In today’s tech-focused world, being a PCBA engineer matters a lot. Technology changes fast, and people want better electronic devices. To succeed in this field, you must improve your skills often. Learning new things and gaining hands-on experience make you a better engineer. By working on your skills, you can grow your career and make a big difference in the industry.

Key Takeaways

Learn the basics of PCB design to build a strong base. Know important rules like IPC-2221 to make good circuit boards.

Understand schematics and circuit diagrams. This helps you share ideas with engineers and fix problems easily.

Keep up with industry rules. Knowing standards like IPC and ISO improves your designs and helps your career.

Pay attention to heat control. Managing heat well makes PCBs work better and last longer.

Meet people and find mentors. Talking to skilled professionals gives helpful advice and helps your career grow.

Build a Strong Foundation as a PCBA Engineer

Learn PCB Design Basics

To be a great PCBA engineer, know PCB design basics. These basics help you make strong and useful circuit boards. Start by learning rules like IPC-2221, which explains layouts, materials, and details. Knowing these rules helps your designs meet industry needs.

Standard | What It Covers |

|---|---|

IPC-2221 | General rules for PCB design, including layout and materials. |

IPC-2612/2612A | Tips for clear and consistent PCB drawings. |

IEC 60617 | Symbols for electrical diagrams used worldwide. |

IEEE 315 | A full set of symbols for electrical and electronic diagrams. |

Following these rules makes your designs work well and easy to build. This knowledge is key for making professional PCBs and avoiding costly mistakes.

Know Schematics and Circuit Diagrams

Schematics and circuit diagrams are like maps for PCBs. They show how parts connect and signals move through the board. By studying them, you can see what each part does and group them by jobs. For example, learn how amplifiers make signals stronger or how oscillators create frequencies.

Learning the symbols in these diagrams is also important. It helps you talk clearly with other engineers and avoid mistakes. This skill is useful for designing new boards and fixing old ones. Knowing schematics makes you better at handling tricky PCB tasks.

Understand How PCBs Are Made

Knowing how PCBs are made helps you design boards that are easy to produce. Learn about rules like IPC-A-610, which talks about soldering, placing parts, and keeping boards clean. ISO 9001 is another rule that focuses on quality and improving processes.

Standard | What It Covers |

|---|---|

IPC-A-610 | Rules for soldering, part placement, and keeping PCBs clean. |

ISO 9001 | Rules for managing quality and improving customer satisfaction. |

These rules help you make boards that meet high standards and save money. Understanding how PCBs are made connects design to production. This ensures your projects turn out well.

Learn About Industry Standards and Rules

To do well as a PCBA engineer, you need to know and use industry rules. These rules make sure your designs are high-quality and work well in real life. Standards like IPC, ISO, and IEEE give steps to create strong and reliable products.

Why Rules Are Important

Industry rules, like IPC, are very important for PCB design and making. They help you make good products by giving clear steps for design, building, and testing. Following these rules makes your work match global standards, reduces confusion, and improves teamwork. For example:

IPC rules make products last longer and work better.

They help teams talk clearly, improving quality and meeting rules.

Using these rules lowers mistakes and makes products more reliable.

Important Rules to Learn

Learn the most common rules used in electronics. Here are some key ones:

Standard | What It Does |

|---|---|

IPC-A-610 | Explains good soldering and building practices. |

IPC-2221 | Covers basic PCB design ideas like layout and materials. |

ISO 9001 | Focuses on managing quality to make customers happy. |

Knowing these rules helps your designs meet industry needs and avoids expensive fixes.

How Rules Help Your Career

Learning industry rules makes your skills better and helps your career grow. Companies like engineers who follow rules and make reliable designs. Using these rules shows you care about quality and are professional, making you stand out in the PCBA field.

Tip: Check for updates to rules like IPC and ISO often. Staying updated helps you follow rules and keep up with changes in the industry.

Develop Advanced Technical Skills in PCB Design

Improve Routing and Layout Techniques

Routing and layout are key parts of good PCB design. To get better, focus on improving signal flow and cutting down interference. Use ground planes to keep signals steady and reduce noise. Fewer vias in your design can lower signal distortion and boost performance. Controlled impedance helps signals move smoothly, especially in fast circuits.

