Printed circuit board assembly (PCBA), which refers to the process of adding parts to a plain PCB, is essential in electronics. This transformation turns the board into a crucial component of the devices we use daily, such as phones and medical tools. In 2021, the PCB market was valued at $75 billion, highlighting the significance of PCBA meaning in electronics for modern technology. Special inspection tools are employed to quickly check many parts, enhancing the performance and longevity of devices.

Key Takeaways

PCBA turns a simple PCB into a working part by adding pieces like resistors and chips, helping devices work.

The PCBA process makes production faster and more precise, so factories can make many devices quickly and dependably.

Quality tests, like Automated Optical Inspection, check that PCBA is done well, lowering mistakes and making devices more reliable.

What Is PCBA and How Does It Differ from PCB?

PCB: The base of electronic devices

A printed circuit board (PCB) is the base for most electronics. It holds and connects parts in an organized way. Think of it as the skeleton that keeps everything together. PCBs are made from strong materials like fiberglass or plastic. These materials are covered with copper, which creates paths for electricity to move between parts.

Without a PCB, devices would need messy wires that might fail. PCBs make gadgets smaller and more reliable. From phones to computers, every electronic device starts with a PCB.

PCBA: The complete and working board

A PCB is just an empty board, but a printed circuit board assembly (PCBA) is finished and ready to work. It has all the parts, like resistors and chips, attached to it. This turns the plain board into a working piece of a device.

Making a PCBA involves adding parts and securing them with solder. After assembly, it is tested to ensure it works correctly. A PCBA acts like the “brain” of a device, helping it do tasks. For example, in a phone, the PCBA handles data, connects to networks, and powers the screen.

Main differences between PCB and PCBA

Though PCB and PCBA are connected, they are not the same. Here are the main differences:

Definition: A PCB is just the board with copper paths. A PCBA has all the parts added and ready to work.

Functionality: A PCB cannot do anything alone. A PCBA can work as part of a device.

Manufacturing stage: A PCB is made early in production. A PCBA is made later and is ready to use.

Complexity: A PCB is simple to make. A PCBA needs more steps like soldering and testing.

Knowing these differences shows how both are important in making electronics. The PCB starts the process, while the PCBA makes the device work.

Why Is PCBA Important in Electronics Manufacturing?

Making electronic devices work properly

PCBA is crucial for making devices function. Without it, a PCB is just an empty board. Adding parts like resistors and chips makes the board useful. This process helps devices do their jobs. For example, in a smartphone, the PCBA lets it process data, connect online, and show pictures. By putting the right parts together correctly, PCBA ensures devices work well and last long.

Helping make many devices quickly

Electronics need to be made fast and accurately. PCBA makes this possible. Machines place parts on boards with great precision. This lets factories produce thousands of devices quickly. Ever wonder how gadgets are made so fast? PCBA is the reason. It cuts mistakes, saves time, and keeps all devices the same. This is why electronics are affordable and easy to find.

Supporting new technology

PCBA helps create advanced gadgets. It allows engineers to build things like smartwatches and drones. Using special methods, PCBA makes smaller and faster devices possible. Think about how quickly technology improves. PCBA plays a big role in that. It helps turn new ideas into real products, pushing technology forward.

The PCBA Process: Key Steps Explained

Solder paste application

The first step in the pcba process is adding solder paste. Solder paste is a mix of tiny solder bits and flux. This mix helps parts stick well to the printed circuit board. A stencil is used to place the paste on copper pads. Only areas where parts will go get the paste.

Applying solder paste correctly is very important. The size of the solder powder and the amount of paste matter a lot. Studies, like Size Matters – The Effects of Solder Powder Size on Solder Paste Performance, show that small electronics need precise paste placement. Careful work here lowers mistakes and makes the assembly better.

