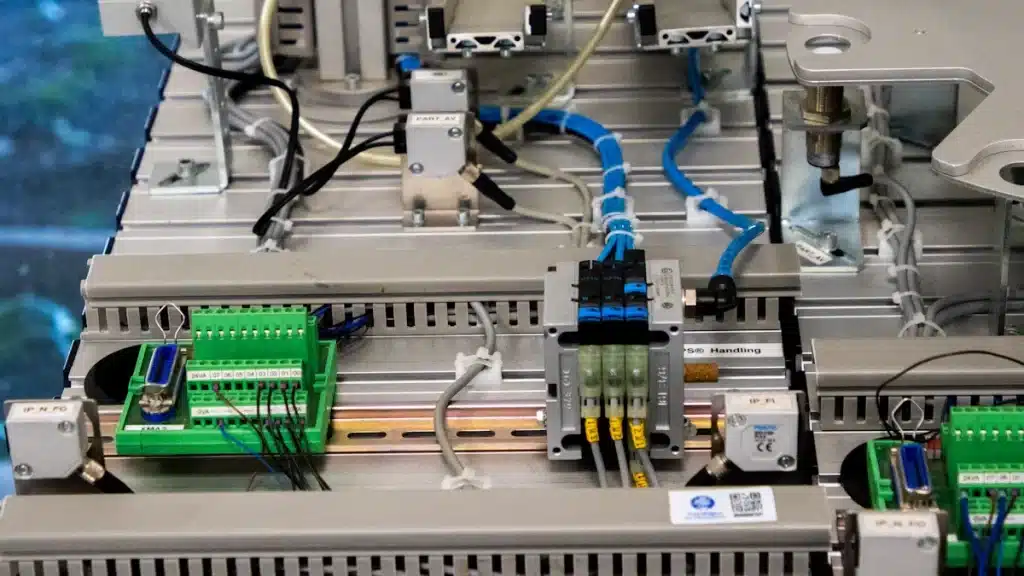

Choosing the right tools is important for PROFINET circuit board assembly. Good tools provide accurate results, saving time and avoiding mistakes. PROFINET circuit board assembly requires exact connections and steady performance, which necessitates advanced machines. Modern automated tools simplify the process with less manual effort. A strong setup also helps maintain consistency and meet new demands. Utilizing the best tools enhances the speed and reliability of your PROFINET circuit board assembly.

Key Takeaways

Use modern tools like solder paste printers and pick-and-place machines. These tools help make PROFINET assembly faster and more accurate.

Use automated inspection systems to find mistakes early. This saves time and lowers production costs.

Clean and maintain your equipment often. This stops breakdowns and keeps the machines working well, making better boards.

Get reflow soldering machines to make strong solder joints. Strong joints are important for PROFINET systems to last longer.

Use testing equipment to check if boards work properly. This ensures they follow industry rules and meet user needs.

Solder Paste Printers for PROFINET Circuit Board Assembly

Role in Ensuring Accurate Solder Application

Solder paste printers are key for applying solder correctly. They place solder paste precisely on the PCB pads. This precision is needed for strong electrical connections. PROFINET systems rely on these connections to work well and stay reliable.

Research shows solder paste printing is vital for quality devices. For instance, 3D solder paste inspection (SPI) systems find mistakes in solder placement. These systems use advanced imaging to check for problems. Proper stencil design and cleaning also improve solder quality. This lowers the chance of errors during assembly.

Key Point | Description |

|---|---|

Role of Solder Paste Printing | Makes accurate solder deposits for strong electrical connections. |

Impact of 3D SPI Systems | Uses 3D imaging to find and fix solder issues. |

Importance of Stencil Design | Good design and cleaning improve solder application quality. |

Features That Improve Precision and Consistency

Modern solder paste printers have features to boost accuracy. Closed-loop systems monitor and adjust the process for better results. Built-in inspection tools check quality in real time. AI software helps find problems quickly, reducing delays and improving prints.

These features are helpful for PROFINET circuit board assembly. They ensure the soldering process meets strict industrial standards. By using these tools, you can make assembly faster and more reliable.

Benefits for PROFINET Circuit Board Quality

Good solder paste printers improve the quality of PROFINET boards. Accurate soldering reduces mistakes and ensures the boards work well. This is important for reliable PROFINET communication systems.

Consistent soldering also makes connections stronger and longer-lasting. This is crucial for devices used in tough industrial settings. Advanced solder paste printers help create better boards. They ensure smooth network performance and long-term reliability.

