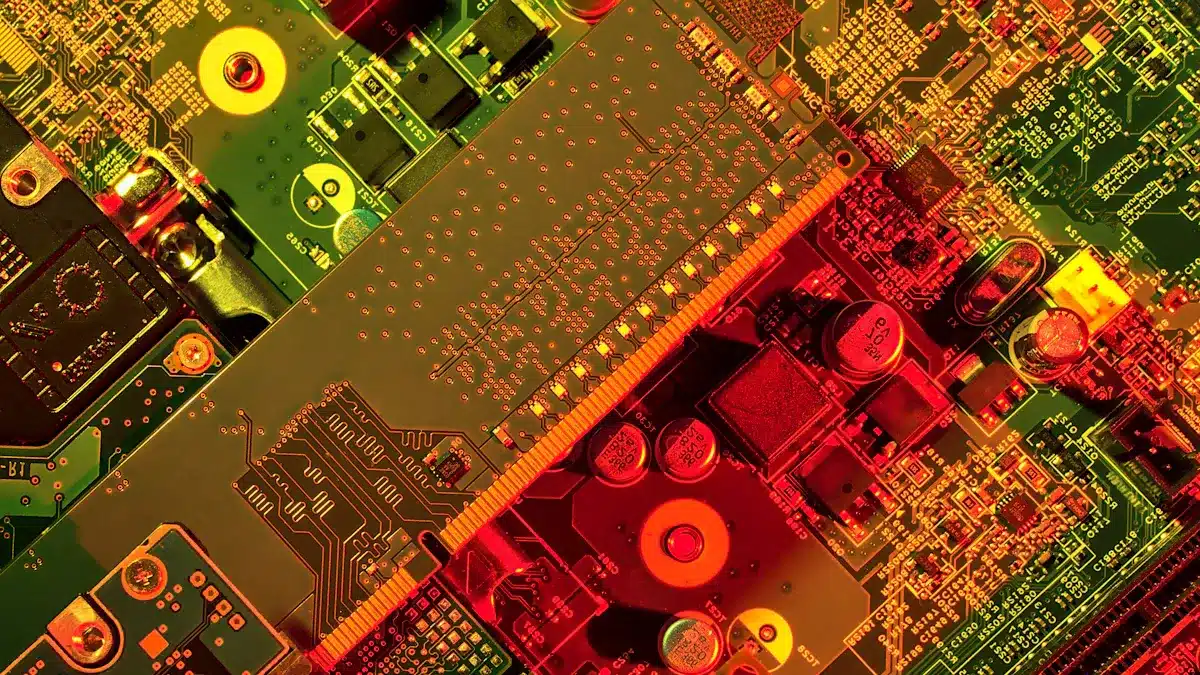

Printed Circuit Boards (PCBs), also known as circuit PCB boards, are very important for electronic devices. They act as a base for electrical connections, helping different parts work together well. Printed Circuit Board Assemblies (PCBAs) are PCBs that come with all the needed electronic parts. Knowing these differences is important for choosing the best option for your project.

The worldwide market for circuit PCB boards is doing well. In 2024, it is expected to reach USD 82,248.74 million. By 2033, it may grow to USD 113,734.26 million. This growth shows how important PCBs and PCBAs are in areas like consumer electronics, cars, and medical devices.

Key Takeaways

Understand the difference: A PCB is just a board. A PCBA is a board with all the parts. This difference is important for planning projects.

Choose the right materials: Picking the right materials for PCBs is key. It affects how reliable and well they work. Think about heat resistance and flexibility.

Design matters: A good PCB layout can reduce electrical problems. Focus on design for assembly (DFA) and manufacturing (DFM) to make things easier.

Know your budget: The costs for PCBs and PCBAs change based on size and complexity. Plan your budget well to avoid surprise costs.

Explore applications: PCBs and PCBAs are used in many fields. They are found in consumer electronics and aerospace. Knowing where they are used helps you make better choices.

PCBs Defined

Printed Circuit Boards (PCBs) are very important parts in electronics. They act like a backbone for electrical connections. This helps different electronic parts talk to each other well. Knowing how PCBs are made and the types available can help you choose the right one for your projects.