Timing-sensitive circuits need special care with routing. Differential pair routing and length matching are important techniques. They keep signals clear and reduce electromagnetic interference (EMI). For example, paired traces in differential signaling cancel out noise. Length matching makes sure signals arrive together, avoiding timing problems.

Designers often face tight spaces when working with microcontrollers or small PCBs. A case study shows that following IPC-2223 standards for rigid-flex boards can improve bending and cut errors. Using these methods helps you make designs that work well and are reliable.

Tip: Try simulation tools to check your routing before production. This finds problems early and ensures your PCB works as planned.

Focus on Thermal Management and Heat Dissipation

Managing heat is very important for keeping your PCB reliable. Too much heat can harm parts and shorten the life of your design. Use thermal analysis to find where heat builds up during use. This helps you decide on stackup design, materials, and where to place parts.

Good thermal management includes using thermal vias to move heat away, picking materials that conduct heat well, and adding cooling tools like heat sinks or fans. New cooling methods, like liquid immersion cooling, are energy-efficient and handle high heat loads well.

Evidence Type | Description |

|---|---|

Market Growth | The need for heat solutions is making the market grow. |

Advancements in Technologies | New materials and designs are improving heat control. |

Demand in Data Centers | Data centers need better cooling for their computers. |

Modern Cooling Methods | Liquid cooling saves energy and handles more heat. |

By focusing on heat control, your PCB works better in different conditions. This improves how it functions and lowers the chance of part failures.

Note: Plan for heat control early in your design. This saves time and avoids costly fixes later.

Conduct Signal Integrity and Power Analysis

Signal integrity and power analysis are crucial for great PCB performance. Signal integrity ensures signals stay clear, while power analysis checks energy needs for smooth operation.

Start by studying transient behavior to spot overshoot or undershoot caused by ringing. Use S-parameters to model how parts behave, and check impulse responses to test channel models. Eye diagrams are helpful for seeing signal levels, jitter, and errors, making sure your design meets standards.

Analysis Type | Description |

|---|---|

Transient behavior | Finds overshoot/undershoot from ringing between parts. |

S-parameters and transfer function | Models how parts behave using reflection data. |

Impulse response | Tests channel models for input/output pairs. |

Eye diagram | Shows signal levels, jitter, and errors for compliance. |

Power analysis is also vital in PCB design. SPICE simulations help check if parts work well together. Waveform analysis shows signal issues like crosstalk and reflections.

Studies show signal analysis is key for dense PCBs. For instance, better via design can cut RF signal reflection, improving signal clarity. By doing detailed signal and power checks, you create strong and efficient designs.

Tip: Use simulation tools often to find and fix signal issues before production.

Perform Thorough Quality Checks and Testing

Thorough quality checks make sure your PCB designs work well. Finding problems early saves money, improves reliability, and builds customer trust. Let’s look at key methods and their benefits.

Main Inspection Methods

Different methods help find defects and meet industry rules. Here are some common ones:

Inspection Method | Advantages | Limitations |

|---|---|---|

Automated Optical Inspection (AOI) | Fast, non-intrusive, spots small issues quickly | Only finds visible defects, may miss hidden ones on complex boards |

Automated X-Ray Inspection (AXI) | Finds hidden defects, great for complex boards | Needs special tools, not for all uses |

Functional Testing (FCT) | Checks if it works in real conditions | Takes time, needs special tools |

Environmental and Reliability Testing | Tests strength under tough conditions | Can be hard and costly |

Each method has pros and cons. AOI is good for visible flaws, while AXI finds hidden ones in layered boards. Functional testing checks if the board works, and environmental testing sees how strong it is under stress.

Tip: Use more than one method to catch all problems and test thoroughly.

Why Quality Checks Matter

Quality checks give many benefits beyond finding defects:

Catching problems early avoids costly fixes and recalls.

Ensures only good boards are sold, making products reliable.

Builds trust by delivering high-quality items every time.

Gives feedback to improve how things are made.

By focusing on quality checks, you make better designs and grow your reputation.

Real-Life Testing Success Stories

Testing works well in many industries. Here are some examples:

Industry | How It Helps | Example |

|---|---|---|

Retail | Predicts failures early, avoiding problems during busy times. | A store predicts checkout issues during holidays to prevent delays. |

Manufacturing | AI tools predict repairs, cutting downtime. | AI checks machine data to plan repairs, keeping production running. |

Automotive | Strict controls lower defects and improve quality. | A car parts maker cut defects by 75% with better processes. |

For example, a car parts company used strict rules and cut defects by 75%. In factories, AI predicts repairs, keeping machines working and saving time.

