If you want to work with circuit boards, you must know the difference between a pcb and a pcba. A printed circuit board, or pcb, is a flat board made from materials like fiberglass. It has copper lines but does not have any electronic parts. A pcba is a pcb with all the electronic parts put on it. Knowing the difference helps you pick the right one for your project and circuit boards. This choice changes the price, how hard it is, and how well your device works.

PCBs are easier and cost less, but PCBAs are more reliable and ready to use in devices.

Market Overview | Value / Statistic |

|---|---|

~$68.4 billion | |

Projected Market Size (2032-2033) | $85.88B–$105.8B |

Asia Pacific Market Share | Over 50% |

Smartphone Shipments (2026) | 1.37 billion units |

Electric Vehicle Sales (2026) | 6.75 million units |

Key Takeaways

A PCB is just a board with copper lines and no parts. A PCBA has all the electronic parts on it and is ready to use.

Picking a PCB or a PCBA changes your project’s cost, speed, and how well it works.

PCBs are good for testing, small projects, or if you want to add parts yourself. PCBAs are better for finished products and big orders that need to work well.

Good design and teamwork help make both PCBs and PCBAs better and more successful.

Knowing what PCBs and PCBAs do helps you make smart choices. This can save money and help you build strong, working electronics.

Printed Circuit Board (PCB)

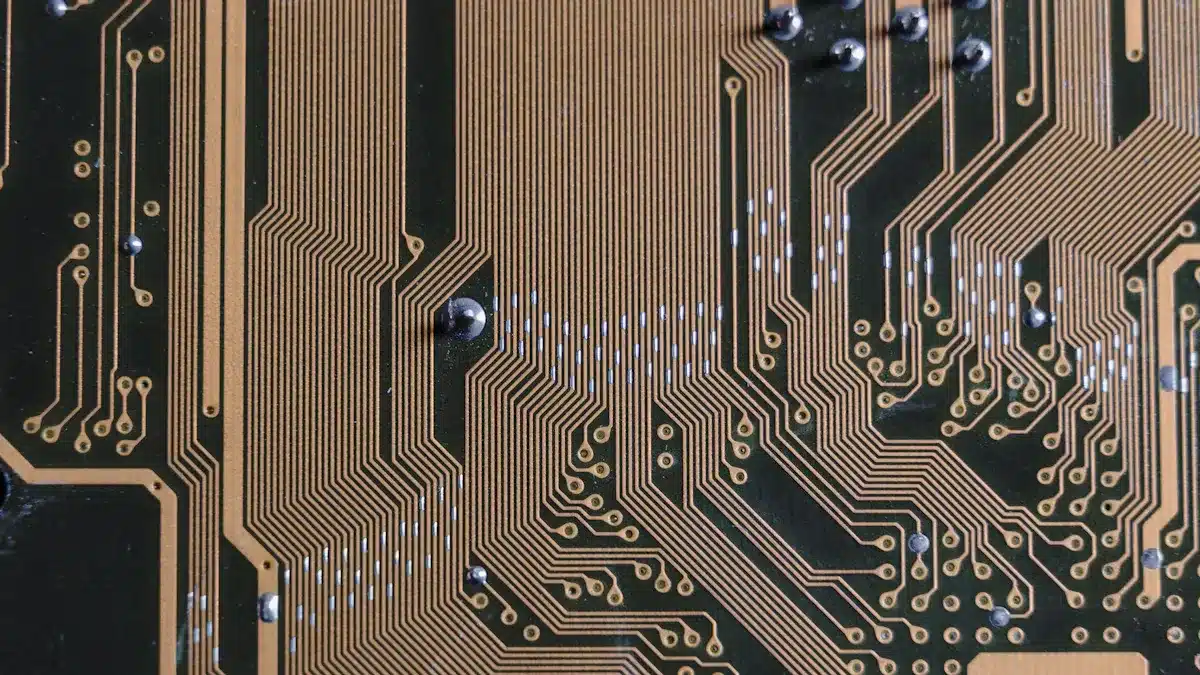

PCB Structure

A printed circuit board is a flat board with copper lines. It does not have any electronic parts yet. The base layer is made from strong materials like FR-4 or CEM-1. These materials help the pcb keep its shape and strength. Copper tracks are placed on top of the base. They let electricity move around the board. A solder mask covers the copper tracks to protect them. It also helps when you add parts during pcb fabrication. The silkscreen layer puts labels and marks on the board. This makes it easier to put the board together.

