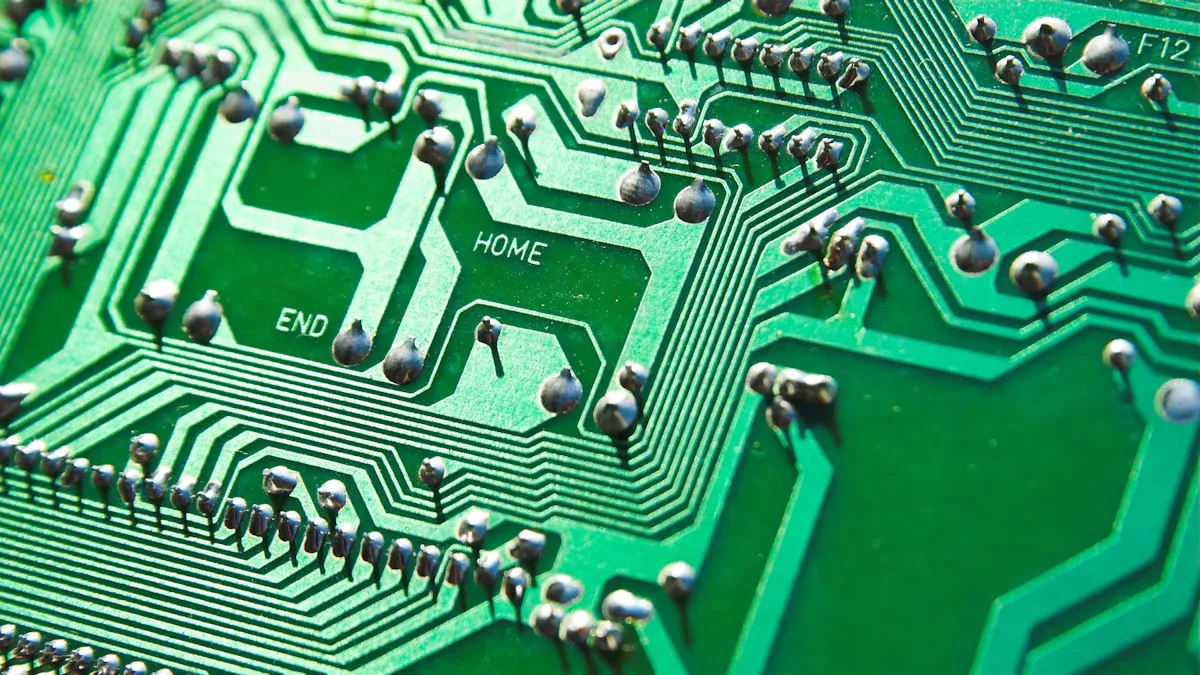

Printed Circuit Board Assembly, or PCBA, stands for the process of adding and soldering components onto a circuit board to make it functional. This essential step transforms a bare board into a working device that powers everyday technology.

PCBA stands for a significant advancement in modern electronics, as it greatly enhances production efficiency and quality. By streamlining the process, it saves costs and minimizes errors. Companies adhering to strict standards, such as achieving a 96% success rate, experience substantial improvements in their operations. These advancements result in faster innovation and more reliable products.

Key Takeaways

PCBA means Printed Circuit Board Assembly. It turns a plain PCB into a working device by adding parts.

The PCBA process makes production faster, lowers costs, and makes products more reliable with careful assembly and testing.

Knowing the difference between PCB and PCBA is important. PCB is just the board, but PCBA is the full assembly that makes devices work.

PCBA is important in many fields like electronics, cars, medical tools, and space tech. It helps make devices safe and useful.

The PCBA market is growing fast because of new technology and the need for smaller, smarter gadgets.

What PCBA Stands For

Definition of PCBA

PCBA means Printed Circuit Board Assembly. It is the process of putting electronic parts onto a circuit board to make it work. This changes a plain PCB into a working PCBA that powers many devices you use every day. PCBA acts as a link between design and working electronics in manufacturing.