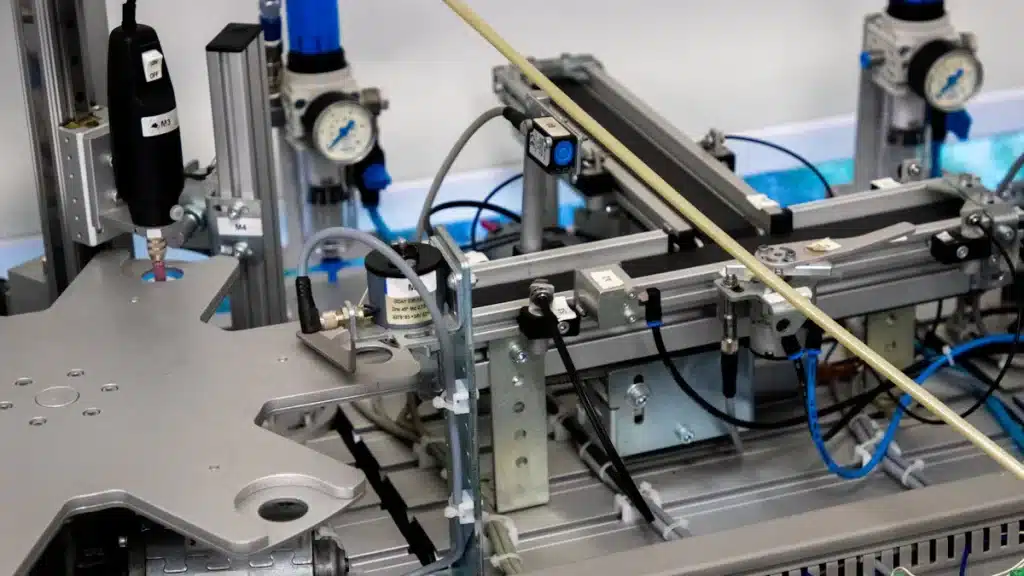

Pick-and-Place Machines for PROFINET Assembly

Why Accurate Component Placement Matters

Pick-and-place machines are important for placing parts on circuit boards. For PROFINET assembly, exact placement ensures strong connections and good performance. These machines use tools like linear encoders to place parts very precisely. They can align parts perfectly, even tiny ones with fine spacing.

Placing parts accurately also helps keep quality consistent. This is crucial for industrial networking systems. Modern machines use open-loop or closed-loop systems to improve accuracy. These systems help create high-quality boards for PROFINET communication.

Why Precision Matters:

Linear encoders fix positions for very precise placement.

Machines with +/- .001” accuracy work well for tiny parts.

Closed-loop systems improve repeatability and product quality.

Features That Make Machines Faster and More Accurate

Today’s pick-and-place machines have features to improve speed and precision. They use centering methods like lasers, cameras, or mechanical tools to align parts correctly. Machines with fine-pitch abilities can handle very small components easily.

The machine’s design also helps. Steel frames keep the machine steady and reduce shaking. User-friendly software makes operating the machine simple. These features make PROFINET assembly faster and more efficient.

Helpful Features:

Fine-pitch ability for tiny parts.

Laser and camera tools for accurate alignment.

Steel frames for stability and precision.

How They Improve Assembly Efficiency

Pick-and-place machines make PROFINET assembly quicker and smoother. They can handle over 100 different parts in less than 4 seconds per cycle. These machines connect with SCADA and PROFINET systems for easier operation.

Automation reduces the need for manual work. Only two people are needed to manage systems with up to 16 robots. Automation saves time and lowers mistakes, ensuring better assembly. Investing in these machines boosts efficiency for industrial projects.