How a pcb is built changes how your device works. Good pcb fabrication helps the board handle heat and keeps signals clear. It also helps the board last longer. The way you design the layers and copper tracks matters. It helps your circuit boards work well and stay strong.

Some materials used in pcb manufacturing are:

FR-4: This is strong, does not burn easily, and is good for multi-layer pcbs.

FR-2: This is cheaper and used for simple, single-sided printed circuit boards.

CEM-1 and CEM-3: These are used for single or double-sided pcbs. They balance cost and strength.

Aluminum and ceramic: These are used for special pcbs that need to handle more heat or high frequencies.

PCB Types

You can pick from different types of pcbs for your needs. Here is a table to help you compare:

PCB Type | Key Features | Common Uses |

|---|---|---|

Single-sided | Parts on one side, simple design | Toys, calculators |

Double-sided | Copper on both sides, more complex | Radios, power supplies |

Multi-layer | Many layers, high density | Computers, smartphones |

Rigid | Hard, does not bend | TVs, desktop computers |

Flexible | Can bend and twist | Wearables, cameras |

Rigid-flex | Mix of hard and flexible sections | Medical devices, aerospace |

Each pcb type is good for different uses. Multi-layer pcbs are best for complex devices. Single-sided ones are good for simple electronics.

PCB Role

A printed circuit board is like the backbone of your device. It holds all the parts in place. Copper tracks connect the parts together. PCBs let electricity move between things like resistors, chips, and sensors. They help your device stay small and safe. They also make it easier to build. Good pcb fabrication and manufacturing help your circuit boards last longer and work better.

PCBs are important in many things you use every day. You find them in phones, computers, cars, and medical tools. They help your devices work well by keeping signals strong and parts cool. When you know about pcb structure and types, you can make better choices for your projects.

PCBA Overview

PCBA Definition

A pcba, or printed circuit board assembly, is a pcb that has all its electronic parts attached. You start with a bare pcb, then add components like resistors, capacitors, and chips. This process turns the simple board into a working part of your device. When you look at a pcba, you see a finished board ready to go into products like phones, computers, and circuit boards. Printed circuit board assemblies are much more complex than bare pcbs. They cost more because they need extra steps and special machines.