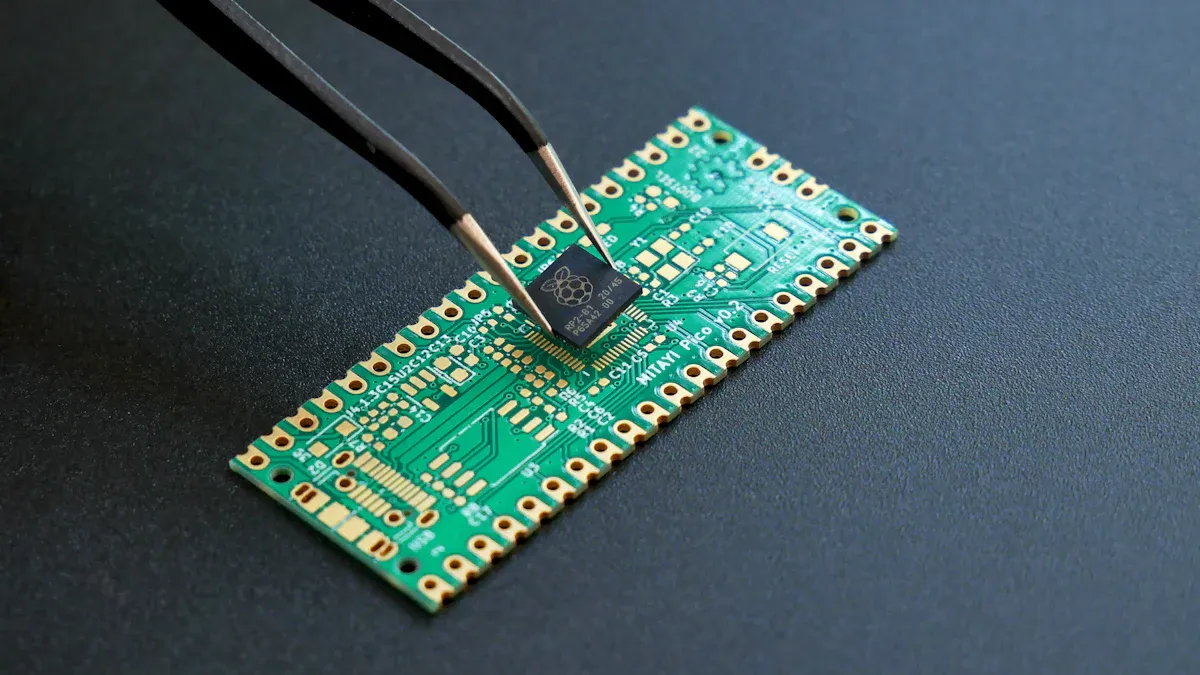

The PCBA process has steps like placing parts, soldering, and testing. These steps make sure each board works well and meets quality rules. Using machines for assembly makes it more accurate and reliable than doing it by hand. This makes PCBA very important in making modern electronics.

Components of a Printed Circuit Board Assembly

A PCBA has important parts that work together to do specific jobs. These parts include:

Resistors: Manage how much electrical current flows.

Capacitors: Hold and release electrical energy when needed.

Diodes: Let current flow one way but block it the other way.

Integrated Circuits (ICs): Tiny circuits that do complex tasks.

Connectors: Link signals and power between board parts.

Each part is chosen based on what the device needs. Tools like the BOM Portal help engineers pick and manage these parts. For example, the BOM tool can suggest cheaper or better parts. This helps make sure the PCBA meets both technical needs and budget limits.

Overview of the Assembly Process

The PCBA process turns a simple PCB into a working PCBA. Here are the main steps:

Solder Paste Application: A stencil puts solder paste on areas where parts go.

Component Placement: Machines place parts on the board very accurately.

Reflow Soldering: Heat melts the solder paste to hold parts in place.

Inspection and Testing: Checks ensure the board works and meets standards.

Final Assembly: Extra parts are added, and the board gets final tests.

Using machines for PCBA saves time and money. It also makes sure solder joints are the same quality. Double-sided mounting allows smaller and lighter designs. These features make PCBA key for making reliable and efficient electronics.