Feature | Details |

|---|---|

Cycle Time | Less than 4 seconds |

Number of Robots | 6 |

Parts Handled | Over 100 parts |

Application | Electronics Manufacturing |

Integration | Works with SCADA and PROFINET systems |

Feature | Details |

|---|---|

Operators Needed | Just 2 people |

Robots in System | 16 |

Control System | Industry 4.0 MES-based |

Application | Electronics Manufacturing |

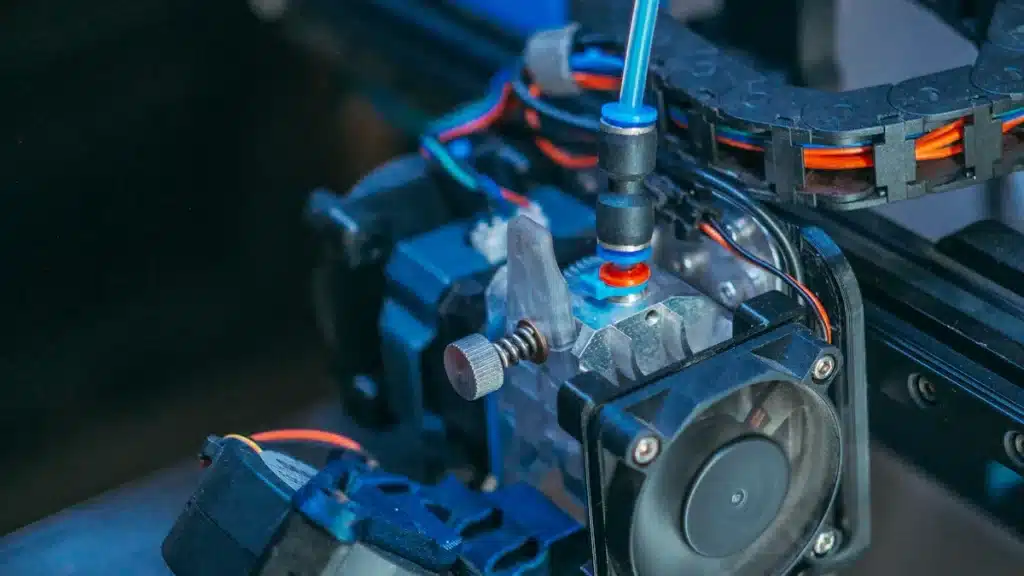

Reflow Soldering Machines for PROFINET Circuit Boards

Role in Achieving Reliable Solder Joints

Reflow soldering machines help make strong solder joints. They automate the process, reducing mistakes and improving consistency. These machines are precise and handle tricky soldering tasks well. They are great for small, tightly spaced parts. Programmable robotic systems allow repeatable results on many boards.

Key Advantages:

Consistent soldering supports PROFINET systems.

Robots ensure accuracy every time.

Studies show reflow soldering creates reliable joints. Tests on 20 boards showed great results in spreading and sticking. Even under heat stress, only tiny cracks appeared. This proves the joints are durable.

Advanced Temperature Control Features

Temperature control is key in reflow soldering machines. They use exact heat settings to avoid defects. Each step in the process is carefully managed for the best results.

Stage | Purpose | Temperature (°C) | Ramp Rate (°C/s) | Time (minutes) |

|---|---|---|---|---|

Ramp to Soak Zone | Slowly heats to prevent damage. | 150-160 | 1-5 | 1-3 |

Thermal Soak Zone | Keeps steady heat for even warming. | 150-160 | N/A | 1-3 |

Reflow Zone | Reaches high heat to melt solder and bond parts. | 180-250 | N/A | 15-60 |

Cooling Zone | Quickly cools to harden solder and avoid flaws. | N/A | 2-4 | N/A |

Reflow ovens have zones for different tasks. The preheat zone warms slowly to avoid shock. The soak zone spreads heat evenly. The reflow zone melts solder to connect parts. The cooling zone hardens the solder quickly. Managing these zones well ensures perfect soldering.

Benefits for High-Quality PROFINET Assembly

Reflow soldering machines improve PROFINET board quality. Automation reduces manual work, making results consistent. These machines handle complex soldering for dense boards. Good temperature control stops problems like bent parts or weak soldering.

Automation also saves time and effort. Many boards can be processed at once. Investing in these machines ensures PROFINET boards meet high standards for reliability and performance.

Automated Optical Inspection Systems for PROFINET Boards

Why Finding Defects Early Matters

Automated optical inspection (AOI) systems help find problems in PROFINET boards. They use smart cameras and software to spot mistakes. These systems catch soldering errors, misplaced parts, or missing pieces quickly.

Finding problems early saves money and keeps boards working well. AOI machines also check for scratches, stains, or broken circuits. They alert workers to fix issues right away. Automation lowers the chance of mistakes that could cause failures later.

Features That Help Check Quality

Modern AOI systems have tools to make inspections better. These tools ensure boards are checked carefully and correctly:

Feature | What It Does |

|---|---|

Artificial Intelligence | Finds problems without needing special test setups. |

High-Precision Inspection | Checks parts with accuracy as small as 0.001 mm. |

Parts Throughput | Can inspect up to 300 parts every minute. |

Multi-Camera Systems | Uses many cameras to see parts from different angles. |

Customizable Software | Lets users create tests that fit their needs. |

These features help keep PROFINET boards high-quality while fixing issues faster than older methods.