Note: Learn from these examples to improve your testing and get great results.

Steps for Better Testing

Follow these steps for effective testing:

Start Early: Add testing to your design process from the beginning. This finds problems before production starts.

Use Good Tools: Use tools like AOI and AXI for accurate checks. Simulations can also predict how your design will perform.

Keep Records: Write down testing steps and results. This helps track progress and improve future designs.

Work Together: Team up with manufacturing and quality teams to set testing goals and methods.

By doing these steps, your PCBs will meet top standards and work well in real life.

Advance Your Career as a PCBA Engineer

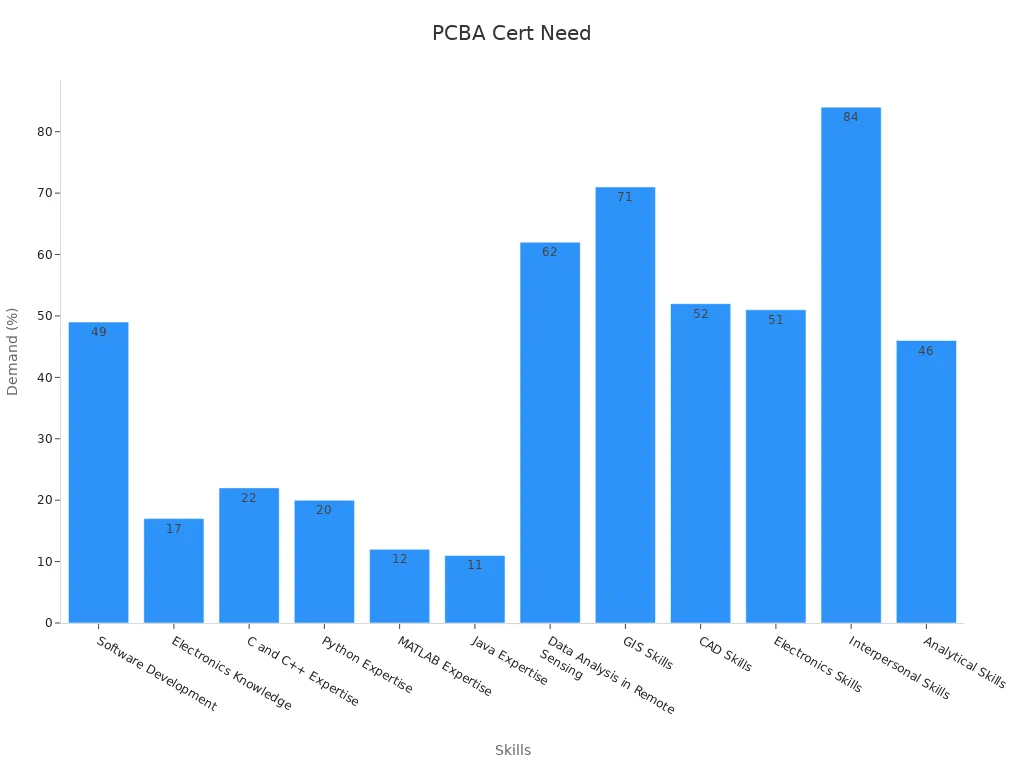

Earn Certifications and Learn Key Skills

Getting certifications and learning special skills can help your career. Employers like engineers with proven knowledge and recognized certificates. Certifications such as IPC CID (Certified Interconnect Designer) or IPC-A-610 show your expertise and focus on quality. These credentials improve your resume and make you stand out in job applications.

To stay competitive, learn skills that are in high demand. Knowing software development, electronics, and programming languages like Python or MATLAB is very useful. The table below shows how much these skills are needed in the PCBA field:

Skill Type | Demand Percentage |

|---|---|

Software Development | 49% |

Electronics Knowledge | 17% |

Python Expertise | 20% |

MATLAB Expertise | 12% |

CAD Skills | 52% |

Interpersonal Skills | 84% |

By earning certifications and learning these skills, you become a valuable and flexible professional in the PCB industry.