Construction of PCBs

Making a PCB uses several key materials and steps. Most times, makers use materials like FR-4, CEM-1, and Polyimide. Each material has special features that make it good for certain uses. Here’s a quick look at some common materials used in making PCBs:

Material | Properties |

|---|---|

FR-4 | Woven glass fiber epoxy, fire-resistant, high heat resistance, good for high power boards. |

CEM-1 | Mix of paper, woven glass epoxy, and phenol, a good choice for budget-friendly uses. |

CEM-2 | Higher heat resistance than CEM-1. |

CEM-3 | Good for double-sided PCBs with plated holes. |

Polytetrafluoroethylene (PTFE) | Man-made polymer, high heat resistance (160-280˚C), great for fast, high frequency, microwave, and RF boards. |

Polyimide | Best for flexible PCBs, known for its electrical features, strength, chemical resistance, and flexibility over a wide temperature range. |

PCBs have a non-conductive base that holds conductive paths. These paths are carved onto the surface, forming a network that links different parts. This design allows for effective electrical connections, making PCBs the basic building blocks of modern electronics.

Types of Circuit PCB Boards

There are many types of circuit PCB boards, each made for specific uses. Here’s a list of the main types and their features:

Type of PCB | Features | Advantages | Limitations |

|---|---|---|---|

Single-sided | Conductive paths on one side, simple design, low component count. | Cost-effective, easy to make. | Limited routing options, not good for complex circuits. |

Double-sided | Conductive paths on both sides, uses vias for connections. | Higher component count, better routing. | More complex to make than single-sided. |

Multi-layer | Three or more layers, complex routing, better signal quality. | High component count, good for advanced uses. | More costly and complex to make. |

Each type of PCB has a special role in electronics. For example, single-sided PCBs are often used in simple devices, while multi-layer PCBs are needed for advanced uses that require high performance.

PCBAs Defined

Printed Circuit Board Assemblies (PCBAs) are very important parts in electronics. A PCBA is a printed circuit board that is fully put together. It has all the electronic parts needed to work. This means the board can do its job well. On the other hand, a PCB is just a blank board with no parts. Here’s a quick comparison:

Term | Definition |

|---|---|

PCB | |

PCBA | A finished PCB that has all the parts needed to work. |

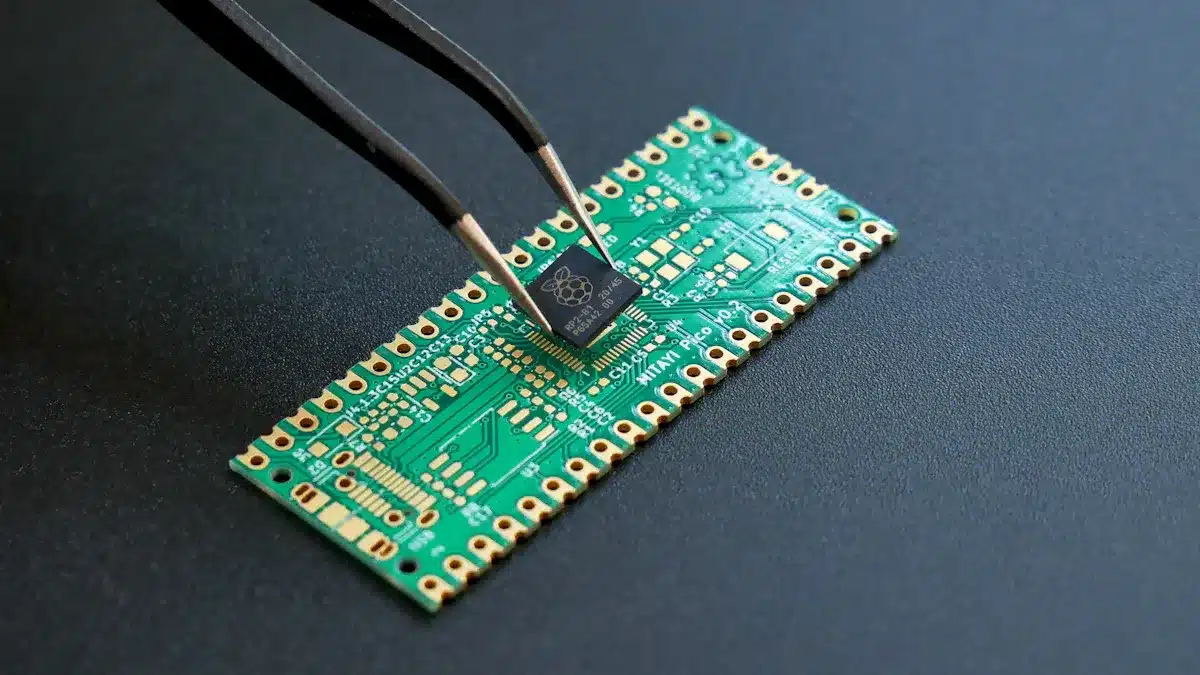

Construction of PCBAs

Making a PCBA has several important steps. Each step makes sure the final product is good quality and works well. Here’s a breakdown of the process:

Step | Description |

|---|---|

Design | You make a diagram and layout using software like Eagle or Altium Designer. |

Fabrication | This means choosing materials, printing circuit patterns, etching, drilling, and adding finishes. |

Solder Paste Application | You put solder paste on certain areas of the PCB using a stencil. |

Pick and Place | Machines automatically place parts onto the board. |

Reflow Soldering | The board heats up to melt the solder paste and make connections. |

Inspection and Testing | Quality checks happen using methods like Automated Optical Inspection (AOI) and functional testing. |

Techniques like Surface Mount Technology (SMT) and Through-Hole Technology (THT) are very important in this process. These methods help put the parts together quickly and make sure they are attached well to the board.

Types of PCBAs

There are different types of PCBAs for various uses in electronics. Here are some common types and what they are mainly used for:

Type of PCBA | Primary Applications |

|---|---|

Single Sided PCBA | |

Double Sided PCBA | Industrial control systems that are more complex |

Multi-layer PCBA | Computer motherboards and graphics cards |

Rigid PCBA | Aerospace and defense systems |

Flexible PCBA | Wearable devices like smartwatches |

Rigid-Flex PCBA | Aerospace and military uses |

High-Frequency PCBA | RF and microwave communication systems |

Aluminum Backed PCBA | LED lighting systems that need heat management |

Knowing these types helps you pick the right printed circuit board assembly for your needs. PCBAs are key to making sure electronic devices work well and reliably.

PCB vs PCBA: Key Differences

When you look at PCBs and PCBAs, you see big differences in how they are made and their costs. Knowing these differences helps you choose the best option for your projects.

Manufacturing Processes

The ways to make PCBs and PCBAs are different in how complicated they are and the steps needed. Here’s a quick comparison:

Aspect | PCB | PCBA |

|---|---|---|

Complexity | Easier to make | Harder because of assembly |

Cost | Usually cheaper | More costly because of parts and assembly |

Functionality | Not working yet | Works fully with parts attached |

Lead Time | Faster | Slower because of extra steps like getting parts and assembly |

For PCBs, the process mainly includes etching, layering, and drilling. You create a bare printed circuit board that acts as a base for electrical connections. But for PCBAs, the process is more detailed. You need to design the layout, make the board, put on solder paste, place parts, and then solder them. This complexity can lead to more mistakes, especially with tiny parts.

Tip: Always make sure your PCB design is ready for manufacturing. Bad designs can cause delays and higher costs during assembly.

Cost Considerations

Cost is another important thing to think about when comparing PCBs and PCBAs. The costs for each can be very different. Here are some key points to keep in mind:

Adding parts and assembly can raise the cost of a PCBA to around $30.

The extra steps in making a PCBA lead to longer wait times.

The cost for prototypes is usually higher than for mass production because smaller runs are less efficient. Important factors that affect PCB prices include material choice, design complexity, volume, quality, and testing needs. For example, standard materials can cost about $2-$3 per square foot, while special materials can go up to $25-$30 per square foot.

Feature | PCB | PCBA |

|---|---|---|

Definition | Bare printed circuit board | PCB with mounted components |

Functionality | Not working on its own | Fully working as a circuit |

Components | No parts | Has ICs, capacitors, resistors, etc. |

Manufacturing Process | Etching, layering, drilling | Pick & place, soldering, inspection |

Applications | Prototyping, initial design | Ready-to-use in end products |

Applications of PCBs and PCBAs

PCBs and PCBAs are very important in many industries. Knowing where these parts are used helps you see how they matter in today’s technology.

Industries Using PCBs

Many industries need circuit PCB boards for their electronics. Here are some main areas that use PCBs:

Consumer Electronics: Items like smartphones, tablets, and TVs need PCBs to work.

Automotive: Cars use PCBs for engine controls, entertainment systems, and safety features.

Telecommunications: Devices like routers, switches, and cell towers depend on PCBs for communication.

