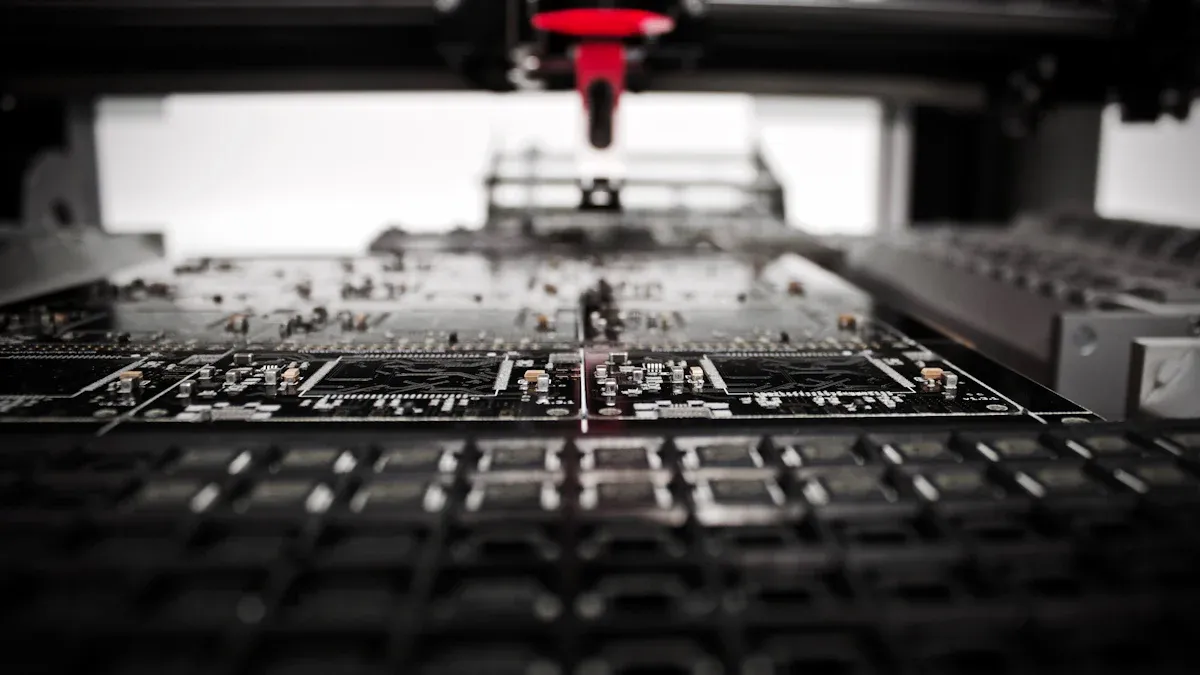

Predictive maintenance sensor PCB assembly is revolutionizing the way PCB assembly is conducted. These sensors monitor machine health and detect early issues. Addressing problems promptly prevents costly breakdowns from occurring. This approach ensures consistent production and minimizes downtime. Additionally, it reduces expenses by enhancing maintenance strategies. With predictive maintenance sensor PCB assembly, you can enhance the reliability and efficiency of your manufacturing processes.

Key Takeaways

Predictive maintenance sensors check machines all the time to find issues early and stop expensive breakdowns.

These sensors cut downtime a lot, making production smoother and fixing machines during less busy times.

They improve PCB quality by keeping machines working well, spotting problems early, and keeping high standards.

Buying predictive maintenance sensors saves money over time by lowering repair costs, reducing waste, and making work more efficient.

Understanding Predictive Maintenance Sensors in PCB Assembly

What Are Predictive Maintenance Sensors?