Keep Up with PCB Trends and Tools

The PCB industry changes quickly because of new technology and market needs. Staying informed about trends helps you stay ahead. For example, smaller devices have increased the need for High-Density Interconnect (HDI) and flexible PCBs. Electric vehicles (EVs) and advanced driver-assistance systems (ADAS) also require better PCB designs.

Trend/Driver | Description |

|---|---|

Miniaturization | Smaller devices need HDI and flexible PCBs. |

Automotive Growth | EVs and ADAS increase PCB use in cars. |

Consumer Electronics | Better PCB designs improve phones and wearables. |

Regional Focus | Big investments in PCB factories in Asia-Pacific, like India’s $100 million project. |

Try using new tools and software to make PCB design easier. Programs like Altium Designer and KiCad have great features for creating schematics and managing parts lists. Learning these tools can make your work faster and more accurate.

Tip: Sign up for industry newsletters and join webinars to learn about new tools and trends.

Grow Your Network in the PCBA Industry

Networking is important for growing your career. Meeting other PCBA professionals can lead to new jobs and teamwork opportunities. Attend trade shows, events, and conferences to connect with experts and learn from them. LinkedIn is also a great place to meet people and join discussions about PCB design.

Mentorship is another great way to grow. Find experienced engineers who can guide you and share career advice. A strong network helps you learn new things and stay updated on job openings and industry news.

Note: Join online forums and groups to share your knowledge and learn from others.

Find Mentors and Keep Learning Regularly

Having a mentor is very helpful for growing as a PCBA engineer. Experienced mentors can teach you important lessons and share useful tips. They help you solve tough problems, learn best practices, and avoid common errors.

For instance, Manuja Joshi’s internship at Cadence Design Systems shows how mentors can help. With their advice, she learned advanced skills and understood the industry better. Similarly, Kowsik S’s work with the SAE Collegiate Club of Amrita shows how mentors encourage hands-on learning. By working with senior engineers, he improved his PCB design skills and worked on vehicle projects.

Tip: Look for mentors who are experts in areas you want to improve. Their knowledge can guide you to focus on the right tools and skills.

Learning new things is just as important. The PCBA field changes quickly, so staying updated helps you stay ahead. Join workshops, online classes, or webinars to learn about new trends and tools. Websites like Coursera, Udemy, and LinkedIn Learning offer lessons on PCB design, signal clarity, and heat control.

Learning Platform | What You Can Learn |

|---|---|

Coursera | Basics of PCB design |

Udemy | Signal clarity techniques |

LinkedIn Learning | Managing heat in designs |

By mixing mentorship with regular learning, you can grow your skills and career. These steps not only make you better at technical tasks but also help you handle industry changes with confidence.

Note: Make time every week to learn something new. This habit will keep your skills sharp and your knowledge fresh.

Practical Tips for Success in PCB Design and Assembly

Optimize Component Placement for Performance

Placing parts correctly on a PCB is very important. Each part has a job, and its spot affects how the board works. For example, hot parts like MOSFETs should be far from heat-sensitive ones. Keeping enough space between parts helps avoid heat problems, noise, and power issues.

Here are ways to place parts better:

Group parts by their job to make routing easier.

Put decoupling capacitors near power pins to keep voltage steady.

Keep parts away from PCB edges to avoid damage.

Leave space between parts to help heat spread out.

Tip: Use thermal vias and copper pours to handle heat better. This makes the board last longer and work reliably.

Bad placement can cause circuits to fail and products to break. Planning the layout carefully helps the board work well in different situations.

Avoid Common Mistakes in PCB Design

PCB design mistakes can cost time and money to fix. Many happen because of poor planning or skipping reviews. For example, missing a design review might leave short circuits unnoticed, causing the board to fail later.

Here are mistakes to avoid:

Skipping Design Reviews: Always check your design for errors like short circuits.

Bad Component Placement: Wrong placement can cause problems with signals and performance.

Ignoring Heat Control: Not managing heat can damage the board.

Missing Files: Make sure files like Gerber and assembly drawings are ready for production.

Note: Work with your team to review designs before production. This step finds problems early and saves time.

Fixing these mistakes improves your PCB quality and avoids costly changes.