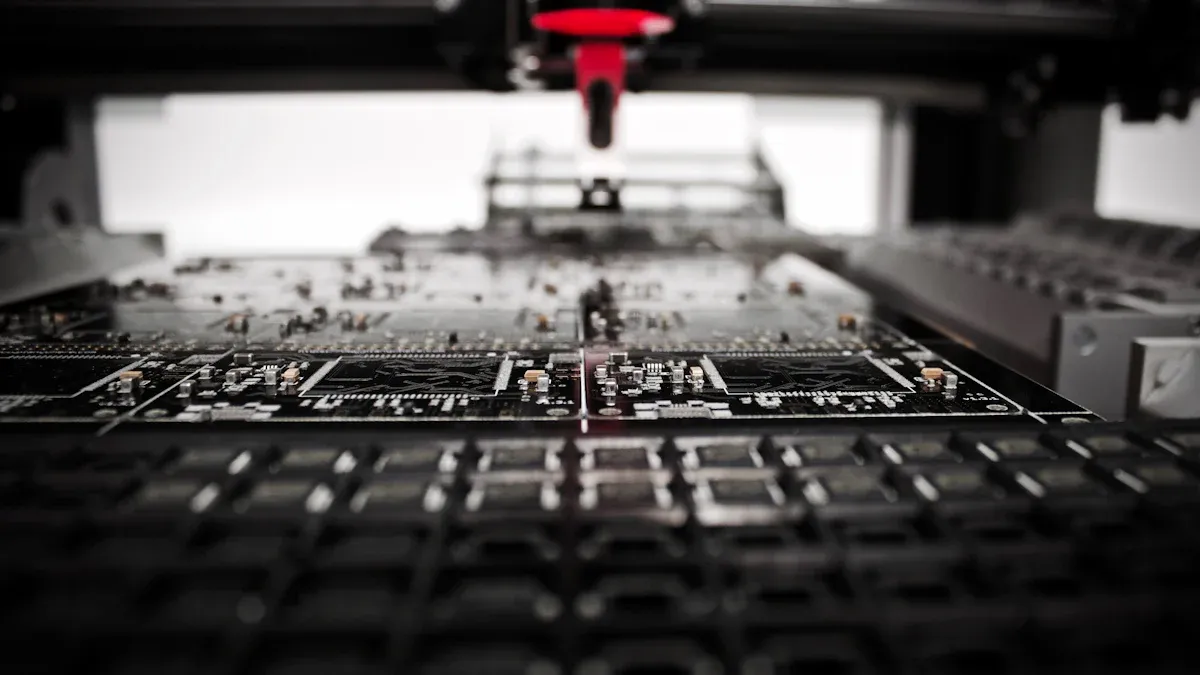

Component placement

After the solder paste is added, parts are placed on the board. Machines called pick-and-place systems do this job. These machines put parts like resistors and chips in the right spots. As a circuit board assembler, you make sure every part lines up with the paste.

Placing parts correctly is very important. If parts are not aligned, the device might not work. Research, like Improve SMT Assembly Yields Using Root Cause Analysis in Stencil Design, shows this step is key for good results. Using advanced machines helps avoid mistakes and speeds up production.

Reflow soldering

Reflow soldering attaches parts to the board. After placing parts, the board goes through a reflow oven. The oven heats the solder paste until it melts and then cools it. This creates strong connections between parts and the board.

This step is crucial for making the printed circuit board assembly last. The oven’s heat must be just right to avoid problems. Proper reflow soldering ensures strong connections and fewer defects.

Inspection and testing

Inspection and testing check the quality of the pcba process. Automated Optical Inspection (AOI) finds problems like missing parts or solder errors. X-ray inspection looks for hidden issues, like gaps in solder joints. Functional tests make sure the printed circuit board assembly works properly.

Data shows these methods work well. AOI finds 95% of defects, cutting down on rework costs. X-ray inspection catches 98% of hidden problems. These checks ensure the final product is high quality.

Final assembly and quality control

The last step in the pcba process is putting everything together. After testing, the printed circuit board assembly is added to the device. This includes connecting it to parts like screens or batteries. Quality control tests, like environmental stress screening (ESS), check if the device works in tough conditions.

Metrics help measure success. High First Pass Yield (FPY) means most devices pass tests the first time. A low defect rate shows good manufacturing. By focusing on these, you deliver reliable devices to customers.

Metric | Description |

|---|---|

First Pass Yield (FPY) | Shows how many products pass testing the first time. |

Defect Rate | Percentage of products with problems. Lower is better. |

Return Rate | Products sent back by customers. High rates show issues. |

Failure Rate | How often products fail during use. Lower is better. |

Reliability Metrics | Includes MTBF and MTTR to check product reliability. |

Cost of Quality (COQ) | Tracks costs for quality checks and fixing problems. |

Process Capability Index | Measures how stable and consistent the process is. |

By following these steps, the printed circuit board assembly meets high standards and works well in modern devices.

PCBA changes simple boards into working parts for devices. It helps gadgets work better and last longer. By adding parts, it boosts efficiency and makes products more reliable. This process is key to improving modern electronics.

Aspect | How It Helps Electronics Work Better |

|---|---|

Combining Parts | Puts many parts together in one device |

Better Efficiency | Makes devices work faster and use less energy |

Stronger Quality | Ensures gadgets are dependable and work well |

FAQ

What does PCBA do in making electronics?

PCBA turns a simple PCB into a working part. It helps devices work well and meet high-quality needs in electronics.

How does PCBA make devices more reliable?

PCBA makes devices stronger by attaching parts securely. It also tests them carefully to avoid problems and keep them working.

Why is checking important in the PCBA process?

Checking finds mistakes early in the process. Tools like AOI and X-ray help ensure quality, save time, and make things better.

See Also

Understanding PCBA: Its Importance in Electronic Devices

Defining PCBA: Significance in the Electronics Industry

Exploring PCBA: A Comprehensive Explanation of Its Meaning