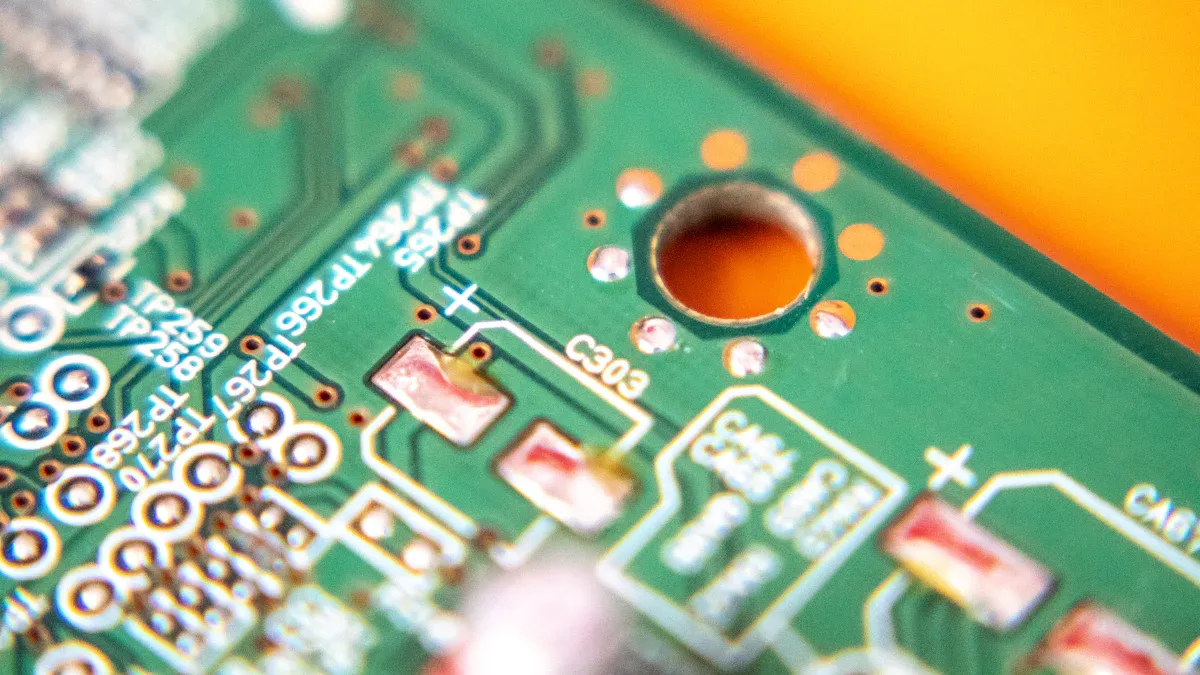

Predictive maintenance sensors are tools that check machine health. They find early signs of wear or problems. These sensors gather live data like vibration, heat, and sound. This data helps predict issues before machines stop working.

There are different sensors for different jobs. Piezo accelerometers are great for high-frequency vibrations. MEMS accelerometers are cheaper and work across wider ranges. MEMS microphones and ultrasonic sensors detect small sound changes. The table below shows how these sensors compare:

Sensor Type | Cost (1k unit price) | 3 dB Bandwidth | DC Response | Noise/SNR | Battery Life for Wireless CbM | Self-Test |

|---|---|---|---|---|---|---|

Piezo Accelerometer | $25 to $500+ | 2.5 kHz to 30 kHz+ | No | <1 µg/√Hz to 50 µg/√Hz | Short to Medium | No |

MEMS Accelerometer | $10 to $30* | 3 kHz to 20 kHz+ | Yes | <25 µg/√Hz to 100 µg/√Hz | Medium to Long | Yes |

MEMS Microphone | <$1 to $2 | 20 kHz | No | 57 dB to 74 dB | Long | No |

MEMS Ultrasonic | <$1 to $2 | 100 kHz | No | 65 dB | Long | No |

These sensors are key to keeping machines running well. They help factories avoid delays and save time.