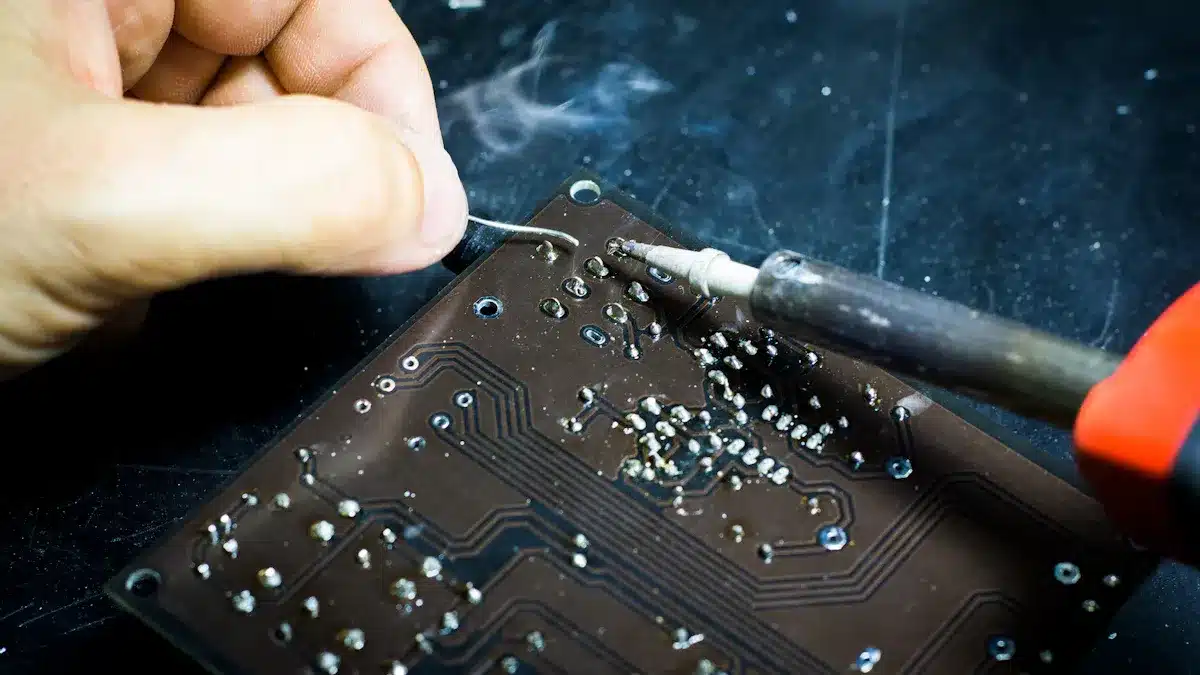

Assembly Process

You can turn a pcb into a pcba by following these steps:

Prepare the bare pcb and gather all needed materials, such as the bill of materials and solder paste stencil.

Apply solder paste to the pcb pads using a stencil.

Use pick-and-place machines to put surface mount components onto the solder-pasted pads.

Place the pcb in a reflow oven. The heat melts the solder paste and connects the components to the board.

For through-hole parts, insert them by hand or machine, then use wave soldering.

Inspect the assembled board with machines and by hand to check for errors or defects.

This pcb assembly process changes a simple pcb into a pcba that works in real devices. Quality checks, like automated optical inspection and x-ray inspection, help make sure each printed circuit board assembly meets high standards.

Components on PCBA

You find many types of electronic parts on pcbas. Each part has a special job. Here is a table to show you some common components and what they do:

Component | Function |

|---|---|

Resistors | Limit current, divide voltage, and protect other parts. |

Capacitors | Store energy, filter signals, and smooth power. |

Inductors | Store energy in a magnetic field, filter signals, and delay current. |

Diodes | Let current flow in one direction, protect circuits, and change AC to DC. |

Transistors | Switch and amplify signals. |

Integrated Circuits (ICs) | Perform complex tasks in a small space. |

Sensors | Detect things like heat, light, or pressure and send signals. |

Relays | Use a small current to control a larger one, adding safety. |

Connectors | Link the pcba to other boards or devices. |

Fuses | Break the circuit if too much current flows, keeping things safe. |

PCBA design and pcb assembly add many steps and circuit boards become more advanced. You need to think about how each part works together. This makes pcbas more expensive and harder to make than simple pcbs. When you work with and circuit boards, you must understand the difference between a pcb and a pcba. This knowledge helps you choose the right option for your project.

PCBs and Circuit Boards Comparison

Key Differences

It is important to know how a pcb and a pcba are different before you start. A pcb is just the base board. It has copper lines and layers but no parts. A pcba is a pcb with all the parts put on it. This means it can work in your device. The table below shows how they are not the same:

Aspect | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

Structure | Bare board with substrate, copper layers, solder mask, and silkscreen; no components mounted | Fully assembled board with electronic components mounted and soldered |

Function | Provides support and electrical pathways; not functional alone | Functional electronic circuit ready for use |

Manufacturing Process | Design, substrate preparation, etching, solder mask, silkscreen | PCB steps plus component sourcing, placement, soldering, and testing |

Applications | Base for electronic devices; cannot operate independently | Used in finished products like smartphones, computers, cars, medical devices |

Cost Implications | Less expensive as it is unassembled | More expensive due to components and assembly processes |

A pcb is like a blank canvas. A pcba is like a finished painting. The pcb gives you the base for your circuit boards. Only a pcba can make your device work.

Cost Factors

When you plan your project, you need to think about cost. The price of a pcb is not the same as a pcba. Many things can change the cost for both. Here are the main things you should know:

Materials and Components: The kind of substrate, copper thickness, and parts you pick can make costs go up or down.

Board Size and Complexity: Bigger boards and more layers need more work and materials. Special features like blind or buried vias also add to the price.

Quantity and Production Volume: If you order more boards, the price for each one goes down. Small batches or prototypes cost more per board.

Lead Time Requirements: If you need your boards fast, you pay more for rush orders.