How AOI Systems Improve PROFINET Boards

AOI systems make PROFINET boards better by speeding up inspections. They cut the time to check each part from one minute to 200 milliseconds. This makes inspections 97% faster. Clear images help find problems, ensuring boards meet strict standards.

Automation reduces human mistakes, so workers can focus on other tasks. AOI systems give consistent results and keep PROFINET networks reliable. Using these systems ensures your boards work well in tough industrial settings.

Functional Test Equipment for PROFINET Circuit Board Assembly

Role in Verifying Circuit Board Functionality

Functional test tools check if PROFINET boards work correctly. These tools mimic real-world conditions like power and signals. This helps confirm the board’s performance and reliability. Testing ensures the board meets industry rules and works as expected.

This is usually the last step in testing. It checks the entire board, including power and signals. It also verifies specific parts and connections. This ensures the board is ready to be used in PROFINET systems.

Functional testing checks:

If the board works in real conditions.

If it follows industry standards.

Power and signal stability.

Features That Enhance Testing Accuracy

Modern test tools have features to improve accuracy and speed. Automation reduces manual work and lowers mistakes. It ensures consistent results for many boards, keeping quality high.

Precise sensors and flexible software allow custom tests. These features help find even tiny problems. They ensure the board’s design meets strict rules. The tools also support certifications, giving reliable data for product use.

Key features include:

Automation for steady results.

Precise sensors for detailed checks.

Flexible software for custom tests.

Benefits of Early Issue Detection

Functional test tools help find problems early in assembly. Fixing issues early saves money and time. It ensures the boards work well in PROFINET systems.

Research shows testing improves software and keeps it consistent. By focusing on user needs, boards can perform better. This approach boosts reliability and avoids costly failures in tough environments.

Early issue detection helps:

Save money by fixing problems early.

Improve software and consistency.

Ensure user satisfaction and reliability.

Cleaning and Maintenance Tools for PROFINET Assembly Equipment

Why Cleaning Keeps Equipment Working Well

Cleaning is important to keep PROFINET assembly tools working properly. Dust and dirt can build up on machines and slow them down. Regular cleaning stops these problems and helps machines work smoothly. Clean tools make sure circuit boards are made correctly.

Skipping cleaning can cause machines to break or work poorly. This can mess up your production schedule. For example, solder paste printers and pick-and-place machines need clean surfaces to work right. Cleaning often saves money by avoiding expensive repairs.

Tip: Clean your equipment regularly to keep it in great shape.

What Makes Cleaning Systems Useful

Good cleaning systems make maintenance easier and more effective. Automated cleaning tools save time and do a thorough job. Ultrasonic cleaners are great for removing sticky dirt from small parts.

Vacuum cleaners work well for cleaning tight spaces. Some tools let you adjust settings to match your machine’s needs. Compact designs fit easily into your workspace without taking up much room.

Features to Look For:

Ultrasonic cleaners for small parts.

Vacuum tools for tight spaces.

Adjustable settings for custom cleaning.

How Maintenance Helps Machines Last Longer

Taking care of your PROFINET tools makes them last longer. Maintenance keeps machines running well and avoids delays. It also helps find problems early before they get worse.

Well-maintained tools make automation more reliable. This is important for PROFINET systems that need precise operations. Regular care ensures your machines work consistently and support your projects for a long time.

Note: Combine cleaning with regular checks to get the best results.

Using top tools for PROFINET board assembly makes work easier. Advanced machines like reflow soldering and AOI systems help avoid mistakes. These tools use automation to improve accuracy and keep results steady. For instance, modern AOI machines find tiny problems that people might miss. This stops waste and saves money on fixing errors.

Buying good equipment helps automation run smoothly. It also ensures your boards pass strict tests and meet standards. With advanced tools, you can build strong and reliable PROFINET boards for tough jobs.

Tip: Use automated tools with smart features for better assembly results.

FAQ

What equipment is most important for PROFINET board assembly?

Automation tools like pick-and-place and reflow machines are key. They help with accuracy and steady results, which PROFINET systems need.

How does automation help with circuit board assembly?

Automation speeds up work and reduces mistakes. It makes sure all boards meet industry rules, especially for complex PROFINET setups.

Why is testing needed for PROFINET boards?

Testing checks if the board works in real conditions. It confirms power, signals, and that the board follows industry rules.

How does cleaning help assembly equipment last longer?

Cleaning removes dirt that can slow machines down. Tools like ultrasonic cleaners and vacuums keep equipment working well for a long time.

Why use advanced inspection systems?

Inspection systems find problems fast and accurately. They improve quality by catching mistakes early, saving time and materials.