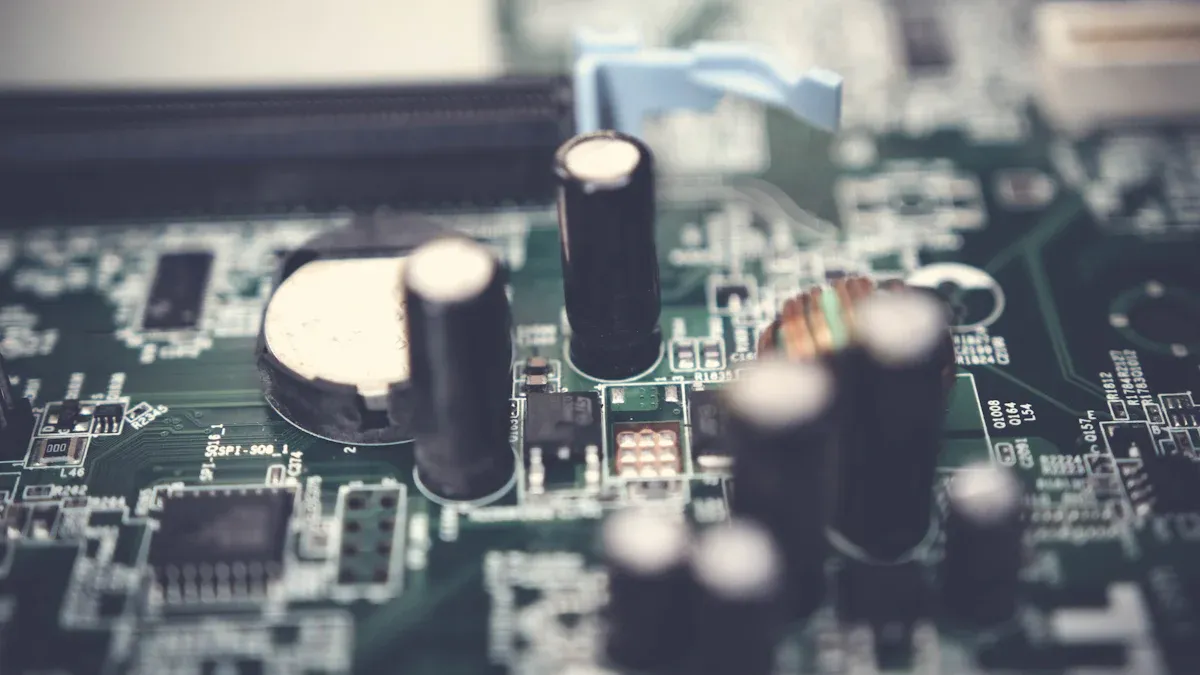

A printed circuit board (PCB) serves as the foundation of electronics. It is a flat board constructed from non-conductive materials, with thin metal paths added to its surface for connections. However, on its own, a PCB cannot function or perform any tasks. This is where printed circuit board assembly (PCBA) comes into play. A PCBA is essentially a PCB that has been equipped with components such as resistors and chips, transforming it into a functional and useful device.

The distinction between PCBA vs PCB is straightforward. A PCB acts like the framework of a circuit, while a PCBA represents the complete, operational system. This evolution in electronics manufacturing has significantly accelerated industry growth. For instance, the wireless technology sector is expanding at a rate of approximately 6% each year.

Key Takeaways

A PCB is a flat board with copper paths. A PCBA is a PCB with parts added to make it work.

There are different PCB types like single-layer, double-layer, and flexible ones. Each type is made for specific uses.

Making a PCBA involves steps like heating, soldering, and testing. These steps make sure the board works well.

Testing is very important in PCBA. It helps find problems early so devices are safe and work properly.

Many industries, like electronics, cars, and healthcare, use PCBs and PCBAs for their modern devices and tools.

Understanding PCB (Printed Circuit Board)

What is a PCB?