Labor and Location: Where you make your pcb or pcba changes the cost. Labor costs are higher in some places.

Here is a table to help you compare the cost factors:

Cost Aspect | PCB Manufacturing Costs | PCBA Costs |

|---|---|---|

Primary Cost Drivers | Material costs (substrate, copper thickness, solder mask, surface finish), process complexity (layers, trace width, drill holes) | Component sourcing, assembly labor, testing |

Material Examples | FR-4 substrate, copper thickness, solder mask colors, surface finishes (HASL, ENIG) | Components vary by brand, package type, availability, and performance |

Process Complexity | More layers and smaller traces need advanced machines and more time | SMT, THT soldering, AOI testing, and handling complex packages increase assembly costs |

Quantity Impact | Higher volumes reduce per-unit cost; prototypes and small batches have higher unit costs | Similar volume effects; small runs increase setup and labor costs |

Additional Factors | Board size, complexity, lead time, special drilling, impedance control, and board outline complexity | Labor location, quality control, testing, and lead time requirements affect final assembly cost |

Tip: You can save money if you design your pcb to be simple and order more at once.

Applications

You can find pcbs and pcbas in almost every electronic device. Each one has its own job in different industries. A pcb acts as the base for your device. A pcba is the part that makes your device work. Here are some common uses:

Industry Sector | ||

|---|---|---|

Medical | Implantable devices, lab and imaging equipment; often use high-density interconnect (HDI) and flex pcbs for compactness | Medical imaging, implantable devices, lab equipment, surgical and emergency medicine tools |

Computer & Business | Desktop and laptop motherboards, office machines; mostly rigid pcbs | Personal computers, laptops, tablets, servers, printers, and business machines |

Automotive | Onboard computers managing systems like temperature, navigation, safety; often use flex pcbs for vibration resistance and size | Engine drive systems, climate control, displays, audio, anti-theft, airbag safety, ignition, obstacle detection |

Military & Defense | Vehicles, networked computers, defense systems requiring high reliability and security | Communications equipment, control systems (radar jamming, missile detection), instrumentation |

Telecommunications | LED displays, high-frequency amplifiers, filtering devices | Cell towers, office communication equipment (modems, routers), LED displays |

Industrial & IoT | Manufacturing equipment, power equipment, measuring tools, smart garden and weather monitoring, greenhouse control | Smart manufacturing (AI camera modules for pcb inspection), agriculture electronics, smart waste collection |

Consumer Electronics | Motherboards, display panels, power supply boards | Smartphones, smart home appliances, TVs, LCD monitors, wearables, microwaves, ovens, fridges, smartwatches |

You see pcbs in the base of many products. Only pcbas can make those products work. For example, in a car, the pcba connects all the sensors and controls the engine, brakes, and safety systems. In your phone, the pcba lets you make calls, use apps, and take photos.

Note: You need both pcbs and pcbas to build strong and circuit boards for any modern device.

Choosing PCB or PCBA

When to Use PCB

Pick a pcb if you want to try out new ideas. A pcb is just a board with copper lines and no parts. You can change your design fast if you need to. Many people use pcbs for small projects or when they want to solder parts by hand. If you have the right tools, you can save money by putting parts on yourself. This is good for small batches or if you want to pick your own parts.

Use a pcb when:

You are testing or making a new design.

You need to change or test your design often.

You have tools and know how to put parts on.

You only need a few boards and setup costs are high.

Tip: A pcb is cheaper and faster if you only need a few boards or want to try different designs.

When to Use PCBA

Pick a pcba if you need a board that works right away. A pcba has all the parts already put on and soldered. This is best for finished products or big orders. It is also good if you do not have the tools to put parts on yourself. A pcba saves time and lowers mistakes because experts do the work. Many companies, like car makers and phone makers, use pcbas for devices that must work well.

Pick a pcba when:

You need a finished product to sell or use.

You are making many boards and need them fast.

Your project needs to work well and pass tests.

Your device has lots of parts or special features.

Note: A pcba is needed for things like phones, computers, cars, and medical tools that must work right and pass strict checks.

Decision Factors

When you choose between a pcb and a pcba, think about what your project needs. Every project is different, so look at what is most important for you.