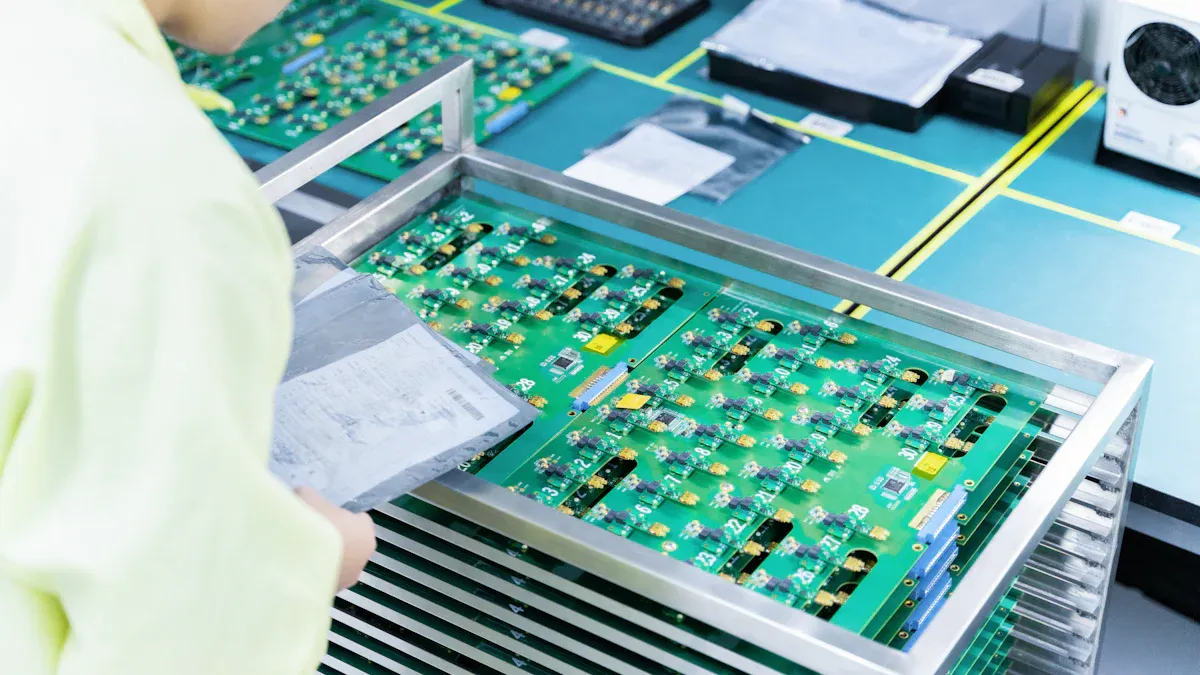

Role of Predictive Maintenance Sensors in PCB Assembly

In PCB assembly, these sensors are very important. They watch machines all the time to spot problems early. This keeps the process steady and improves product quality.

Sensors also help machines last longer by catching issues early. For example, they find worn parts so you can replace them. This saves money and avoids big repairs. Sensors also predict how long machines will work, helping plan maintenance better.

Using these sensors in PCB assembly reduces downtime. It keeps production smooth and saves costs. These tools help you fix problems before they happen, making work easier and more efficient.

Benefits of Predictive Maintenance Sensors in PCB Assembly

Making Equipment More Reliable

Predictive maintenance sensors help keep machines working well. They check machines all the time for problems. Sensors find early signs of wear or damage. Fixing these issues early makes machines last longer. For example, they can spot strange vibrations or high temperatures. These signs often mean something might break soon. Solving these problems early keeps machines running smoothly.

These systems also help plan repairs better. Instead of guessing, you use real-time data to decide. This stops unneeded fixes and focuses on real problems. Your machines stay in great shape, and work stays efficient.

Reducing Downtime

Downtime is a big problem in PCB assembly. It stops work, costs money, and delays orders. Predictive maintenance helps avoid downtime by spotting issues early. Sensors watch machines and warn you about problems fast.

For example, they can find a worn belt or loose part. Fixing these quickly avoids sudden stops. Predictive tools can also tell when a machine might fail. You can then fix it during non-busy times. This way, downtime is less, and work stays on track.