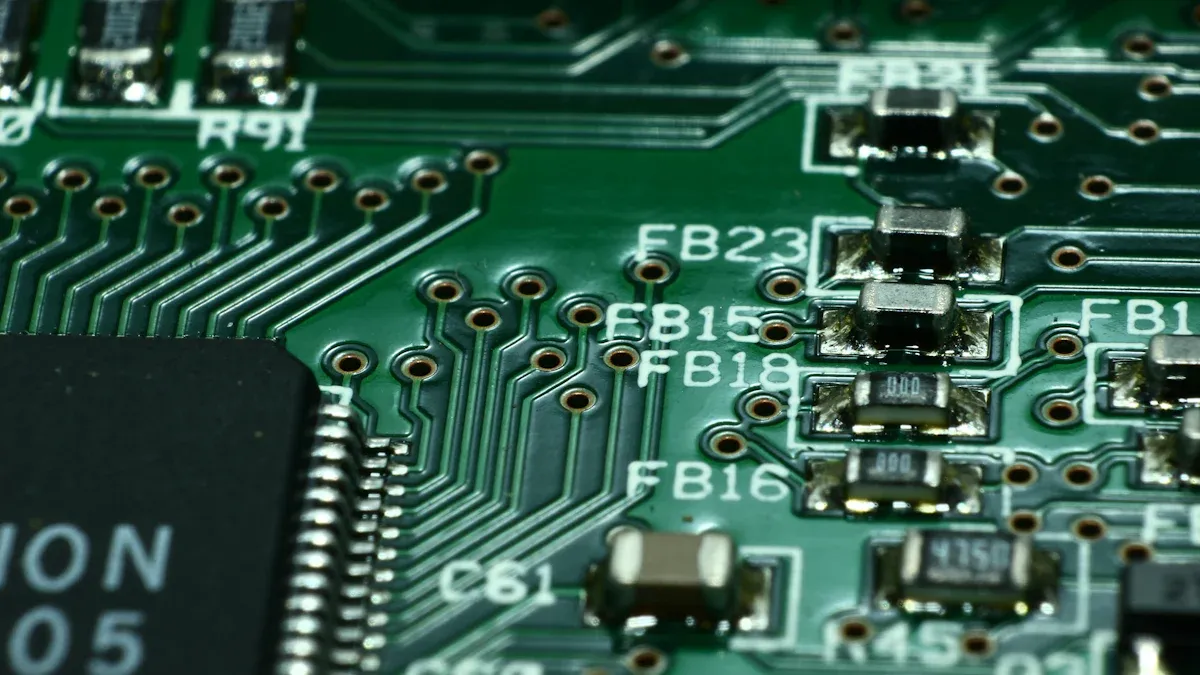

A printed circuit board (PCB) is the base of electronics. It connects parts using copper pathways, pads, and features. These pathways let electricity flow through the circuit. A PCB has layers like a base, copper, solder mask, and silkscreen.

PCBs are made from strong materials like FR4 laminates. These laminates use glass fibers for strength. The resin, often FR4, gives the board its properties. For example:

Prepreg layers, made of resin and glass fibers, set thickness and performance.

Engineers use tools to improve PCB designs. They check for signal issues and fix problems like crosstalk.

Different Types of PCBs

There are many types of PCBs for different uses:

Single-layer PCBs: One copper layer, used in simple devices like calculators.

Double-layer PCBs: Two copper layers, found in devices like power supplies.

Multilayer PCBs: Three or more layers, used in phones and computers.

Rigid PCBs: Hard boards, used in cars and other tough environments.

Flexible PCBs: Bendable boards, great for wearable gadgets.

Rigid-flex PCBs: Mix of hard and bendy parts, used in airplanes.

Each type fits specific needs based on the device’s complexity.

How PCBs Are Used in Electronics

PCBs are vital in many devices. For example:

Consumer Electronics: Phones, laptops, and TVs need PCBs to work.

Automotive Industry: PCBs manage engines and navigation systems.

Medical Devices: Machines like MRI scanners and pacemakers use PCBs.

Industrial Applications: PCBs are key in robots and factory machines.

Engineers face challenges when testing PCBs, like short circuits. Fixing soldering issues can stop these problems. Careful design and testing make PCBs work better.

