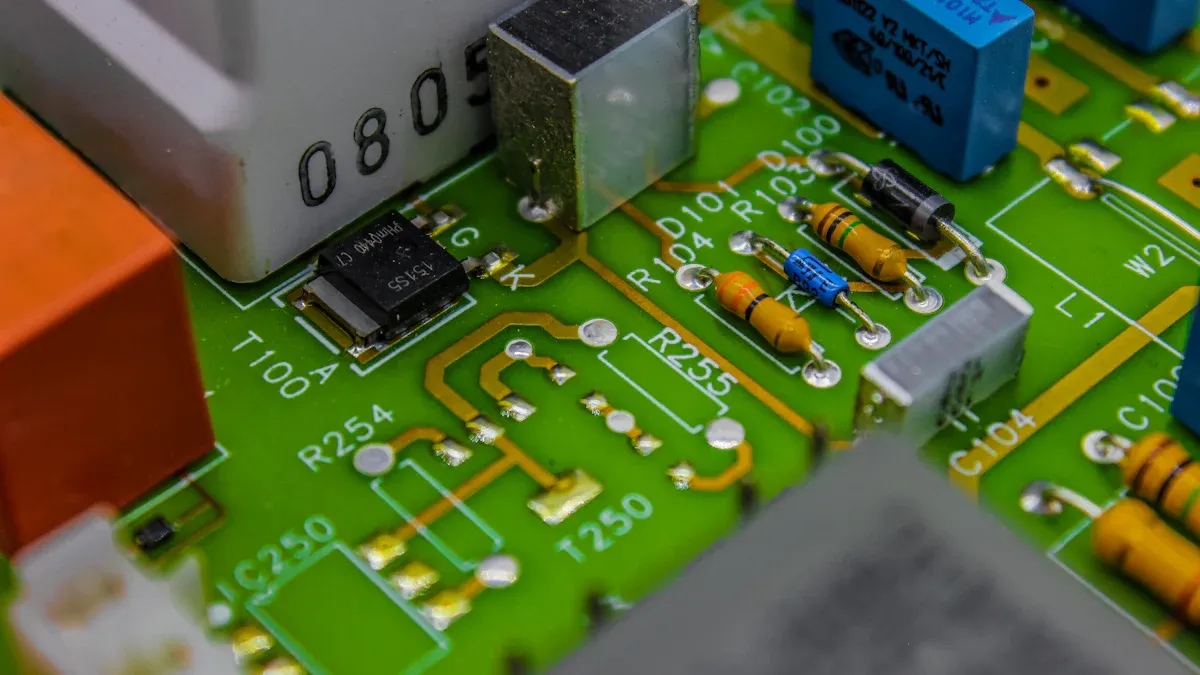

PCB Fabrication and Quality Verification

The PCB fabrication step turns your design into a real board. This includes making layers, drilling holes, and adding copper lines. Quality checks are very important during this stage.

Look for visible issues like scratches or misaligned parts.

Use AOI to find hidden errors.

ICT checks if each part works properly.

Functional tests see how the PCB works in a device.

Stress tests check if it lasts under tough conditions.

Quality checks make sure PCBAs are reliable. Keep checking and improving during fabrication.

By following these steps, you can make sure the PCB is ready for assembly. Send all needed files to the manufacturer to avoid delays.

Step by Step Guide to the SMT Process

Surface Mount Technology (SMT) is an important part of making PCBAs. It places small parts directly onto the surface of a PCB. This guide explains the main steps in the SMT process.

Solder Paste Application

The first step is putting solder paste on the PCB. Solder paste is a mix of tiny solder bits and flux. It helps stick parts to the PCB and makes strong connections.

A stencil is used to apply the paste only where needed. The stencil ensures the paste goes on the right spots, like pads for the parts. It’s important to apply the paste evenly. Too much or too little can cause problems like weak joints or solder bridges.

Tip: Check the stencil often for damage. A worn stencil can cause mistakes and lower the quality of the paste application.

Pick-and-Place Assembly

After the paste is applied, parts are placed on the PCB. A pick-and-place machine does this job. These machines are very fast and accurate, placing many parts in a short time.

Modern machines use cameras to ensure parts are placed correctly. They can handle tiny parts like resistors and bigger ones like chips. This technology makes PCBAs more reliable.

Thinner PCBs last longer under stress than thicker ones.

Smaller attachment pads can improve solder joint strength.

Laminate carriers last much longer than ceramic ones in heat tests.

These improvements show why accuracy and materials matter in this step.

Reflow Soldering Process

Next, the PCB goes into a reflow oven to melt the solder paste. The heat makes the solder flow and connect the parts to the PCB.

The oven has different heat zones for preheating, soaking, and reflowing. The temperature must be controlled carefully to avoid damaging the PCB or parts.

Note: Watching the reflow process live helps catch and fix problems quickly. This keeps quality high and reduces delays.