Better PCB Quality

Sensors also improve how good your PCBs are. They keep machines working at their best. This helps make products that meet high standards. Automated checks with sensors catch mistakes early. This stops bad parts from being used.

Looking at past data helps find and fix problems. Sensors show why defects happen and how to stop them. Watching production in real-time helps fix issues fast. Predictive tools can even warn about future defects. Fixing these early saves waste and keeps customers happy.

Reducing Operational Costs

Predictive maintenance tools help cut costs in PCB assembly. They check machine health live to avoid big repairs. Spotting problems early stops expensive breakdowns and delays.

A major way they save money is by improving processes. Sensors collect data to find where machines waste energy. For example, if a machine uses too much power, you’ll get an alert. Fixing this lowers energy bills and helps machines last longer.

These tools also reduce waste. Broken machines can make bad PCBs, wasting materials. Keeping machines in top shape avoids mistakes and improves quality. This saves money and keeps customers happy.

Another cost-saving method is better efficiency. Instead of fixing machines on a schedule, repair them only when needed. This cuts labor costs and avoids unnecessary stops. For instance, replacing a worn part during quiet hours prevents delays.

Tip: Predictive maintenance sensors may cost more at first, but they save money over time. You’ll spend less on repairs, energy, and wasted materials while keeping production steady.

These tools help you make smarter choices for your machines. Using live data, you can improve processes, cut waste, and save money. Predictive maintenance makes PCB assembly cheaper and more efficient.

How Predictive Maintenance Sensors Work in PCB Assembly

Collecting Data in Real-Time

Predictive maintenance sensors gather live data from machines during PCB assembly. They check things like vibration, heat, and sound to see if machines are working well. This constant data stream helps find problems early before they become expensive.

Sensors catch issues as they happen. For example, if a machine shakes oddly, sensors send an alert right away. This lets you fix the problem fast, avoiding delays and keeping work running smoothly. IoT devices help by making data collection and sharing easy.

Here’s why real-time data is helpful for PCB assembly:

Fix machines based on their condition, not a set schedule.

Predict when machines might break, so you can act early.

Keep everything safe by following safety rules with constant checks.

The table below shows how real-time data helps:

Evidence Type | Description |

|---|---|

ROI | Preventive maintenance can give up to 500% return on investment. |

Cost Savings | Predictive maintenance saves 12% more than reactive maintenance. |

Maintenance Time Reduction | Maintenance time can drop by 75% with predictive tools. |

Cost Reduction | Early fixes avoid costly emergency repairs. |

Safety Improvement | Regular checks keep workers safe and meet safety standards. |

Using real-time data makes maintenance smarter and keeps PCB assembly running well.

Using Predictive Data

Predictive data turns raw numbers into useful ideas. It uses smart tools like AI to study sensor data. In PCB assembly, this helps spot patterns that show machines might fail soon.

For example, automated systems use this data to find problems fast. These systems learn from new issues, getting better at spotting defects. Fixing problems early keeps production smooth and reduces mistakes.

Here’s how predictive data helps:

Benchmark Type | Description |

|---|---|

Efficiency Improvement | AI predicts repairs, cutting downtime and improving work. |

Accuracy Enhancement | AI fine-tunes settings like soldering heat for better results. |

Cost-Effectiveness | AI reduces waste and manages materials better, saving money. |

Maintenance Prediction | AI spots issues early, so repairs can be planned ahead. |

Workflow Automation | AI handles boring tasks, freeing workers for important jobs. |

Adding predictive tools makes work faster and products better.

Creating Useful Maintenance Tips

The main goal of predictive maintenance is to give helpful advice for fixing machines. Sensors collect and study data to help you decide what to fix and when.

Before predictive tools, factories often waited for machines to break. This caused high costs and wasted time. Now, sensors help find problems early. You can plan repairs during quiet times and avoid big delays.