Factor | Why It Matters |

|---|---|

Project Stage | Use a pcb for early tests; use a pcba for finished products |

Production Volume | Small batches are better with pcbs; big batches are better with pcbas |

Assembly Skills | If you can put parts on, use pcbs; if not, use pcbas |

Cost and Lead Time | pcbs cost less and come faster; pcbas cost more but save time later |

Quality Requirements | High standards or rules often mean you need a pcba |

Supply Chain Management | pcbas need good tracking and getting of parts |

Plan for updates, old parts, and long-term help |

Ask yourself:

Do you need to change things often? Use a pcb.

Do you want a board ready to use? Pick a pcba.

Can you put parts on and get them? If not, use a pcba.

Does your project need to meet strict rules? A pcba is often needed.

Remember: Picking the right one helps you save money, avoid waiting, and make strong products.

Design Process and Circuit Boards

PCB Design

You start every successful printed circuit board project with a strong pcb design process. This process shapes how well your circuit boards work and how easy they are to build. Here are the main steps you follow:

Create a schematic diagram. You pick the right components and make sure your design follows the rules.

Arrange the parts on the board. You plan the layout and route the traces, thinking about layer count, trace width, and spacing.

Generate Gerber files. These files tell the manufacturer how to build your pcb. You check for errors before sending them.

Manufacture the pcb. You choose the right materials and use processes like etching and printing.

Each step in pcb design affects the final product. Good planning helps you avoid mistakes and keeps costs low. You also improve signal integrity and thermal management. When you set clear rules and check your work, your pcb will meet performance and reliability needs.

PCBA Design

After you finish your pcb design, you move to pcba design. This step turns your bare pcb into a working board. You select and place all the electronic parts, such as resistors, capacitors, and chips. You must think about how each part fits and works with others. You also plan for assembly, testing, and quality checks.

A strong pcba design helps you avoid problems during assembly. You make sure each part is easy to place and solder. You also check that your board meets safety and EMC standards. Planning for upgrades and future changes can make your pcba last longer.

Tip: Always keep your budget and timeline in mind. Good pcba design balances cost, speed, and quality.

Team Collaboration

You need teamwork to create great pcb and pcba projects. Design, engineering, and manufacturing teams must work together from the start. Early meetings with suppliers help you solve problems before they grow. You should share data using smart formats like ODB++ or IPC-2581. These formats make it easier to update and review designs.

Here are some common challenges you may face:

Trouble seeing what others are doing in real time.

Difficulty merging changes from different team members.

Problems working across different domains and organizations.

You can solve these issues by using strong collaboration tools. Keep a feedback loop open between teams. Share lessons learned to improve future pcb design and circuit boards. When you work well together, you reduce errors and speed up the process for both pcb and pcba projects.

You have learned that a PCB is just a plain board. A PCBA is a board with all the parts on it, so it works. Picking the right one changes how much you spend and how long your project takes. It also affects if your project will work well. Look at the table to see how they are not the same:

Aspect | PCB (Bare Board) | PCBA (Assembled Board) |

|---|---|---|

Function | Foundation only | Fully functional |

Cost/Speed | Lower, faster | Higher, slower |

Think about how much money you have, what you can do, and what your project needs. If you want to learn more, you can check out:

Guides for PCB design and blogs about making boards

Tools like Altium Designer and Altium 365

Making good choices helps you build strong and safe electronics.

FAQ

What is the main difference between a PCB and a PCBA?

A PCB is a blank board with copper traces. A PCBA has all the electronic parts attached. You use a PCB as a base. You use a PCBA in a working device.

Can you reuse a PCB after removing components?

You can reuse a PCB if you remove parts carefully. Heat and force can damage the board. Check for broken traces or pads before using it again.

Why do PCBAs cost more than PCBs?

PCBA costs more because it includes the price of parts, assembly, and testing. You pay for skilled labor and special machines. A PCB only covers the board itself.

How do you choose between PCB and PCBA for your project?

You pick a PCB for testing or small runs. You choose a PCBA for finished products or large orders. Think about your skills, budget, and how fast you need the boards.

See Also

Exploring The Meaning And Importance Of PCBA In Electronics

Defining PCBA And Its Function Within Electronic Devices

Understanding What PCBA Means And Its Electronic Role