The PCBA market is growing fast. By 2034, it could grow from $39.44 billion in 2024 to $55.33 billion. This shows how more industries need advanced electronics.

How PCBA Differs from PCB

Definition of PCB

A PCB, or Printed Circuit Board, is the base of electronics. It is made of a flat material, often fiberglass, with copper lines. These copper lines let electricity move between parts. A PCB alone cannot do anything until parts are added. Think of it as a blank sheet waiting for a drawing.

Making PCBs is simple and cost-effective. The design is printed, and copper is shaped into circuits. This easy process keeps costs low. But without parts, a PCB is just a passive board.

Definition of PCBA

PCBA, or Printed Circuit Board Assembly, is the next step. It adds and connects electronic parts to the PCB. This turns the PCB into a working PCBA that powers devices like phones and computers.

The PCBA process has steps like adding solder paste, placing parts, and heating them. Each step ensures the board works well and meets quality rules. Unlike a PCB, a PCBA is active and ready to use in devices.

Key Differences Between PCB and PCBA

PCB and PCBA sound alike but have different roles. Here’s how they differ:

Aspect | PCB | PCBA |

|---|---|---|

Complexity | Simple design | Complex with many parts |

Cost | Cheaper | Costs more due to assembly |

Manufacturing Process | Easy to make | Needs careful assembly |

Performance Impact | No real function | Fully functional with parts |

A PCB is like the frame of a device, while a PCBA is the finished product. Adding parts makes the board work but also increases cost and complexity. For example, a PCB only has copper lines, but a PCBA has resistors, capacitors, and chips working together.

Tests show how PCBs and PCBAs perform differently. For example, tests check how long a PCBA lasts and how well it works. These tests ensure the PCBA meets expectations and works in real-life situations.

Knowing these differences helps you see why PCBA is so important. A PCB gives the structure, but PCBA makes it a working device you use every day.

Why PCBA Matters

Role in Modern Electronics

PCBA is very important in making electronics work. It changes a plain PCB into a working part of devices like phones, computers, and medical tools. Without PCBA, modern gadgets would not exist as they do now. Adding parts to the board makes sure devices work well and last long. Machines like Surface-Mount Technology (SMT) help make this process accurate and reduce mistakes. This accuracy is key for building high-quality electronics that people need today.

Ensuring Efficiency and Reliability

PCBA makes electronics faster to build and more reliable. Machines handle tasks like soldering and placing parts, saving time and money. This also makes the final product better. For example:

PCBA places parts exactly where they should go.

Good connections improve how well devices work.

Testing by machines finds problems early, so fixes are easier.

Numbers like First Pass Yield (FPY) and defect rates show these benefits. FPY counts how many products pass tests the first time. Defect rates show where things can get better. These numbers prove PCBA helps make better and faster products.

Contribution to Technological Advancements

PCBA helps make smaller, lighter, and stronger devices. Tiny designs let companies build small gadgets without losing power. For example, flexible PCBs make devices lighter and easier to carry. Stronger materials help gadgets last longer and handle tough conditions. These changes make electronics last longer and need fewer repairs. By improving how PCBA works, it has helped create amazing new technologies in fields like healthcare, cars, and space travel.

Applications of PCBA

Consumer Electronics

PCBA is key to gadgets like phones, laptops, and watches. It helps these devices work well and last long. Adding parts like resistors and circuits makes electronics small but powerful. These devices can fit in your pocket or on your wrist.

Smaller and smarter designs are growing the PCB market.

The global PCB market may grow from $78.5 billion in 2023 to $120 billion by 2032.

Smart gadgets and IoT tech increase the need for advanced PCBs.

PCBA helps make devices smaller, faster, and more dependable.

Tip: When using your phone or watch, thank PCBA for its magic.

Automotive Industry

PCBA turns cars into smart machines. It powers systems like EV batteries, ADAS, and displays. The process ensures these systems work safely and efficiently.