Understanding PCBA (Printed Circuit Board Assembly)

What is PCBA?

PCBA means adding parts to a circuit board. This step changes the board into something that works. Parts like resistors and chips are added using special methods. These methods include surface mounting or through-hole mounting. They make sure parts stay in place and work well.

A plain circuit board is just the base. PCBA adds the parts needed to make it work. This process is key for making devices used in electronics, cars, and healthcare.

Steps in the PCBA Process

The PCBA process has many steps to make it work right. Here’s a simple list:

Process Step | Description |

|---|---|

Preheat ramp | Slowly heats the board to remove water and activate flux. |

Thermal soak | Makes the board’s temperature even for better soldering. |

Reflow peak | Melts solder to stick parts firmly. |

Cool down | Quickly cools to stop solder problems. |

Post SMT Cleaning | Cleans off leftover dirt or chemicals. |

AOI Inspection | Uses machines to find mistakes in the assembly. |

Conformal Coating | Adds a layer to protect the board from damage. |

Functional Testing | Checks if the board works as it should. |

Process Auditing | Makes sure the board meets quality rules. |

Traceability | Gives each board a code to track it. |

Each step helps make sure the board is good and works well.

Importance of PCBA in Electronics

PCBA is needed to turn a plain board into a working device. Without it, devices would not work. Testing during PCBA finds and fixes problems early. This makes the product safer and lasts longer. Tests like in-circuit and functional testing help avoid big problems later.

Functional testing checks if the PCBA works in real-life situations. This step makes sure customers are happy and the product is high quality.

PCBA is more than just putting parts together. It shows how design and technology have improved. Knowing about PCBA helps you see how it turns a simple board into the heart of modern devices.

PCBA vs PCB: Key Differences

Structural Differences

The structural differences between PCB and PCBA are easy to see. A PCB is a flat board made of fiberglass or resin. It has copper lines for electricity but no parts attached. A PCBA, however, has all the needed parts like resistors and chips. These parts are added to the PCB, making it work as a complete unit.

Here’s a simple comparison of their structures:

Aspect | PCB | PCBA |

|---|---|---|

Components | None (just the board) | Fully built with electronic parts |

Layers | Copper lines and base material | Copper lines, base, and added components |

Purpose | Acts as a base for parts | Works as a complete electronic system |

Functional Differences

The jobs of a PCB and PCBA are very different. A PCB is just a base for electrical connections. It cannot do anything by itself. A PCBA, on the other hand, is a working system that performs tasks. For example:

A plain PCB might be used for testing ideas.

A PCBA powers devices like phones and medical tools.

The way a PCBA is made affects how well it works. Surface Mount Technology (SMT) helps make small, efficient designs. Through-Hole Technology (THT) is stronger and better for high-power uses.

Tip: How you assemble a PCBA affects how long it lasts. Picking the right method improves performance.

Manufacturing Processes

Making a PCB and a PCBA involves different steps. A PCB is made by adding copper lines to a base and covering it with a protective layer. This creates paths for electricity. Making a PCBA means adding and attaching parts to the PCB. This step turns the board into a working system.

Here are common ways to assemble a PCBA:

Surface Mount Technology (SMT): Great for small, fast-made circuits.

Through-Hole Technology (THT): Best for strong, stable designs.

Mixed Technology: Combines SMT and THT for complex needs.

Ball Grid Array (BGA): Helps with heat control and strong connections for advanced devices.

Where you make your PCBA also matters. China is cheaper for large orders. The U.S. offers better quality and protects ideas better.

Cost and Lead Time in PCB and PCBA

Cost Factors in PCB Fabrication

The price of making a PCB depends on many things. The material used is very important. Common materials like FR4 are cheaper, but special ones cost more. Complex designs also raise the price. For example, boards with many layers or tricky layouts need extra work. Special steps, like tiny trace widths or unique finishes, add to the cost too.