Use Design and Simulation Tools Effectively

Design tools help engineers make better PCBs. These tools show designs, test conditions, and find problems before production. For example, simulation software checks electromagnetic behavior to meet standards.

Here’s how to use these tools well:

Use 3D views to check part placement and alignment.

Run tests to check signals, impedance, and heat control.

Try different scenarios to see how your design handles changes.

Add extra apps to make your tools more powerful.

Tip: Update your tools often to get new features and work faster.

Simulations show real-world conditions, helping you make strong designs. Using these tools saves time and reduces mistakes.

Write Down and Share Your Work Clearly

Writing things down and sharing ideas clearly are very important. They help others understand, copy, and improve your work. Without good records, even great designs can fail during building or fixing. Talking clearly also helps you work well with teammates, bosses, and clients.

Why Writing Things Down is Important

Writing down your work keeps a detailed record of what you did. It shows your choices, steps, and results. This helps others follow your process and make smart decisions. For example, if someone needs to fix a circuit, your notes can guide them. It also makes sure your work follows rules and standards.

Good records stop confusion and keep everyone on the same page. They show how the project has changed over time. This openness builds trust and makes everyone feel responsible.

Tips for Writing Good Records

Here’s how to make your records better:

Use the same format every time for neatness.

Update your notes often so they stay current.

Add pictures, diagrams, and labels to explain hard ideas.

Write simply so everyone can understand.

Tip: Check and update your notes regularly. This keeps them accurate and useful.

Why Talking Clearly is Important in Engineering

Talking clearly is just as important as writing things down. It helps you share ideas, fix problems, and make choices. A good plan for talking keeps everyone in the loop. For example, picking the right way to share information, like emails or meetings, can make people remember things better.

Benefits of Clear Writing and Talking | Tips for Better Communication |

|---|---|

Stops confusion and mistakes | Use the same format for notes |

Keeps everyone informed | Update records often |

Shows project progress and changes | Share updates regularly |

Builds trust and responsibility |

Steps to Talk Better

Follow these steps to improve how you share information:

Find out who needs to know what.

Set clear goals for sharing information.

Pick the best way to share, like emails or meetings.

Give updates often to keep everyone in the loop.

Note: Knowing what each person needs to hear can make projects 35% more successful. Take time to figure out who needs what and when.

A Real-Life Example of Good Communication

Making a plan to share information takes careful thought. Start by figuring out who needs updates and what they need to know. Then, set clear goals and pick the best ways to share. This method keeps everyone informed and avoids confusion. It also helps projects stay on track and finish on time.

By keeping good records and talking clearly, you can work better with others, make fewer mistakes, and get better results. These skills not only help your projects but also make you a stronger and more trusted engineer.

Being a great PCBA engineer takes hard work and learning. Begin by understanding PCB design basics and improving your technical skills. Keep up with new trends in the industry to stay ahead. Use these tips to grow your knowledge and career. In this fast-changing field, being flexible and always learning is very important. By doing this, you can make strong designs and become a trusted expert.

Tip: Learn regularly. Spend time weekly to try new PCB tools or methods.

FAQ

1. What is the most important skill for a PCBA engineer?

Knowing PCB design basics is very important. It helps you make strong and efficient circuit boards. This skill prevents mistakes and ensures your designs follow industry rules.

2. How can you improve your PCB design skills?

Use tools like Altium Designer or KiCad often. Learn rules like IPC-2221 to guide your designs. Try simulations to test your ideas. Keep practicing and learning to get better.

3. Why is thermal management important in PCB design?

Too much heat can harm parts and shorten PCB life. Good heat control keeps your board working well in all conditions. Use heat sinks, thermal vias, and the right materials to manage heat.

4. What certifications should you pursue as a PCBA engineer?

Get certifications like IPC CID or IPC-A-610. These show you know a lot about PCB design and assembly. They also help you stand out when applying for jobs.

5. How do you stay updated with industry trends?

Read newsletters, join webinars, and talk to other engineers. Go to trade shows and forums to learn about new tools and ideas.

Tip: Spend time weekly learning about new tools or trends. Staying informed helps you stay ahead in the fast-changing PCBA field.

See Also

Essential Strategies to Enhance PCB Assembly Productivity

Ways to Optimize Workflow Efficiency in PCBA Production

Ten Professional Insights for Cost-Effective PCBA Assembly