Evidence Description | Impact on Automotive Electronics Performance |

|---|---|

Shows PCBs are vital for better performance with advanced systems. | |

Need for advanced systems in EVs and ADAS | Proves PCBs are key for safer and smarter vehicles. |

Miniaturization and smart tech integration trends | Highlights the need for advanced PCBs in modern cars. |

Safety and emissions rules | Pushes demand for reliable and complex PCBs in vehicles. |

PCBA ensures your car’s electronics are safe, efficient, and ready for today’s roads.

Medical Devices

PCBA is vital in life-saving medical tools. It powers devices like MRI machines, CT scanners, and health monitors. The process ensures accurate results and reliable treatments.

High-quality PCBs send clear signals for better diagnostics.

Smaller designs make devices easy to carry and use.

IoT connections allow real-time tracking, improving healthcare.

PCBA also meets strict safety rules to protect patients. From heart monitors to robotic surgery tools, PCBA makes these devices trustworthy and effective.

Note: PCBA doesn’t just power gadgets; it powers life-saving tools.

Industrial and Aerospace Applications

PCBA is very important in industrial and aerospace systems. These areas need electronics that work in tough conditions. The process ensures each board meets strict quality rules.

In factories, PCBA powers machines, robots, and control systems. For example, plants use PCBAs to automate production lines. The process makes sure boards handle heavy tasks without breaking. PCBAs are found in sensors, motor controllers, and power units. These parts help factories work smoothly.

In aerospace, the needs are even tougher. Planes and spacecraft need boards for harsh environments. Advanced methods make strong and light PCBAs. These boards control navigation, communication, and safety systems. Satellites use PCBAs to manage power and send data. Without PCBA, space missions wouldn’t be possible.

The PCBA process includes careful testing. This ensures boards work well under pressure. In aerospace, one failure can cause big problems. That’s why every step focuses on accuracy and quality.

Did you know? Flexible PCBs are often used in aerospace. These boards bend easily, fitting tight spaces in planes and spacecraft.

Industrial and aerospace uses show why PCBA matters. It turns a plain PCB into a reliable, working part. This technology helps industries create the future.

PCBA, or Printed Circuit Board Assembly, turns a plain PCB into a working device. This process makes sure it is precise, reliable, and meets quality rules like ISO 9001. A PCB is just the base, but PCBA adds parts to make it work as a system.

Better multilayer PCB designs.

Use of AI and IoT in devices.

Eco-friendly manufacturing methods.

From running phones to helping space technology, PCBA pushes progress. It helps make fast, powerful devices and shows why it’s key for future electronics.

FAQ

What is the difference between SMT and THT in PCBA?

SMT means placing parts on the board’s surface. THT means putting parts through holes in the board. SMT works faster and fits smaller designs. THT makes stronger connections, great for tough uses.

Tip: Pick SMT for small gadgets and THT for strength.

How does PCBA testing ensure quality?

PCBA testing finds problems and checks if boards work well. Tests like AOI, X-ray, and functional tests are common. They check soldering, part placement, and performance to meet quality rules.

Note: Testing stops problems and makes devices more reliable.

Can PCBA be eco-friendly?

Yes, eco-friendly ways include lead-free solder, recycling, and saving energy. These steps lower harm to the planet but keep quality high.

♻️ Eco Tip: Choose PCBAs with RoHS labels for greener tech.

Why is reflow soldering important in PCBA?

Reflow soldering melts paste to hold parts on the board. It makes strong connections and speeds up production. This step is key for making good, lasting electronics.

Fun Fact: Reflow ovens can heat up to 250°C or more!

How do you choose components for a PCBA?

Engineers use a BOM to pick parts. They check cost, availability, and how well parts work. BOM tools help find the best options for the design and budget.

Pro Tip: Always check if parts match your PCB design.

See Also

Understanding PCBA: Definition and Its Significance in Electronics

PCBA Defined: Its Importance and Function in Electronics

Exploring PCBA Services: Their Importance in Electronics Production

Defining PCBA: Understanding Its Role in Electronic Devices

Decoding PCBA: Significance and Meaning in Electronics Industry