Medical Devices: Tools for diagnosis and patient monitoring use PCBs for accurate readings.

Industrial Automation: Factories use PCBs in machines and control systems to improve efficiency.

Industries Using PCBAs

Printed circuit board assemblies (PCBAs) are key in more complex uses. Here are some industries that use PCBAs:

Industry | Applications |

|---|---|

Oil and Gas | Systems for drilling control, pipeline monitoring, and refinery automation. |

Aerospace and Defense | Computers for flight control, navigation systems, and radar systems. |

Telecommunications | Cell towers, base stations, and routers. |

Automotive | Engine control units (ECUs), entertainment systems, and advanced driver assistance systems (ADAS). |

Medical Devices | Equipment for diagnosis, patient monitoring systems, and implantable medical devices. |

Renewable Energy Systems | Solar inverters and controls for wind turbines. |

Internet of Things (IoT) | Smart home gadgets and wearable tech. |

Financial Technology (FinTech) | Payment machines and secure authentication devices. |

Industrial Automation | Programmable Logic Controllers (PLCs) and robots. |

Space Exploration | Mars rovers and satellite systems. |

These industries show how flexible PCBAs are in different uses. They allow for advanced features that improve performance and reliability in electronics.

Choosing Between PCB and PCBA

When you need to choose between a printed circuit board (PCB) and a printed circuit board assembly (PCBA), think about your project needs and budget. Each option has different effects on your electronics project.

Project Requirements

Your project needs are very important in deciding if you should pick a PCB or a PCBA. Here are some key things to think about:

Description | |

|---|---|

Design Specifications | Think about details like board size, number of layers, material type, and specific design needs. |

Compliance and Regulatory Requirements | Make sure your design follows industry standards and has the right documents. |

Test and Validation Requirements | Find out what is needed for design checks, testing, and specific points for diagnostics. |

Knowing these needs helps you make a smart choice. For example, if your project has high-density designs, you might run into problems with PCB making limits. This can raise the chance of mistakes. On the other hand, complex PCBAs need careful assembly to avoid problems like misalignment and tombstoning. So, you should focus on design for assembly (DFA) and design for manufacturing (DFM) to get good results.

Budget Constraints

Budget limits are another important thing to think about when choosing between PCB and PCBA. Here are some common points to consider:

Size of the PCB

Delivery time needs

Choices of materials

These points can greatly affect your total costs. For example, a more complex design usually means higher manufacturing costs. Also, the size of the PCB can change material costs and assembly time.

You should also think about technical and logistical reasons that affect manufacturing and assembly costs. Knowing these points is key for managing your budget well. Costs can vary based on different manufacturing methods, material choices, and assembly techniques.

In conclusion, PCBs and PCBAs have different jobs in electronics. PCBs give the basic structure, while PCBAs include all the parts needed to work. Here are some important points to remember:

Material Selection: Picking the right materials affects how reliable and efficient it is.

Design Optimization: A good PCB layout helps reduce electrical problems.

Quality Assurance: A high pass rate during production means better performance.

When choosing between PCB and PCBA, think about your project needs, budget limits, and the skills of your suppliers. Making smart choices will help your electronic projects succeed. Keep in mind, the right choice can greatly improve the reliability and efficiency of your systems.

“Great job on the fast turnaround for our PCBA testing! Great price, great communication, and excellent quality—thank you for doing such excellent work!!

FAQ

What is the main difference between a PCB and a PCBA?

A PCB is just a plain board with no parts. A PCBA is a complete PCB that has all the electronic parts, so it works.

How do I choose the right type of PCB for my project?

Think about what your project needs, like how complex it is, its size, and what materials to use. Check what functions your device needs to do.

What factors affect the cost of PCB manufacturing?

Costs depend on what materials you pick, how complex the design is, the size, and how many you want to make. More complex designs and special materials usually cost more.

How long does it take to manufacture a PCBA?

Making a PCBA usually takes more time than making a PCB because of the assembly steps. It can take several days to weeks, depending on how complex it is.

Can I prototype with a PCB before moving to a PCBA?

Yes, using a PCB for prototyping lets you test your designs and how they work. This step helps find problems before you fully assemble it with parts.

See Also

A Comprehensive Look at PCBWay and Its Competitors

Understanding Key Differences Between PCBA and PCB Designs

Unveiling the Subtle Distinctions Between PCBA and PCB