Here’s a simple list of what affects PCB costs:

Factor | Description |

|---|---|

Material Costs | Different materials have different prices. |

Manufacturing Complexity | More layers or tricky designs cost more. |

Special Processing Requirements | Extra steps for special designs increase costs. |

Shipping Costs | Bigger boards cost more to ship. |

Trace Width and Spacing | Tiny traces need advanced tools, which cost more. |

Drill Hole Size and Quantity | Smaller holes need precise tools, raising costs. |

Surface Treatment | Special finishes can make the board more expensive. |

Copper Thickness | Thicker copper uses more material, increasing the price. |

Planning your design well can help lower these costs.

Cost Factors in PCBA Assembly

The cost of PCBA assembly comes from many parts. Materials, like the board and components, are the biggest expense. Sometimes, the bill of materials (BOM) makes up 95% of the total cost. Other costs include labor, machines, and quality checks.

Here’s what affects PCBA assembly costs:

Cost Factor | Description |

|---|---|

Material Costs | Includes the board and all the electronic parts. |

Labor Costs | Covers workers, machine operators, and inspections. |

Equipment and Overhead Costs | Includes machine upkeep and factory expenses. |

Testing and Quality Control Costs | Makes sure the assembly works well. |

Setup and Tooling Costs | Initial setup for machines and stencils adds to costs. |

Shipping and Handling | Covers moving parts and finished boards. |

To save money, you can use cheaper parts, automate assembly, or pick alternative components.

Lead Time Comparison

The time to make a PCB or PCBA is different. Making a PCB is faster because it’s just the board. But complex designs or special steps can take longer. PCBA takes more time since it includes adding parts, testing, and sourcing components.

Things that affect lead time include:

Board Complexity and Size: Bigger or more detailed boards take longer.

Component Types and Quantity: Rare parts can delay the process.

Production Volume: Large orders need more time.

Turnaround Time: Faster delivery costs more.

Quality Requirements: Extra testing adds time but ensures reliability.

By planning carefully, you can save both time and money.

Design Steps for PCB and PCBA

PCB Design and Testing

Making a good PCB starts with clear planning. Set clear goals early so everyone knows the plan. A strong design helps avoid mistakes and meets all needs. Planning the system connects ideas to real work. A detailed layout helps reduce errors.

Testing early with prototypes is very important. It helps find problems before making many boards. Follow these tips during design and testing:

Focus on safety and reliability to ensure the PCB works well.

Test the board to check if it meets user needs.

Use quality checks during production to keep it consistent.

These steps help you create a strong PCB for your project.

Moving from PCB to PCBA

Turning a PCB into a PCBA means adding parts to it. This step makes the PCB a working board. Parts are added using surface mounting or through-hole methods. Surface mounting is great for small designs. Through-hole mounting is better for strong, high-power boards.

To make this process smooth, use good-quality parts. Make sure parts are placed correctly during assembly. Testing at this stage finds mistakes early. This ensures the PCBA works properly and meets standards.

Testing and Quality Checks

Testing and quality checks are key to making sure PCBs and PCBAs work well. Different tests check if the final product is reliable. For example:

Test Type | What It Checks |

|---|---|

Electrical Performance | Tests how well the PCB handles electricity. |

Temperature Changes | Checks if the PCB can handle hot and cold changes. |

Long-Term Heat Resistance | Tests if the PCB works under long heat exposure. |

Sudden Temperature Shifts | Checks if the PCB survives quick temperature changes. |

Other tests, like in-circuit testing, find broken connections. Looking at the board closely ensures parts are placed and soldered right. These steps catch problems early. By focusing on quality, you can make a PCBA that works well and satisfies users.

Applications of PCB and PCBA in Industries

Consumer Electronics

PCBs and PCBAs are key in consumer electronics. They are the base for gadgets like phones, laptops, and smartwatches. These boards allow small designs and efficient circuits, which modern devices need. Asia-Pacific leads this market, holding over 60% of the share for consumer electronic PCBA boards. By 2028, the global market for these boards may reach USD 350 billion, growing 7.5% yearly. This growth comes from demand for high-density PCBs, 5G, and IoT devices.

Tip: Design PCBs for gadgets with small size and low energy use.