SMT Step | What It Does | Why It Matters |

|---|---|---|

Collects data about how production is going. | Helps set a standard for performance. | |

Fixing inconsistencies | Finds and fixes problems in the process. | Reduces mistakes and improves quality. |

Watching the process | Tracks production in real-time. | Allows quick fixes to avoid delays. |

Improving to meet goals | Adjusts steps to reach the best performance. | Boosts speed and lowers costs. |

By following these steps, you can make sure the SMT process runs smoothly and creates high-quality PCBAs.

Step by Step Guide to the THT Process

Through-Hole Technology (THT) is a way to build pcbAs by putting parts into drilled holes on the board. This method works well for parts needing strong connections or handling high power. Let’s look at the main steps in the THT process.

Component Insertion

The first step is placing parts into the PCB. THT parts have long leads that fit into the board’s holes. These leads are soldered to make strong electrical connections.

Manual Insertion: For small batches or special parts, you can insert them by hand. This gives more control but takes longer.

Automated Insertion: For big batches, machines do the job. They are faster and make fewer mistakes.

Tip: Check the direction of parts like diodes and capacitors. Wrong placement can break the circuit.

Good part placement helps the pcbA stay strong and work well.

Wave Soldering

After placing parts, the PCB goes to wave soldering. This step uses molten solder to attach the leads to the board. It makes strong and lasting connections.

Here’s how it works:

Flux Application: Flux is added to clean the board and help solder stick.

Preheating: The board is warmed to stop damage and spread solder evenly.

Solder Wave: The board passes over molten solder, which connects the leads and pads.

Note: Wave soldering is great for making many boards quickly. But it doesn’t work for surface-mounted parts, as they might fall off.

This step is key to making sure your pcbA is strong and works well.

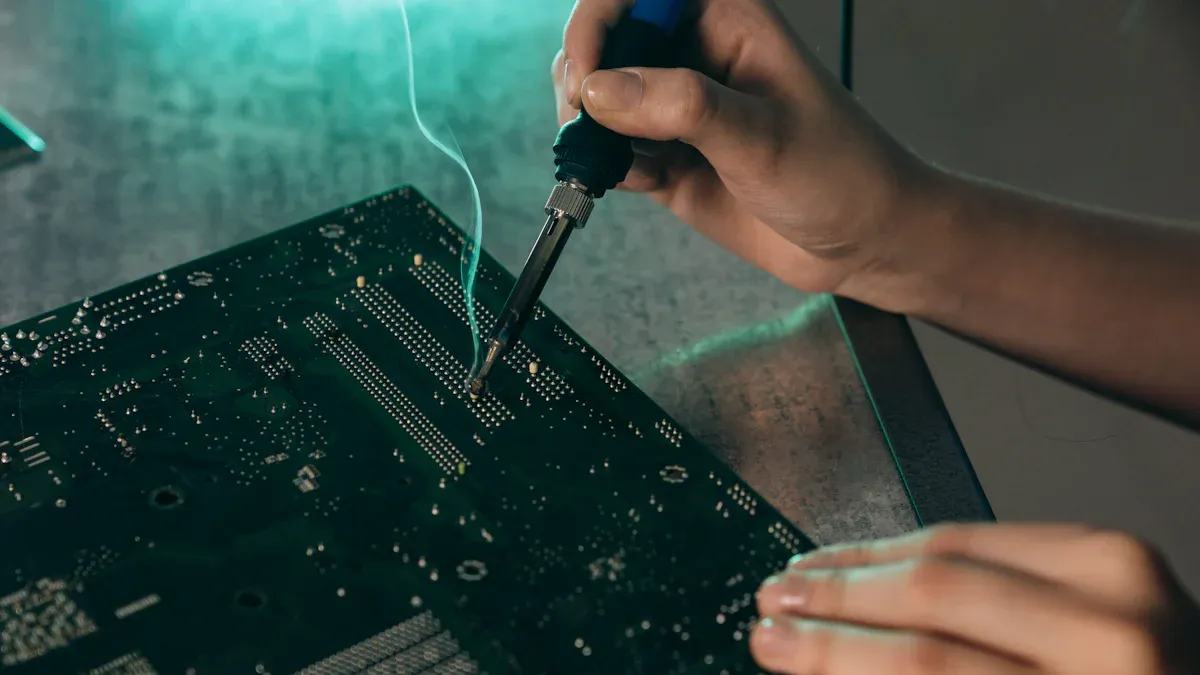

Manual Soldering for Special Parts

Some parts, like connectors or big transformers, can’t use machines. For these, manual soldering is needed. This step needs care to avoid damaging the board or parts.

Use a soldering iron with temperature control to avoid overheating.

Add just enough solder to stop bridges between leads.

Check each joint to make sure it’s shiny and solid.

Pro Tip: Practice soldering on old boards before working on real ones. This helps you get better and avoid mistakes.