Here’s why these tips are useful:

Vibration checks show if machines need repairs soon.

Combining predictive tools with live monitoring can:

Boost machine efficiency by 20%.

Lower defect rates by 15%.

Automated checks improve accuracy and save money by reducing mistakes.

The table below shows real-world examples of how these tips help:

Industry | Solution Implemented | Key Outcomes |

|---|---|---|

Oil & Gas | Digital Workflow Builder | Less downtime; better cost savings |

Manufacturing | Predictive Workflows | Fewer machine failures; more productivity |

Manufacturing | IoT sensors and AI | 15% less downtime; saved $20 million yearly |

Energy | AI-powered predictive systems | 30% fewer generator issues; saved millions |

Transportation | Real-time engine monitoring | 25% fewer breakdowns; faster deliveries |

Using these tips helps plan repairs better, keep machines running, and save money.

Applications of Predictive Maintenance Sensors in PCB Assembly

Case Study: Cutting Downtime in PCB Manufacturing

Unplanned downtime can stop production and cause big problems. A PCB maker had frequent machine failures, leading to delays and higher costs. They used predictive maintenance sensors to change how they worked.

The sensors checked machines live and found early wear signs. For example, vibration sensors noticed odd movements in a conveyor motor. The team replaced the motor during planned maintenance, avoiding sudden failure.

The results were impressive:

Downtime dropped by 30%.

Maintenance expenses fell by 20%.

Production schedules became steady.

Predictive tools helped the company switch to proactive maintenance. This reduced downtime and made their process more efficient.

Case Study: Boosting PCB Quality with Predictive Maintenance

Making good PCBs needs machines to work perfectly. One company had trouble with bad soldering, causing faulty PCBs. Predictive maintenance sensors solved this issue.

Temperature and vibration sensors watched soldering machines all the time. They found small temperature changes that hurt solder flow. The team fixed the settings right away, keeping quality steady.

Here’s what they achieved:

Defects went down by 25%.

Customers were much happier.

Less material was wasted, saving money.

Using predictive tools kept machines in great shape and improved production. This smart method ensured top-quality PCBs and cut waste.

Takeaway: Predictive maintenance sensors are key to cutting downtime and improving PCB quality. They help spot problems early, keep machines healthy, and ensure smooth production.

Predictive maintenance sensors are important for better PCB assembly. They find problems early, keeping machines working well and efficiently. These tools cut maintenance needs by up to 30%, saving money and improving reliability.

They are also very accurate, with systems reaching 94% accuracy, 99% precision, and 89% recall. This helps spot issues like temperature changes, which improves PCB quality directly.

Key Takeaway: Using predictive maintenance sensors reduces downtime, lowers costs, and ensures high-quality PCBs every time.

FAQ

What types of data do predictive maintenance sensors collect?

These sensors gather data like vibration, heat, sound, and pressure. This helps check machine health and find early problems. By studying this data, you can spot issues and fix them before they stop production.

Are predictive maintenance sensors expensive to implement?

At first, these sensors may cost a lot. But they save money later by stopping breakdowns and cutting repair costs. Many companies see that the savings are worth the price. They are a smart choice for PCB assembly.

How do predictive maintenance sensors improve PCB quality?

Sensors keep machines running at their best. They find problems like heat changes or shaking that harm soldering. Fixing these early keeps quality steady and lowers defects in PCBs.

Can predictive maintenance sensors work with older equipment?

Yes, many sensors can work with old machines. You might need extra parts to connect them. Once set up, they give live updates and help old machines last longer.

How often should you check data from predictive maintenance sensors?

It’s best to watch data all the time. This way, you catch problems quickly. You can also review data regularly to plan fixes better.

Tip: Set up alerts to know about problems without checking constantly.

See Also

Essential Strategies to Enhance PCB Assembly Productivity

Streamlining PCBA Testing for Optimal Precision and Efficiency

Investigating PCBA Testing Methods for Superior Electronics Production