Automotive Industry

Cars depend on PCBs and PCBAs for advanced systems. These include electric engines, entertainment systems, and driver-assist features. Electric and self-driving cars need strong PCB designs. More electrification means PCBs must handle tougher conditions. But, solder joints can weaken under heat stress, so materials must be chosen carefully. For example, solder must balance strength and flexibility to handle temperature changes.

Key Aspect | Description |

|---|---|

Increased Reliability | Electric cars need stronger PCB assemblies. |

Solder Joint Challenges | Regular solder may fail under high heat and stress. |

Critical Material Choices | Materials must handle stress and temperature shifts well. |

Fixing these issues ensures PCBs meet car industry standards.

Medical Devices

PCBs and PCBAs are vital in medical tools like scanners, pacemakers, and imaging machines. These devices need to be precise, safe, and reliable. Rules like FDA standards in the US and ISO 13485 worldwide ensure medical PCBs are high quality. Accurate diagnostics and fast data rely on good circuits. Energy-efficient designs also make devices last longer, helping patients better.

Regulatory Standard | Region/Scope |

|---|---|

FDA regulations | US |

CE marking | Europe |

ISO 13485 | International |

IEC 60601 | Electrical safety |

Note: Focus on safety and follow rules when designing medical PCBs for reliability.

Industrial Applications

PCBs and PCBAs are very important in factories today. They are the main parts of machines used for making and checking products. These boards are found in tools that do jobs like building, packing, and checking quality.

Industrial PCBs must handle tough conditions. They face high heat, shaking, and chemicals. To deal with this, strong materials and smart designs are used. For instance, multilayer PCBs work well in complex machines. Rigid PCBs are strong and good for heavy machines.

You might ask where these boards are used. Here are some examples:

Robotics: PCBs control robot arms on factory lines. They make movements accurate and work smoothly.

Power Systems: PCBAs help manage energy in power grids. They keep systems steady and stop blackouts.

Sensors and Monitoring Devices: These boards read data from sensors checking heat, pressure, and more. This helps improve safety and work speed.

Automation Systems: PCBAs run machines that work automatically. This reduces the need for workers and boosts production.

Industrial PCBs must be very reliable. Testing is key to make sure they work in hard conditions. Knowing these uses shows how PCBs and PCBAs help industries grow and improve.

Tip: Design industrial PCBs to be strong and reliable for tough jobs.

Knowing the difference between PCB and PCBA is important. A PCB is the base, while a PCBA makes it work. This understanding helps you choose wisely about cost and use.

📈 Future Trends:

Predictive checks stop machine failures early.

Robots make assembly quicker and more accurate.

Growth Area | Details |

|---|---|

Halogen-Free PCB Market | May grow 3% yearly in the next five years. |

Legislative Changes | EU rules on halogen use will get stricter. |

Industry Innovations | New materials aim to improve halogen-free PCBs. |

By learning these trends, you can design better and plan ahead.

FAQ

1. What is the main difference between PCB and PCBA?

A PCB is just a plain board with copper lines. A PCBA has parts like resistors and chips added to it. The PCB is the base, but the PCBA is the working system.

2. Can you reuse a PCB after removing components?

Yes, you can reuse a PCB if it’s not damaged. Remove parts carefully with the right tools to protect the copper lines and solder spots. Reusing PCBs can save money for testing or fixing.

Tip: Check the PCB for any damage before reusing it.

3. How do you choose between SMT and THT for assembly?

Pick SMT for small designs and fast production. Choose THT for stronger connections in devices needing more power or handling stress. The choice depends on what the device needs.

4. Why is testing important in PCBA?

Testing makes sure the PCBA works correctly. It finds problems like broken parts or bad connections early. This step makes the product more reliable and less likely to fail.

5. What industries benefit most from PCBA?

Industries like electronics, cars, healthcare, and factories use PCBA a lot. These fields need accurate and dependable circuit boards for their advanced devices.

Note: Each industry has special needs, so design your PCBA to fit them.

See Also

Uncovering Key Distinctions Between PCBA and PCB

Investigating PCBA Testing Methods for Enhanced Electronics Production

Understanding PCBA: Definition and Significance Clarified