Manual soldering is great for tricky or delicate parts that need extra attention.

Testing and Inspection in the PCB Assembly Process

Testing and checking are very important in making sure pcb assemblies work well. Finding problems early and checking performance helps create high-quality boards that follow industry rules. Let’s look at the main ways to test and inspect.

Automated Optical Inspection (AOI)

AOI is one of the first checks in the pcb assembly process. It uses cameras to find problems like bad soldering, missing parts, or misaligned pieces. The system compares the board to a set standard to ensure it’s correct.

AOI is fast and accurate, making it better than manual checks. It catches mistakes early, which improves success rates and reduces the need for fixes.

Tip: Keep the AOI system updated with design changes. This helps find real problems and avoids false alarms.

X-Ray Inspection for Hidden Defects

X-ray inspection finds hidden problems in the pcb assembly process. It’s great for parts like BGAs, where solder joints are hard to see. X-rays create images of the inside of the board.

This method shows issues like gaps, solder bridges, or misaligned parts. It ensures even complex boards meet quality standards. X-ray inspection is especially useful for dense or multilayer boards.

Functional Testing and Circuit Validation

Functional testing is the last step in the pcb assembly process. It checks if the board works as it should in real-life conditions. This includes testing how the board performs and if it’s reliable.

Tests include checking individual parts and the whole circuit. The first batch is inspected to make sure it matches the design before making more. This step is key to ensuring the product works well and satisfies customers.

Why It’s Important | |

|---|---|

Tracking defects | Fixes problems early |

Stable processes | Ensures smooth and reliable production |

First-pass success | Shows better quality and fewer errors |

Customer feedback | Reflects how well the product performs |

Long-term testing | Confirms the product lasts over time |

Performance tracking | Helps improve reliability |

Benefits | Less fixing, better results, and compliance |

Using these testing and inspection methods makes pcb assemblies more reliable and ensures customers get great products.

Final Steps in PCBA Manufacturing and Assembly

Cleaning and Removing Residues

Cleaning is very important in making PCBAs. Leftover flux or solder paste can cause problems. Special cleaning methods remove these residues completely.

Modern systems use heat, pressure, and flow to clean well. For example:

Cleaning Step | What It Does |

|---|---|

Temperature Control | Keeps heat steady for even cleaning. |

Pressure Adjustment | Makes sure sprays clean with enough force. |

Flow Management | Creates movement to clean without breaking tools. |

Changes based on residue type; may need extra rinses. | |

Cleaning Agent Levels | Keeps chemicals at the right amount for each residue. |

Follow these steps to make sure your PCBAs are clean and work well.

Labeling and Traceability

Labeling helps track PCBAs during their use. Systems like RFID store product and manufacturing info on the PCB. This helps find bad parts quickly.

Benefits of traceability include:

Better tracking systems for quality checks.

Faster production and improved product reliability.

Fewer fake parts in the supply chain.

Traceability also helps meet rules like RoHS and WEEE. It creates records for audits and ensures eco-friendly practices.

Packaging and Shipping

Good packaging protects PCBAs during shipping. Using anti-static materials and strong packaging stops damage. These methods have cut shipping damage by 24% and saved 5% on costs.

Automation helps check PCBAs meet standards and speeds up shipping. These steps improve reliability and ensure customers get high-quality products.

Following the steps for PCBA manufacturing helps make great products. Each part, from design to packaging, is important for strong and reliable PCBAs.

Why it matters:

Good planning lowers mistakes and speeds up work.

Testing finds problems and makes products better.

Cleaning and tracking keep products lasting longer and follow rules.

Use these tips in your projects to stay ahead in the fast-changing electronics world. Improve your process now to create amazing products in the future!

FAQ

What is the difference between SMT and THT in PCBA assembly?

SMT places parts on the PCB’s surface. THT puts parts into drilled holes. SMT is quicker and works for small designs. THT makes stronger connections for high-power or stressed parts.

Why are DFM and DFA checks important in PCBA manufacturing?

DFM makes sure your PCB design is easy to produce. DFA helps make assembly simpler and faster. Both lower mistakes, cut costs, and improve product quality.

How does reflow soldering work in the SMT process?

Reflow soldering heats the PCB in a special oven. The solder paste melts and connects parts to the board. Controlled heat stops damage and ensures strong solder joints.

What is the purpose of AOI in the inspection process?

AOI uses cameras to find problems like missing parts or bad soldering. It checks the PCB against a standard to ensure accuracy. This reduces errors and avoids manual inspections.

How does traceability improve PCBA quality?

Traceability records each PCBA’s production details. It finds faulty batches, follows rules, and blocks fake parts. This boosts reliability and builds customer trust.

Tip: Keep your traceability system updated with design or process changes for better tracking.

See Also

Understanding The Key Stages Of PCBA Production

Exploring The SMT Process In PCBA Assembly

A Detailed Walkthrough Of PCBA Manufacturing Steps